Used RUDOLPH / AUGUST NSX 105 #293607882 for sale

URL successfully copied!

Tap to zoom

ID: 293607882

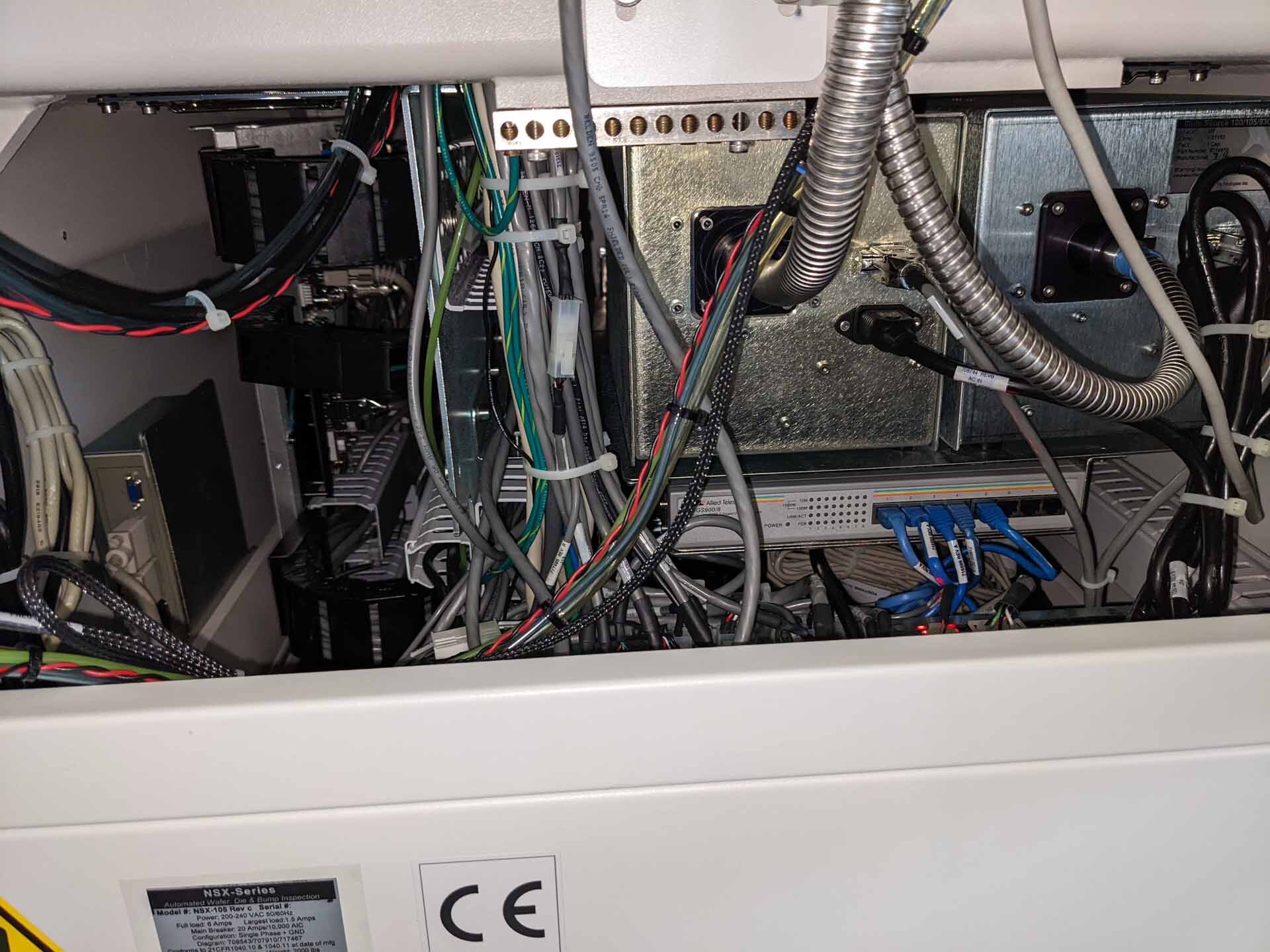

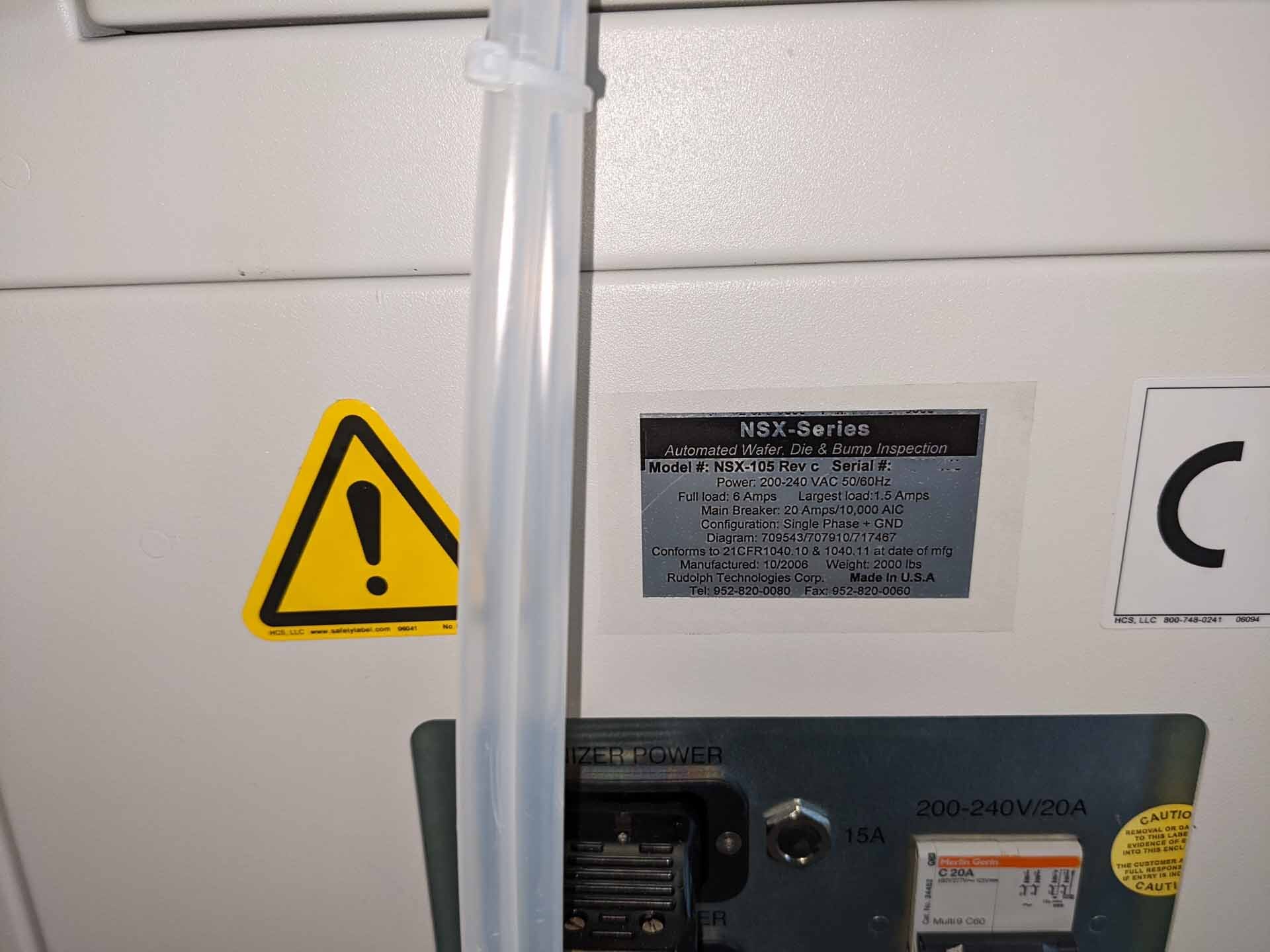

Vintage: 2006

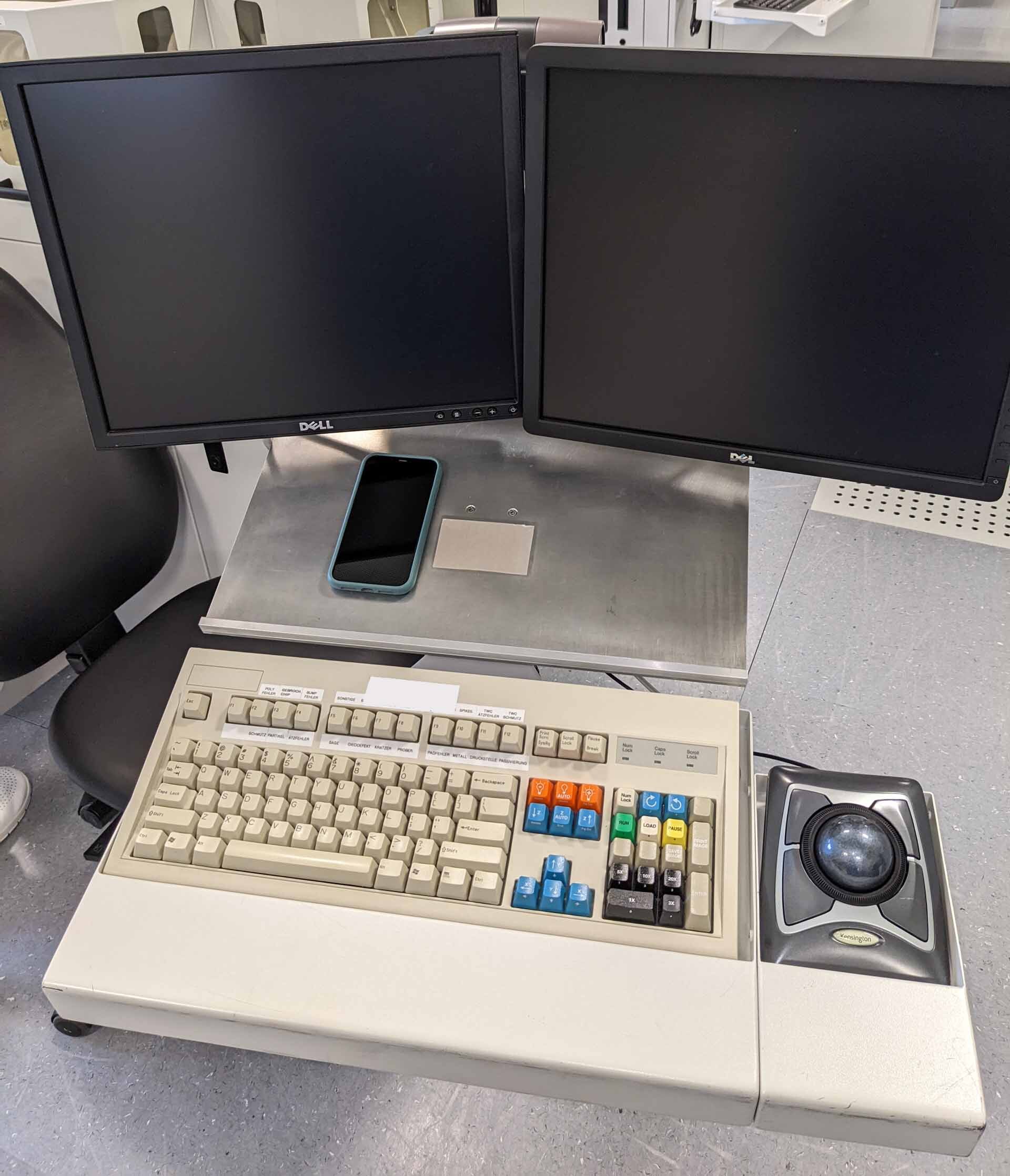

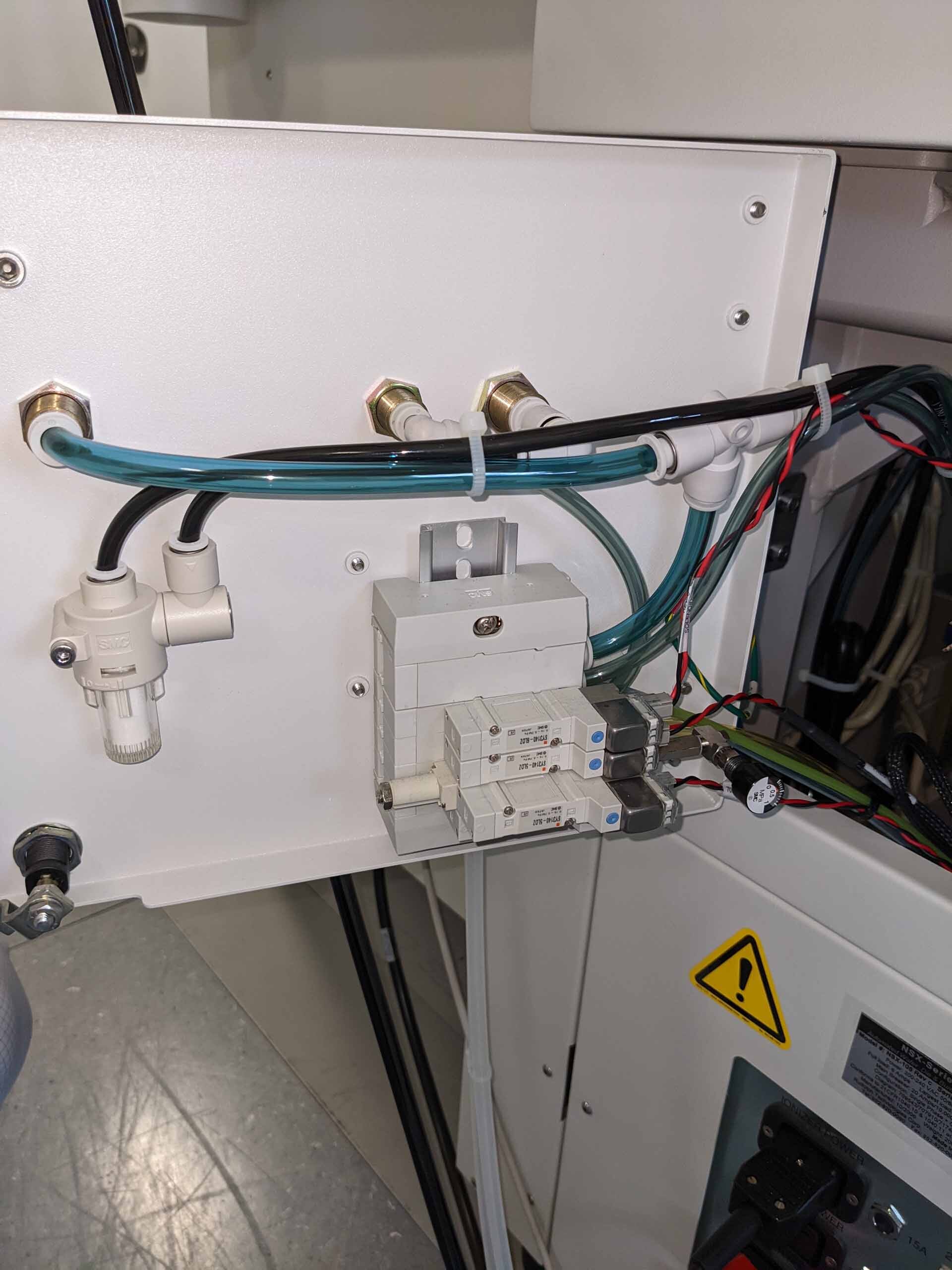

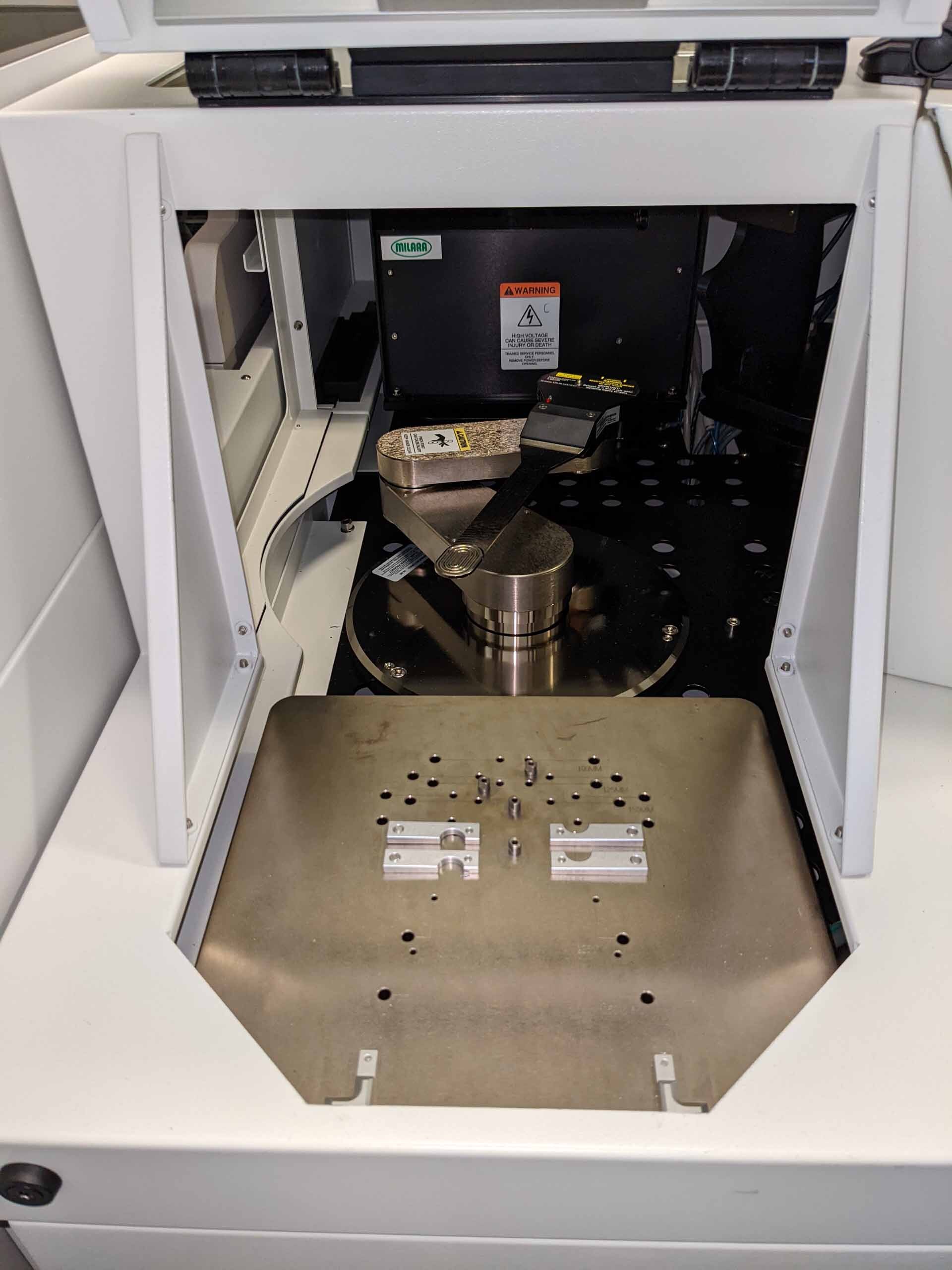

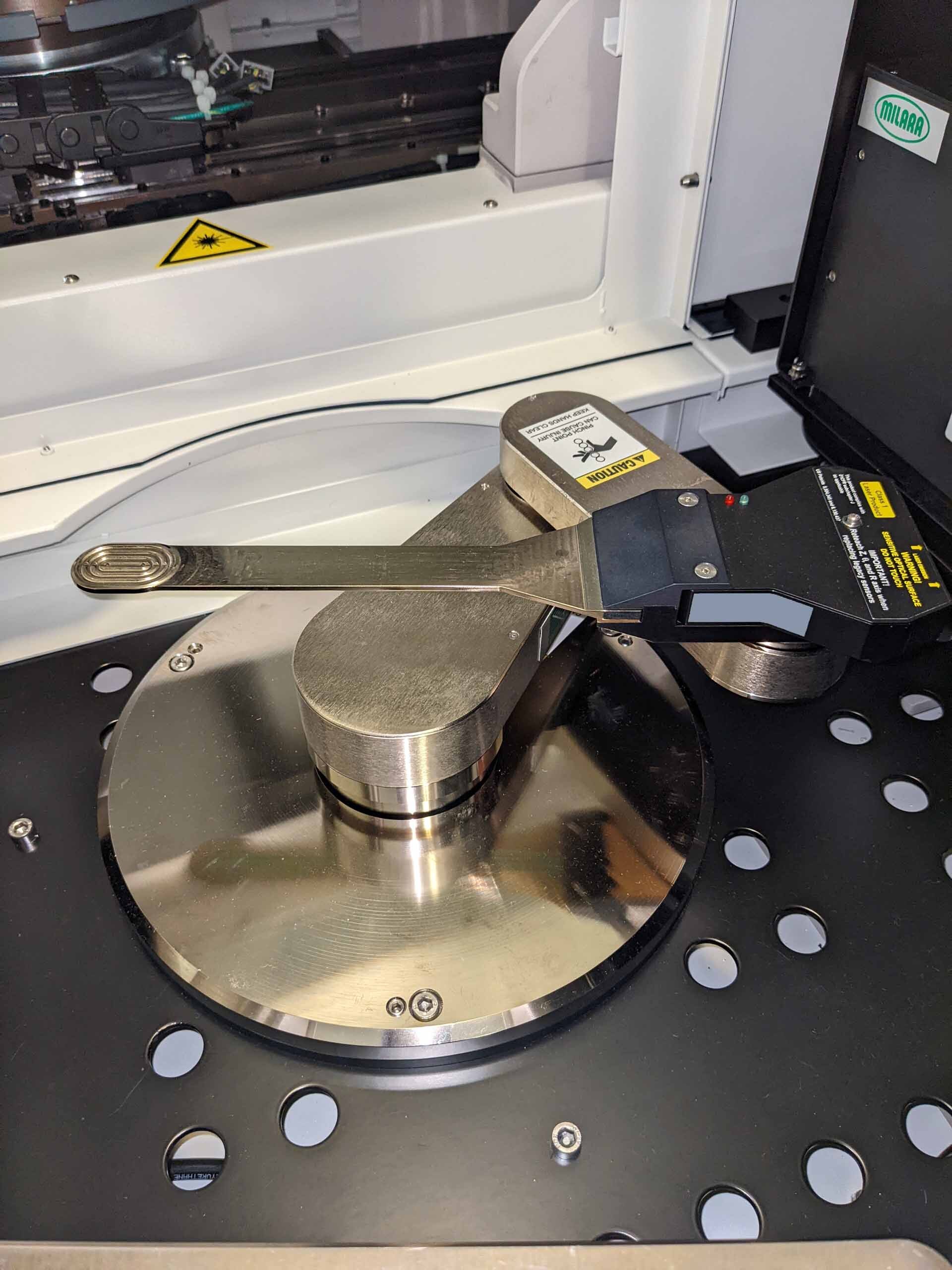

Macro defect inspection system

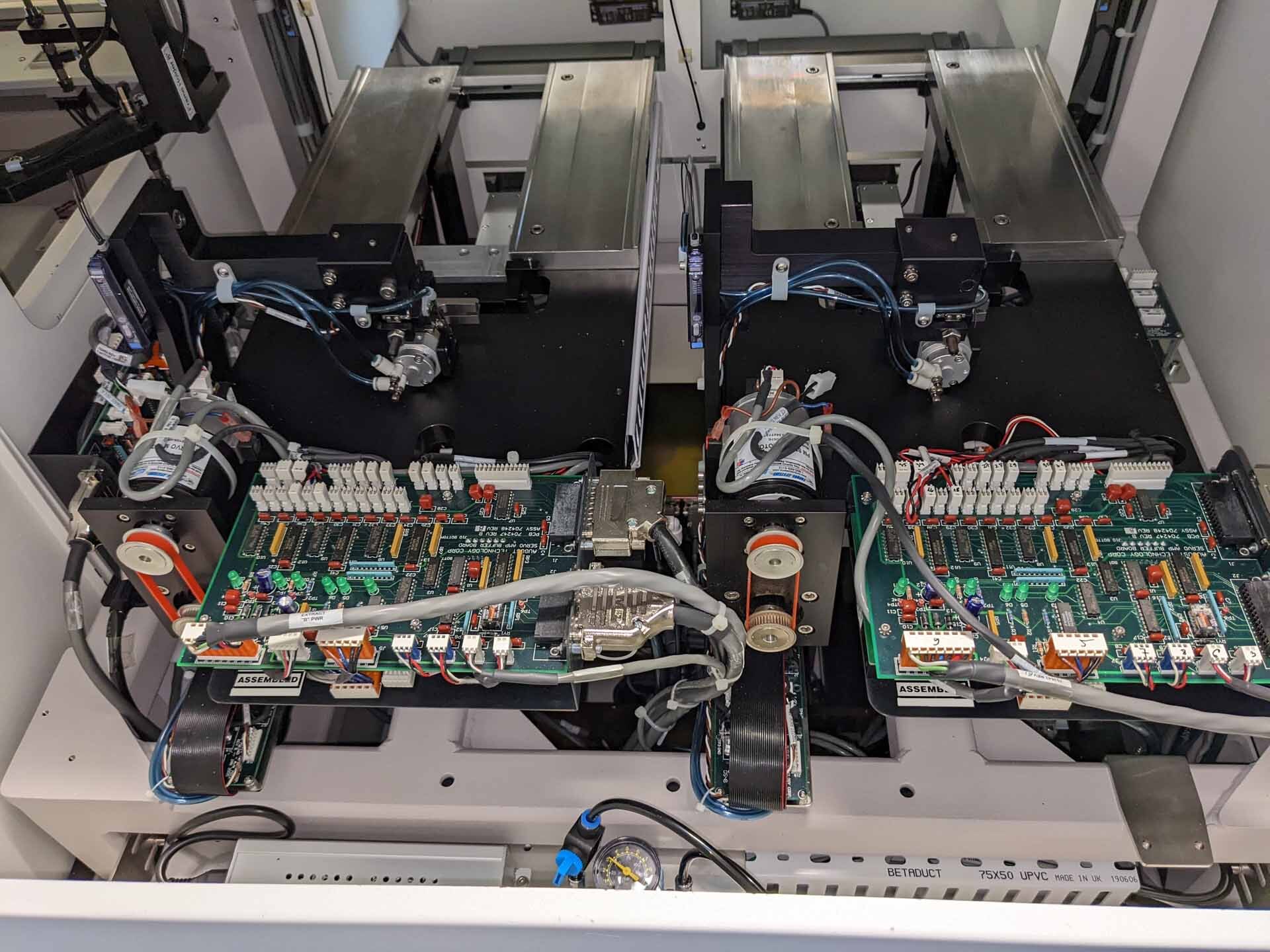

Includes:

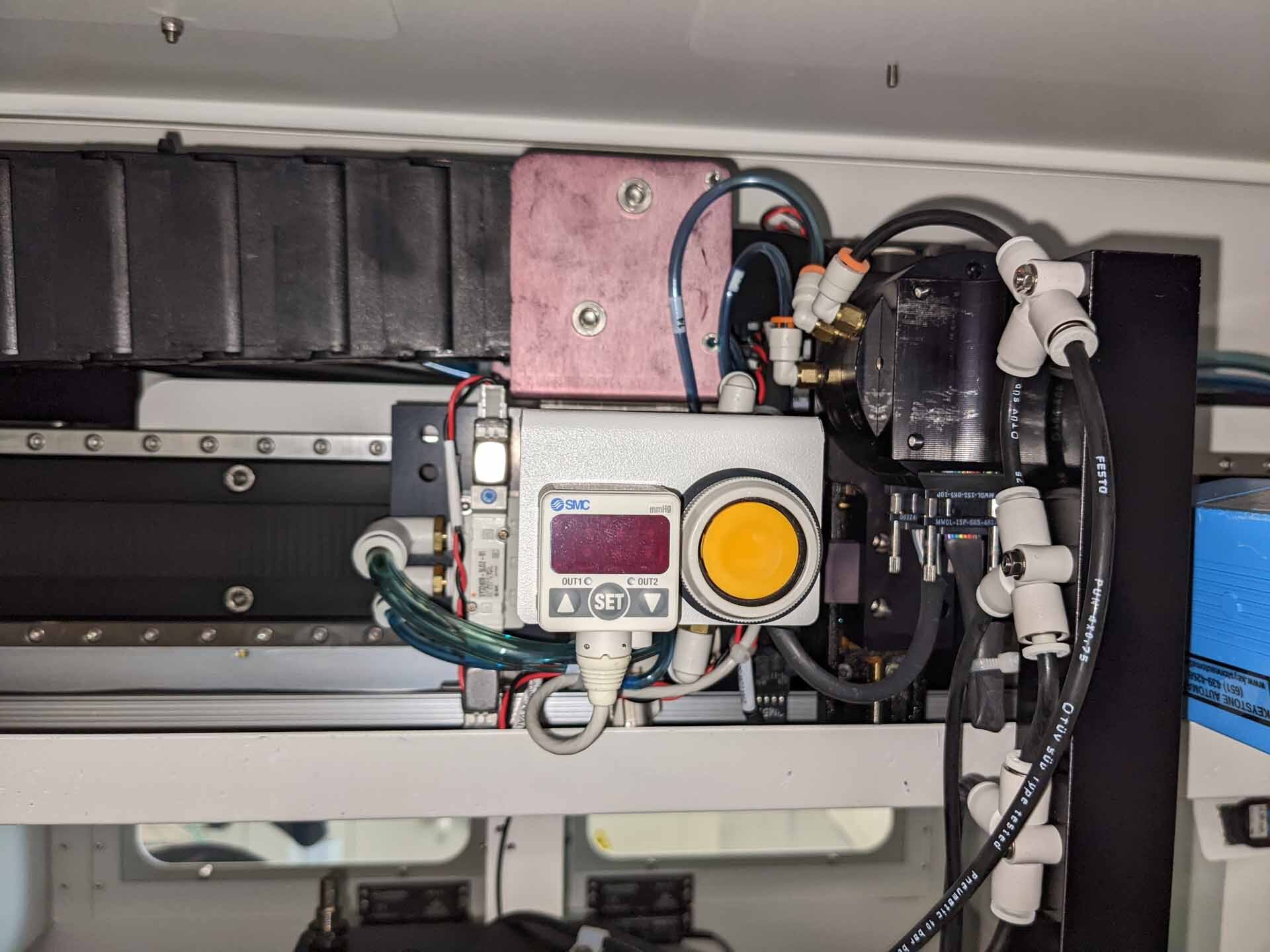

Wafer handler

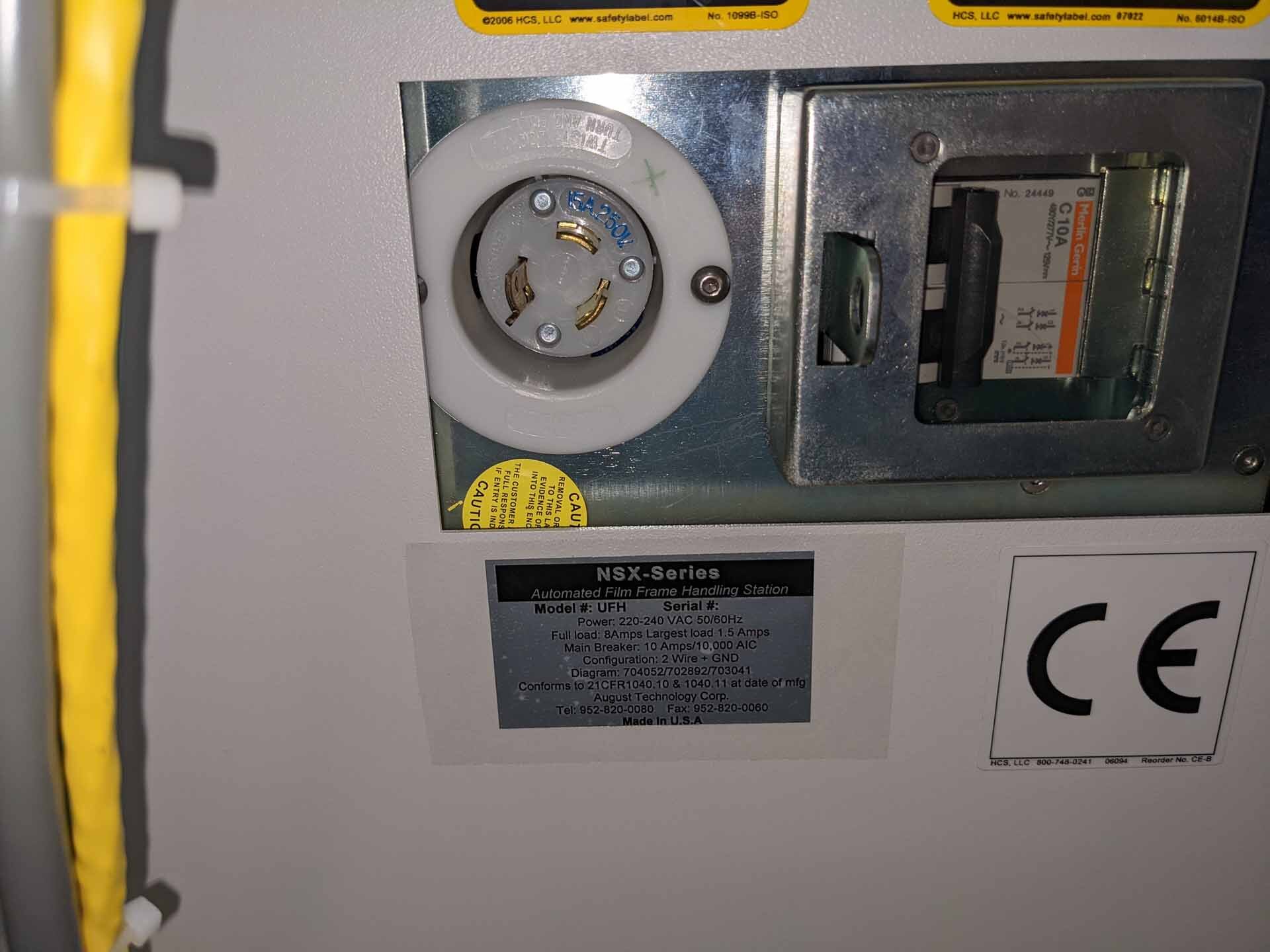

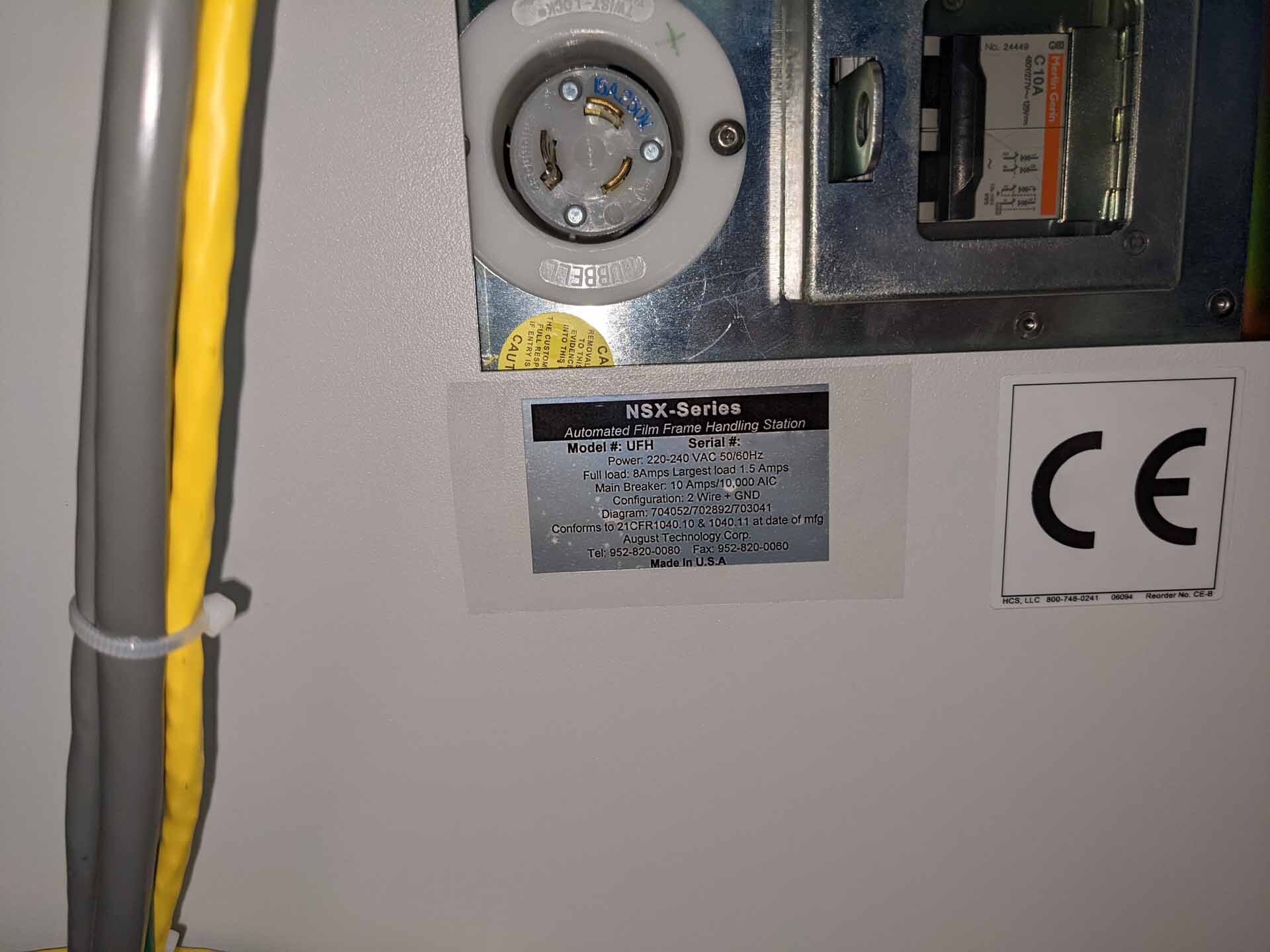

Universal film frame handler

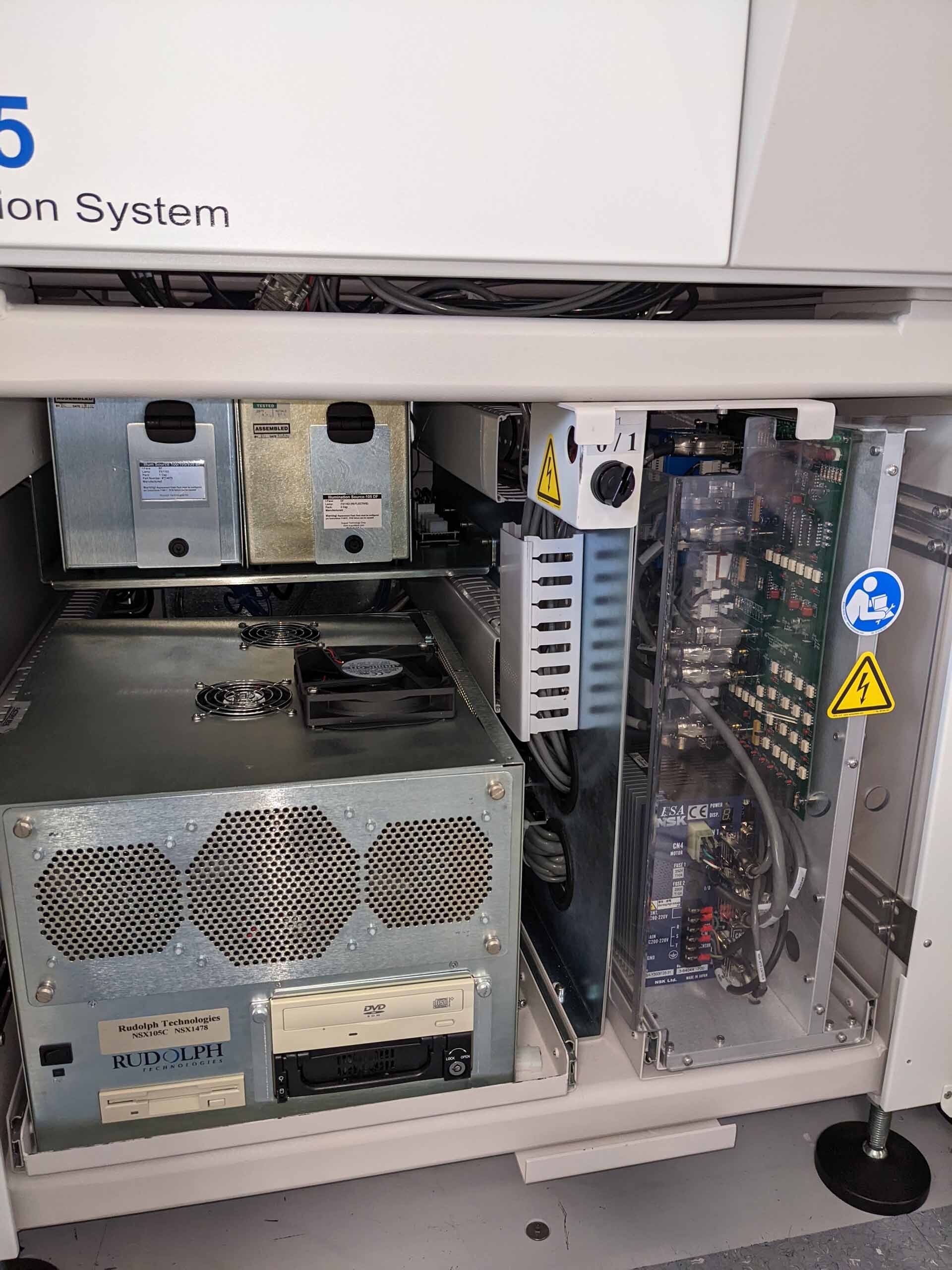

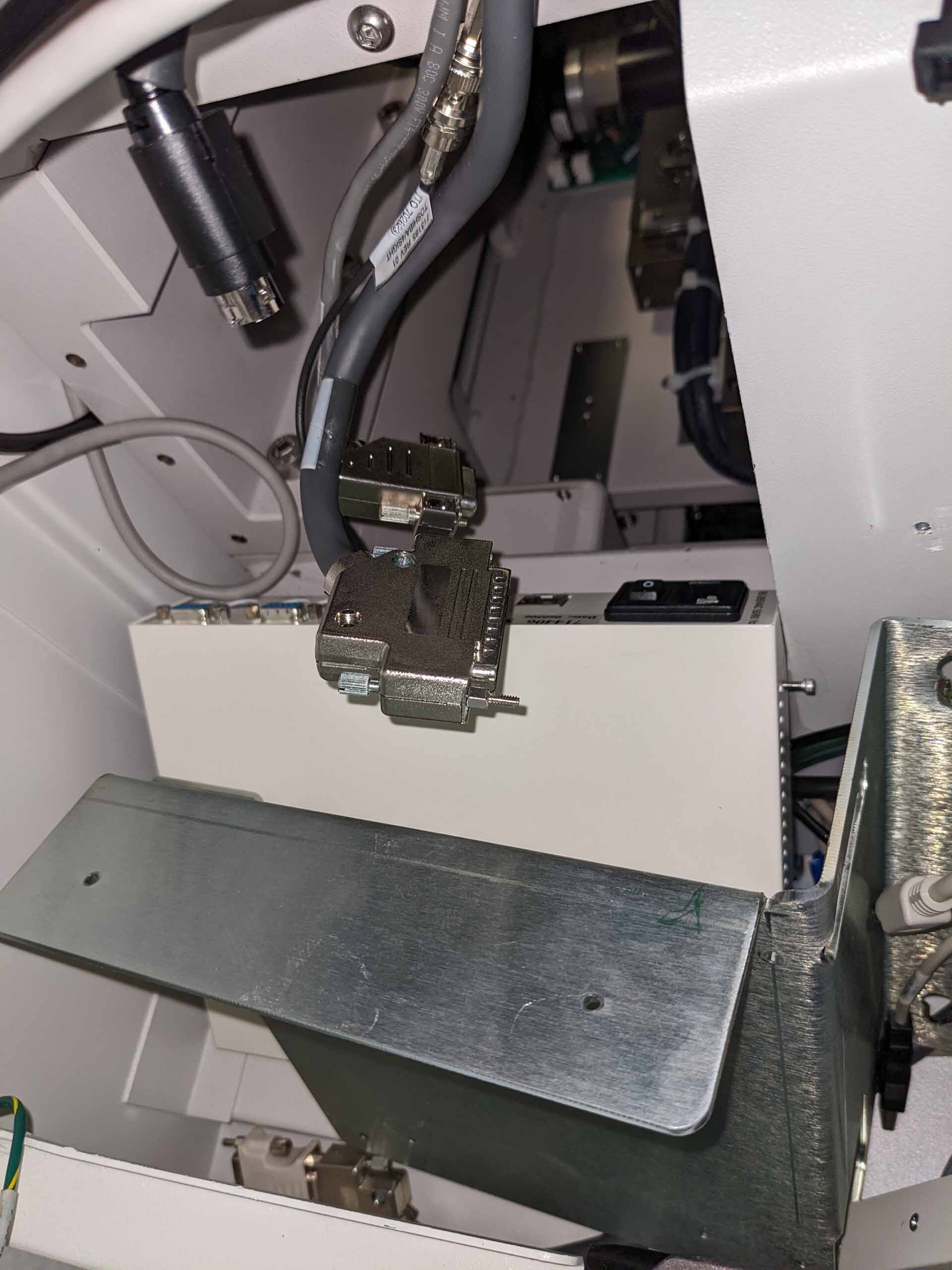

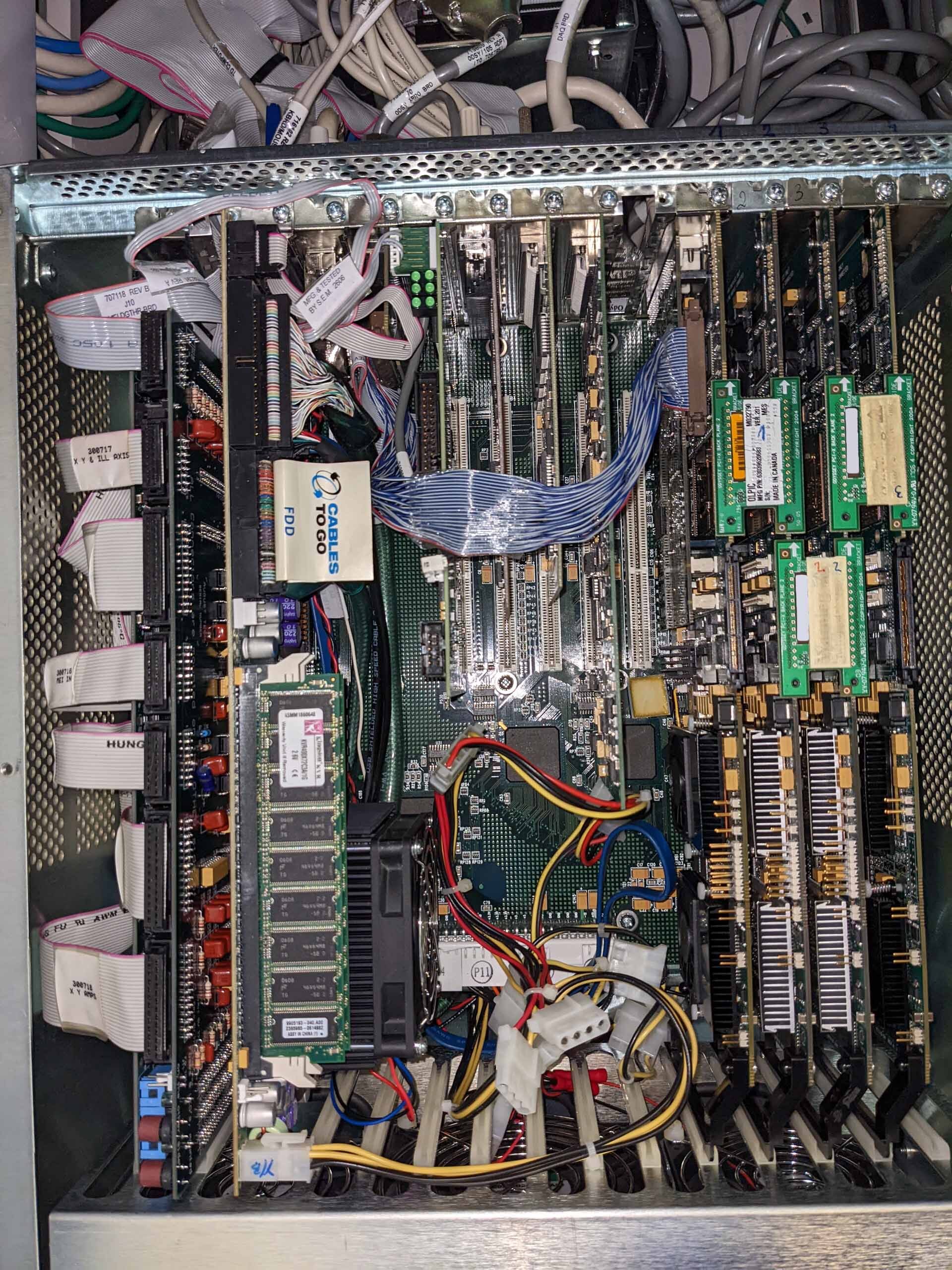

Missing / Damaged parts:

X-Stage encoder

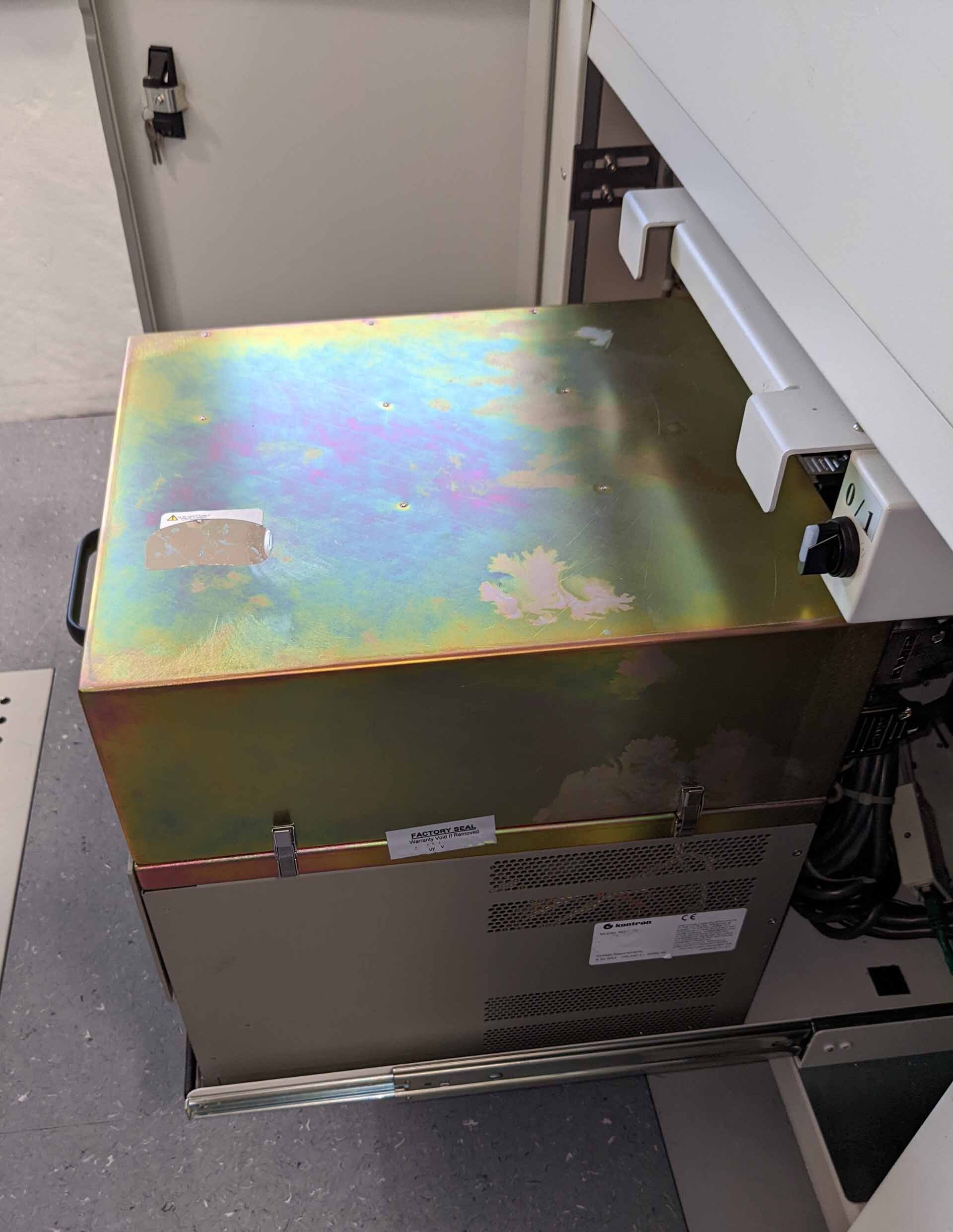

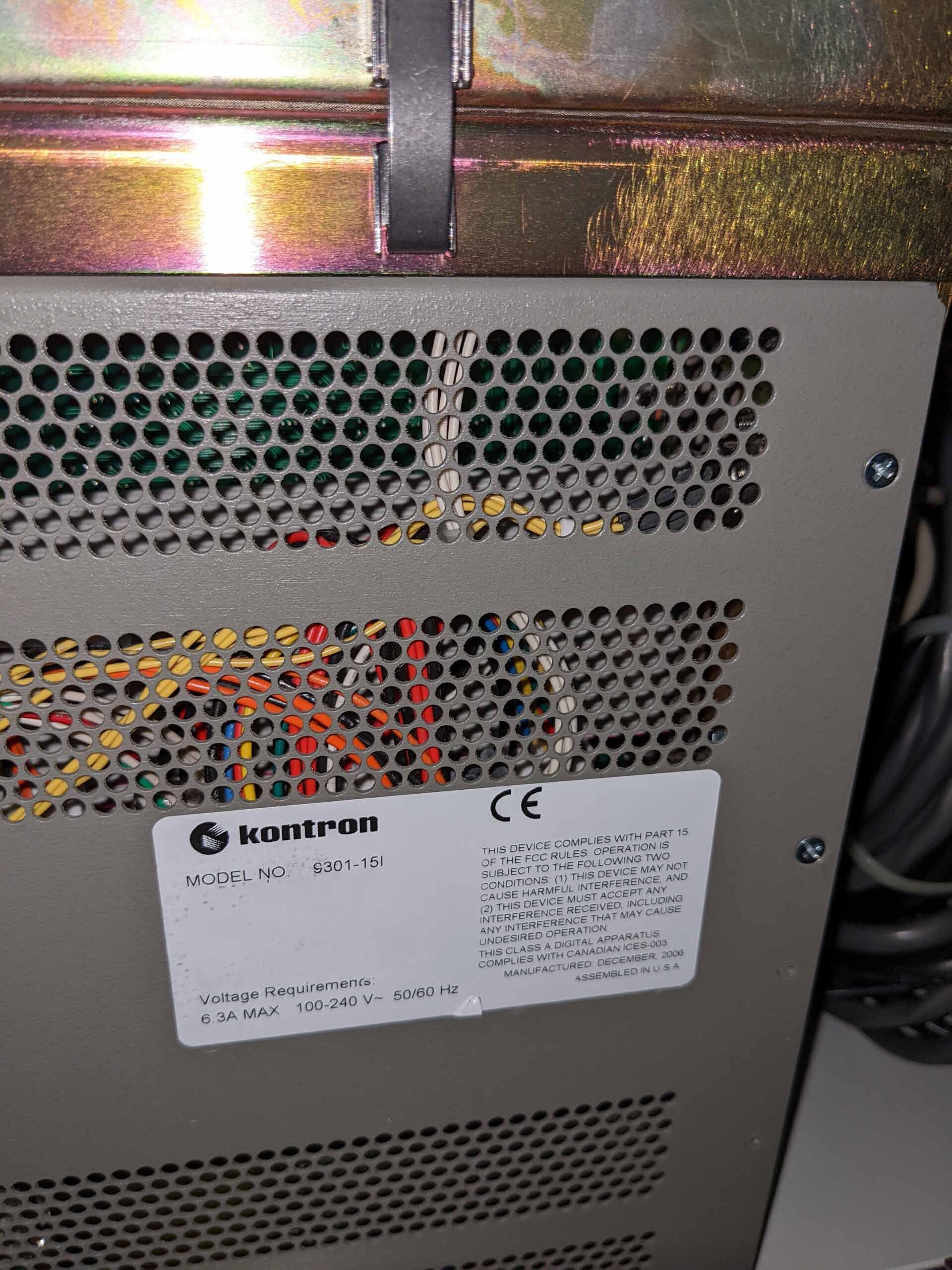

NSK Controller

Matrox PC

PS Stage, 24 V

2006 vintage.

RUDOLPH / AUGUST NSX 105 is a high-performance mask and wafer inspection equipment that provides a modern cost-effective solution for the inspection and repair of semiconductor masks and wafers. This system is designed to precisely identify and find defects in ICs using advanced inspection technologies such as 3D image recognition, image stitching, dual-beam laser, and advanced image processing algorithms. AUGUST NSX-105 utilizes two lasers in a 'dual-beam' design. These lasers allow for high-precision analysis of wafer and mask patterns regarding their shape, size, and other characteristics. All images generated by the unit can be stored in its onboard memory for use in further processing and analysis. The machine also includes an option for onboard image stitching, which can be used to link multiple images together to analyze large fields faster and more accurately. RUDOLPH NSX 105 is equipped with an advanced software suite that allows users to accurately inspect complex patterns efficiently and quickly. Its 3D image recognition feature allows for fast and accurate detection of even very small defects and patterns. In addition, the software used for this tool includes additional advanced features, such as integrated boundary detection and defect clustering algorithms. The asset is compact, lightweight and easy to operate. It features a simple interface, enabling operators to quickly adjust critical parameters or set up custom inspection procedures. It can also be used in a wider range of applications and contexts, such as IC production lines and IC encapsulation systems. RUDOLPH NSX 105 is a reliable and efficient solution for inspecting and repairing semiconductor masks and wafers. Its advanced image recognition and image stitching features ensure high-precision analysis, while its easy-to-use and flexible user interface makes it suitable for a variety of uses. The combination of these features makes the model an excellent choice for any semiconductor production environment that requires accurate, reliable, and cost-effective mask and wafer inspection.

There are no reviews yet