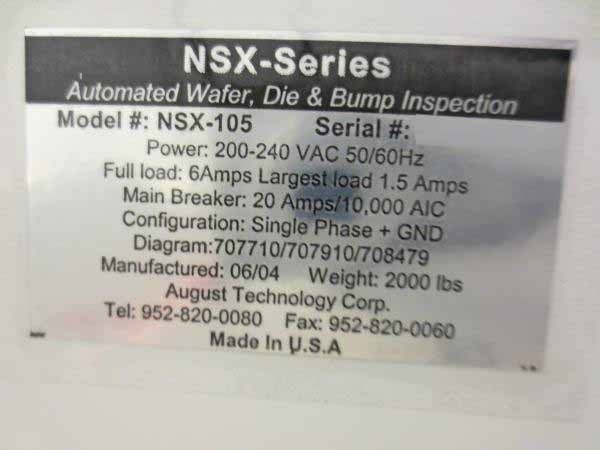

Used RUDOLPH / AUGUST NSX 105 #9191496 for sale

URL successfully copied!

Tap to zoom

ID: 9191496

Wafer Size: 8"

Vintage: 2004

Inspection system, 8"

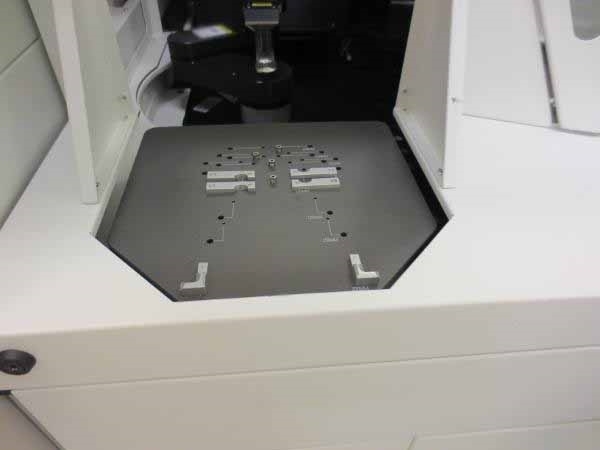

(2) Load ports, 6"-8"

BROOKS AUTOMATION Robot and aligner

Wafer stage, 12"

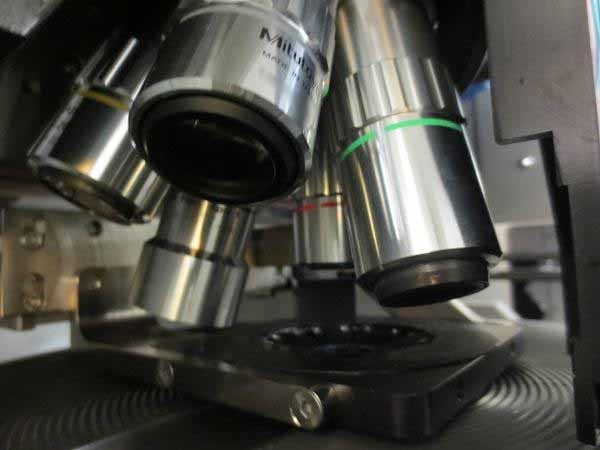

(5) Optic lens with SONY CCD 3D camera

2004 vintage.

RUDOLPH / AUGUST NSX 105 is a High-speed Mask & Wafer Inspection Equipment. This system is used to detect the presence of particles, scratches and other defects in semi-conductor wafer and photomask substrates. It is an advanced machine vision unit which provides fully automatic detection and analysis of particles down to 10 microns as well as scratches. The machine operates by using full-field polarized strobe light imaging, which is then used with particle counting algorithms to detect the presence of particles and other contaminants. The tool can detect semi-transparent particles and areas of uneven contamination over very large areas, making the asset ideal for inspecting large areas of wafers at once. It has an integrated proprietary tracking model which allows inspectors to track the progress of the inspection. The RudyAUGUST NSX-105 includes a high-resolution color camera and state-of-the-art optics. The camera can be configured in both line scan and area scan formats, allowing the operator to adjust the equipment to the best image quality for the particular application. The system also includes custom image processing software which can be configured for visual inspection, statistical analysis, and other purposes. This unit works in conjunction with a number of accessories, including a sample holder, liquid disperser, and tensioner unit. The sample holder facilitates the presentation of the sample to the camera and allows precise points of focus to be determined. The liquid disperser unit is used to spray dry or liquid wet chemistry onto the sample, while the tensioner unit can be used to precisely apply tension to the sample surface in order to detect scratches. Inspection results are stored on a hard drive. The results can be analyzed, printed, and stored for future reference. The RudyRUDOLPH NSX 105 is a reliable, high quality machine which is trusted by many manufacturers in the semiconductor industry to detect defects. With its advanced masking and wafer inspection capabilities, this tool provides a powerful tool to quickly and accurately identify potential problems with semi-conductor substrates.

There are no reviews yet