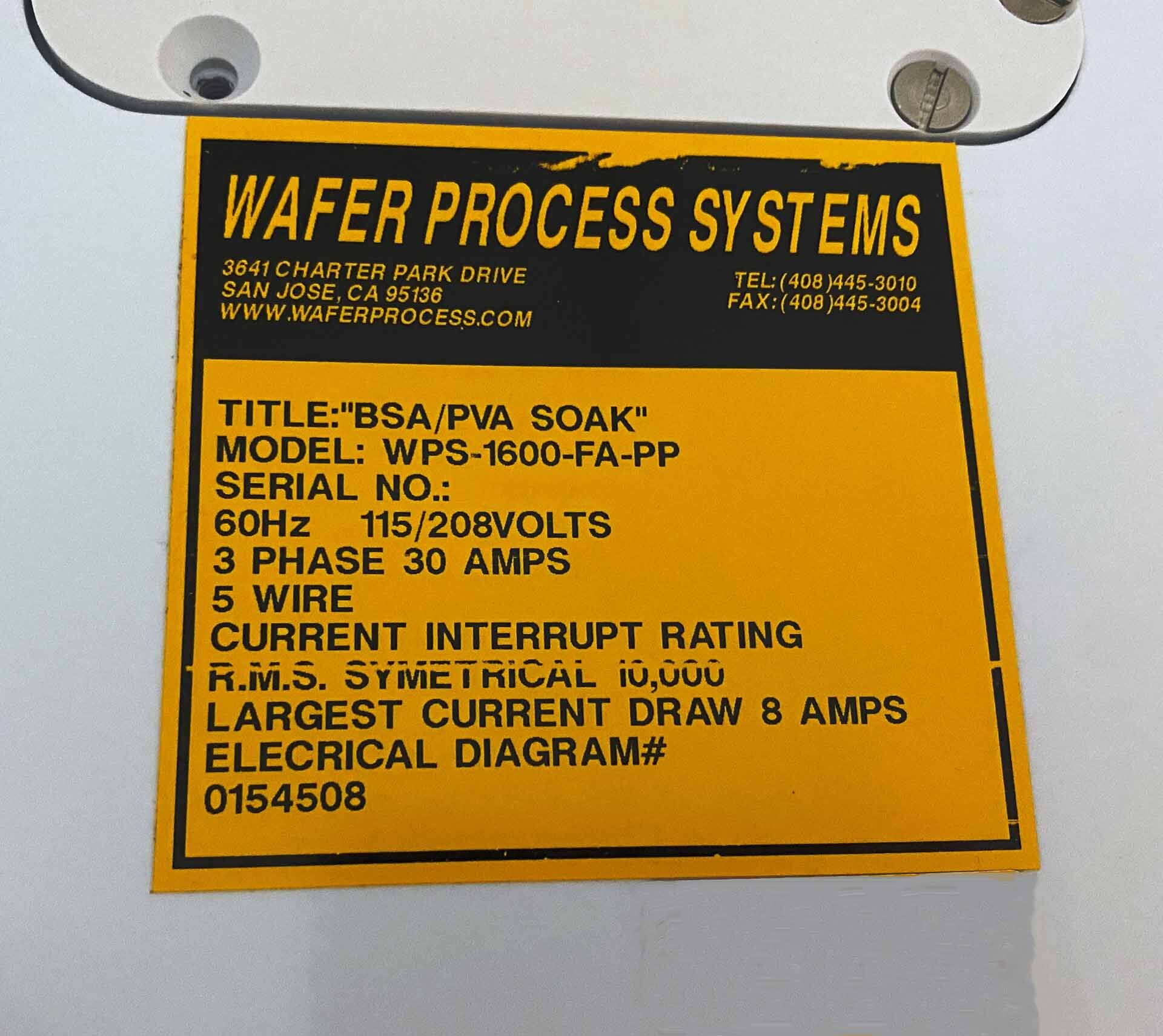

Used WAFER PROCESS SYSTEMS / WPS WPS-1600-FA-PP #293632755 for sale

URL successfully copied!

Tap to zoom

A Wafers Process SystemWAFER PROCESS SYSTEMS / WPS WPS-1600-FA-PP, also referred to as a wet station, is a type of unit designed for semiconductor device manufacturing. This wafer processing equipment is used to produce thin film structures, device layers and contact areas on thin wafers. This system can be used to create heterojunction, OLED and liquid crystal display (LCD) layers while also providing low temperature wafer bonding. WPS WPS-1600-FA-PP is a wet station with a main body configuration. It is capable of multiple pieces of process equipment, including thermal oxidation, spin coating, vision inspection, doping and oxide deposition. Each process is controlled through the user interface, which records the entire process in a traceable electronic log. The control unit also monitors temperature and process gases. WAFER PROCESS SYSTEMS WPS-1600-FA-PP is capable of producing wafers with extremely thin film layers as thin as 5 nanometers (nm) wide. The process starts with a wafer being fed through the slots on the top of the chamber. The wafer is then pre-treated with a series of pre-processing steps and is either coated, thin-film deposited or patterned accordingly and then goes through the post-processing steps. WPS-1600-FA-PP utilizes an advanced view machine and automation software, allowing engineers to set up and control the entire process without any intervention. The unit also includes an inert atmosphere environment and an inert-gas interface tool that provides an oxygen-free environment for the wafer to be processed in. WAFER PROCESS SYSTEMS / WPS WPS-1600-FA-PP is designed for precise, high quality and repeatable processing of thin wafers. The overall asset is capable of high throughput and superior product yield. This unit also boasts a flexible design, allowing for change of process recipes as well as the ability to modify multiple device layers during production. WPS WPS-1600-FA-PP has been designed for increased safety, helping protect against potential risks such as gas supply failure and potential explosions. With all of the features, this wafer processing model is the ideal choice for any company or research center working with thin wafers.

There are no reviews yet