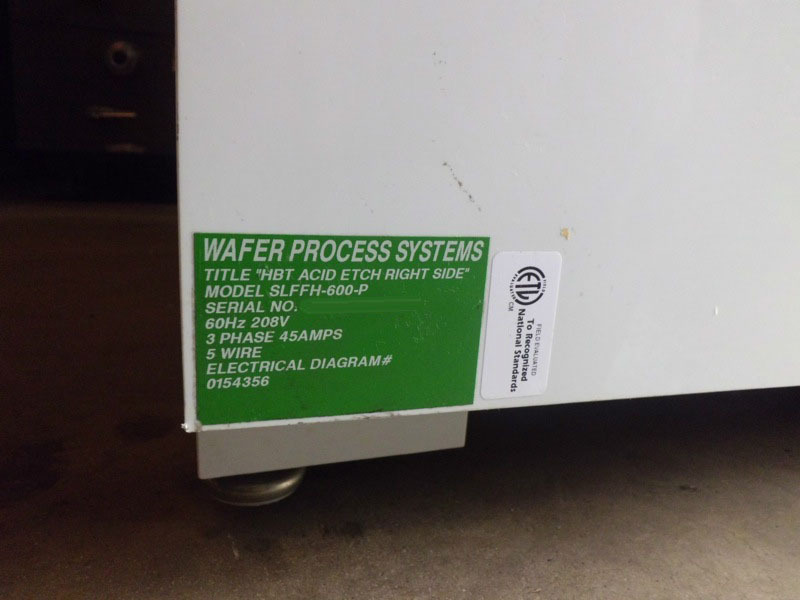

Used WAFER PROCESS SYSTEMS / WPS SLFFH-600-P #9003748 for sale

URL successfully copied!

Tap to zoom

ID: 9003748

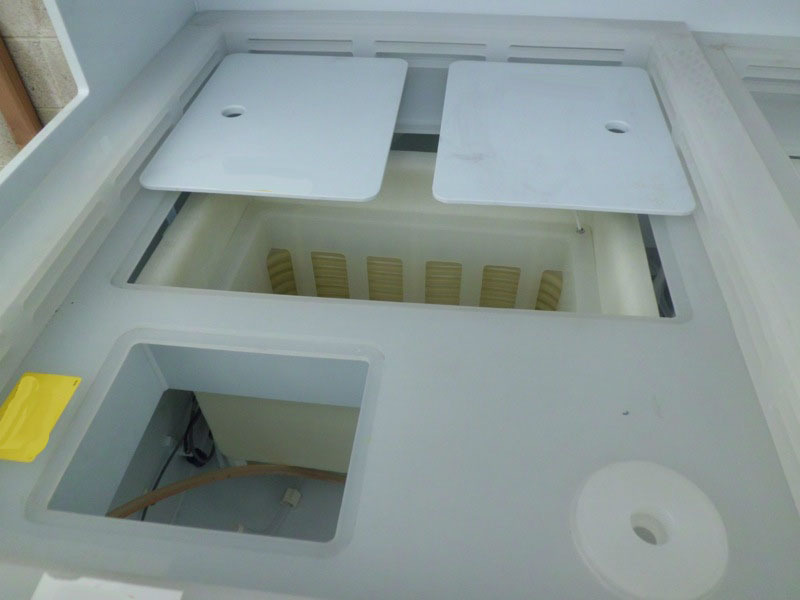

Wet Station

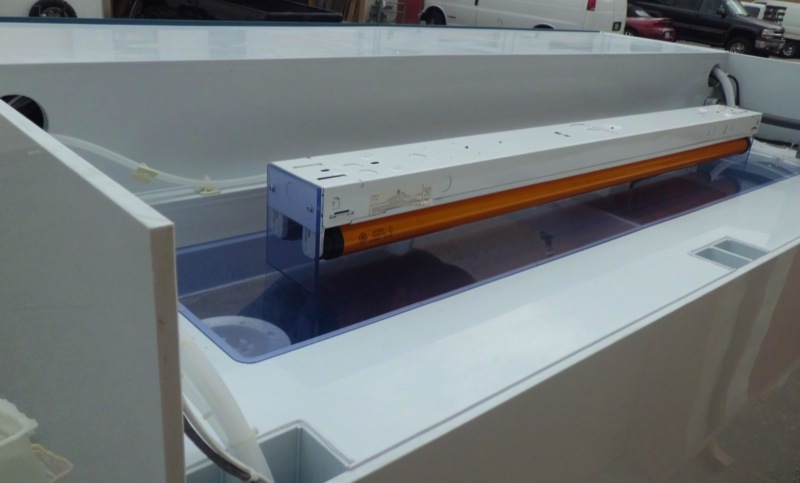

HBT Acid/Corrosive/Etch chemical

60HZ 208V

3 Phase 45 amps

5 Wires

Electrical Diagram # 0154356

Station # 2 HBT PNL 2M/32 34 36

All Controls are made by Wafer Process Systems

1) Switch Panel: WP5 Model 200 ASP Auxiliary

2) EPO: Model 100 Emergency Power off Panel

3) Process Timer: Model 1000T

4) Cycles: Model 20000 QDL Quick Dump Logic

Station # 2 HBT Sink D546

All Controls are made by Wafer Process Systems

1) Resistivity Monitor: Model 900RM

2) Temperature/Time Controller: Model 3000 TTC

3) Process Timer: Model 1000T

4) Cycles: Model 20000 QDL Quick Dump Logic

5) Local Exhaust Ventilation: 1027

Hercules Foot Switch: CAT # 531-SWN Nema Type 2, 4 & 13

Extra parts included.

WAFER PROCESS SYSTEMS / WPS SLFFH-600-P wet station is an automated and fully integrated equipment designed for processing small/large flat wafers in various production environments. It features a series of rotating trays that act as a conveyor, allowing for precise and reproducible product loading and unloading, and two symmetrically positioned heating modules that help ensure uniform temperatures. This system is designed for a variety of processes and materials, including multiple chemical processes, thinning, etching, and cleaning operations, and it can be equipped with optional coating, laser scribing, and robotics systems. WPS SLFFH-600-P can accommodate wafers up to a maximum size of 600mm in diameter and up to 20mm thick, and the unit can process up to six wafers simultaneously with a throughput of up to 500 wafers per hour. The wafers are loaded onto the rotating trays, and up to 6 different processes can be applied to the wafers on a rotational basis. All processes are managed by the machine's dedicated controller, allowing for precise and consistent control over the entire production process. WAFER PROCESS SYSTEMS SLFFH-600-P features a powerful stepper motor for precise speed control, and its advanced dual-pump tool is capable of controlling the velocity and flow of solutions. This wet station also offers a continuous process mode, enabling processing of up to 1,800 wafers with a loading rate of up to 10 wafers per minute. The asset is also designed with a particle collection and recycling model, which allows for a clean and environmentally friendly operation. SLFFH-600-P is highly reliable and robust thanks to its reinforced structure and advanced safety features. The equipment has undergone extensive safety testing to ensure the safety of personnel, and features alarms and emergency stops. Additionally, the system is protected from shock and vibration, and its temperature management unit ensures optimal working conditions. WAFER PROCESS SYSTEMS / WPS SLFFH-600-P is a reliable and efficient wet station ideal for processing thin/large flat wafers for a variety of industries.

There are no reviews yet