Used JST ST0142A0 #9188197 for sale

URL successfully copied!

Tap to zoom

ID: 9188197

Vintage: 2010

Solvent wet bench

Ultrasonic bath with PLC control 12” x 12”

Hot plate with PLC control: 8” x 8” (Plate) Tank larger

Sink with faucet 16” x 12”

2010 vintage.

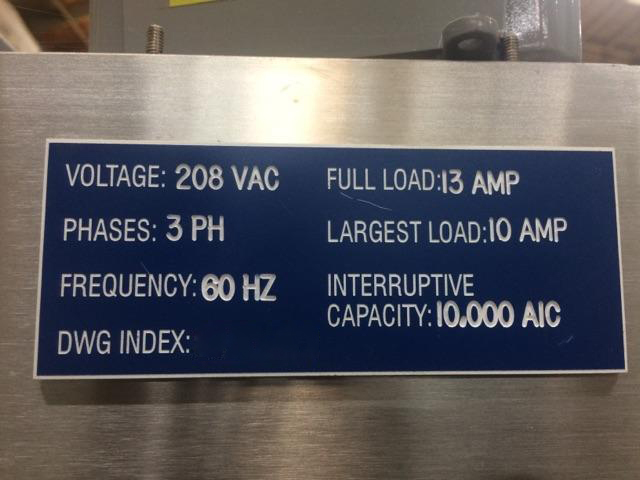

JST ST0142A0 wet station is an automated wet processing equipment designed for use in semiconductor fabrication processes. The system provides excellent quality control and is capable of being integrated with other semiconductor-processing equipment. ST0142A0 is composed of four primary components: a mainframe, an end stage/force table, a wet process arm, and a control module. The mainframe houses the end stage/force table and the wet process arm, and is constructed out of lightweight aluminum alloy material. Its rigid design minimizes noise transmission and ensures reliability. The end stage/force table is able to move along three axes with an average speed of 0.25 m/s. The X-axis provides left/right movement, the Y-axis offers up/down movement, and the Z-axis provides force and tilt. The force applied is adjustable from 0-1000 kgf. Additionally, the end stage/force table can rotate on a single axis with an average speed of 0.31 m/s. The wet process arm consists of an aluminum flex arm which has four axes of movement. These include the X/Y axes which have an average speed of 3 mm/s and a reach of 200 mm, and the roll/tilt axes with an average speed of 2 degrees/s and reach of 20 degrees. The wet process arm is capable of autocarrying up to 3 kg of force, and is also equipped with a four nozzle flow valve for precise and accurate metering of cleaning materials. The control module of JST ST0142A0 wet station includes both manual and software-based operation. In manual mode, the user can control all wet process functions manually. The software-based operation allows the user to program a variety of automated wet process recipes, analyze and control contamination levels, and further customize the wet process. ST0142A0 wet station is well-suited for a variety of applications involved in semiconductor fabrication processes, including, but not limited to, cleaning and surface preparation. The unit's optimized design and superior automation capabilities make it an ideal choice for users seeking a reliable and high-quality wet processing machine.

There are no reviews yet