Used FCI SYSTEM Solvent Auto #9314415 for sale

URL successfully copied!

Tap to zoom

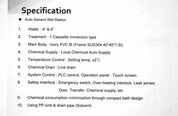

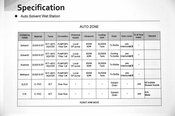

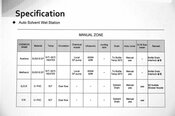

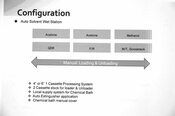

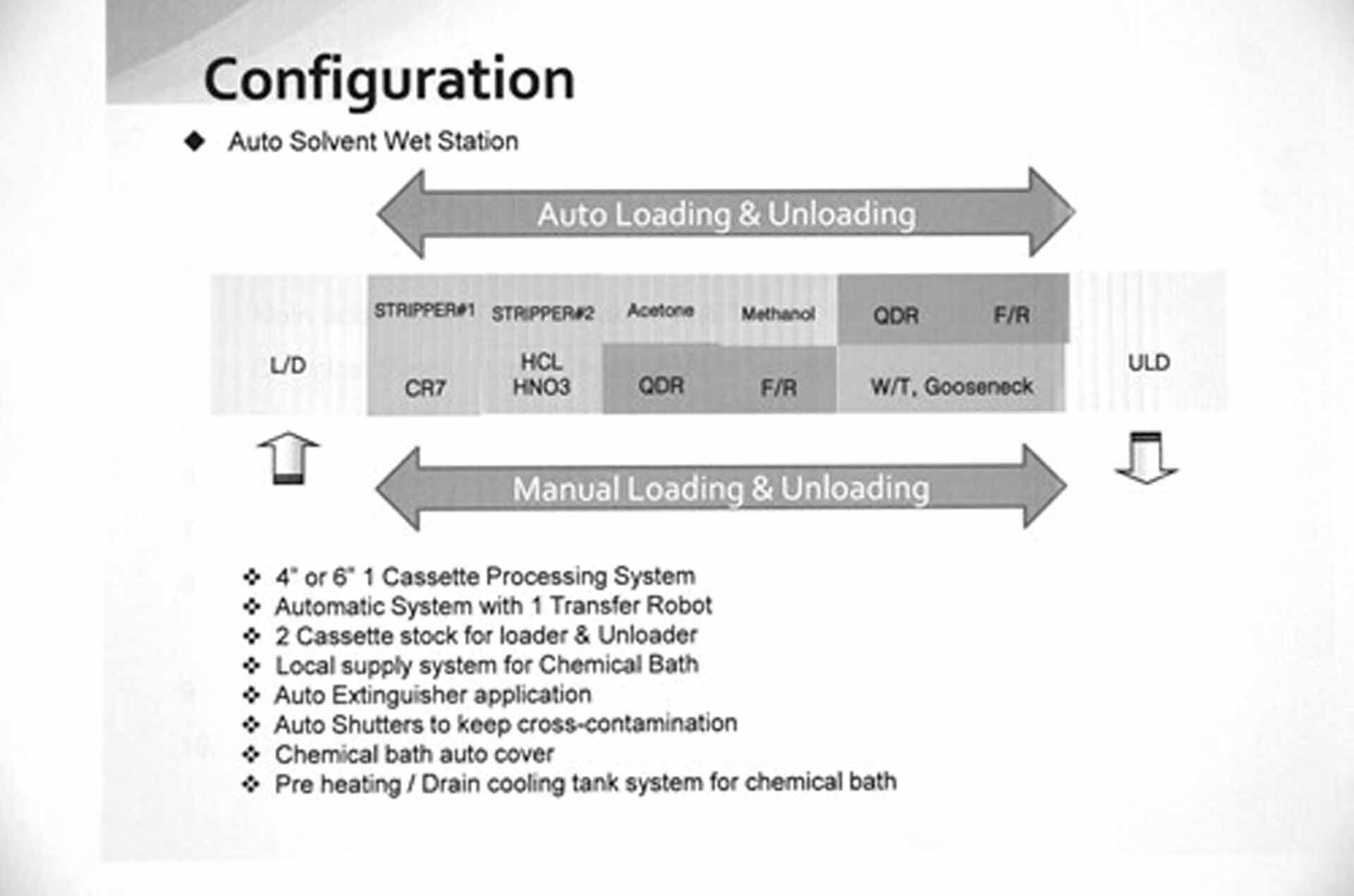

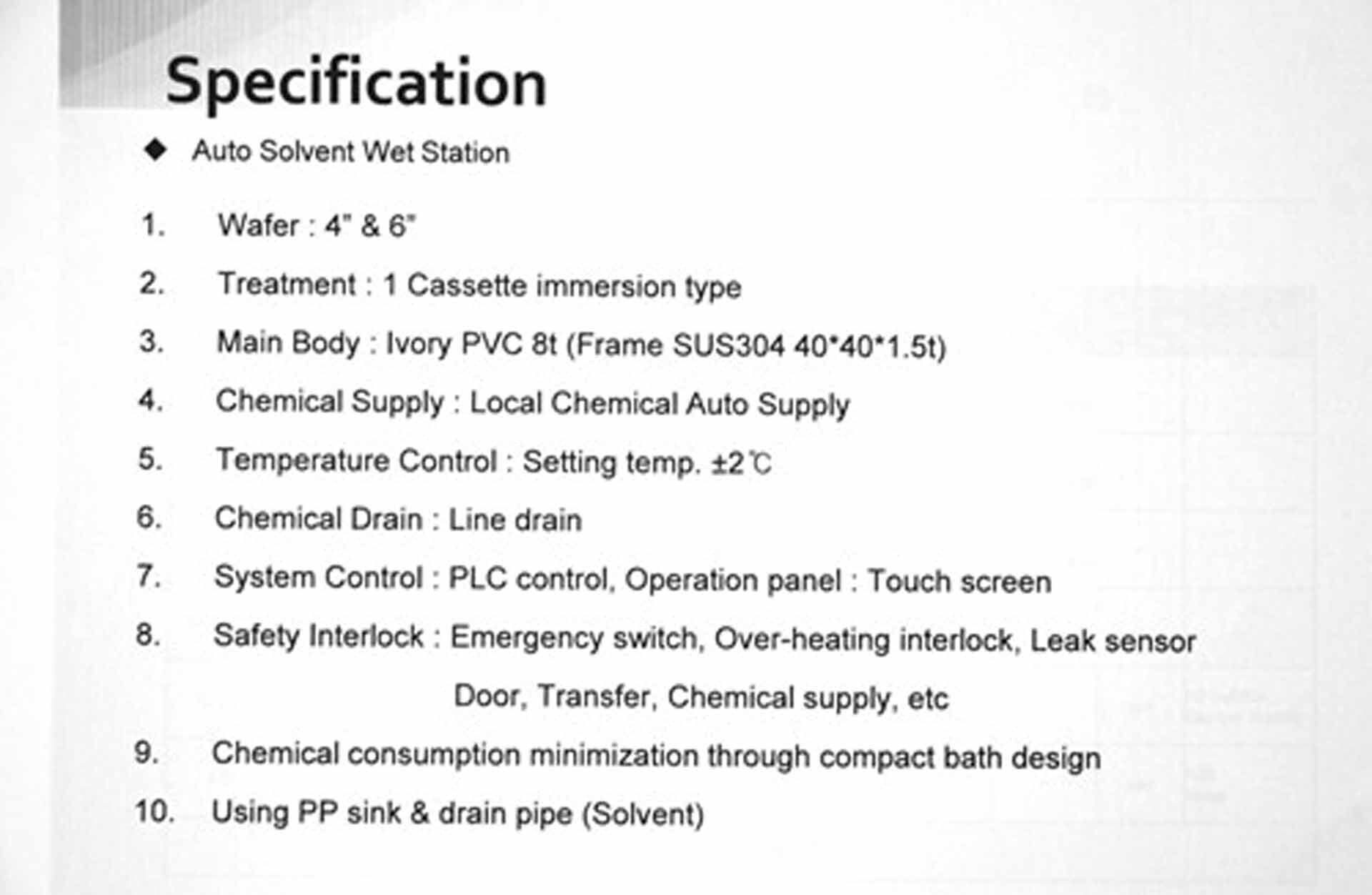

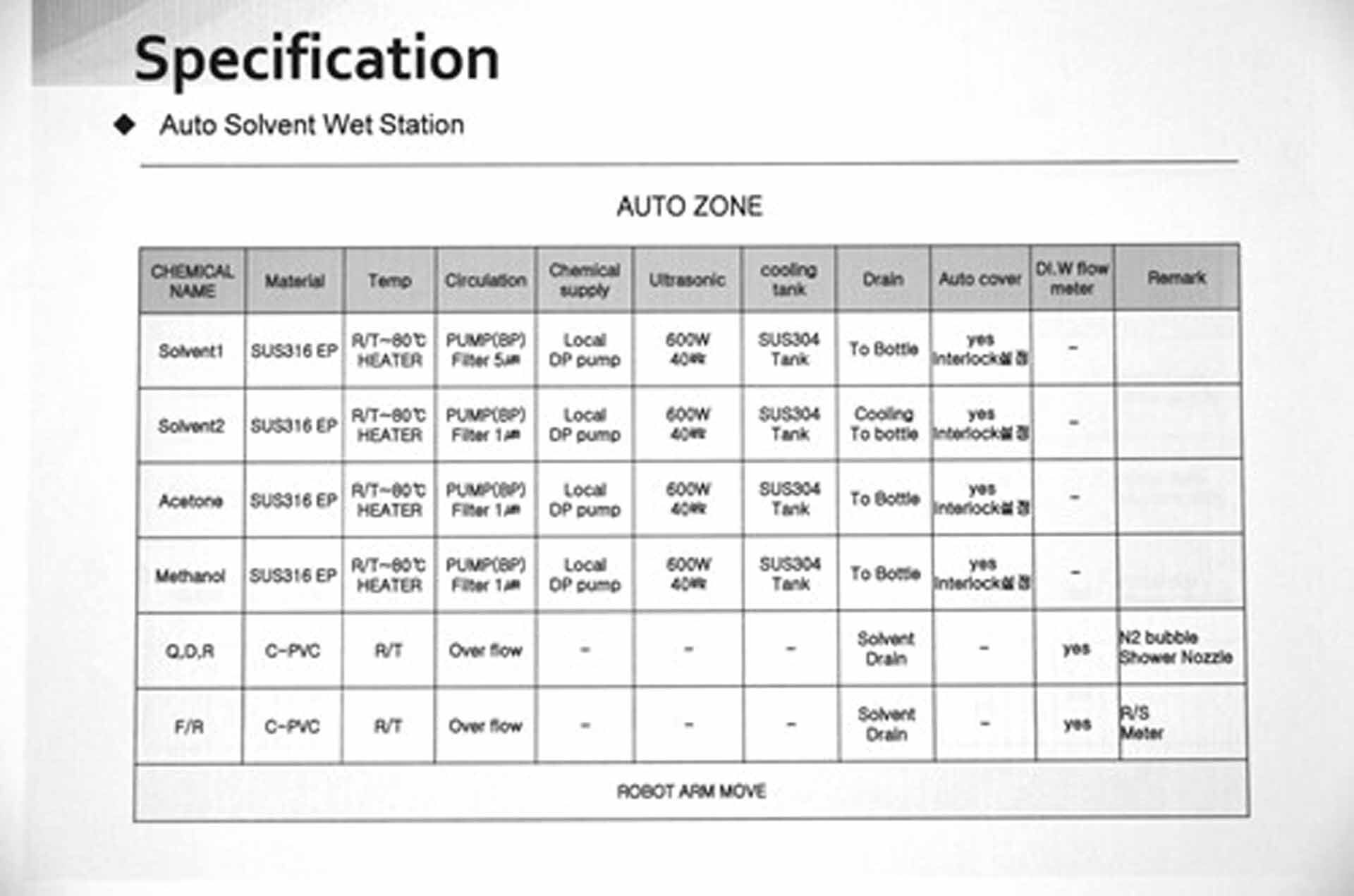

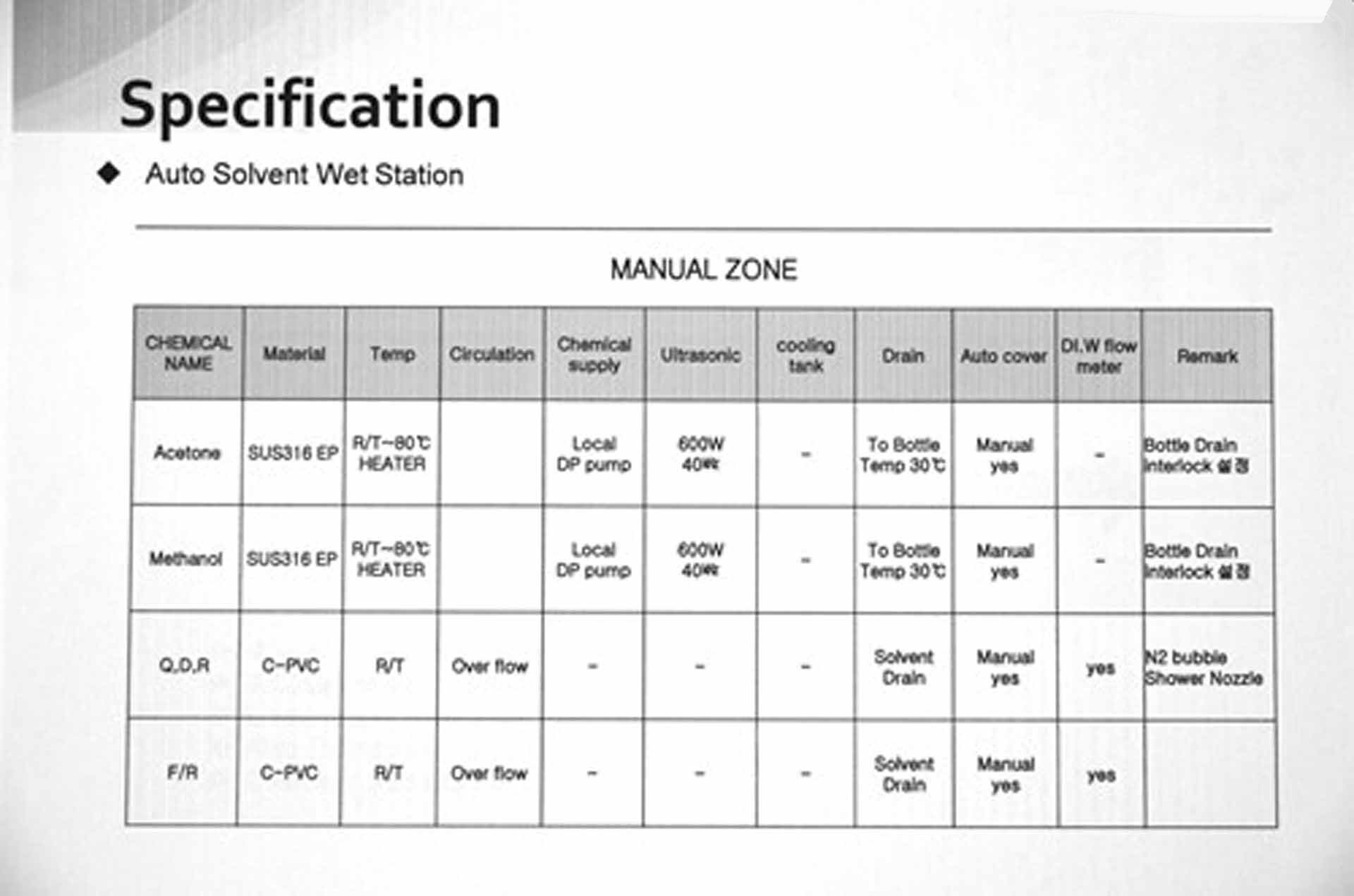

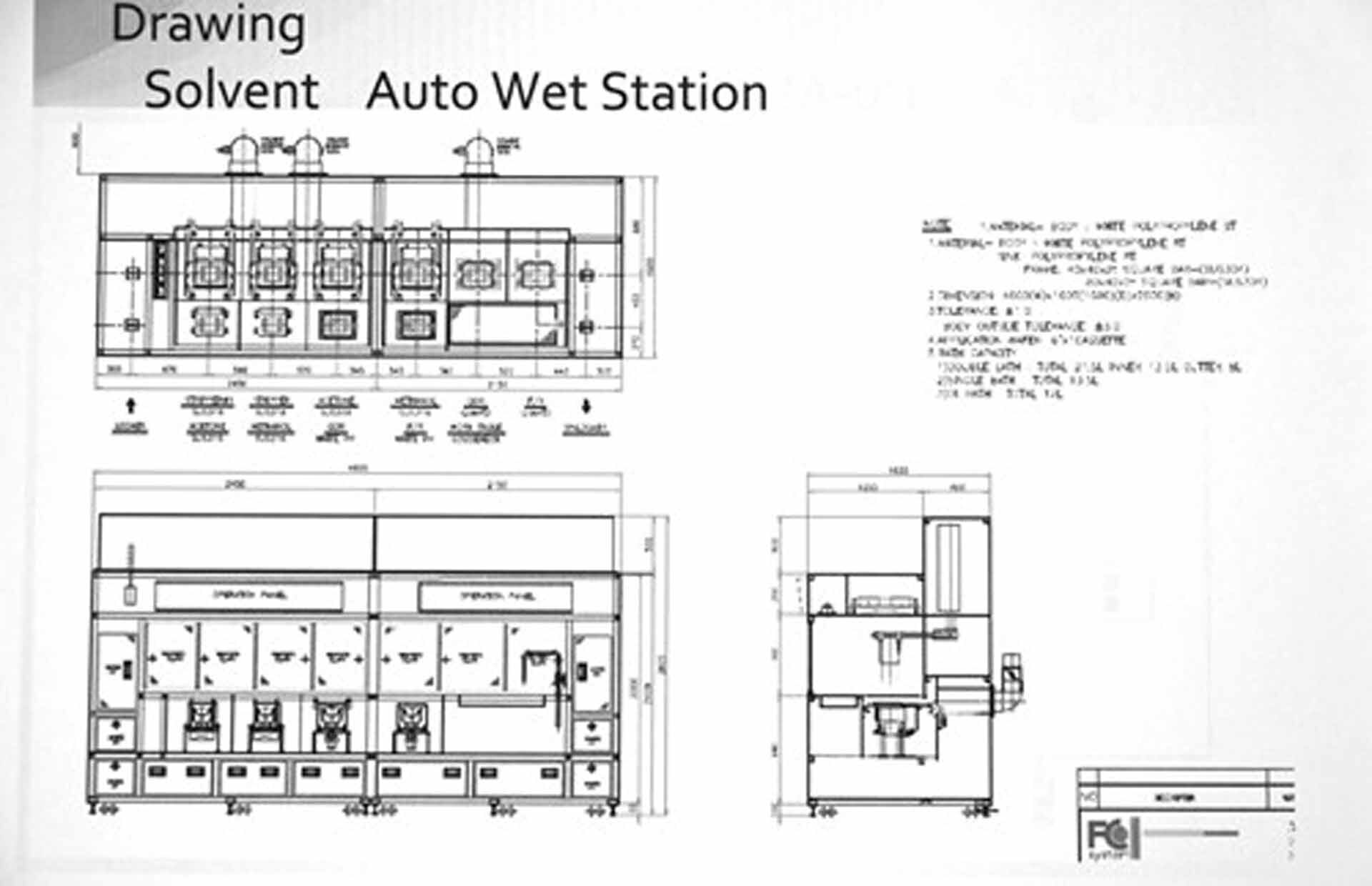

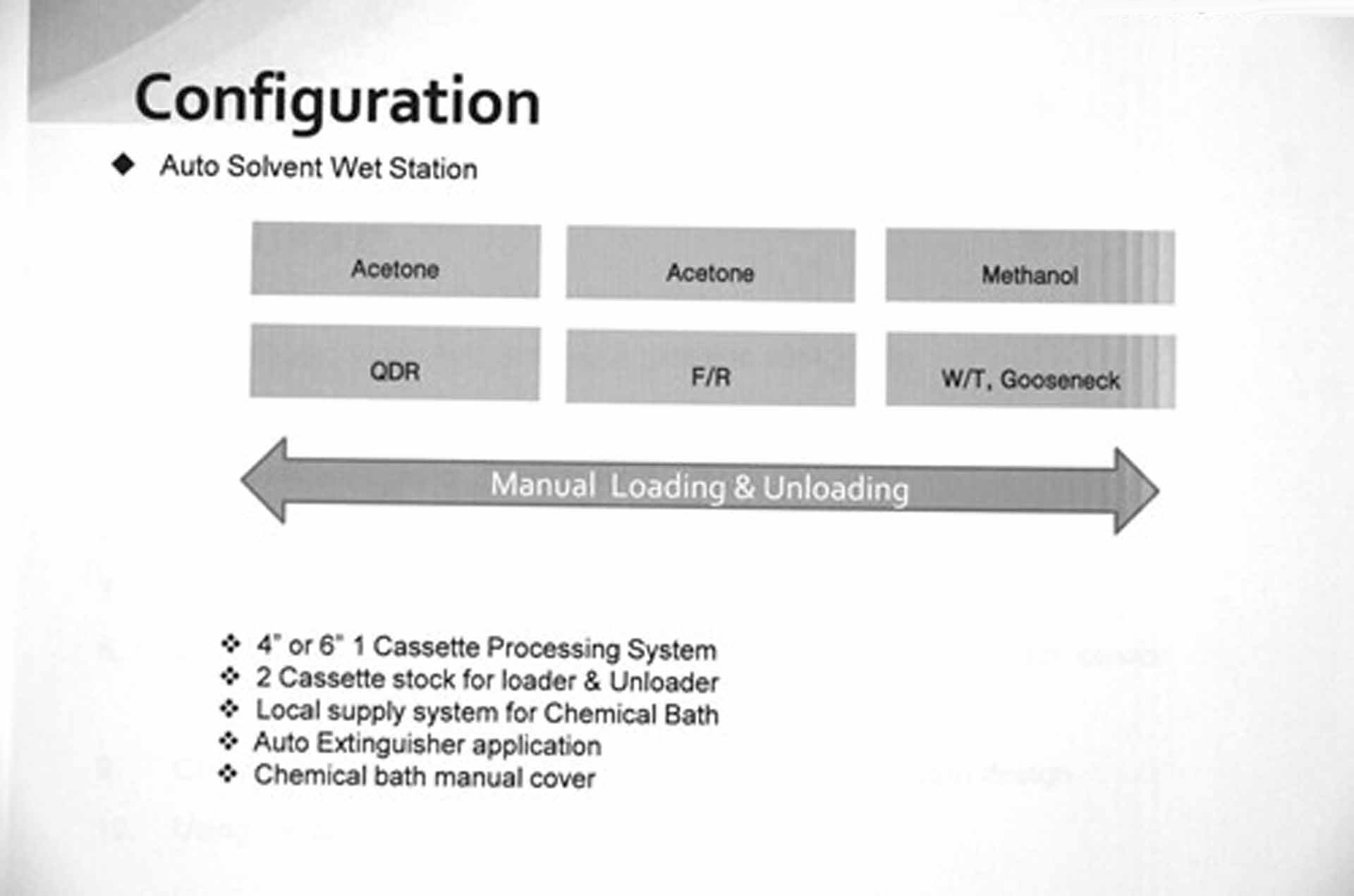

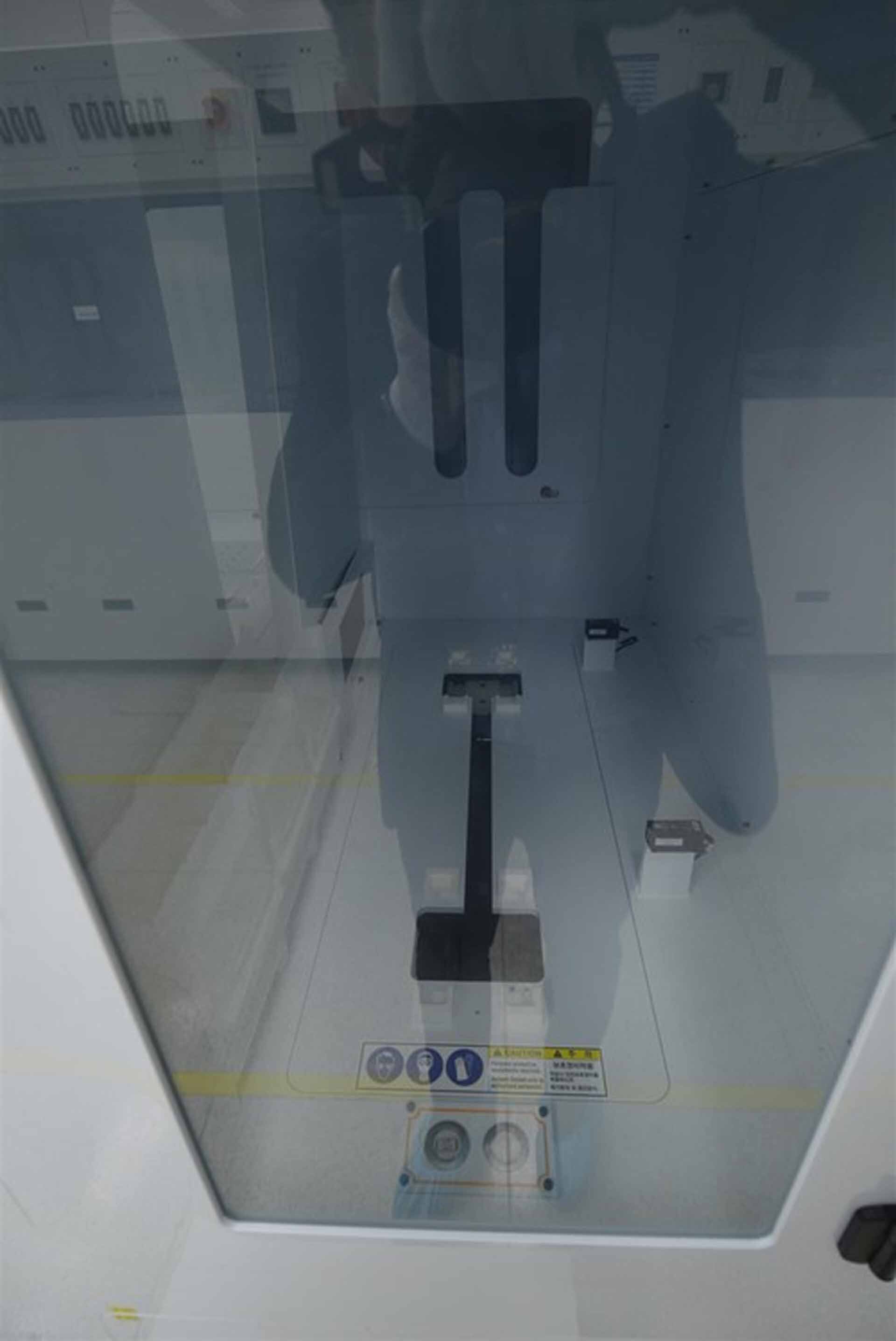

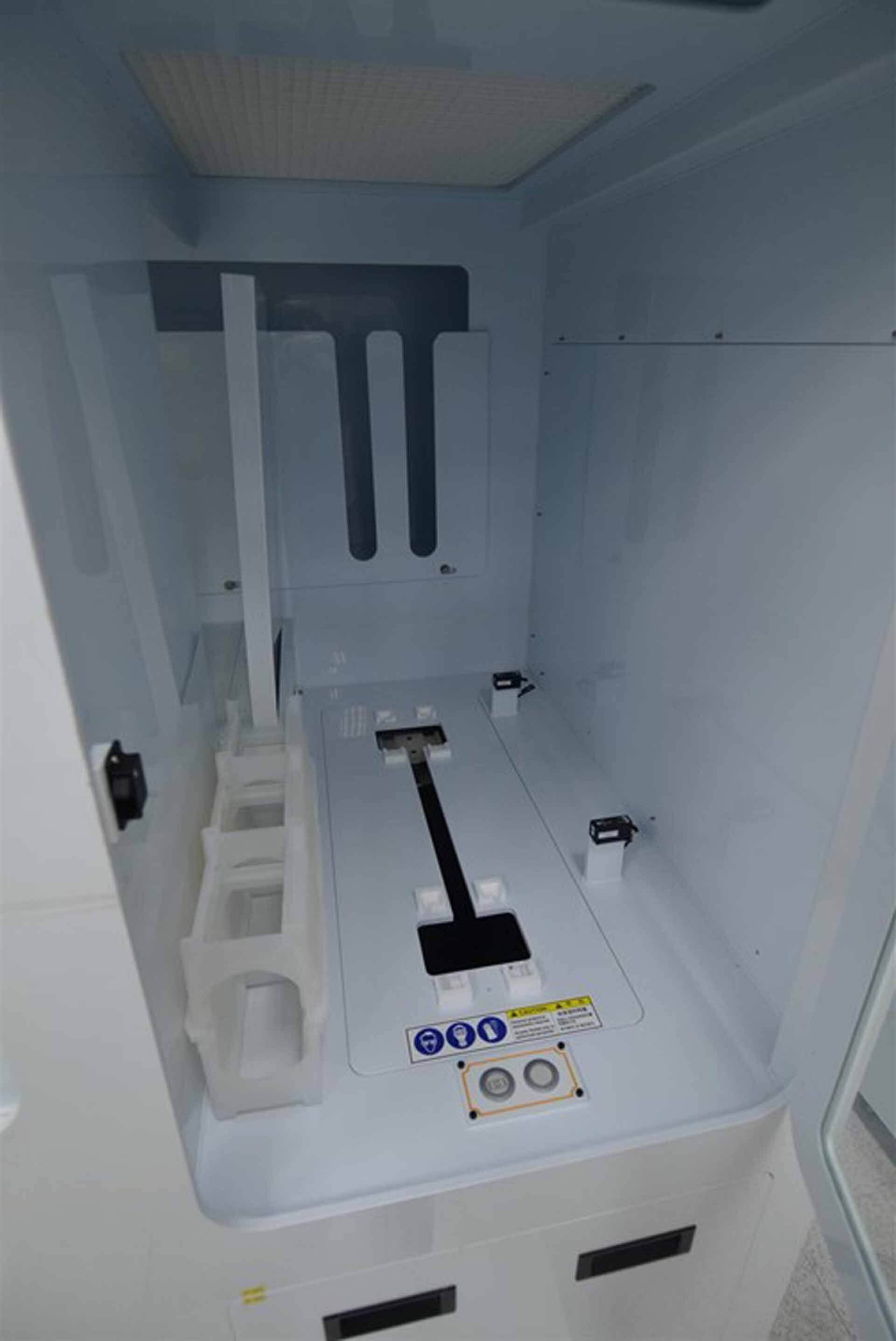

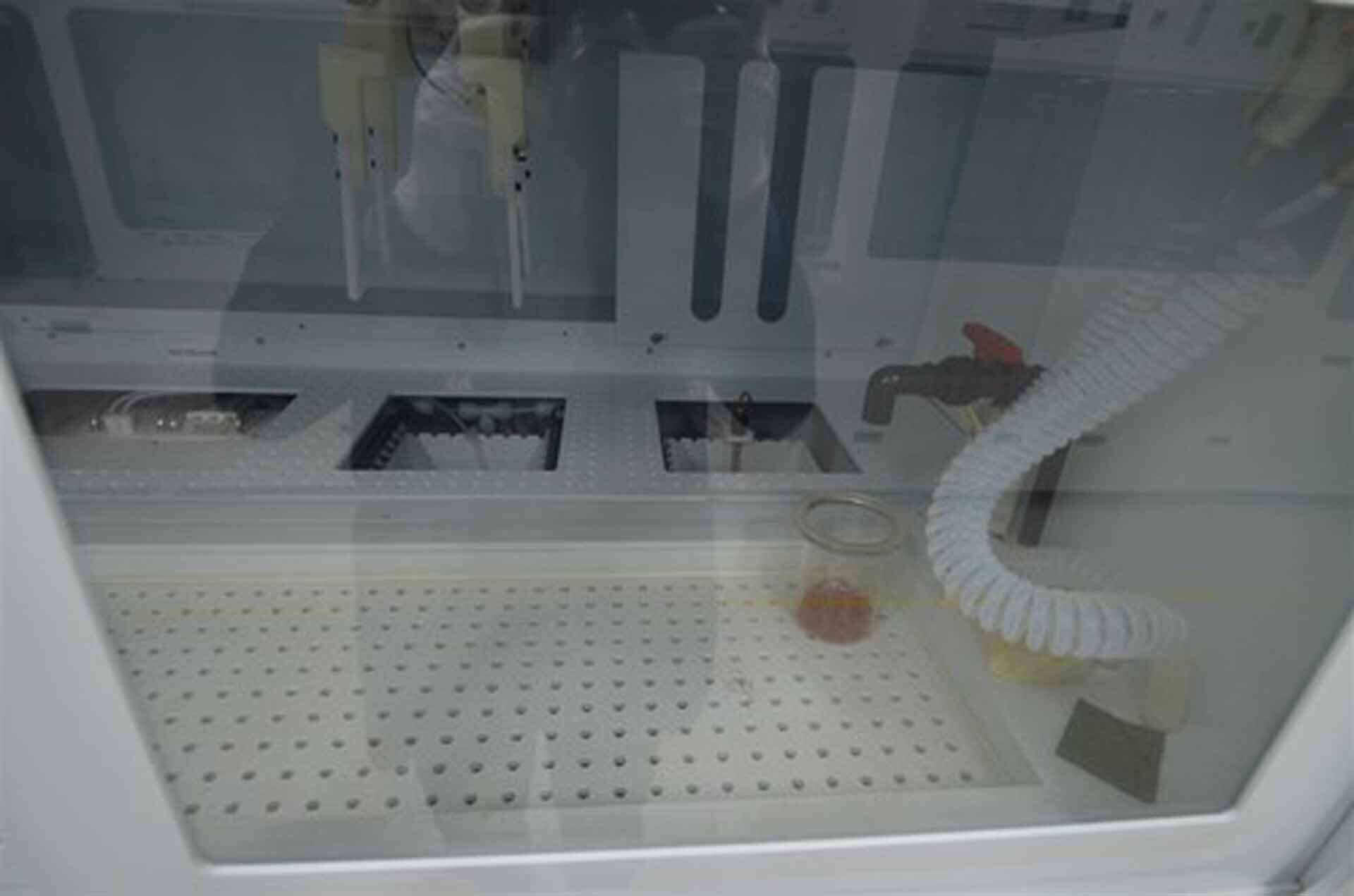

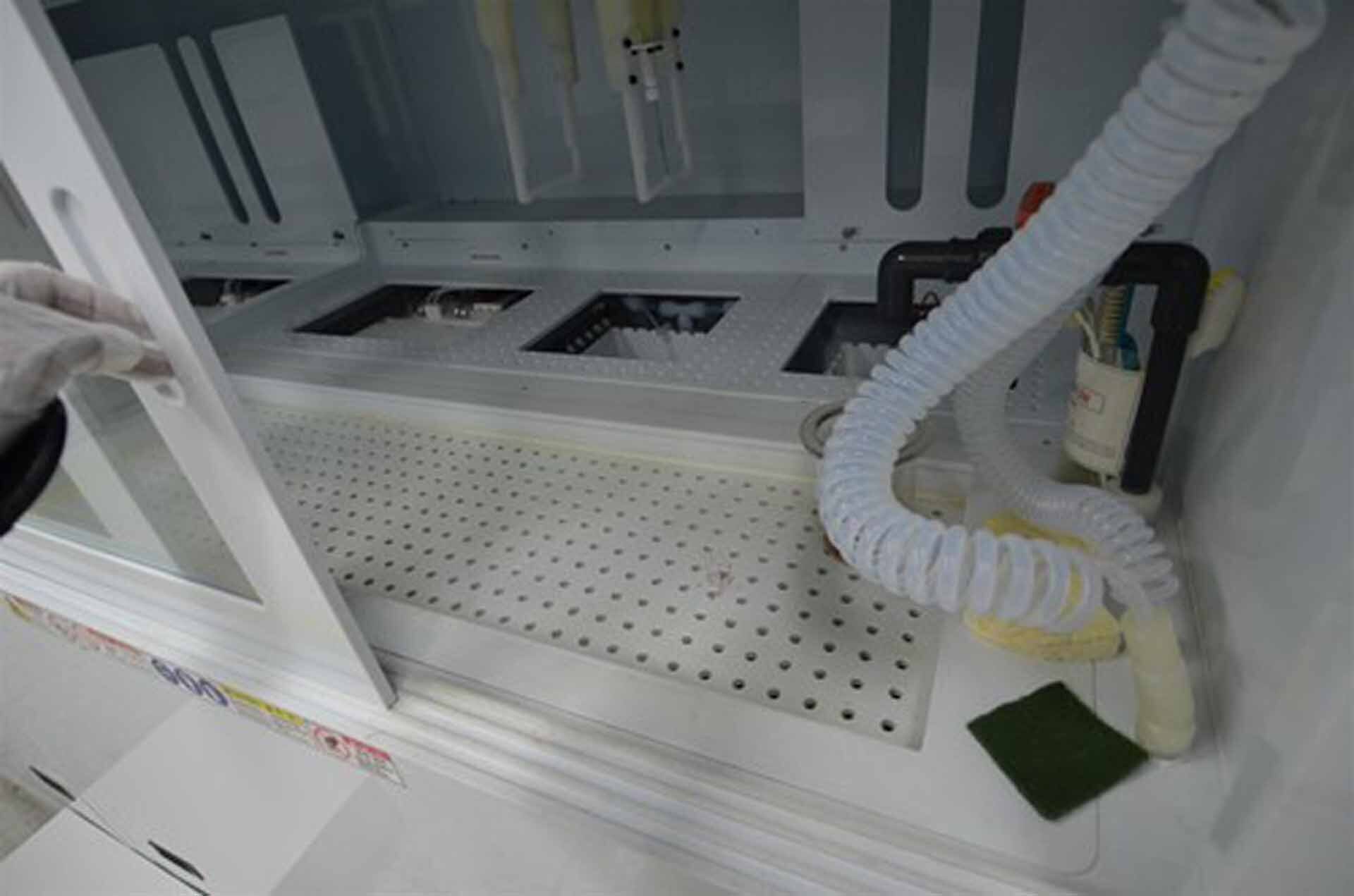

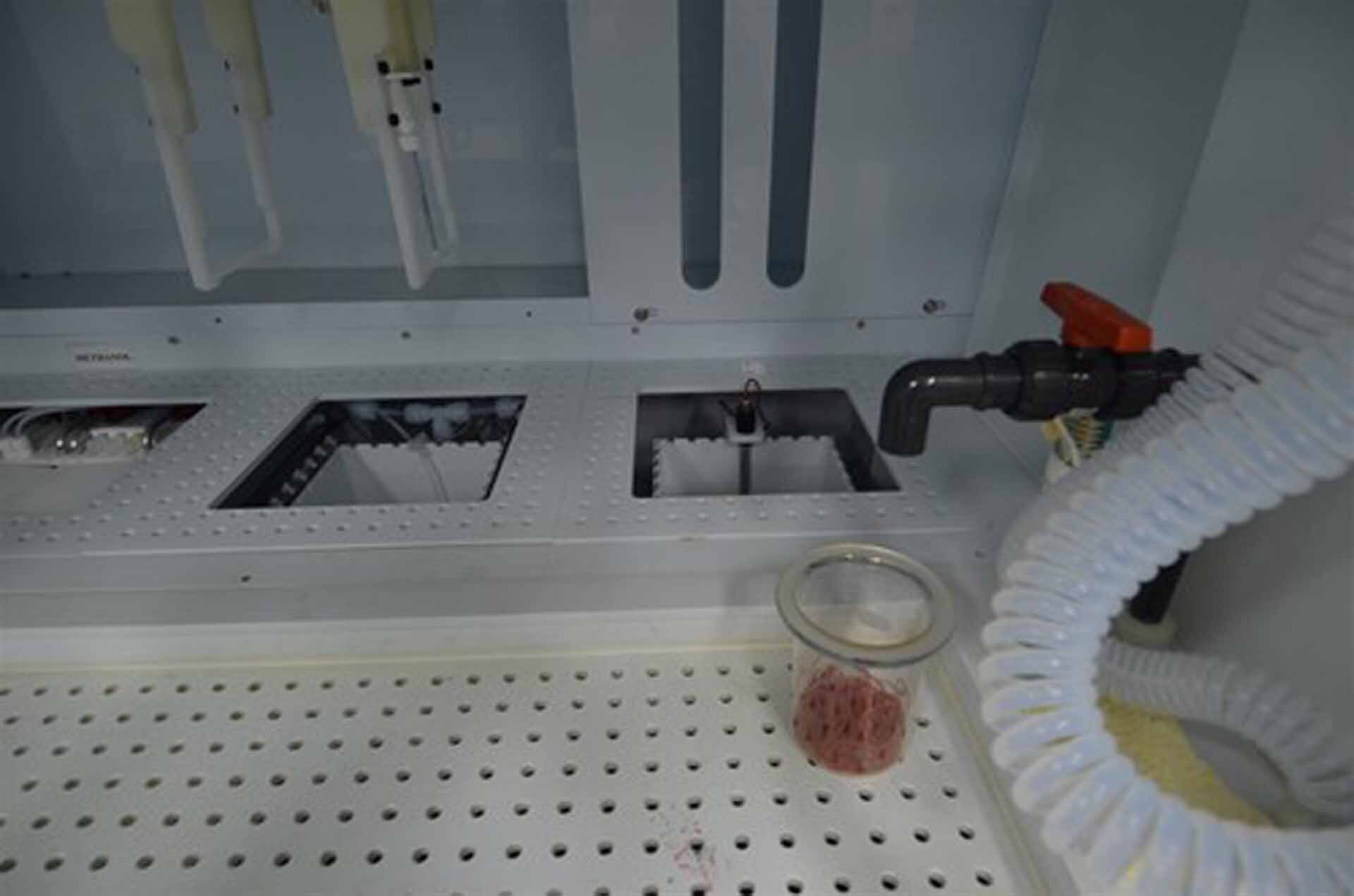

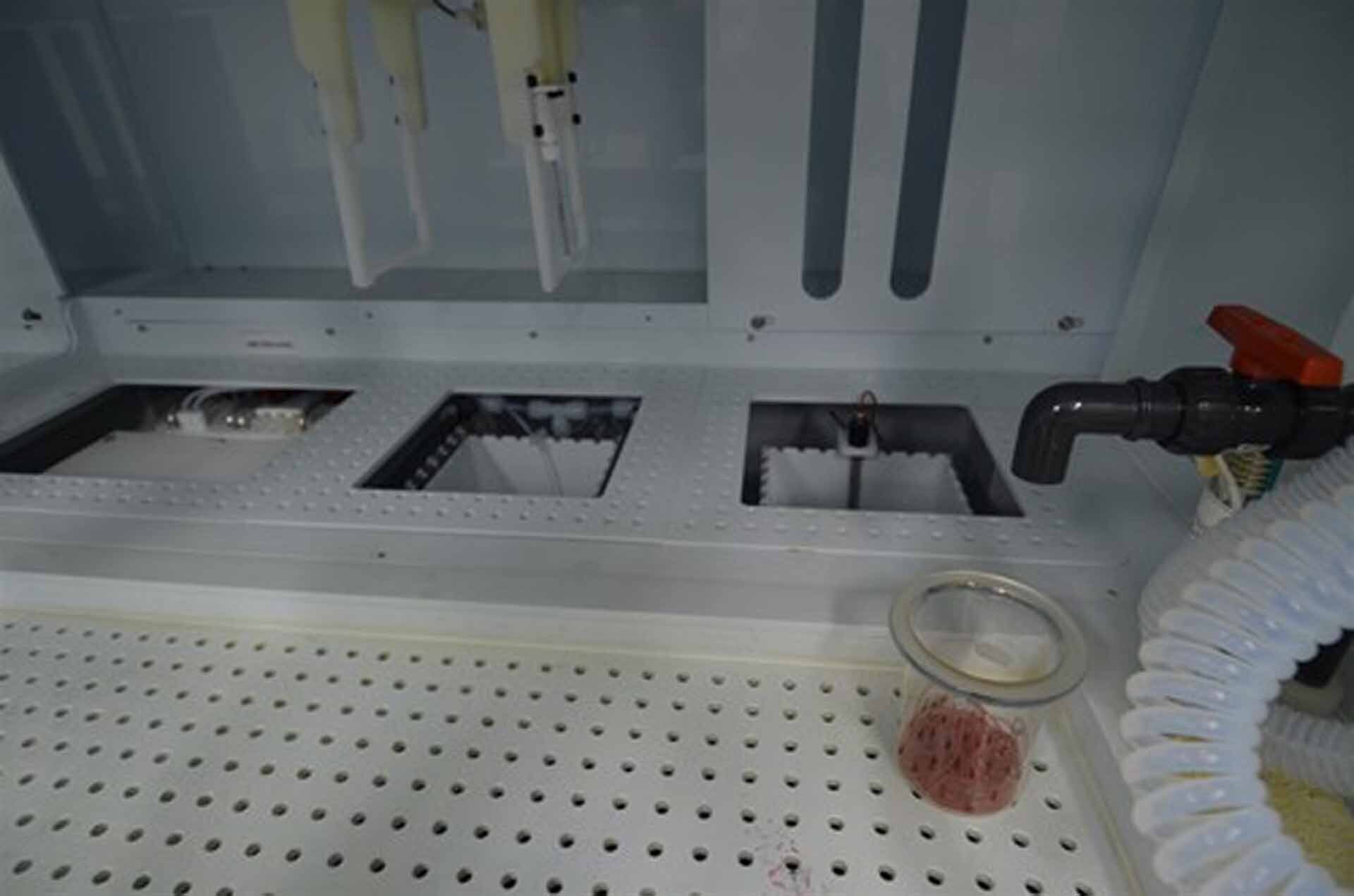

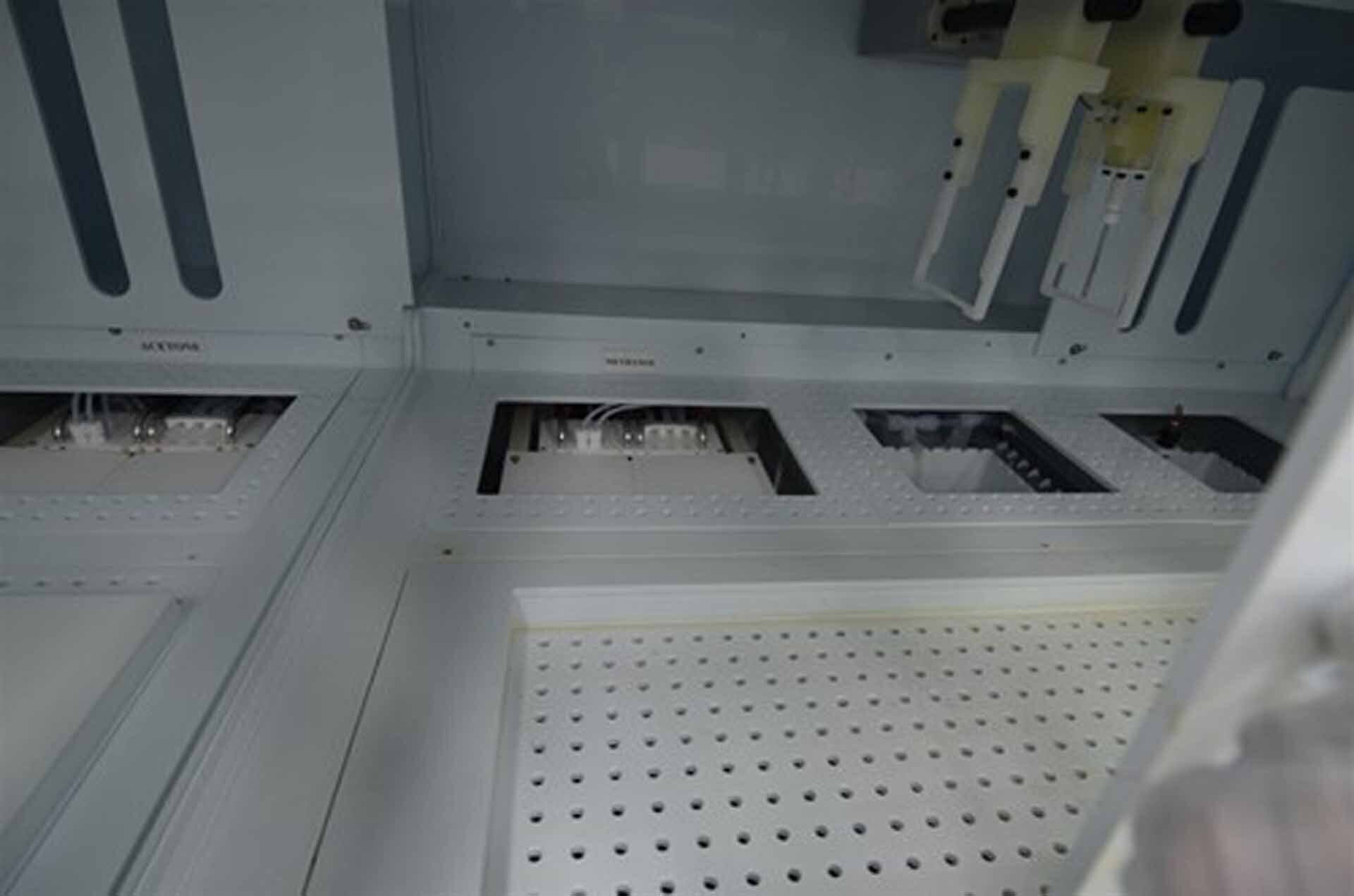

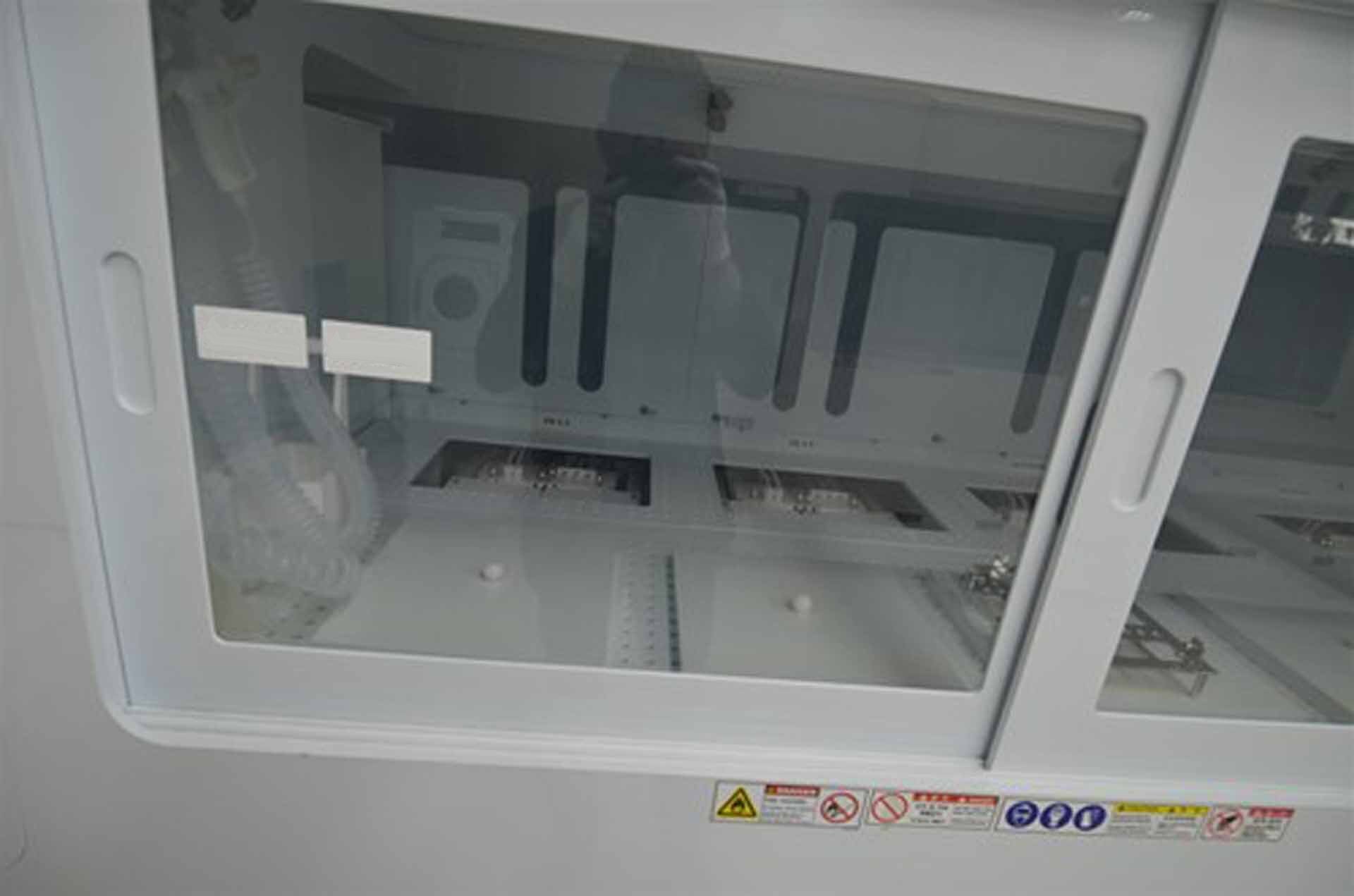

FCI Equipment Solvent Auto is a wet station designed for the purpose of fast and efficient cleaning of electronic equipment. This wet station from FCI is specifically designed to deliver superior filtration and component protection, and its advanced design allows for fast and thorough cleaning of parts without using unnecessary amounts of expensive solvents. This wet station is equipped with integrated advanced filtration technology which ensures that any particles from the cleaning process are suitably filtered and kept out of the filtration equipment. The wet station is fitted with a large capacity tank for holding a variety of solvents. This capacity ensures that the right amount of solvent is always available for any given task. The tank comes with a low-level indicator which allows users to check the levels of solvent or rinse before and after the cleaning process. This ensures that the exact amount of solvent needed is being applied, thus reducing costs and waste. Solvent Auto wet station has a built-in heater which is adjustable for precise temperature control within a range of 0-90C and helps in reducing the time taken for cleaning and preventing residue formation, thereby helping to extend the equipment life. It also includes pulse jets for continuous fluid and air-flow during cleaning. The station's heating element ensures that the solvent being used penetrates well into the parts and also gives an end result of clean surfaces, without compromising integrity. In addition, the wet station is built with an advanced filtration system, consisting of two filtration stages, namely carbon filter and dielectric filter. This ensures the removal of unwanted impurities from the filtration unit, thus maintaining a clean and efficient cleaning environment. Overall, FCI Machine Solvent Auto wet station is designed to provide a user-friendly and efficient way for cleaning and maintaining electronics with minimal intervention. It can be used for a variety of tasks, such as, removing oils and other contaminants from electronic equipment, preparing surfaces for component or assembly operations, and featuring an integrated adjustable heat source that ensures all solvents used are at optimal temperature.

There are no reviews yet