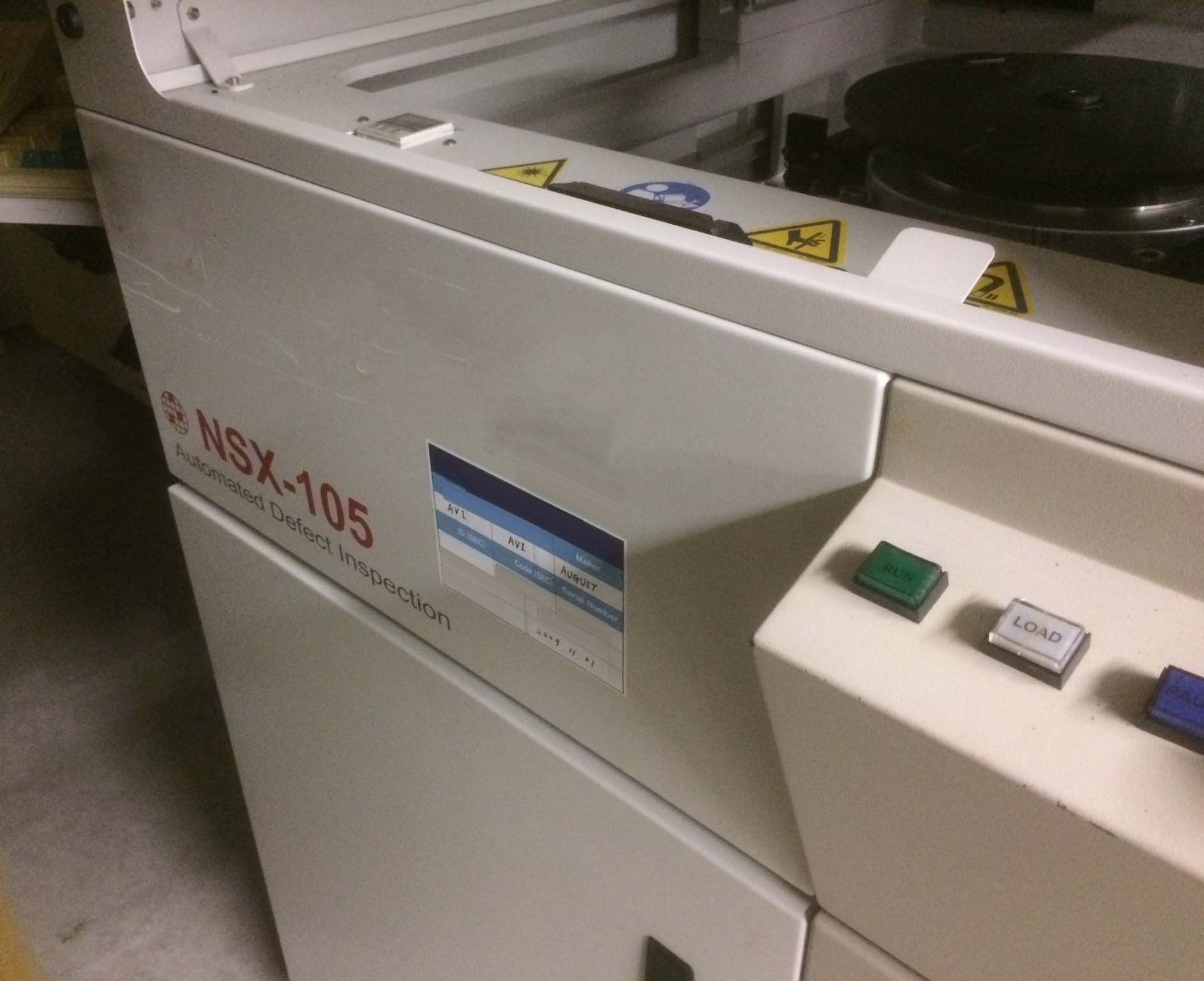

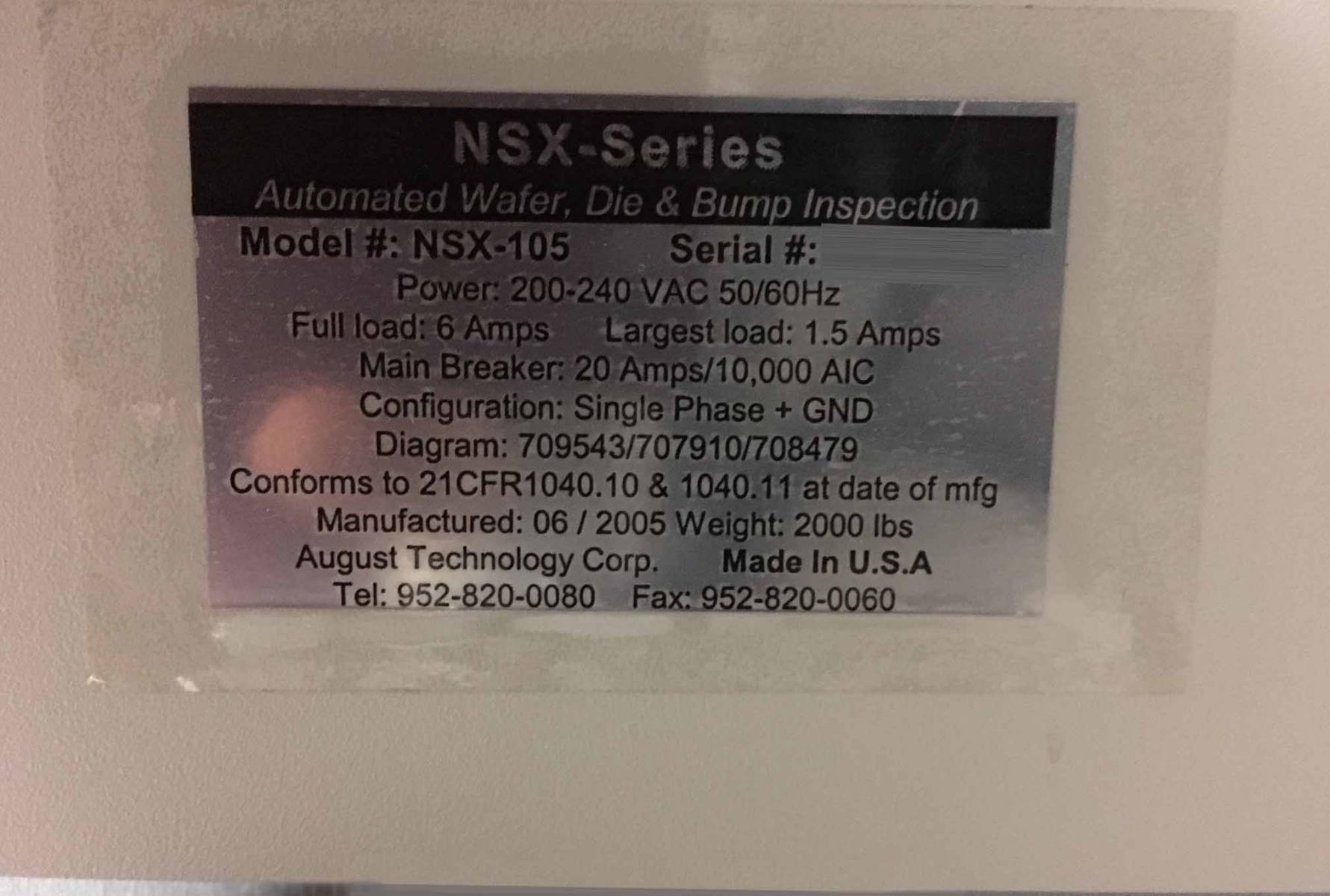

Used RUDOLPH / AUGUST NSX 105 #9177357 for sale

URL successfully copied!

Tap to zoom

ID: 9177357

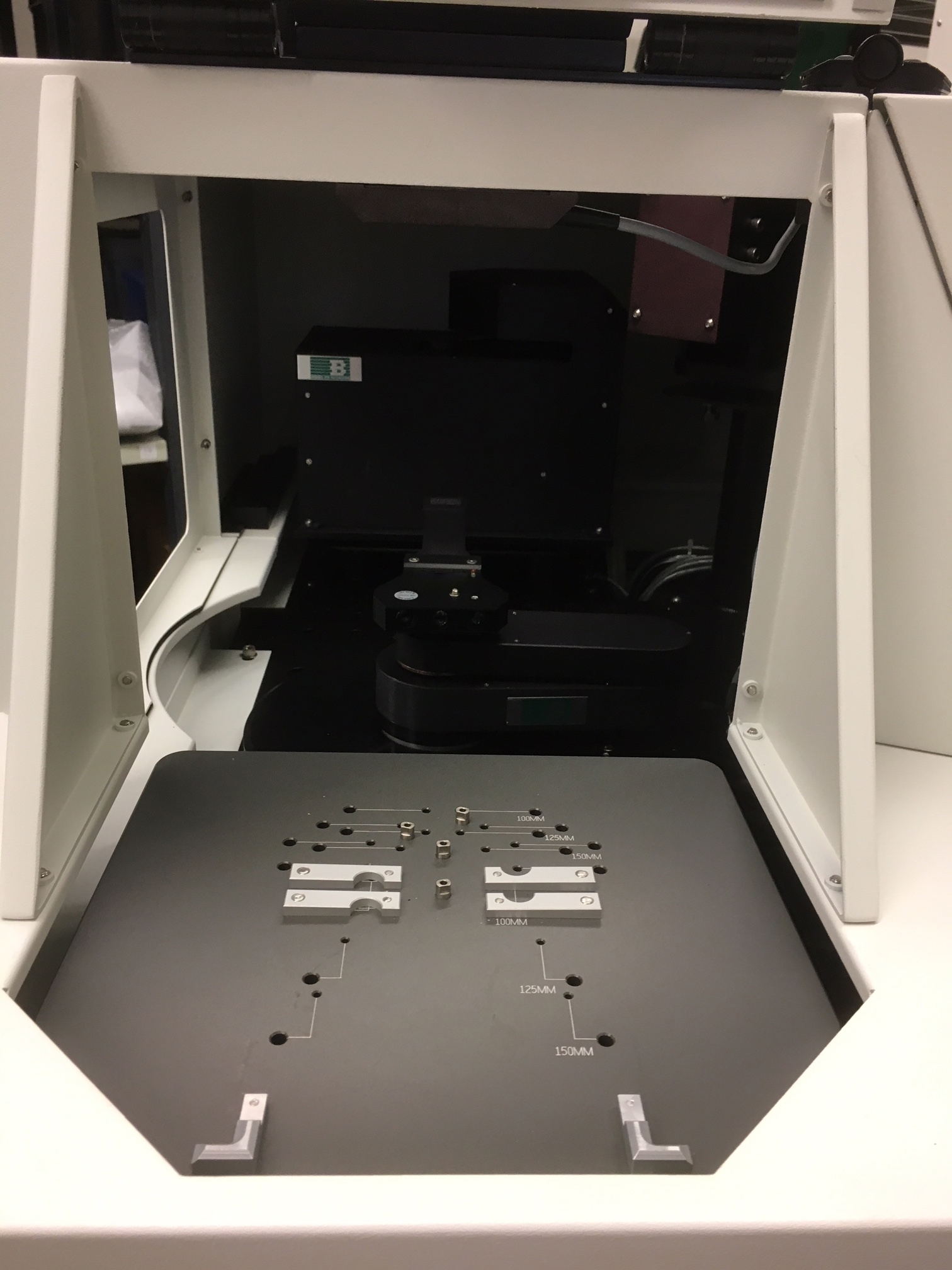

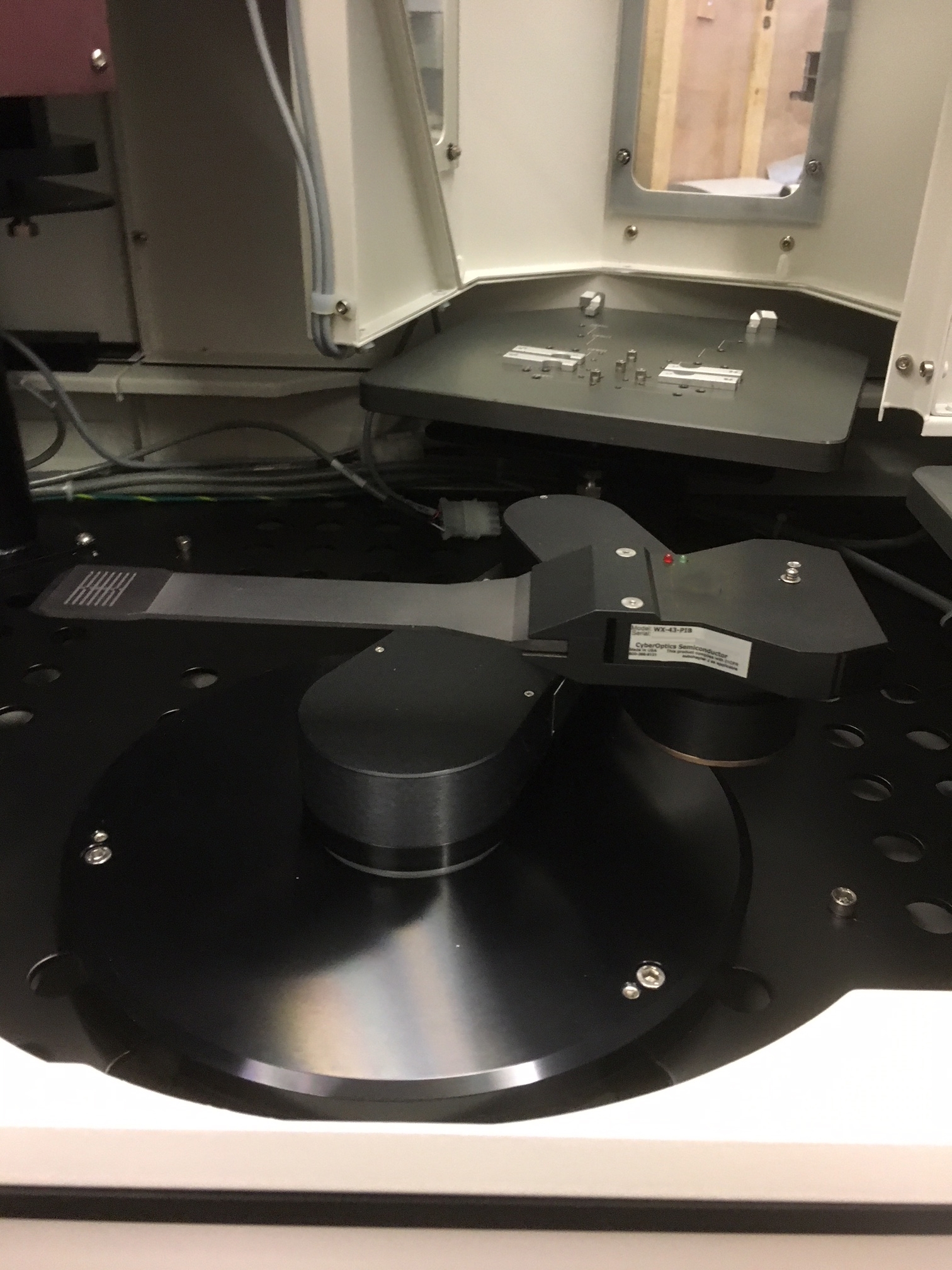

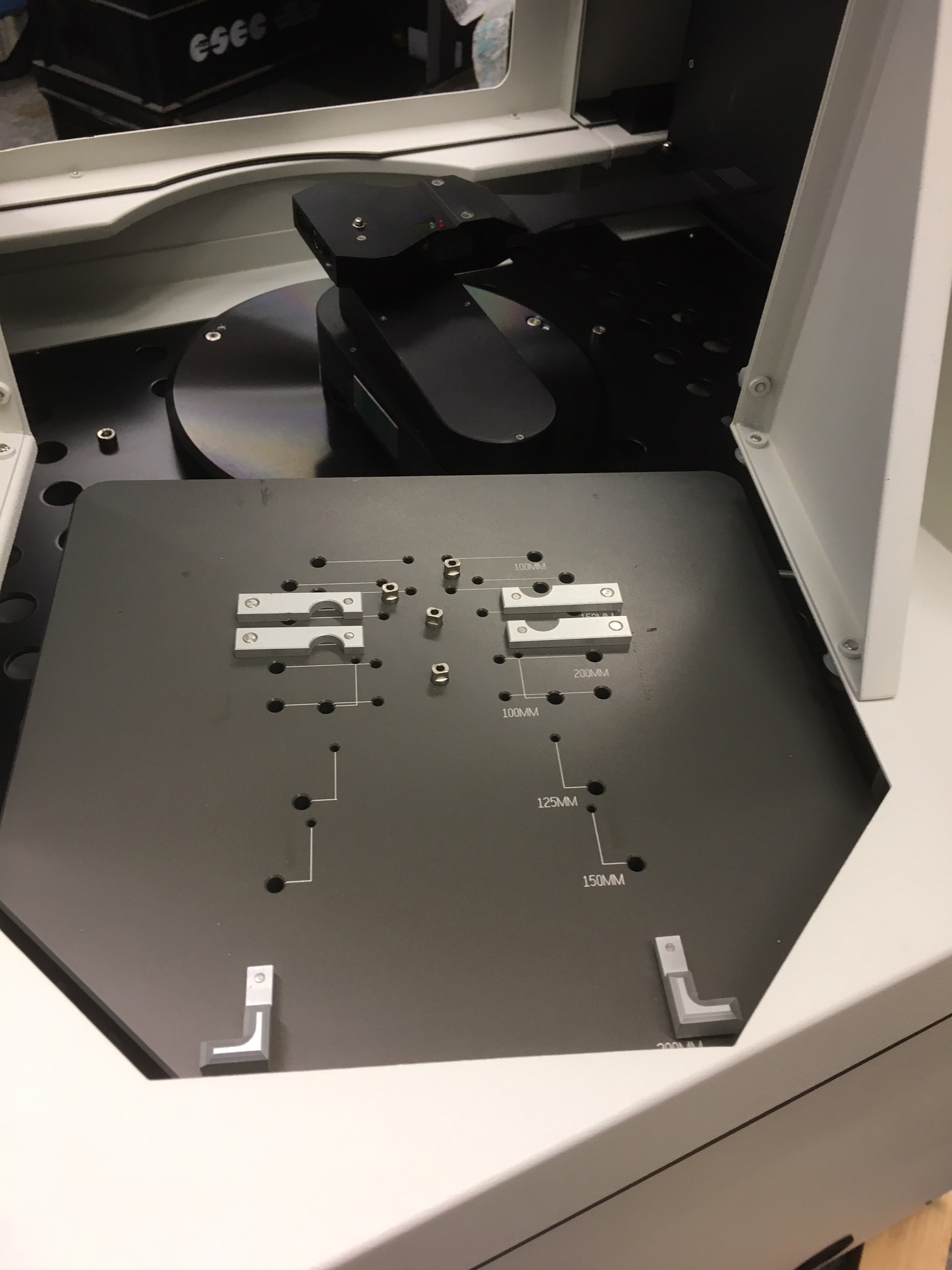

Wafer Size: 12"

Vintage: 2005

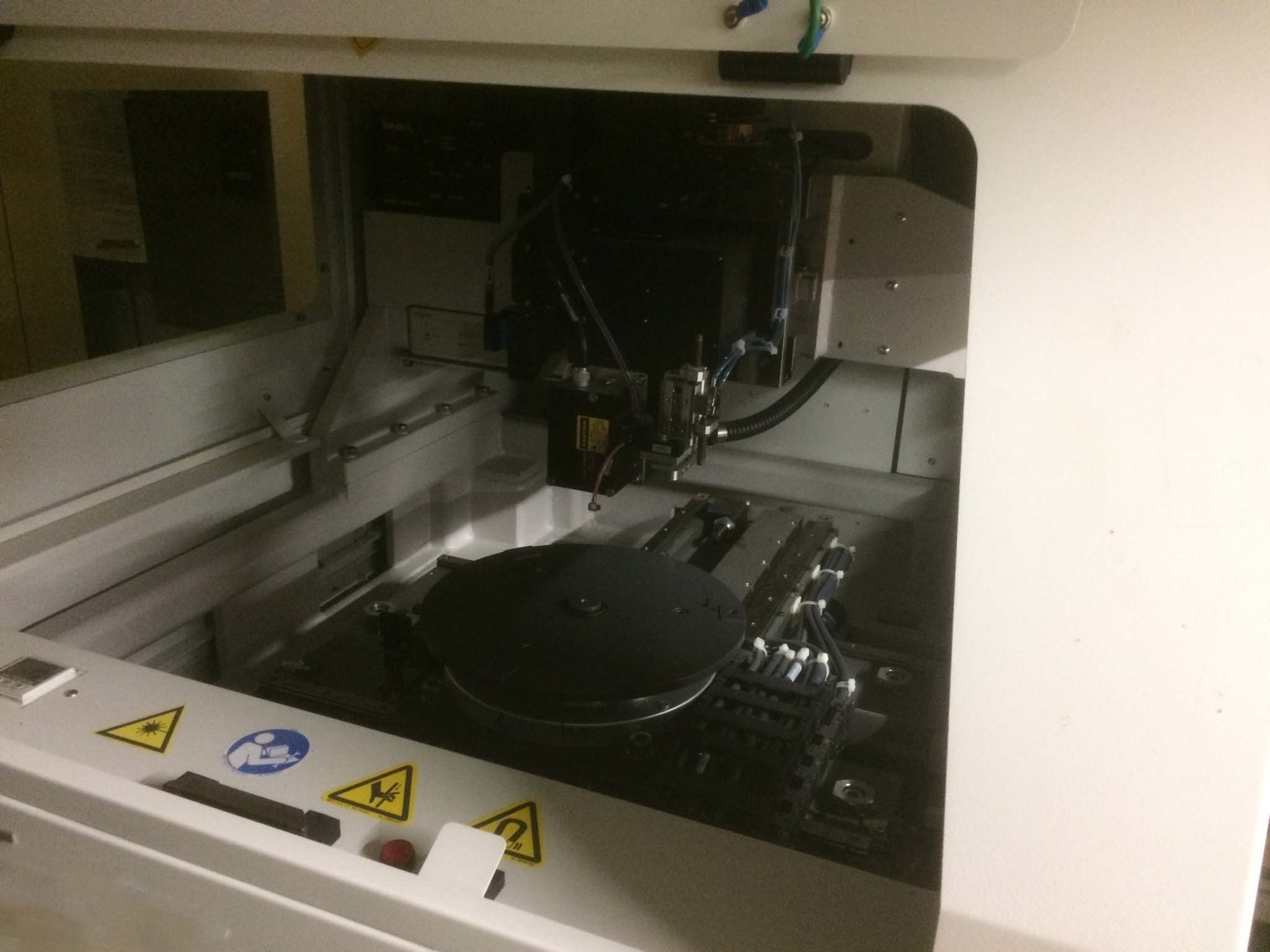

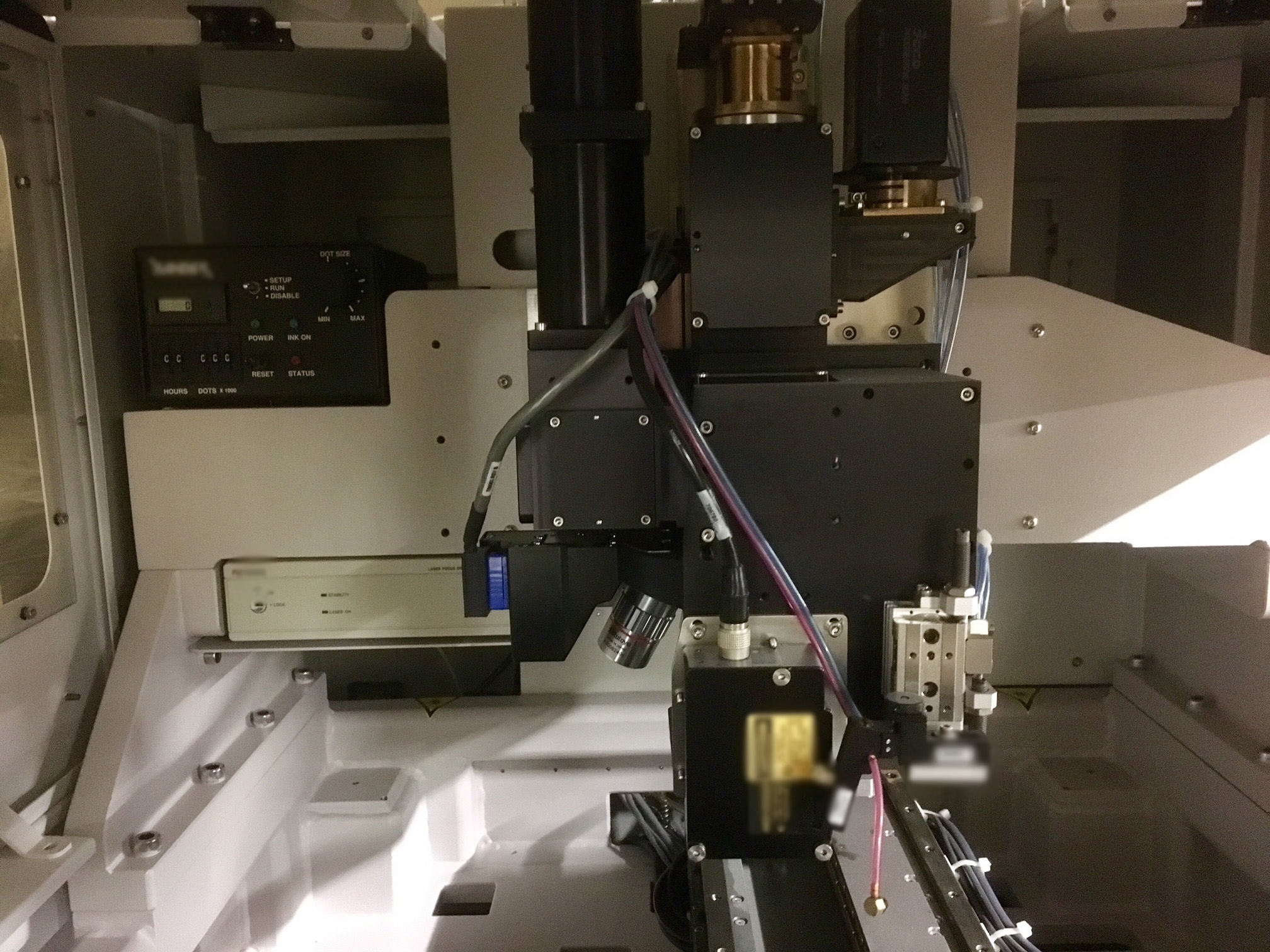

Defect inspection system, 12"

With UltraPort handler

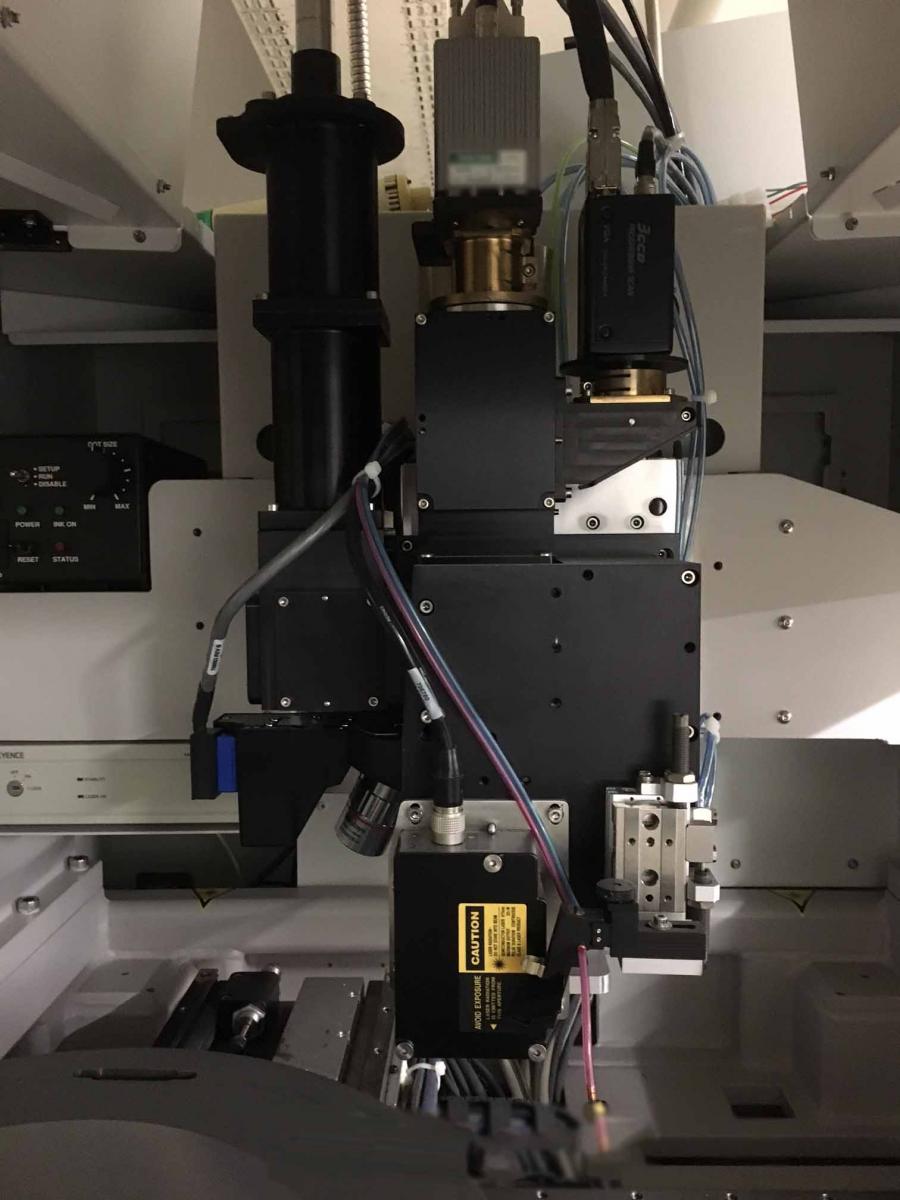

Optics: 1x, 2x, 5x, 10x, 20x

Inspection camera: CCD Monochrome (1.8 MB)

Review camera: 3-CCD Color

Illumination: Speed strobe

Staging continuous scan technology

Linear motor drives inspection axis

Automatic data collection and reporting

Speed laser focus

Wafer handler, 6"

OCR

Inker

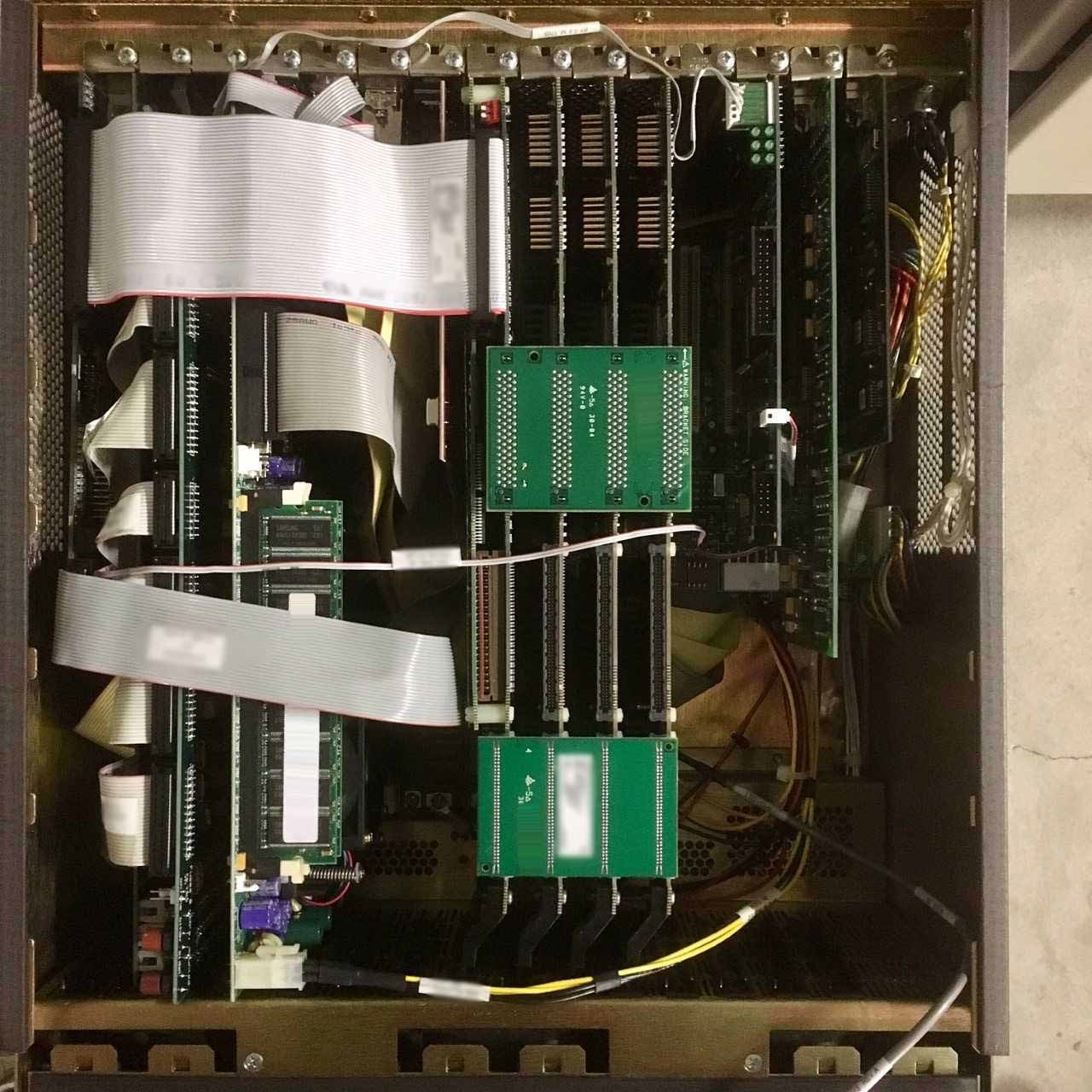

GENESIS Grabber boards

Operating system: Windows

Power supply: 200-240 V, Single phase, 6 A

2005 vintage.

RUDOLPH / AUGUST NSX 105 is a compact, mask and wafer inspection equipment designed for the rapid and accurate detection of defects. The system's automated detection and analysis capabilities are designed to provide detailed information on defects and other non-optical features of thin semiconductor mask and wafer substrates. It is well-suited for use in R&D, process control, or low-volume production environments. This unit uses a hybrid of contact and noncontact optical techniques to detect surface abnormalities on masks and wafers. Its contact head contains an array of 40 high-resolution, parallel lasers that sweep the substrate in a single path and independently measure different features. The contact head is equipped with a micro-manipulator that enables absolute measurement of the height profile of bumps and other microstructures. In addition to its contact approach, the machine employs broadband illumination technology to provide optically based measurements on one, two, or three distinct bands on the wafer. This allows the tool to measure a range of features, from chip outlines and surface roughness to predetermined pattern parameters. The asset is capable of automatically generating a surface plot of features using up to three-dimensional data visualization. It is further equipped with high-accuracy defect localization, surface analysis, and automated defect review capabilities, as well as real-time model stability adjustment and automated defect illustration. AUGUST NSX-105 has the flexibility to be integrated with a dedicated inspection equipment or integrated into a larger process flow. In either case, it can be connected via Ethernet, GPIB (General Purpose Interface Bus) or USB ports. Additionally, it comes with onboard software tools that provide real-time, automated defect detection data, maximizing efficiency. The onboard software includes a defect-orientated image editor, flexible data logging, and more. Overall, RUDOLPH NSX 105 is an advanced, compact system designed for the rapid, reliable detection of defects and other surface features on thin semiconductor mask and wafer substrates. With its combination of advanced contact and noncontact optical techniques, as well as its various automated capabilities, it is well-suited for use in lab or production environments.

There are no reviews yet