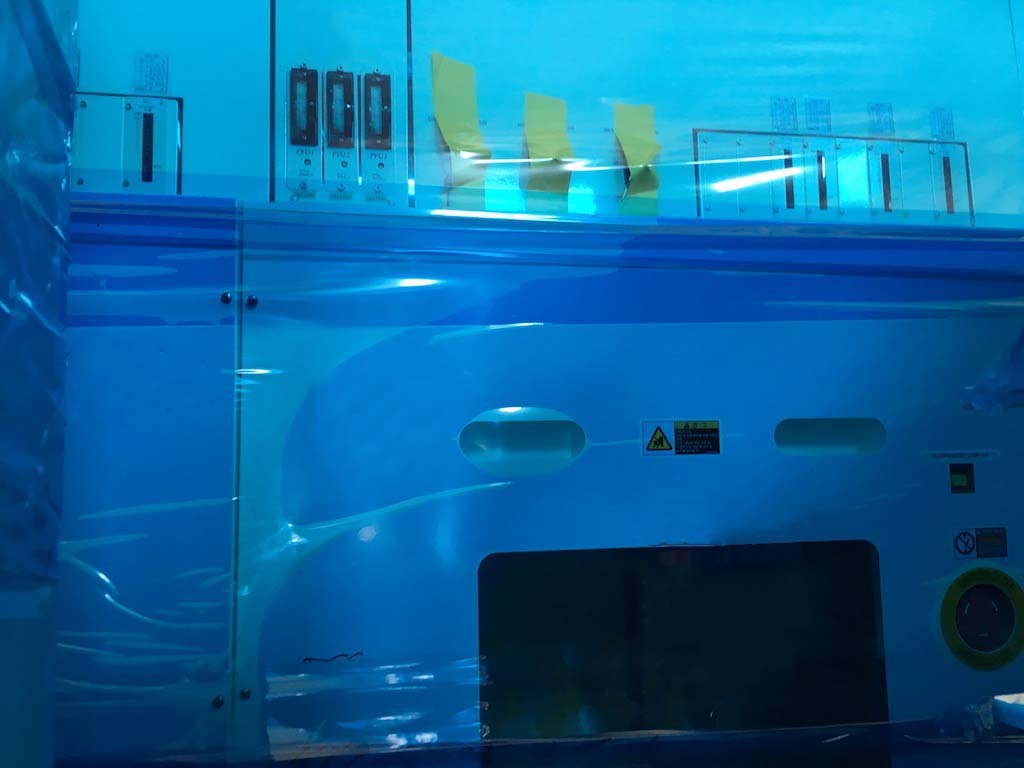

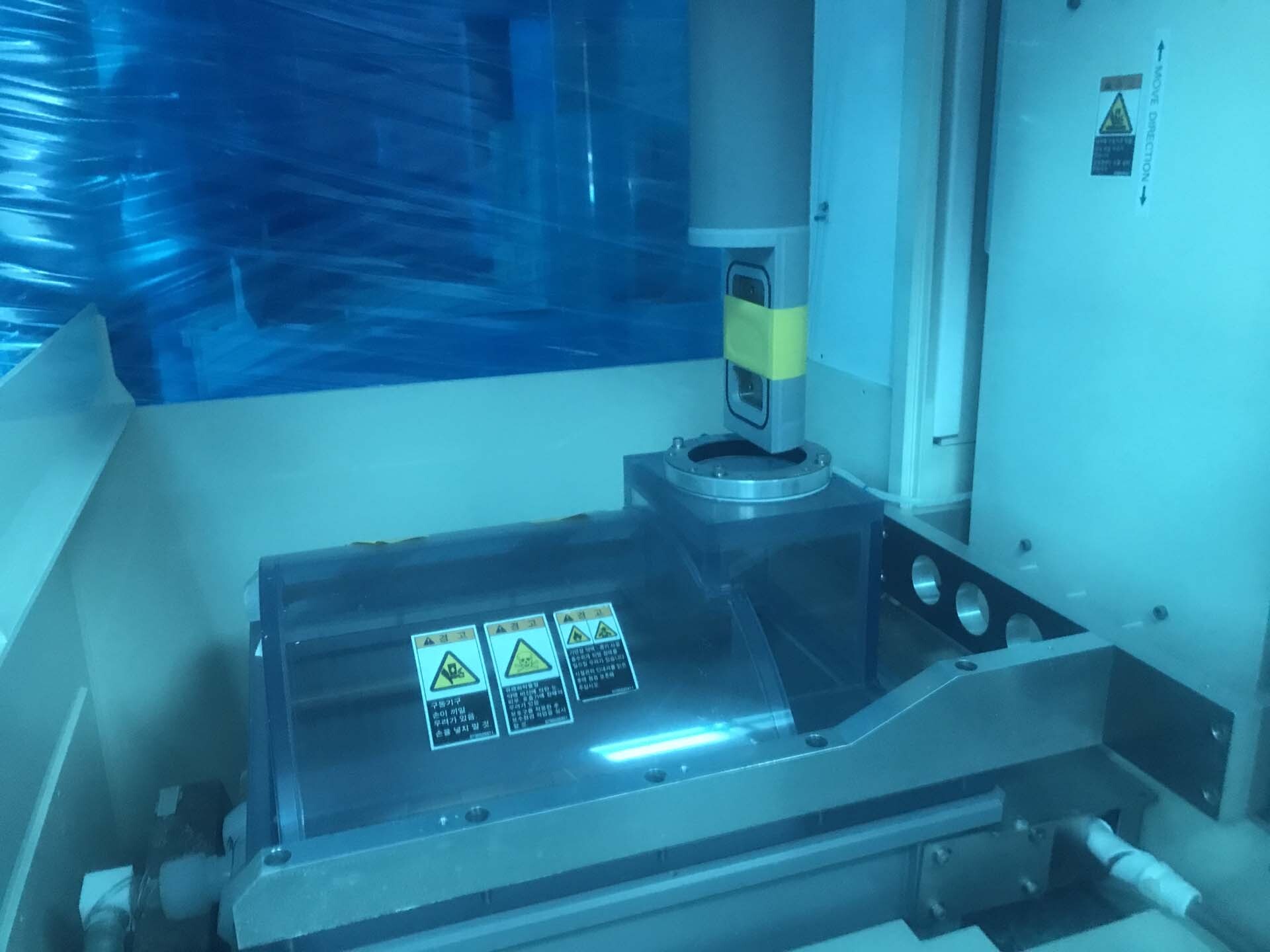

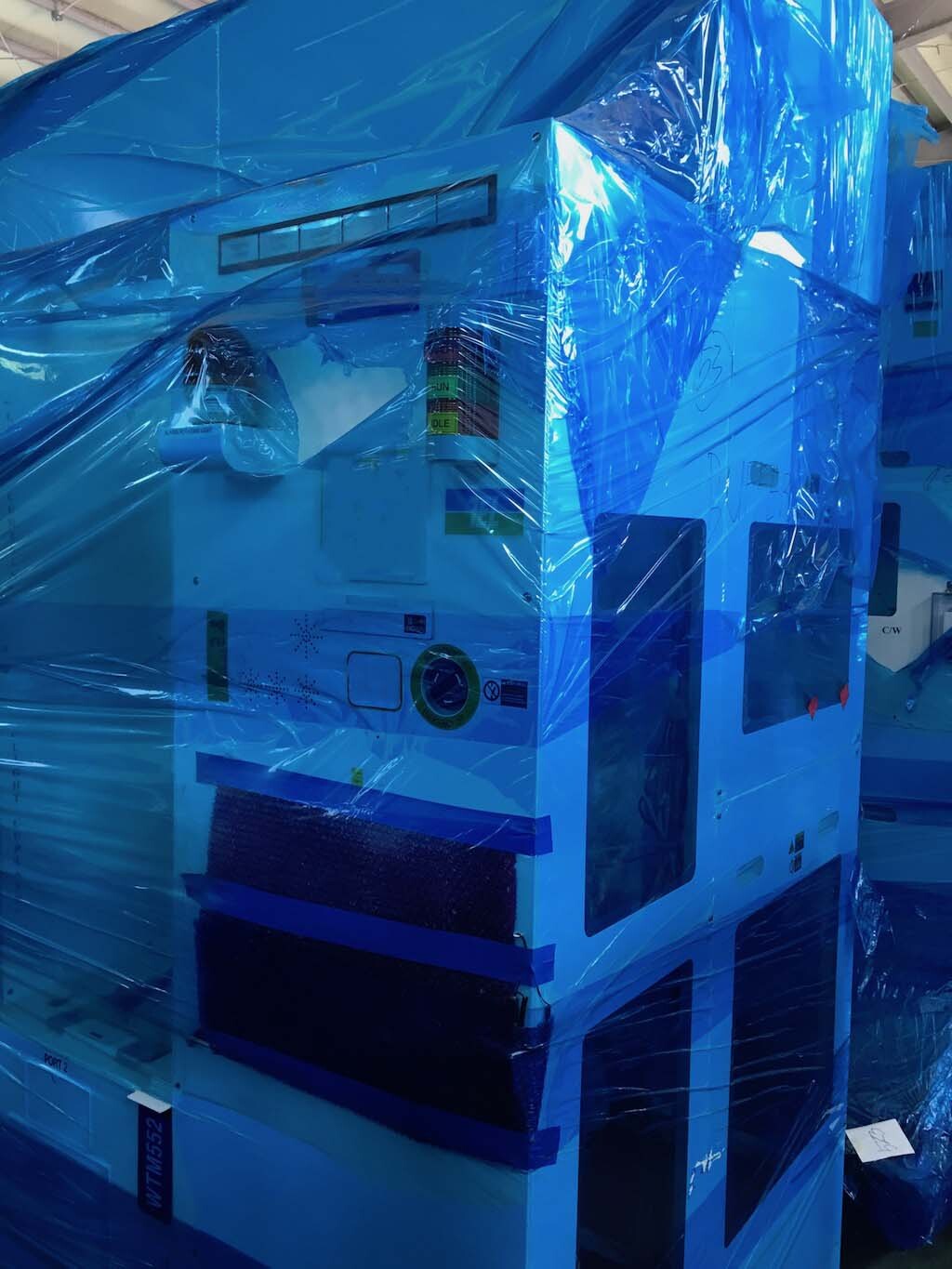

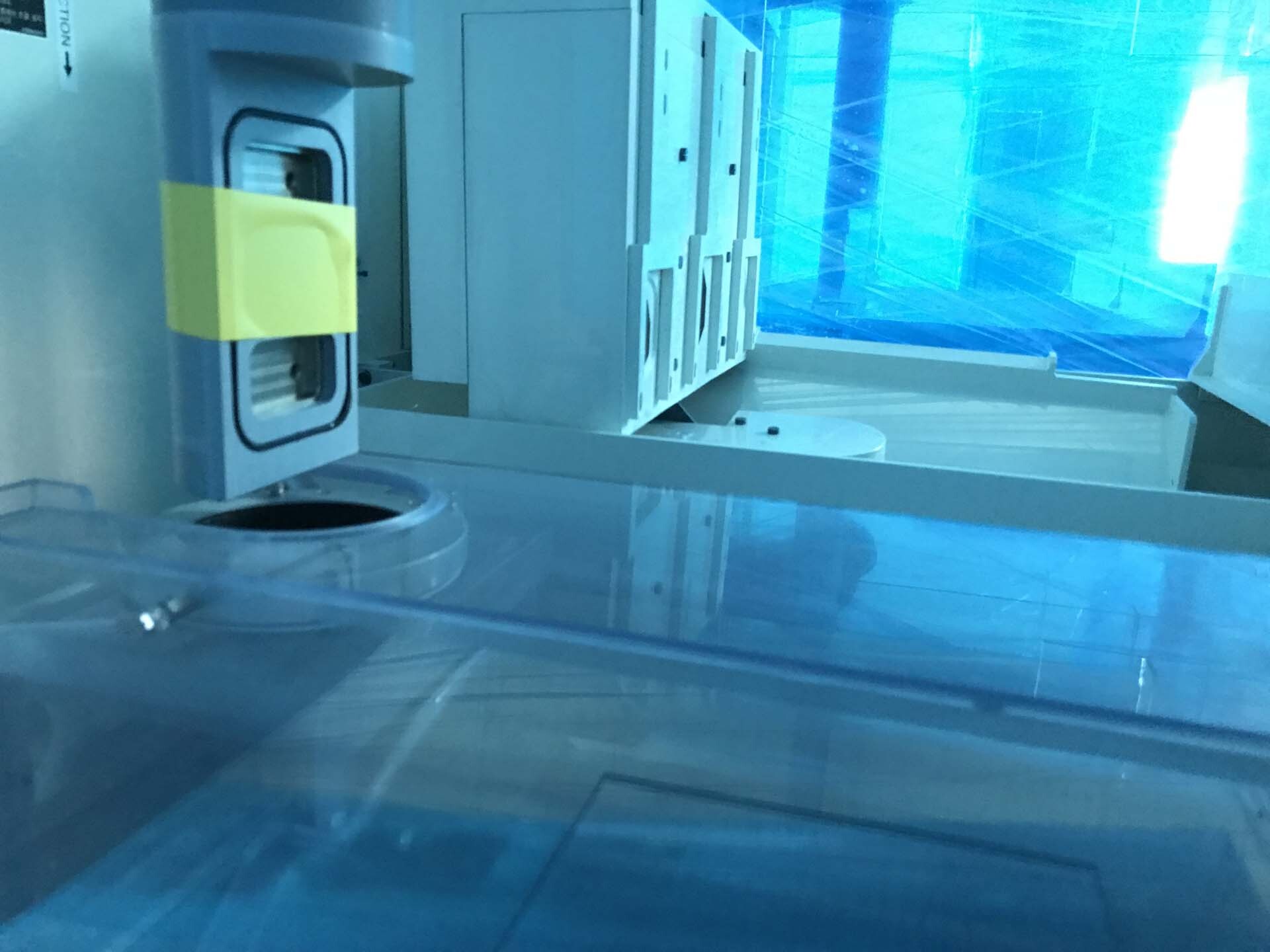

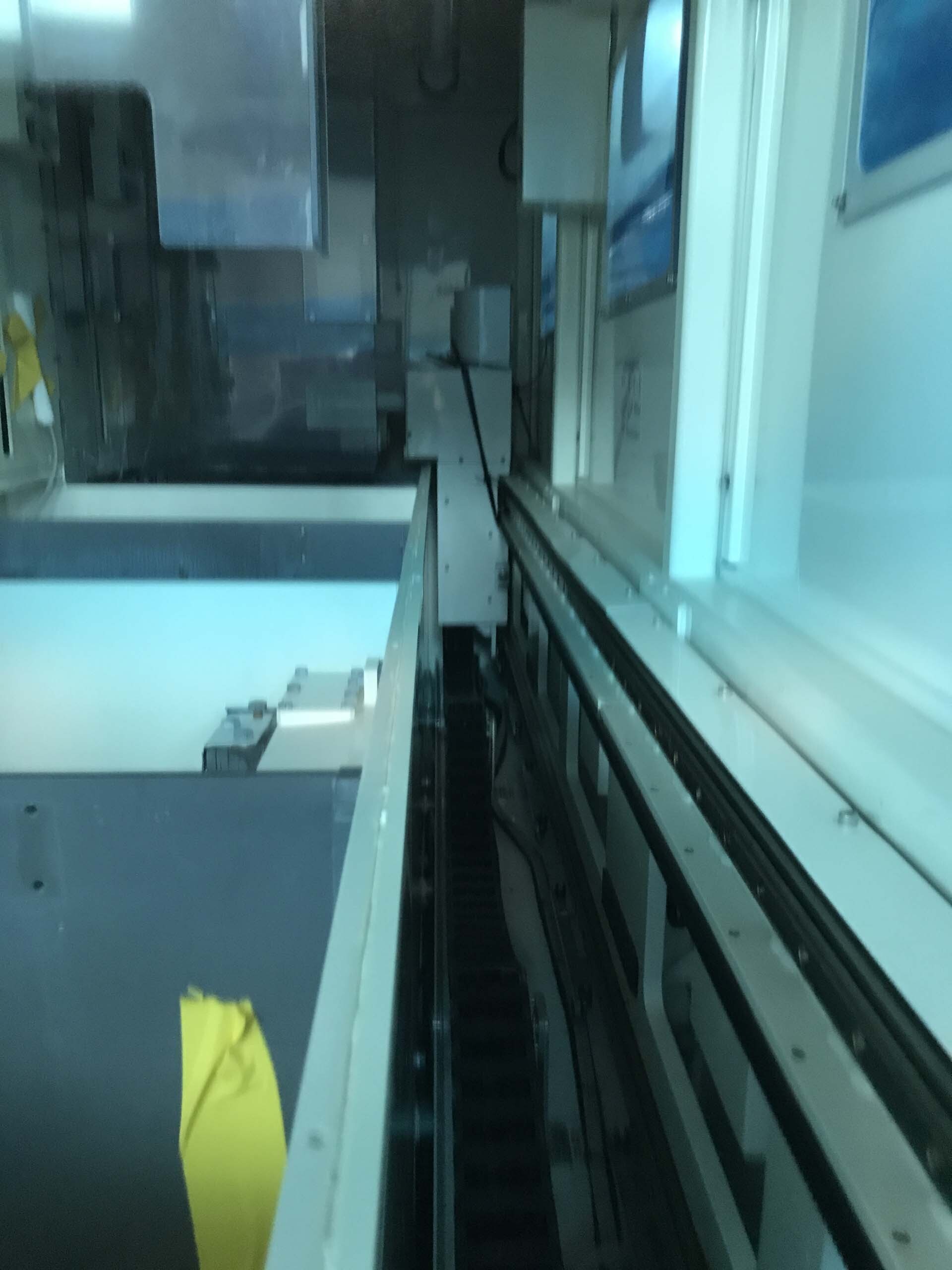

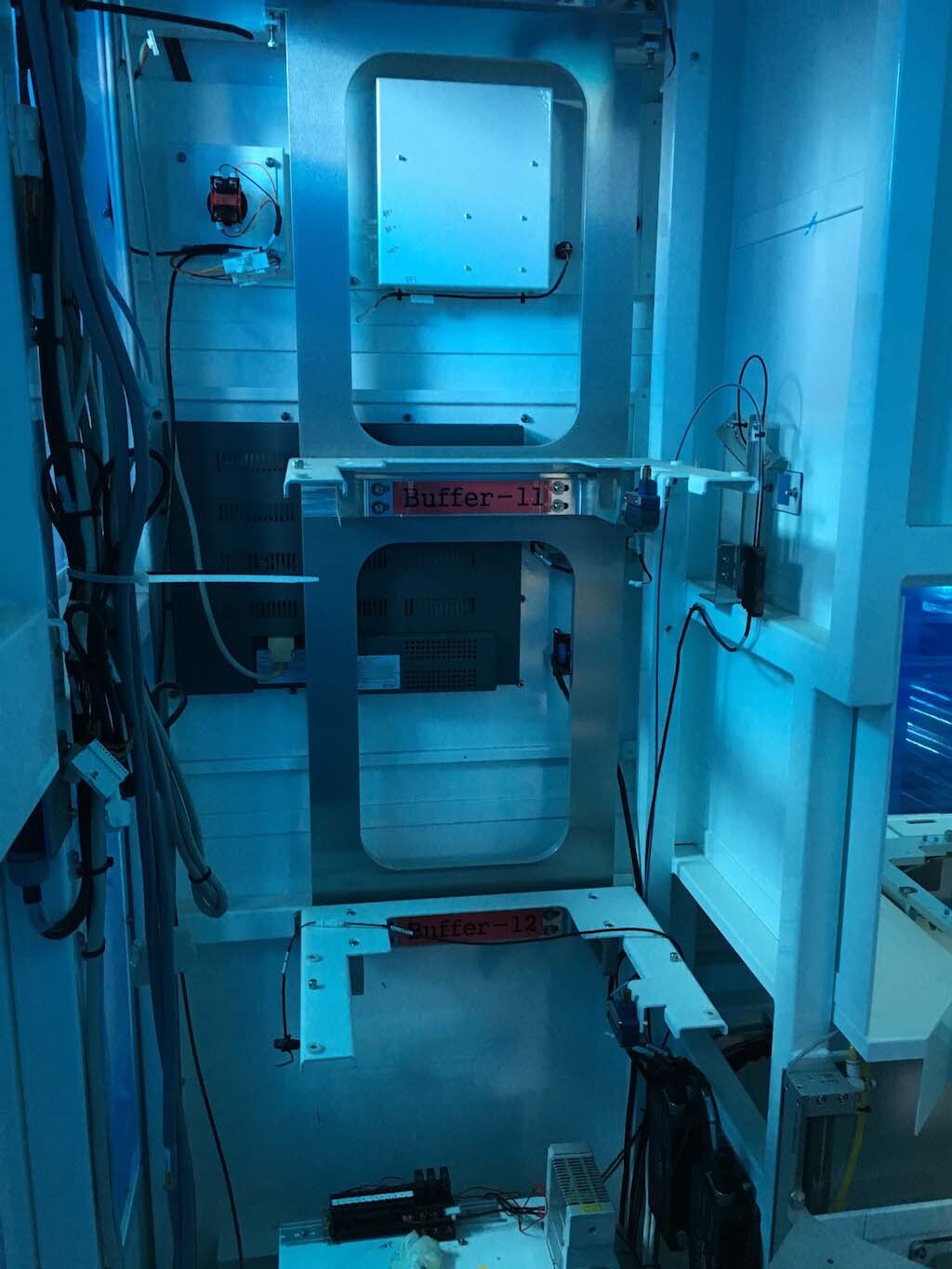

Used TEL / TOKYO ELECTRON UW-300Z #9204046 for sale

URL successfully copied!

Tap to zoom

ID: 9204046

Wafer Size: 12"

Vintage: 2004

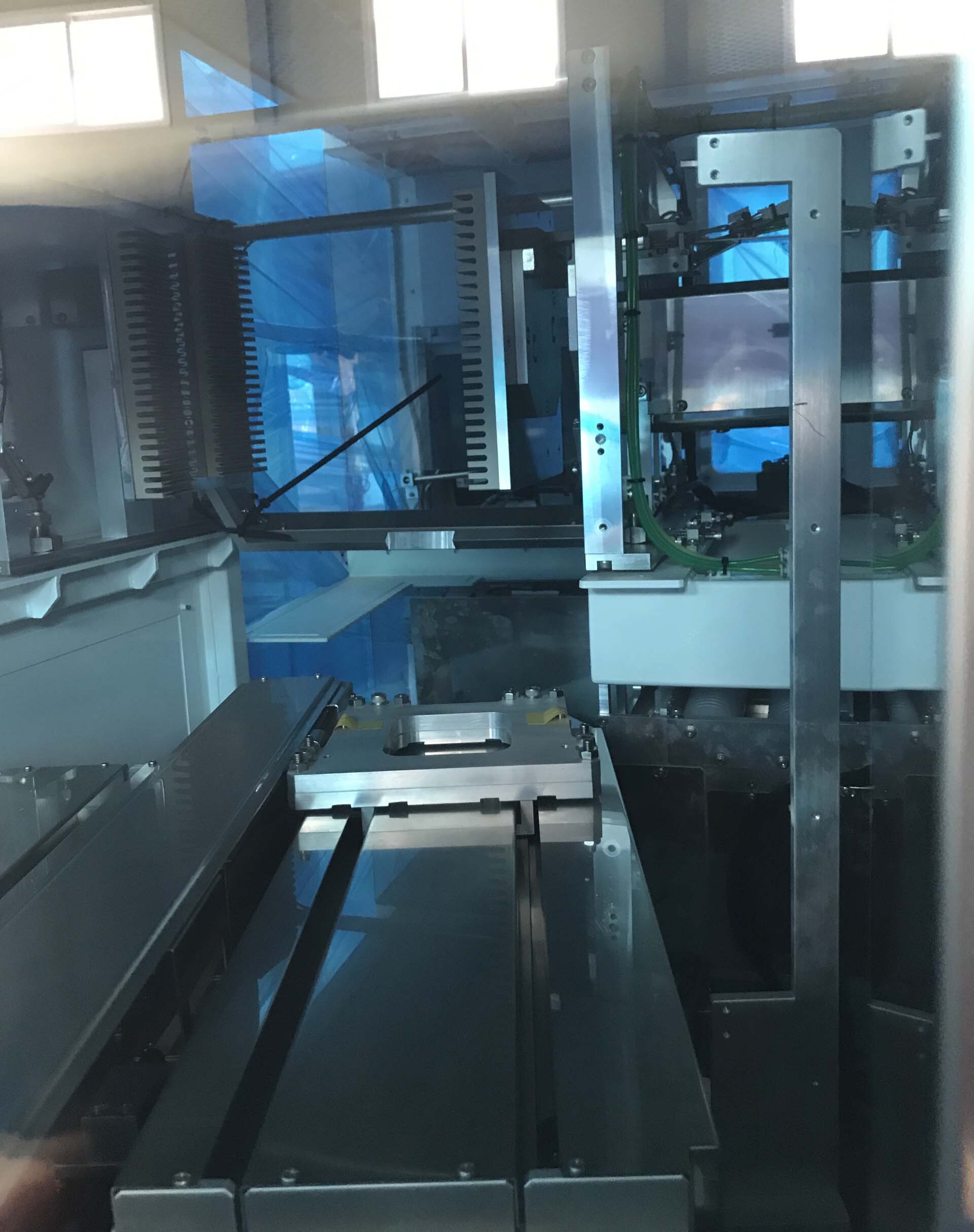

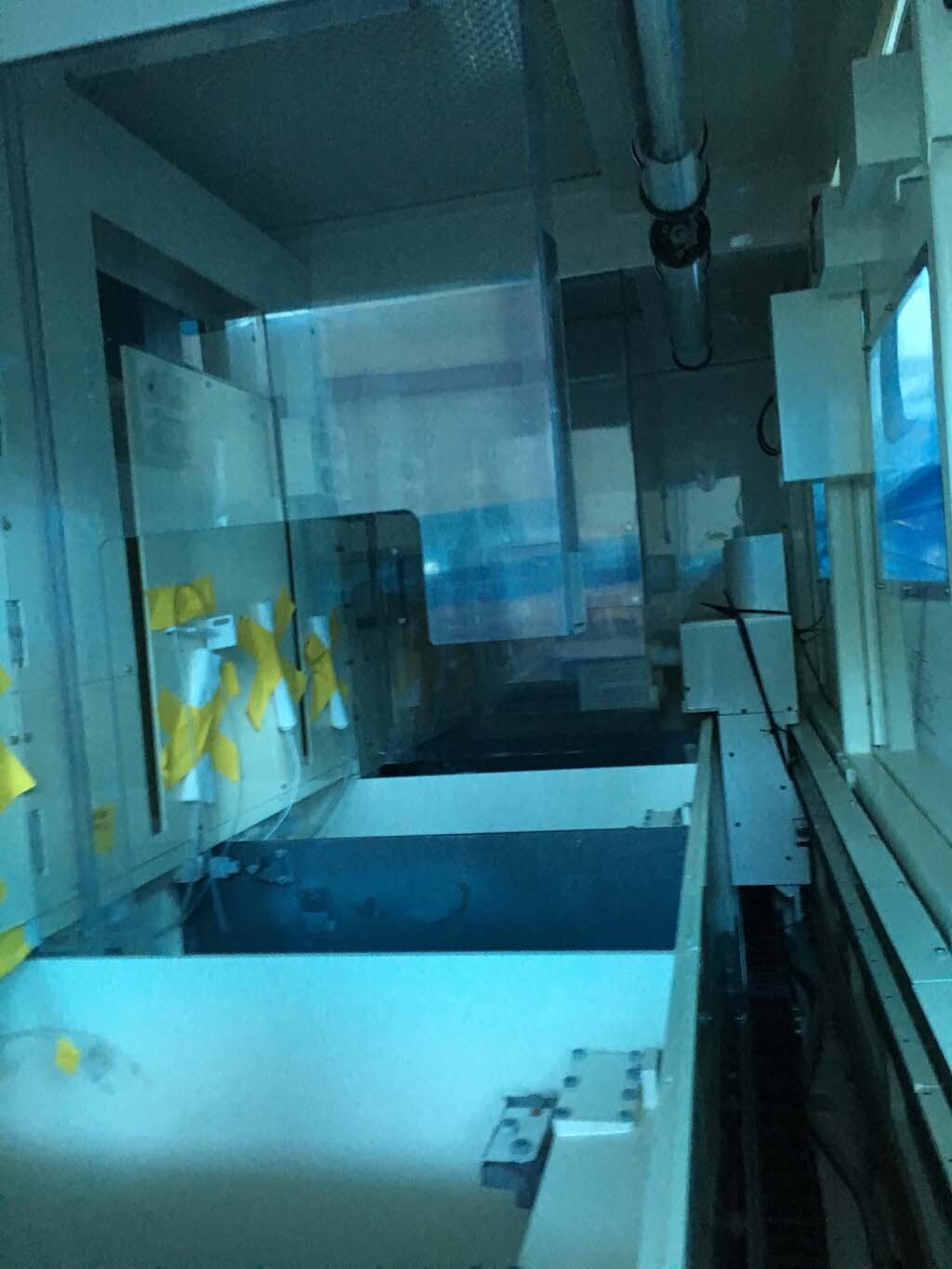

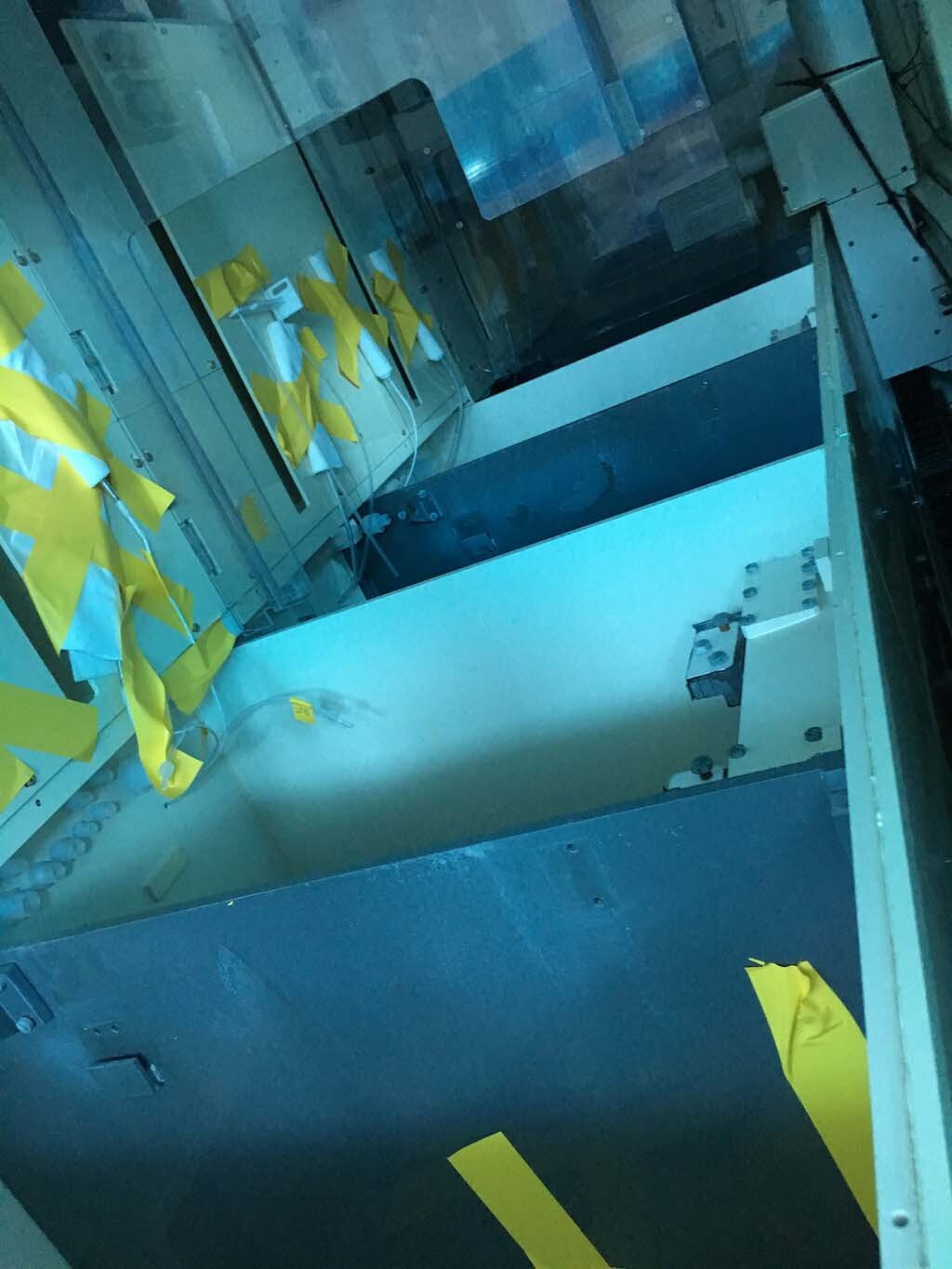

Wet station, 12"

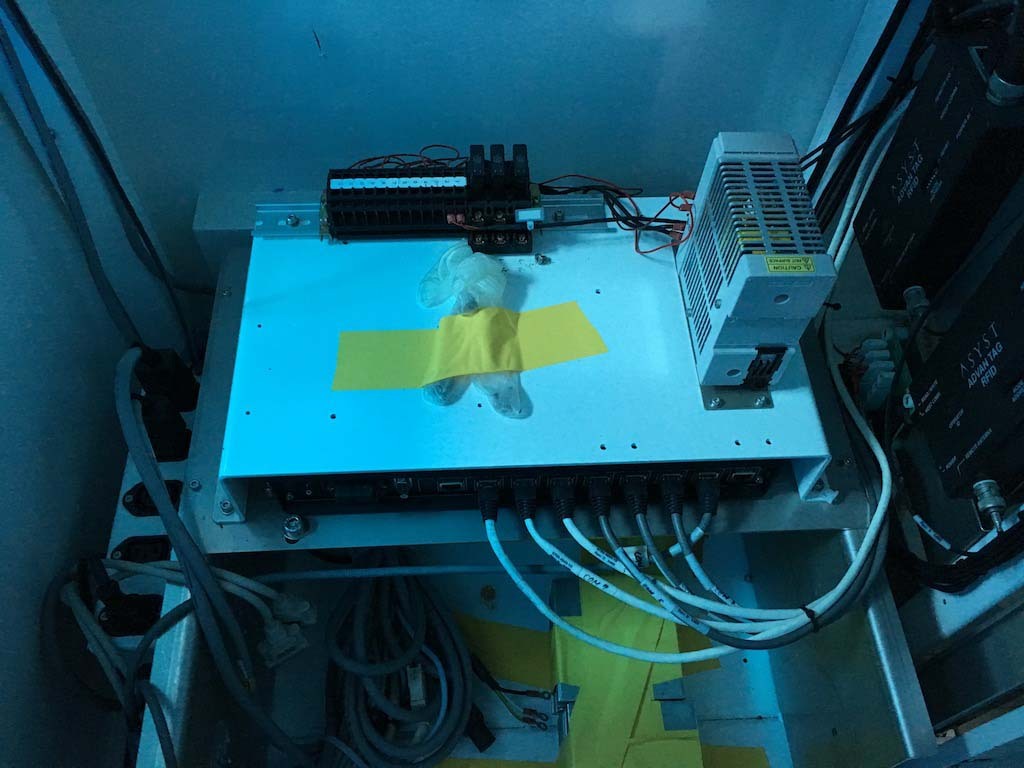

Main computer

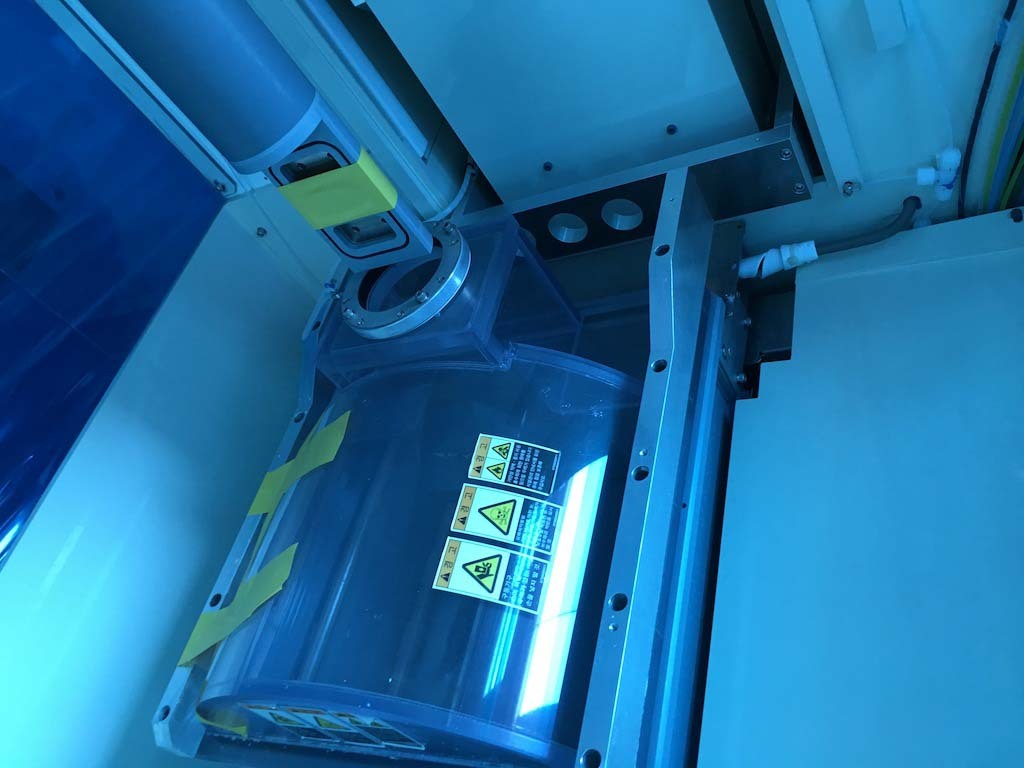

Bath

SRM Tank

Temperature controller

Heater

Exhaust unit

FOUP Type 1: ENTEGRIS (AF3CWFAB20BUAFW)

FOUP Type 2: DAINICHI (SF300-02)

Wafer pitch: Half pitch

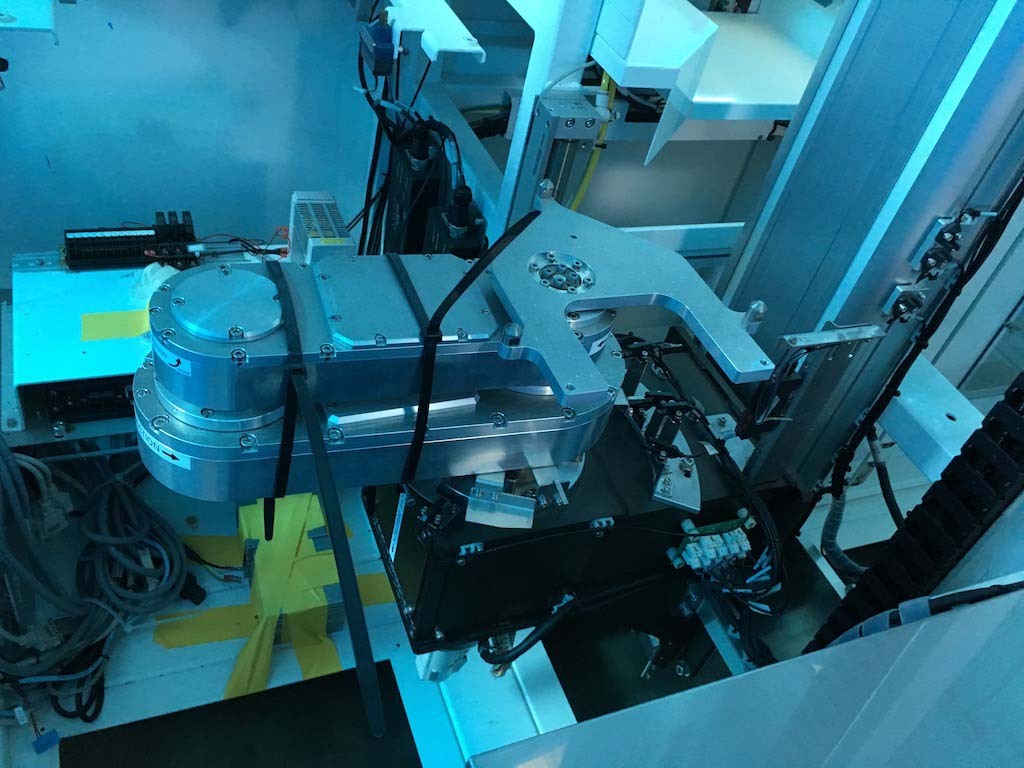

Arm

Wafer flow direction: Rear / Front

Number of wafers in process: (2) FOUP

(25) Slots FOUP

Chemical central supply

SD2 Dryer: Rinse and dry

Stocker: (12) FOUPs

Chemical:

HF

NH4OH

H2O2

HCL

IPA

O3W

Mainframe: Frame per and (2) Bath modules

Chemical bath: (4) Bath modules

Does not include CW and SD2

No factory mutual

External units:

Fire extinguisher

O3 Gas generator

No fluorescent lamp

Adjuster plate SS-304: 15 x 100 x 100 mm

Seismic bracing

Air operated valve

Display bath level sensor: Arm side and M/C

Outer panel material (C/S and SD2): SPCC

Chemical area panel material: Clear PVC

AMHS: OHT

No MMHS

FOUP ID Reader

On-line: GEM: SEMI E5 and E30

I/O Interface: HSMS to LAN (SEMI E37)

Signal tower: Front and maintenance area

CPU: PIII (600 MHz)

Operating system: Windows NT

Media: Floppy and zip

FOUP Station:

Load port:

(2) FOUP

FOUP Present sensor

Notch adjustment function

Shutter

Area sensor

KEYENCE BL601 FOUP ID Reader

FIMS Port (POD Opener):

Jump slot sensor

Wafer number and slot sensor

Carrier transfer: FOUP Check sensor

Stocker: (12) FOUPs

FFU

Location: Upper section LD / ULD (PTFE)

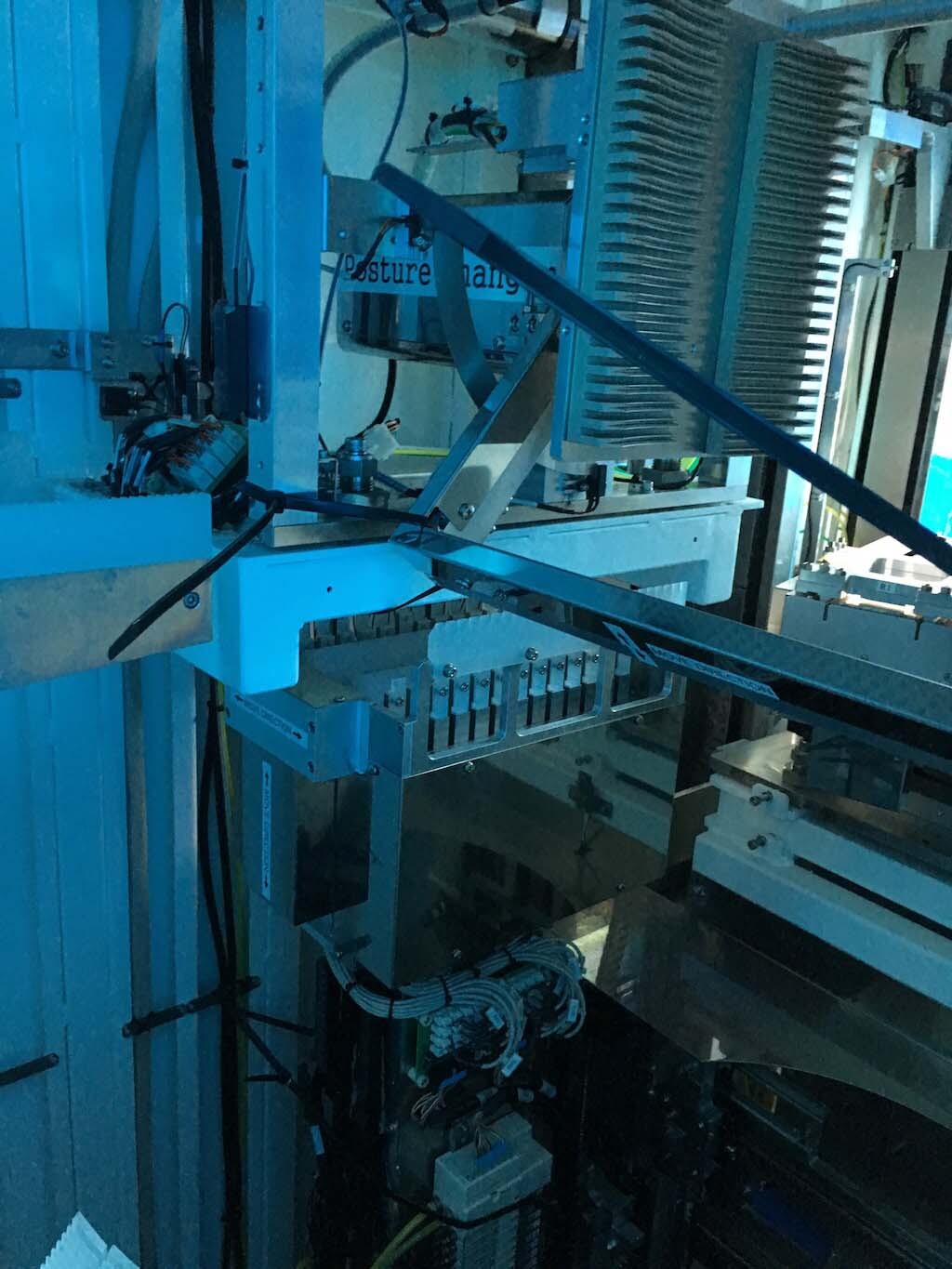

Course / Posture changer:

Pre-post changeover

Process number: 25 Wafers

LD / ULD:

Changes pre-post

Wafer hand turn function

Face to face function: (2) Carriers

Wafer hand material: PCTFE

Ionizer: 5024CE Controller

Other:

Direction access M/C media: Right side

Temporary wafer holder

Process modules:

Module 1: SPOM

Process temperature: 80°C~140°C

Heating method: KOMATSU AIH-64QS CS Heater

Bath material: Quartz

Module 2: QDR (Hot)

Process temperature: 70°C/20°C

No hot DIW gen

Central supply

Bath material: Quartz

No MEGASONIC

DIW Shower (Hot)

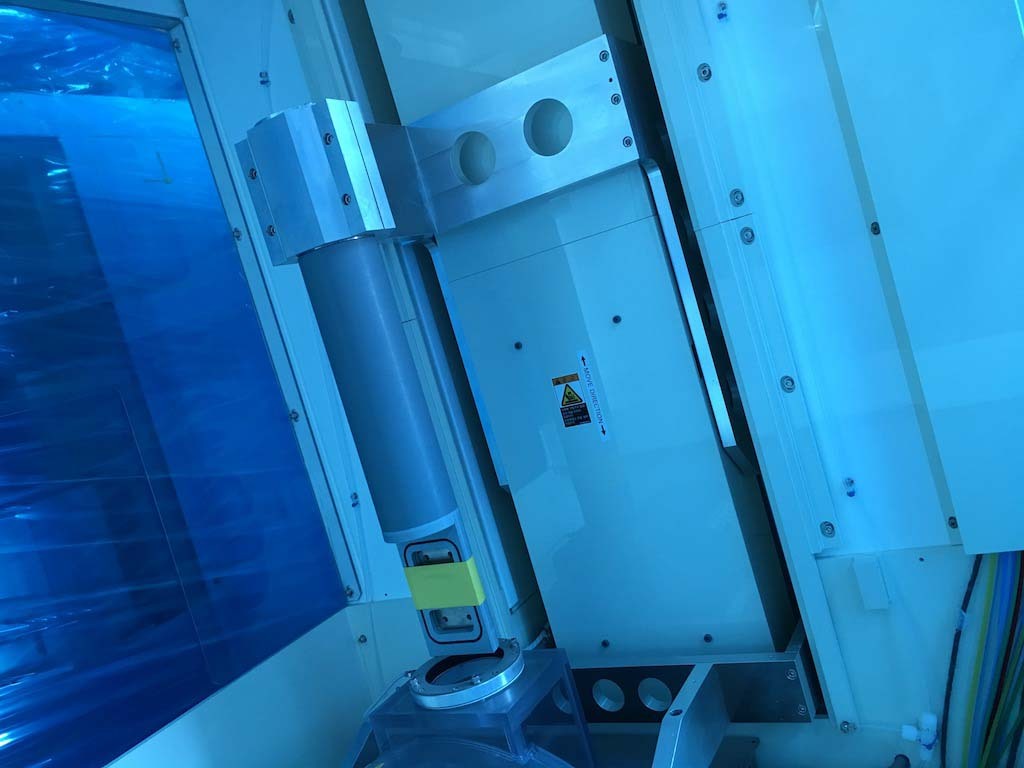

Module 3: SC1(M/S)

Process temperature: 30°C~70°C

Heating method: CS Heater with water jacket

Change mixing ration recipe

Bath material: PTFE

HORIBA CS-131 Concentration monitoring

KOKUSAI Alfa MEGASONIC, 2.4 kW

Module 4: POU

Process temperature: RT°C / Hot 70°C

No hot DIW Gen

Supplied

Bath material: Quartz

Chemical: HCL

SD2 (Rinse + dry)

Facilities:

CDA

N2

DIW

PCW

CM1: H2SO4

CM2: H2O2

CM3: NH4OH

CM4: HCL

CM5: IPA

Exhaust:

General

Solvent (SD2)

Acid (SD2, POU)

Alkali (POU, SC1)

Acid (SPOM, QDR)

Separate drains

AC Power:

EP1 (Normal): 208 VAC, 3 Phase, 125 A

EP2 (CVCF / UPS): 208 VAC, Single phase, 50 A

EP3 (CVCF): 120 VAC, 1 Phase, 5 A

2004 vintage.

TEL / TOKYO ELECTRON UW-300Z is a versatile wet station designed to provide high-end etching, cleaning, and chemical processes to almost any type of substrate. TEL UW300Z utilizes a heated internally heated 480-liter tank which is capable of temperatures ranging from 10 to 75 ℃. This powerful combination of controls provides the user with precise control over all functions of the wet station, optimizing the chemical process. A unique feature of TOKYO ELECTRON UW 300Z is an upper basket, which can be used to hold semiconductor wafers and other substrates to prevent them from touching each other or the walls of the vessel. This basket is designed to tilt and rotate, allowing the user to achieve better process results. UW-300Z can also be outfitted with multiple sizes of quartz or EPDMS spray nozzles, allowing users to apply chemicals with the greatest levels of accuracy. Multiple nozzles can be mounted in each tank, allowing users to create multiple and concurrent processes in different areas. With the addition of a circulation pump, the tank maintains a constant temperature and uniform chemical application. TOKYO ELECTRON UW 300 Z also features a unique safety system, including an automated emergency shutdown switch which is designed to immediately shut off the power in the event of an emergency. Additionally, all pipelines and valves are constructed from stainless steel, providing a corrosion-resistant and long-lasting system. Overall, UW 300Z provides superior performance in a wide range of chemical processes. Its high temperatures and tight control of chemicals provide users with an efficient and reliable system, while its strong construction and safety features guarantee long-term reliability and safety. With TEL UW 300 Z, anyone can easily create precise and optimal chemical processes.

There are no reviews yet