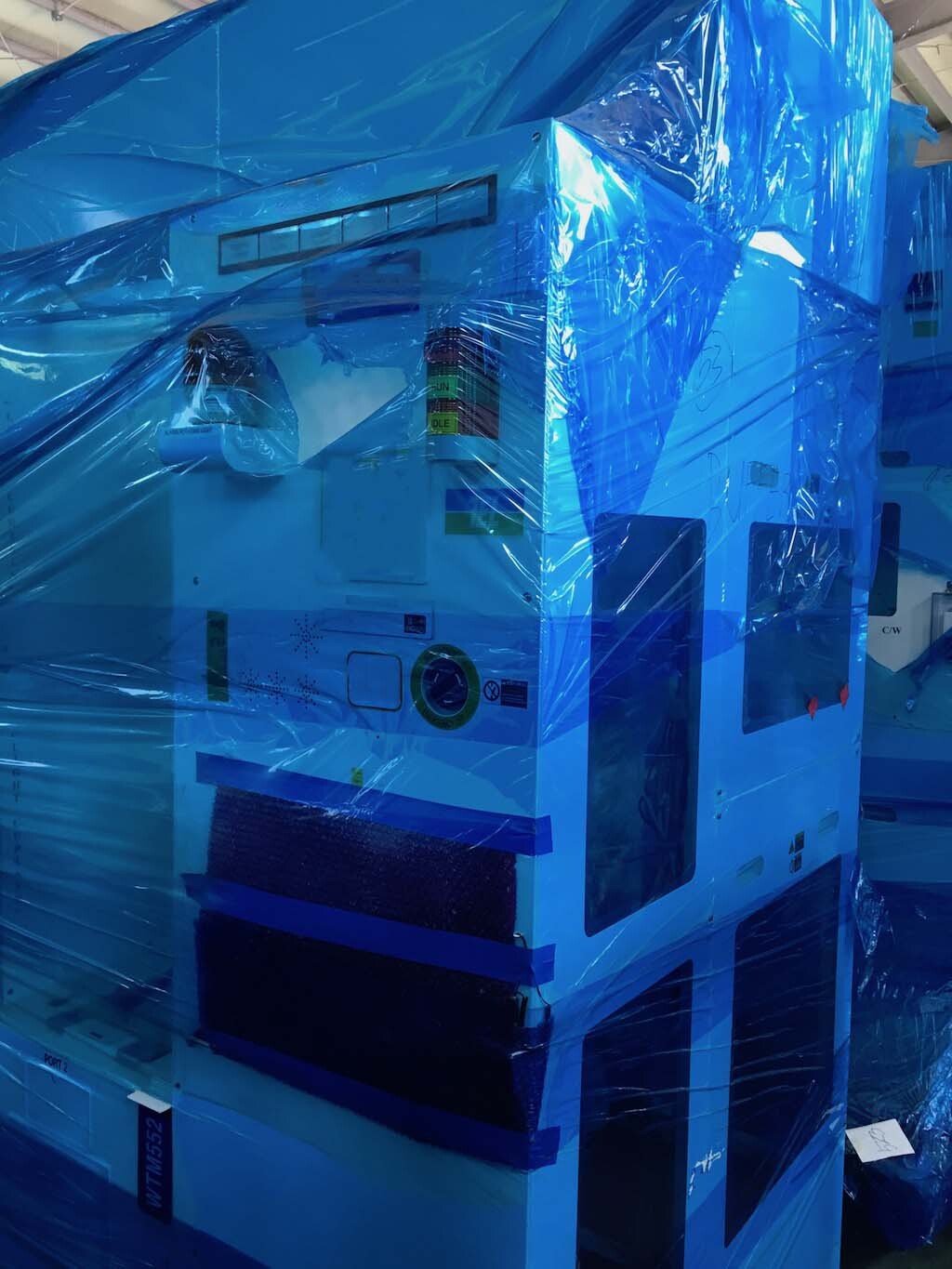

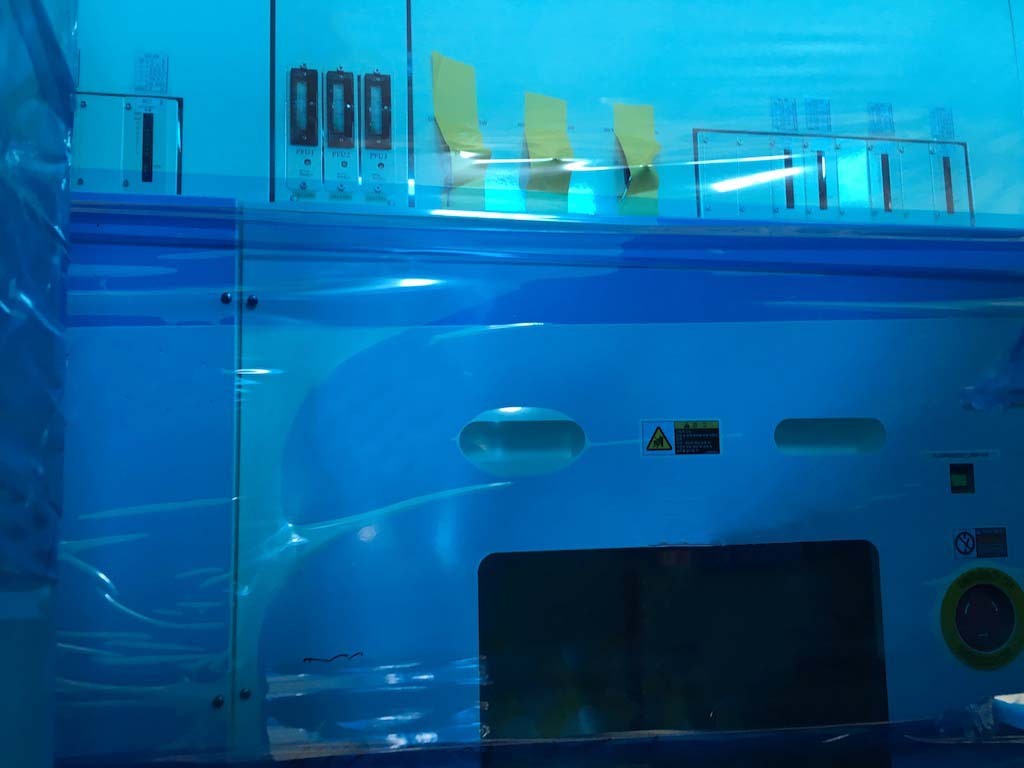

Used TEL / TOKYO ELECTRON UW-300Z #9314664 for sale

URL successfully copied!

Tap to zoom

ID: 9314664

Wafer Size: 12"

Vintage: 2004

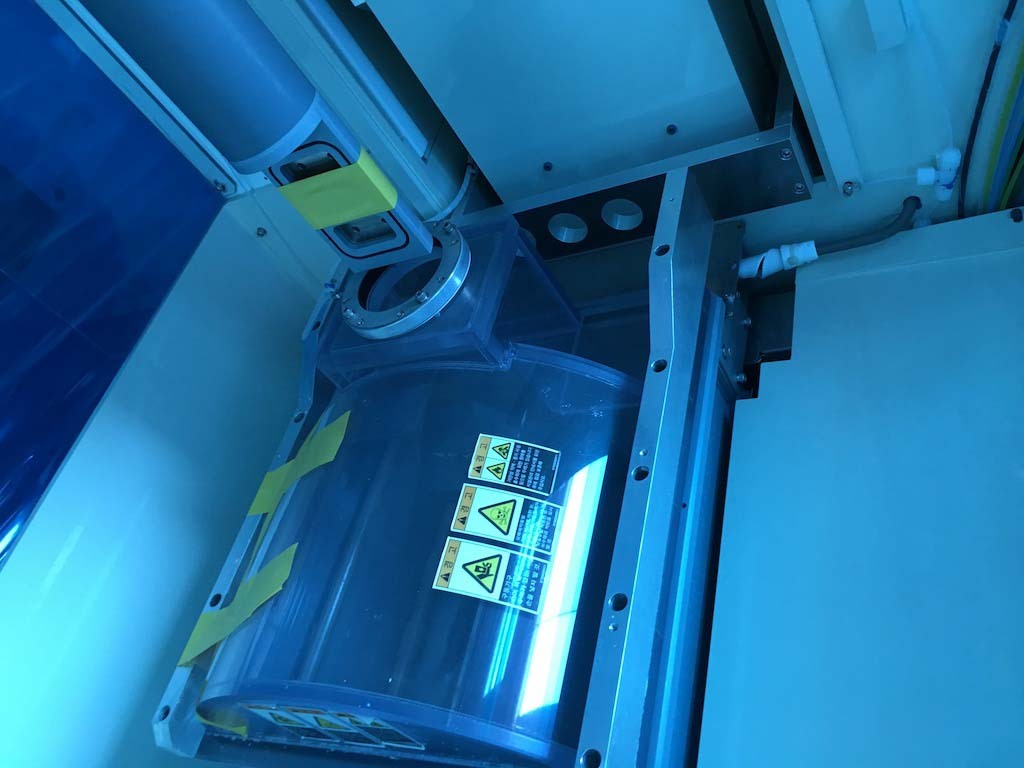

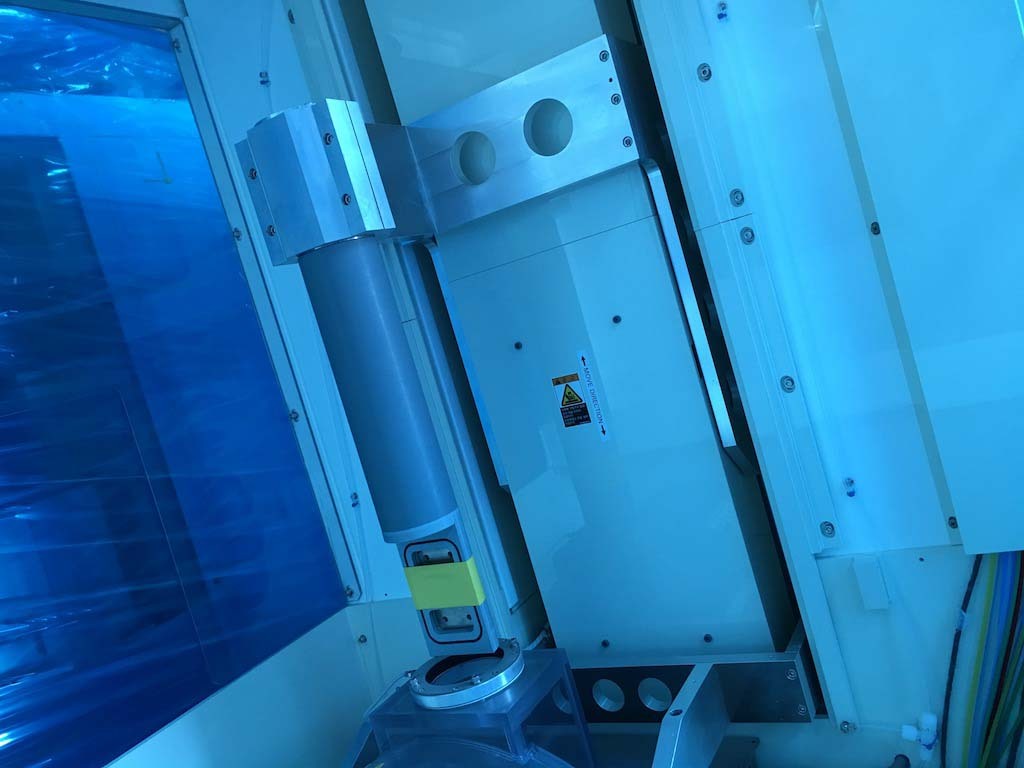

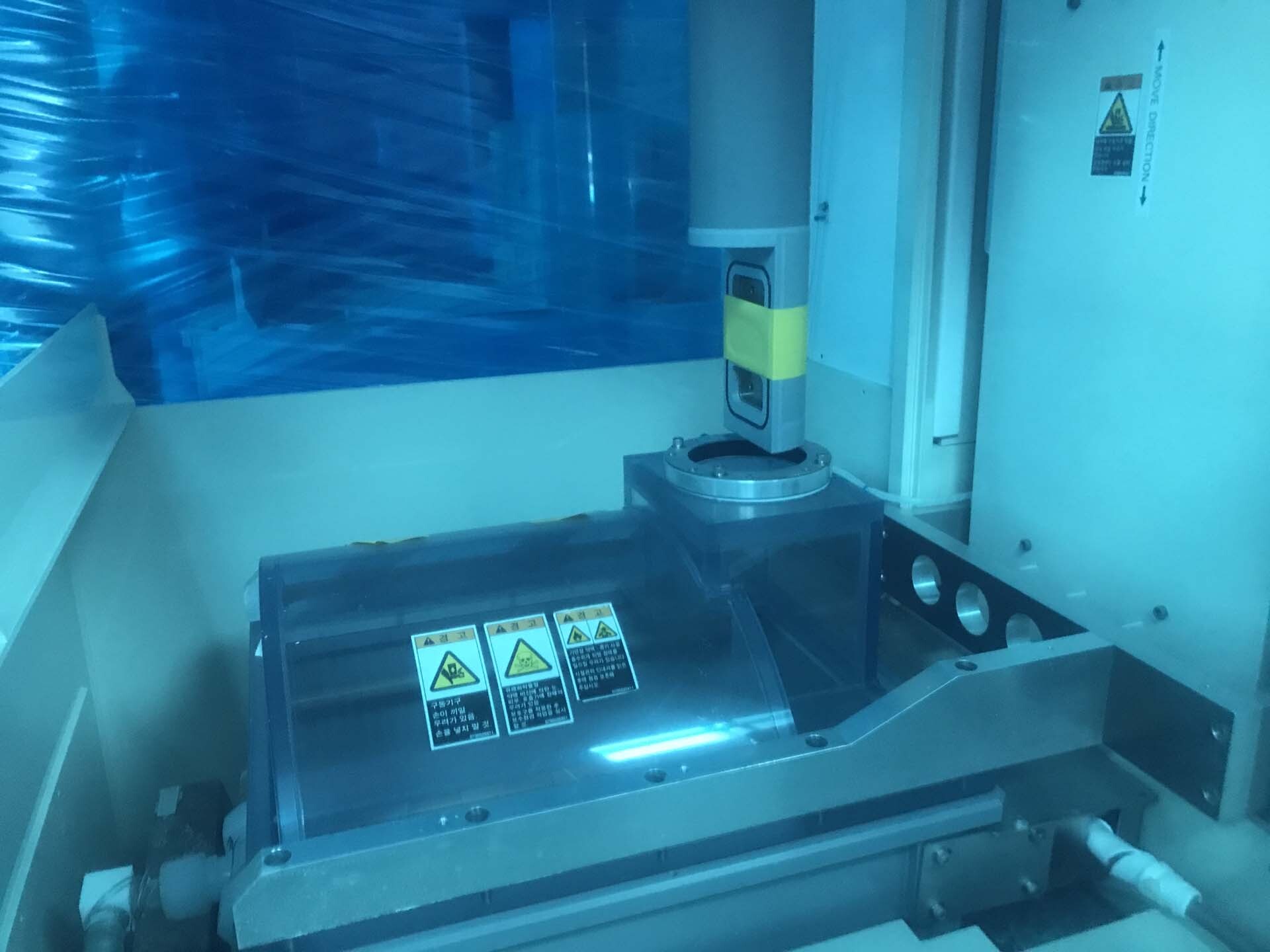

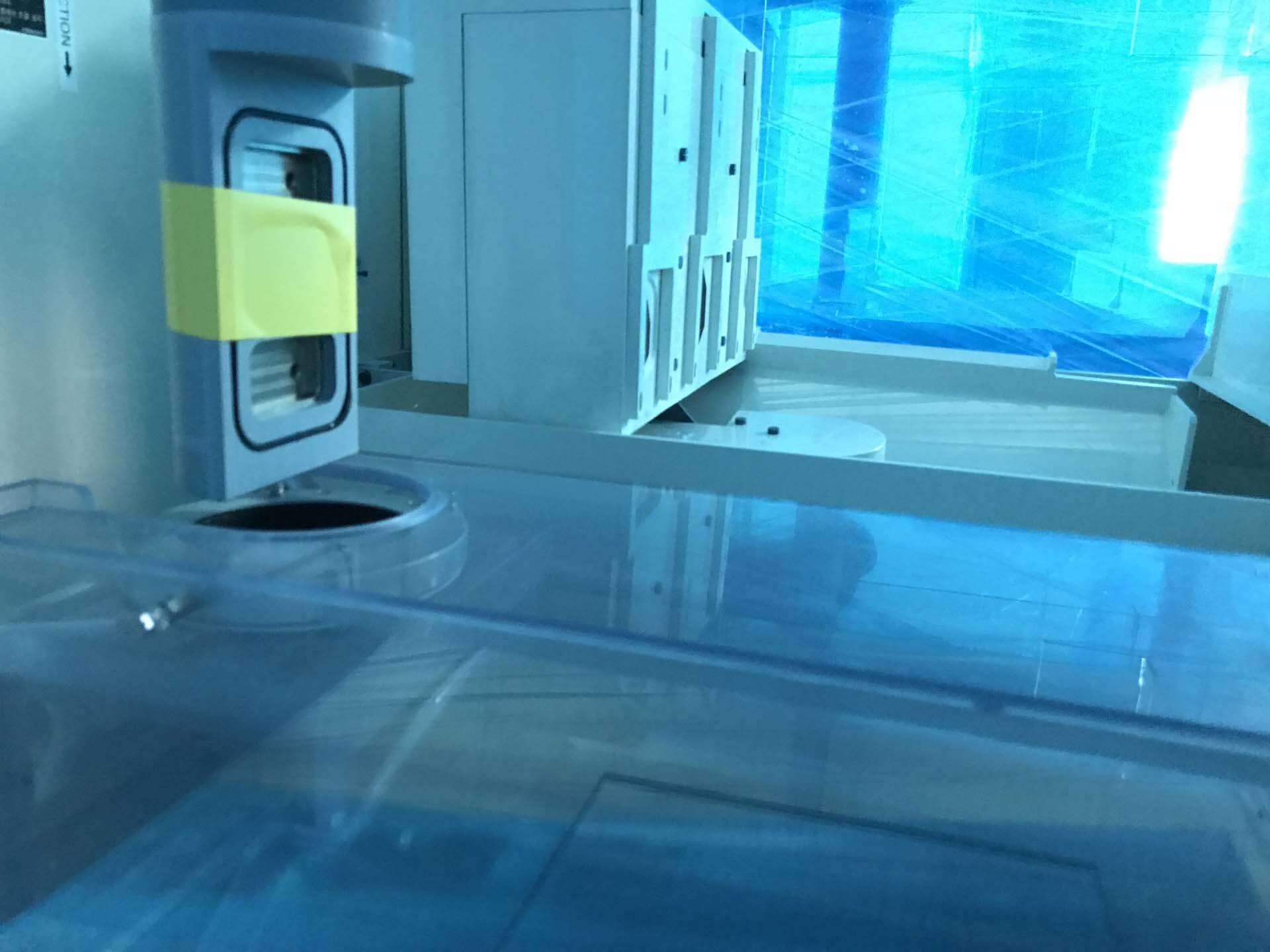

Wet station, 12"

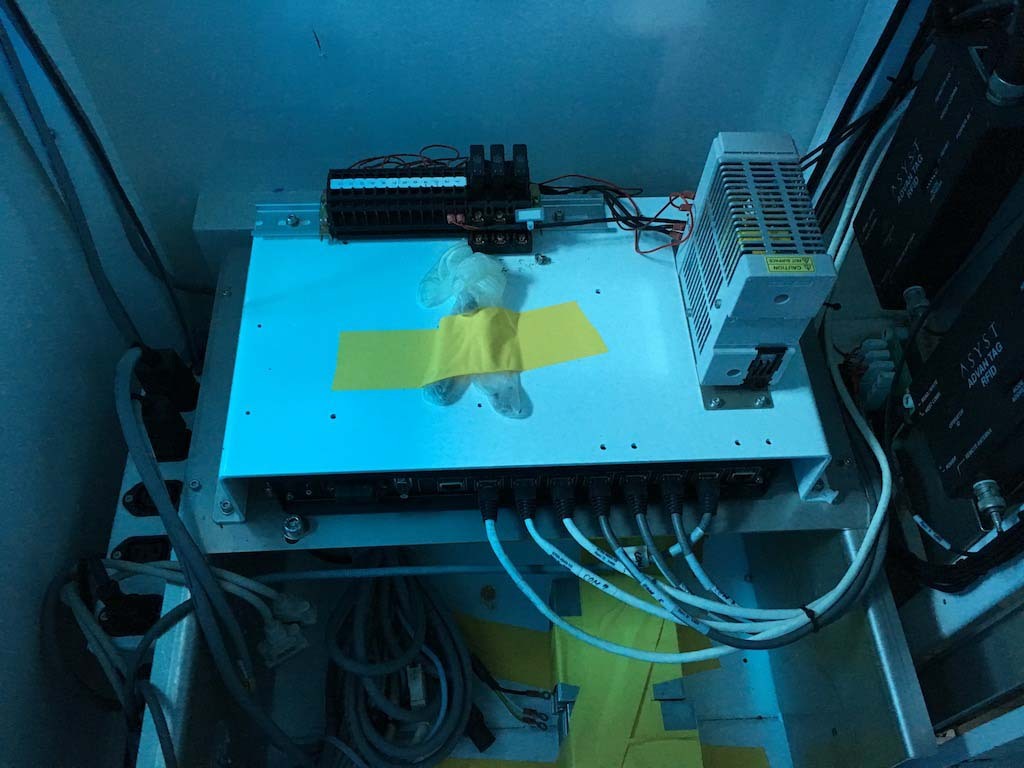

TOADK AQM-100A Resistivity meter measuring system

MITSUBISHI Q06UDHCPU PLC

Gas: H2O2, NH4OH, H2SO2, HCL, IPA

Temperature controller

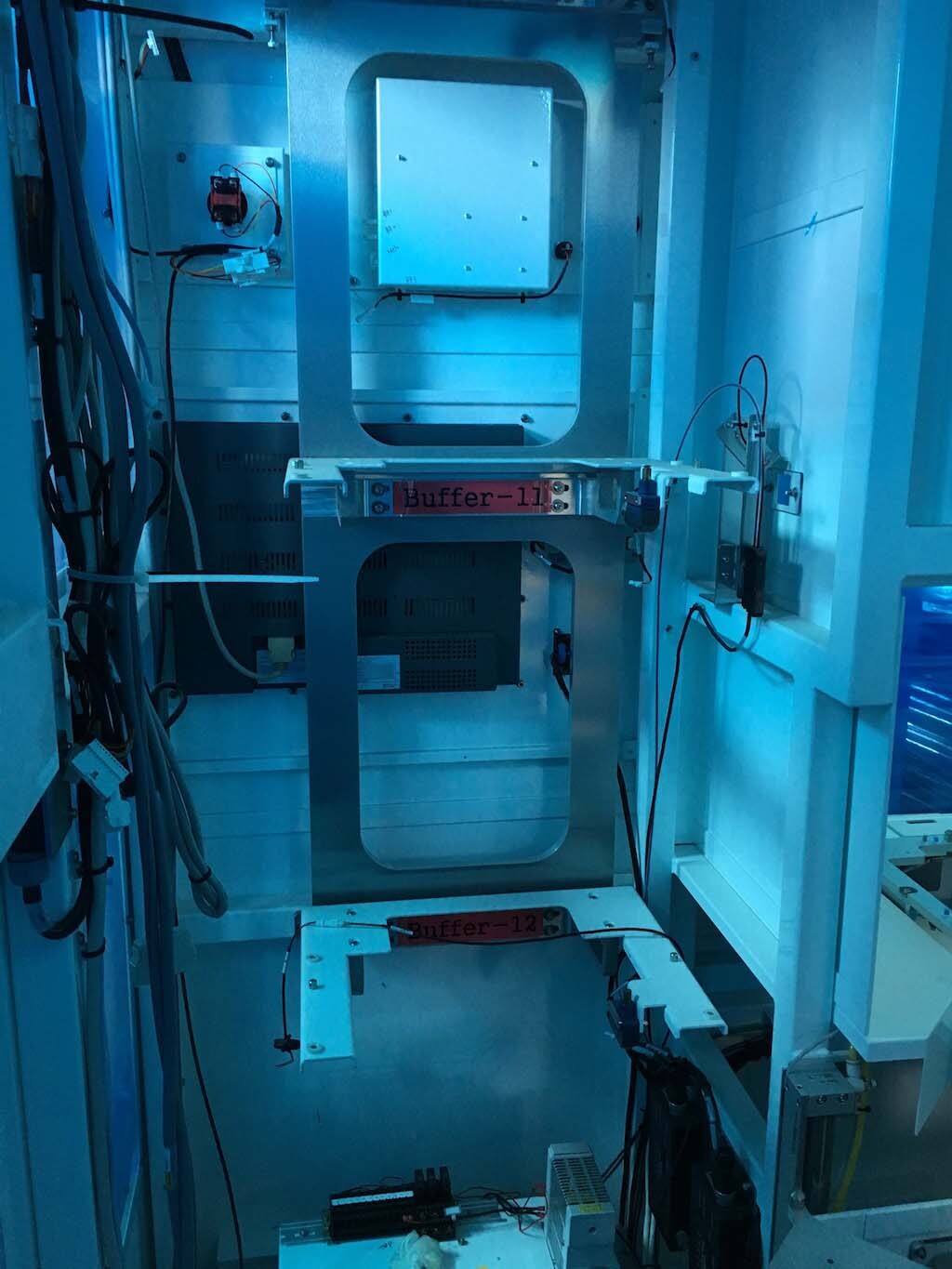

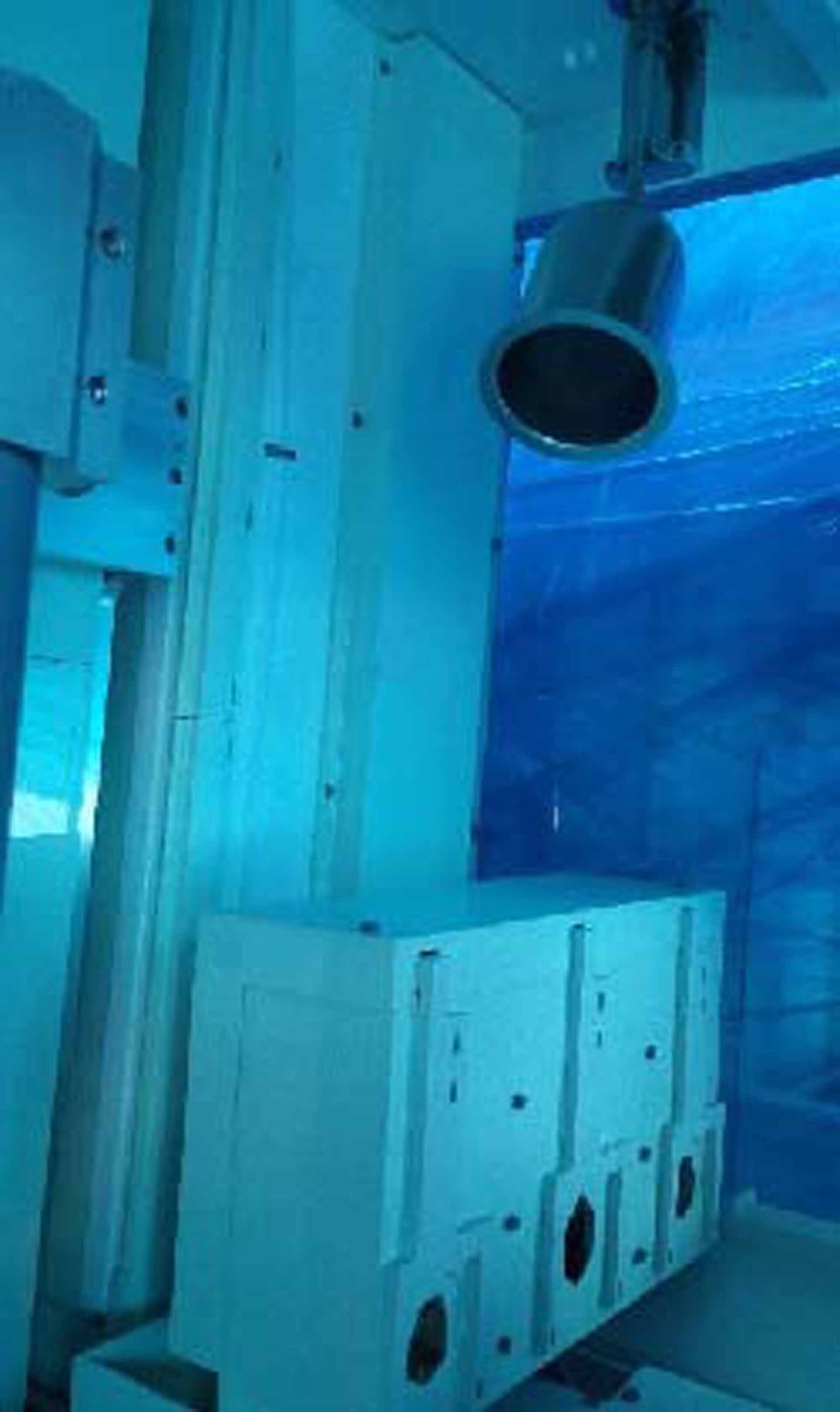

SRM Tank

Exhaust unit

Main PC

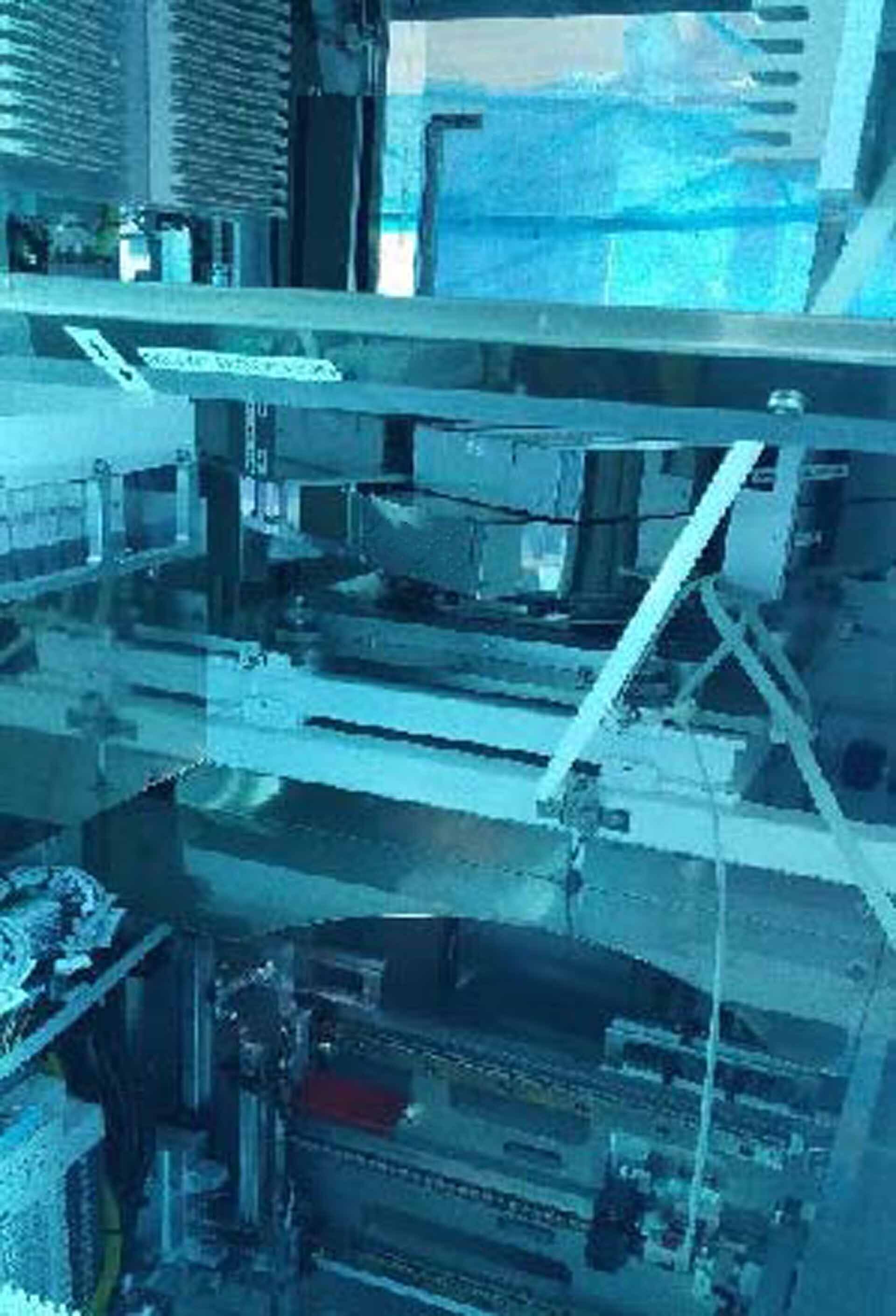

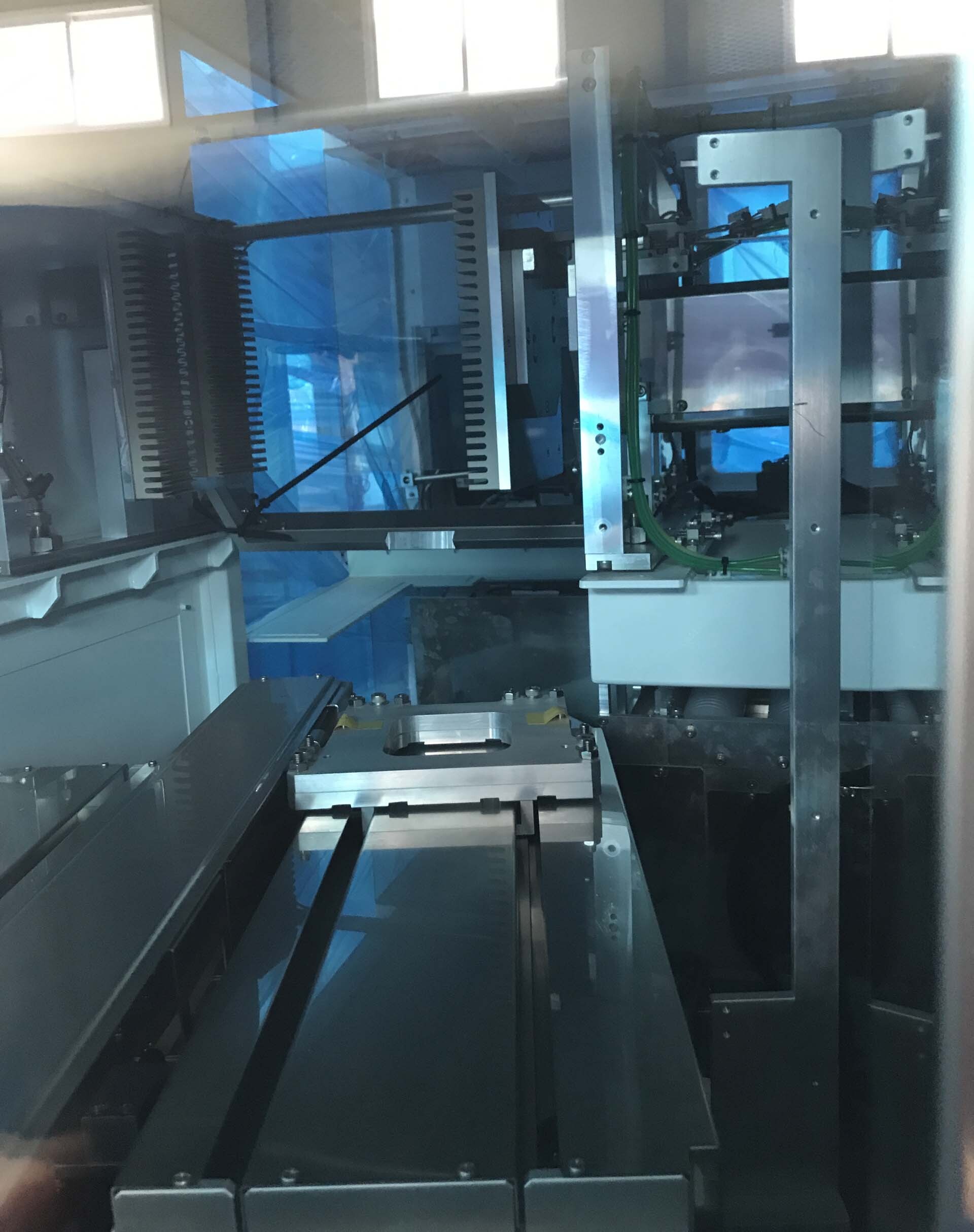

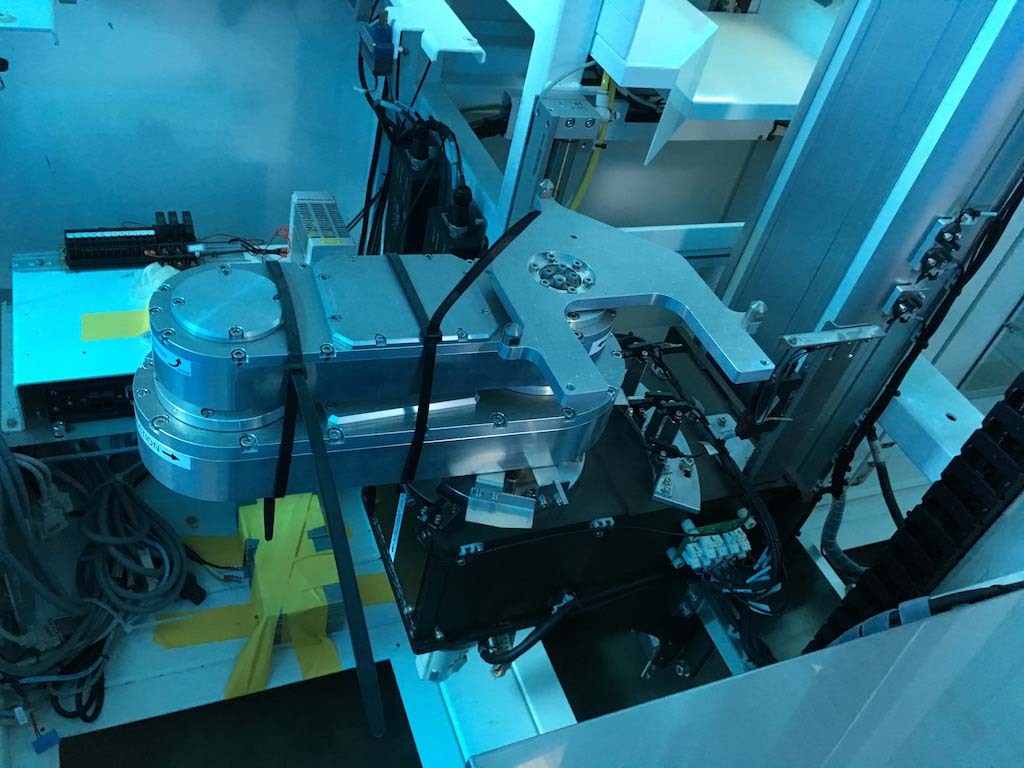

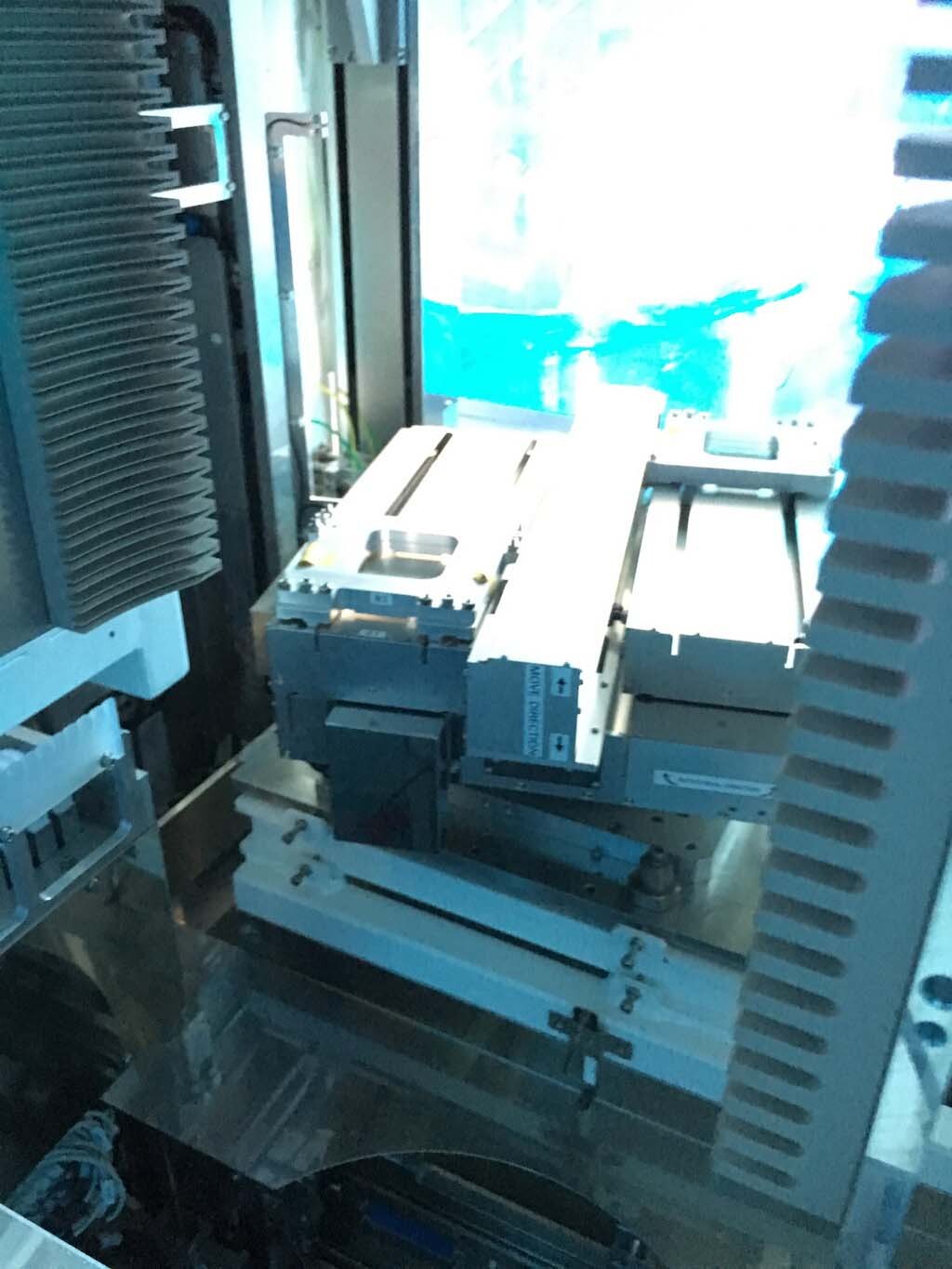

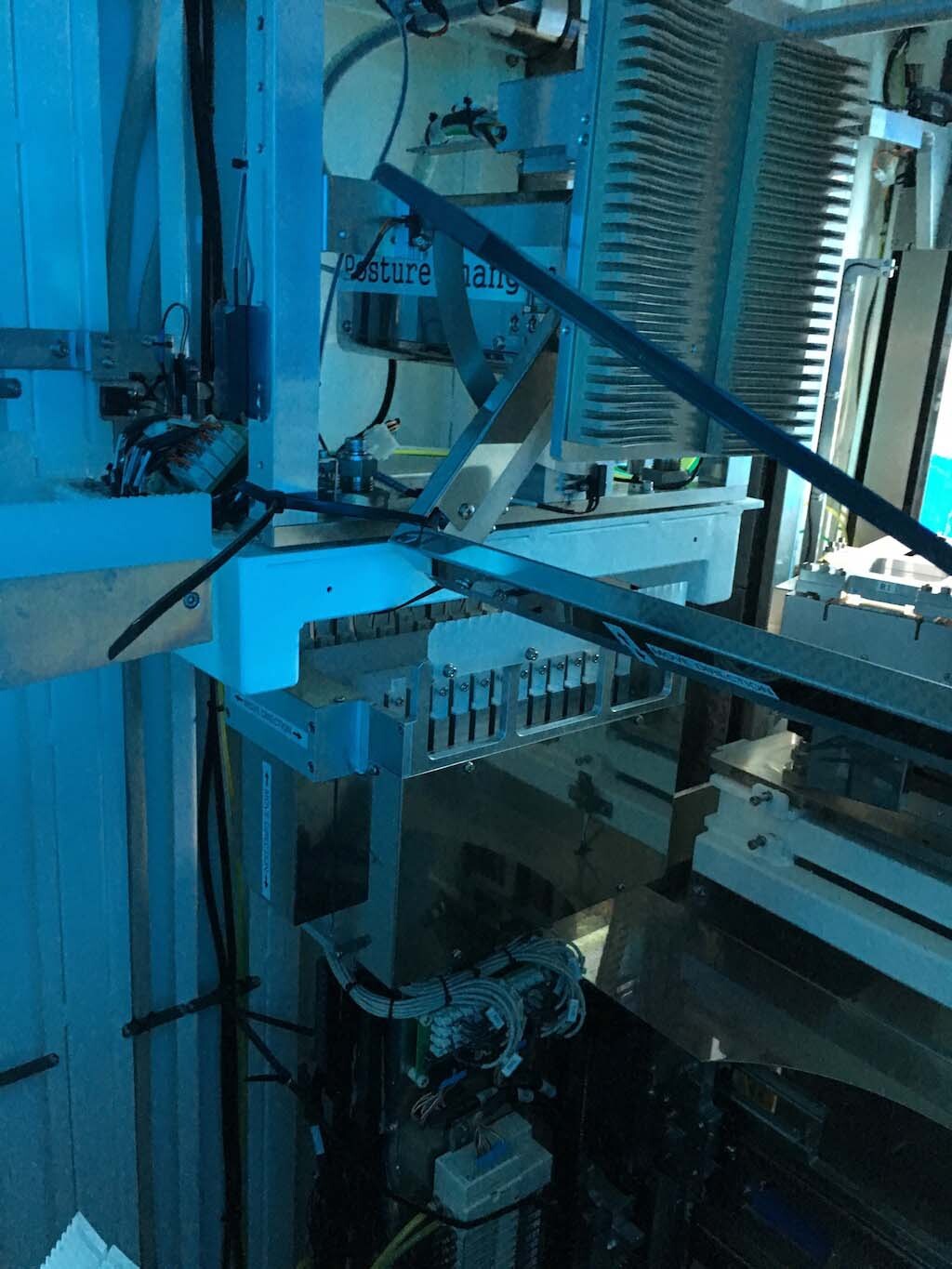

Robot:

RL: VEXTA AKD514H-A / VEXTA PK596AW1-A11

UD: Oriental ARD-A / Oriental ARM98MC-A4

FF-20BT1-T8 Pump

MA901-8FK29-88-3 Heater

Signal tower: (4) Colors (GYWR) PATLITE LED

(2) Teach pendants (Main / Spin dry)

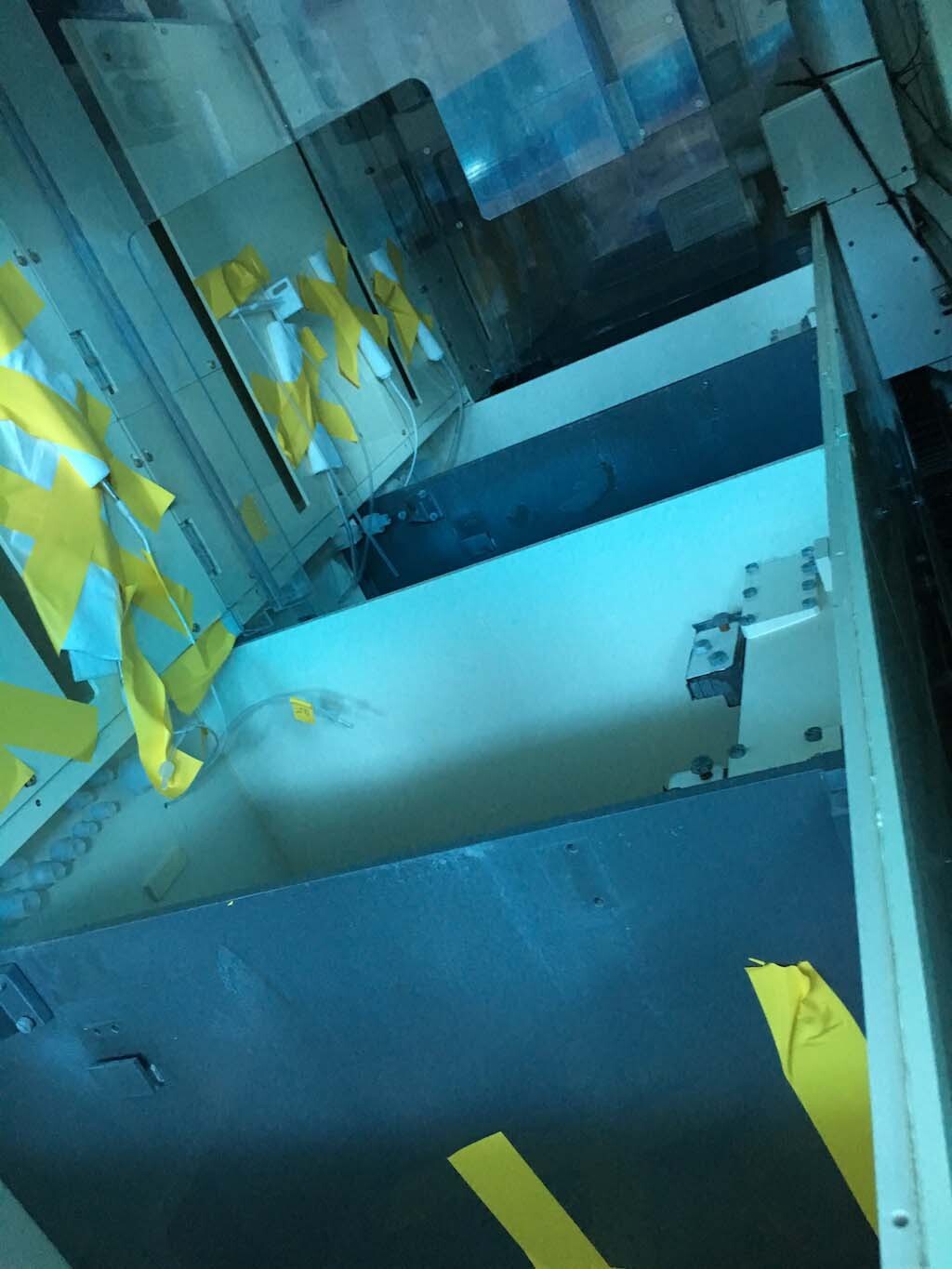

Missing parts

UPS: 208 V, 50 A, Single phase

Power supply: 208 V, 3-Phase, 150 A

2004 vintage.

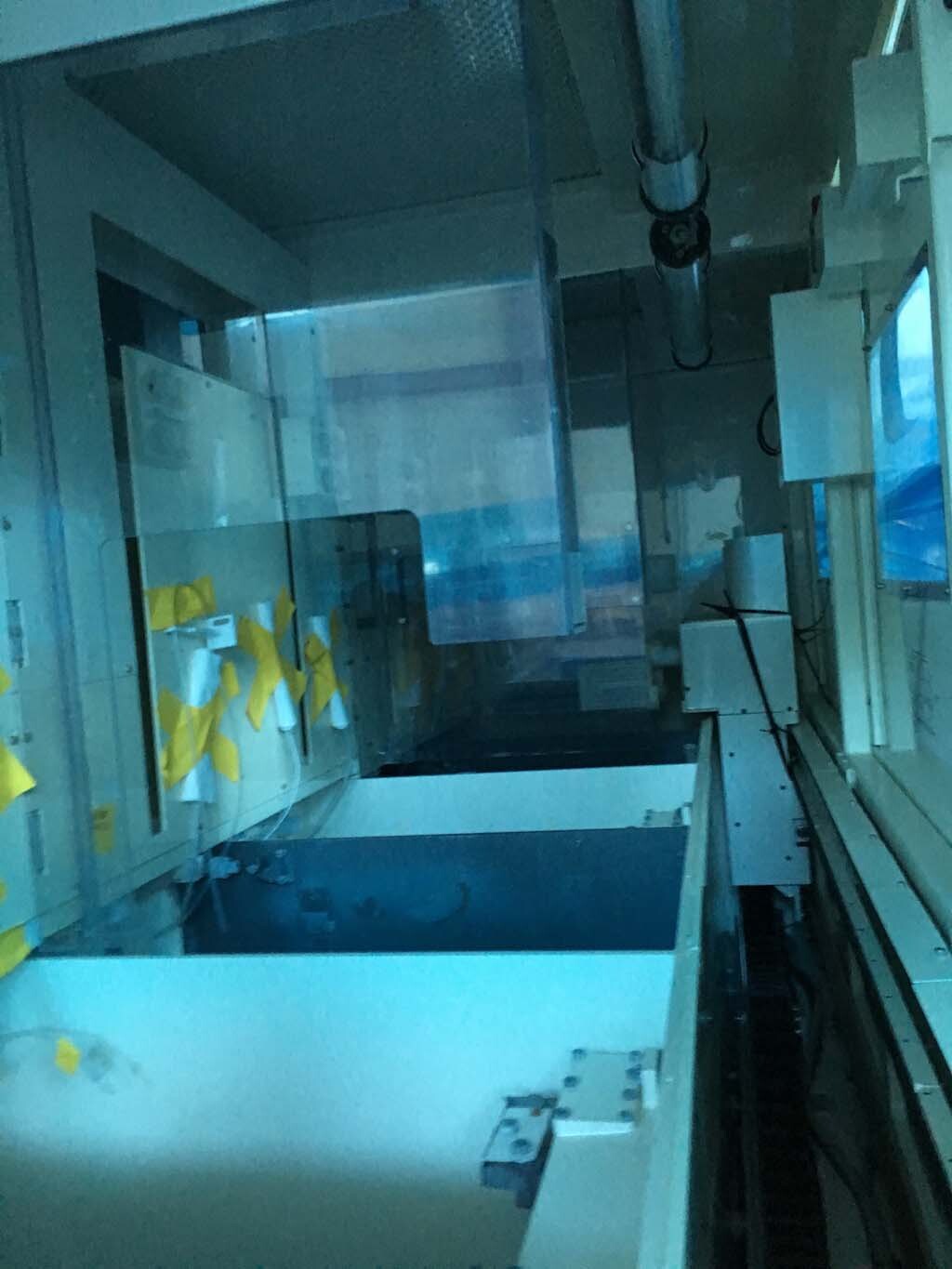

TEL / TOKYO ELECTRON UW-300Z is a wet station specifically designed for use in wet chemical processing applications such as photolithography and developing. TEL UW300Z is a robust and reliable unit that is easy to operate, providing an excellent service life for the most demanding of wet processing applications. The unit offers a high degree of repeatability and reliability, and can process up to 300 wafers in a single batch. The wet station features an intuitive user interface and closely integrates with other TEL wet processing equipment. At the heart of this wet station is a state-of-the-art, fully motorized wafer pallet loader equipment, allowing for great flexibility in wafer transport. The loader mechanism is designed to accommodate a wide variety of wafer sizes from 100mm to 300mm. The wafers are securely held in place during transport to ensure that they remain mechanically stable and to reduce the risk of potential particle contamination. TOKYO ELECTRON UW 300Z also features a wafer handling robot, which utilizes a fully adjustable, three-point adjustment system to precisely orient the wafers for processing. TEL / TOKYO ELECTRON UW 300 Z is also equipped with a number of advanced safety and environmental protection features. A heated air cover is provided to ensure that the hot surface temperatures during operation remain within accepted limits. The unit also features a flow sensor to monitor and control the supply of chemicals to the wet station. This ensures that the precise amount of chemical is specifically tailored to the process requirements, and reduces the risk of chemical runoff or spills. In order to ensure high yield rates, TOKYO ELECTRON UW300Z also has a number of sophisticated defect detection and prevention systems in place. The unit includes a built-in particle detection unit to detect and identify deposits present on the processed wafers. The unit can also be configured to measure key process parameters such as temperature and pressure to detect process anomalies before they cause defects or poor yields. UW-300Z offers all the features necessary for efficient wet processing. By combining a motorized loader machine and wafer handling robot with advanced safety and defect prevention systems, TEL UW-300Z provides state-of-the-art process control and repeatability for the most demanding of wet chemical processing applications.

There are no reviews yet