Used TEL / TOKYO ELECTRON Expedius #9038418 for sale

URL successfully copied!

Tap to zoom

ID: 9038418

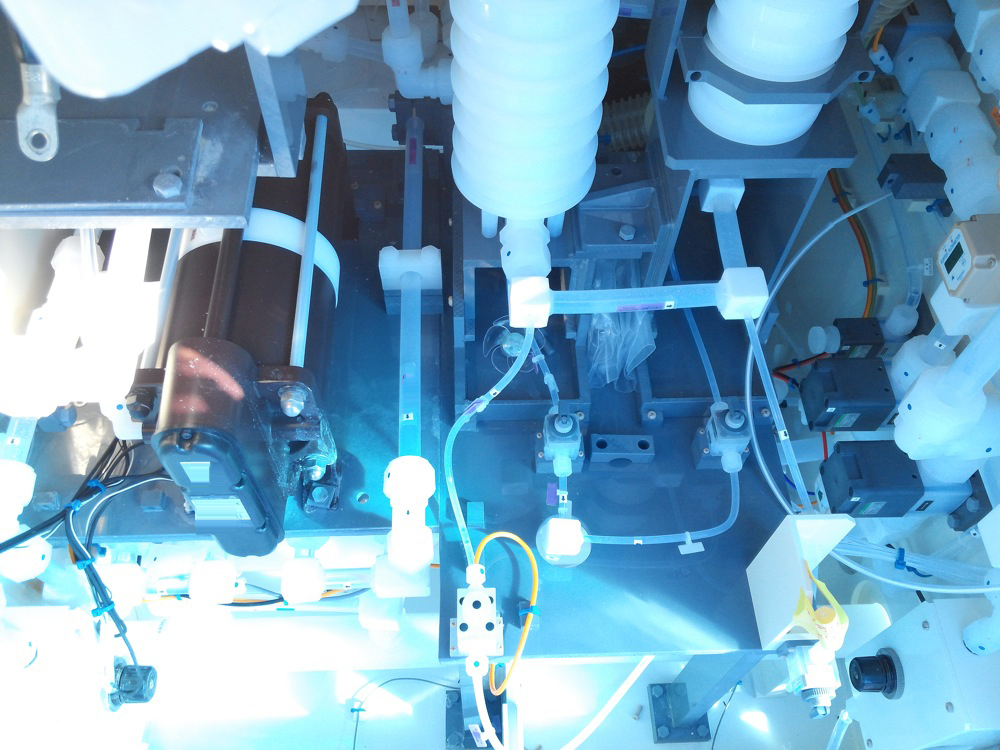

Wet benches, 12"

Basic config: Bath configuration: LD-FIMS-SPM-HQDR-SC1-HQDR-SC1-HQDR-FRD-FRD

Load/unload port: 2 (common)

Wafer size: 300 mm

Batch Size: 50 Wafer

Software: SECS2

Mecha: Motor, servo motor

(3) Robots

Chuck: Quartz

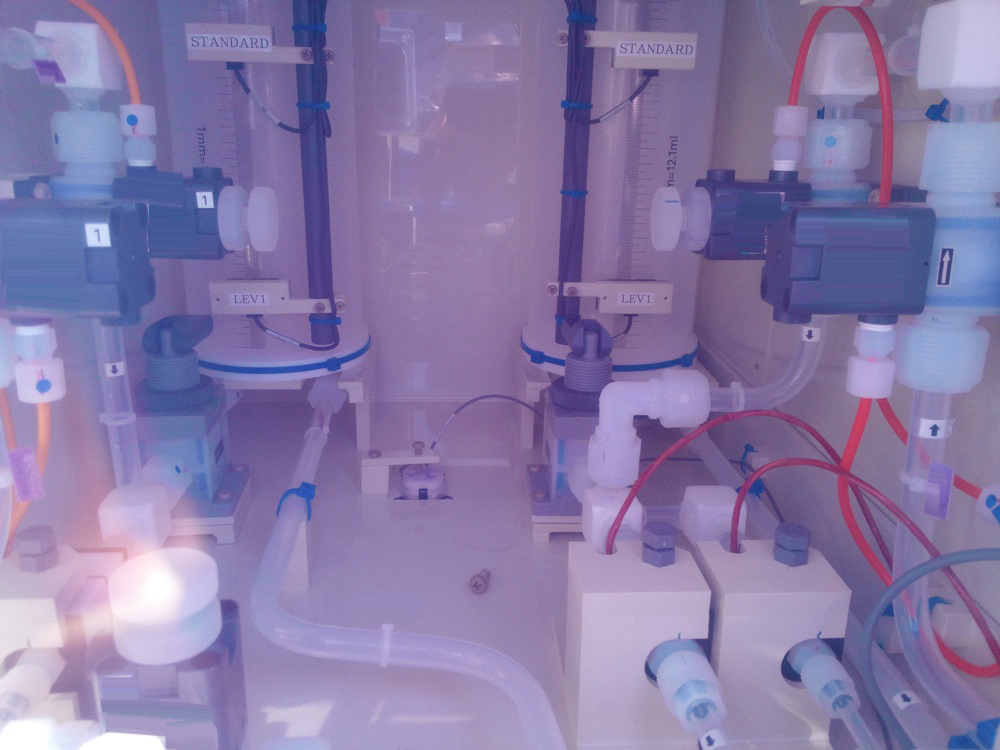

SPM Bath: Matrial Quartz

Heater: 6 kw

Filter: 30 nm

Chemical: H2SO4,H2O2

Wafer Guide: Quartz

QDR Btah: Material Quartz

Heater: None

Filter: None

Chemical: DIW.Hot DIW

Wafer Guide: Quartz

SC1 Bath: Material Quarz

Heater: 6 kw

Filter: 30 nm

Chemical: NH4OH,H2O2

Wafer guide: Quartz

HQDR Bath: Material Quartz

Heater: None

Filter: None

Chemical DIW/HOT DIW

FRD Bath: Material PVDF

Chemical IPA, DIW

Wafter Guide: PVDF

2006 vintage..

TEL / TOKYO ELECTRON Expedius is a wet station for semiconductor fabrication and development. It is a versatile and low-cost solution for the processing of small scale semiconductor components and wafers. It is designed for use in a wide range of applications such as low cost fabrication, thin film deposition, lithography imaging, etching, chemical vapor deposition (CVD), and resist processing. TEL Expedius uses a robust hardware platform and software-defined controls to achieve superior performance and throughput. TOKYO ELECTRON Expedius is equipped with a micrometer-precision tool holder for accurate wafer handling, a digital imaging equipment (DIS), a scanning electron microscope (SEM) for imaging and metrology, a FEM optical digital imaging system (ODIX) for rapid-image scanning, and a CORNERSTONE process control data management unit for process automation. The machine also includes a high-powered variable frequency radiofrequency (RF) generator, a high-powered heat source, and a high-speed precision X/Y motion stage for precise wafer processing, as well as a precision powder dispensing tool. The asset also features the SDTM-2000 process automation software for process control, process monitoring, and process optimization. The software is designed to help achieve optimal overall model performance by allowing users to monitor and control process parameters, such as gas pressure, gas flow rate, and temperature, to ensure consistent results from wafer to wafer. Expedius also features advanced process management functionalities such as an elapse time recorder, an event counter, and a process log. These features allow for precise process tracking and optimization. Additionally, the equipment supports loading and unloading of samples independently, which increases throughput and allows for higher levels of automation. TEL / TOKYO ELECTRON Expedius is designed to meet the demanding requirements of the semiconductor industry, offering superior performance, precision, repeatability, and scalability. It provides a cost-effective solution for the processing of small-scale semiconductor components and wafers, and is a great choice for any wet station application in the industry.

There are no reviews yet