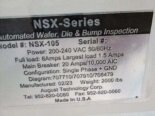

Used RUDOLPH / AUGUST NSX 105 #9228881 for sale

URL successfully copied!

Tap to zoom

ID: 9228881

Wafer Size: 8"

Automatic Vision Inspection (AVI) system, 8"

Loading configuration: Open cassette & FOUP

Inspection camera: 1.8MB Monochrome CCD

Review camera: 3CCD Color

Illumination: High speed strobe

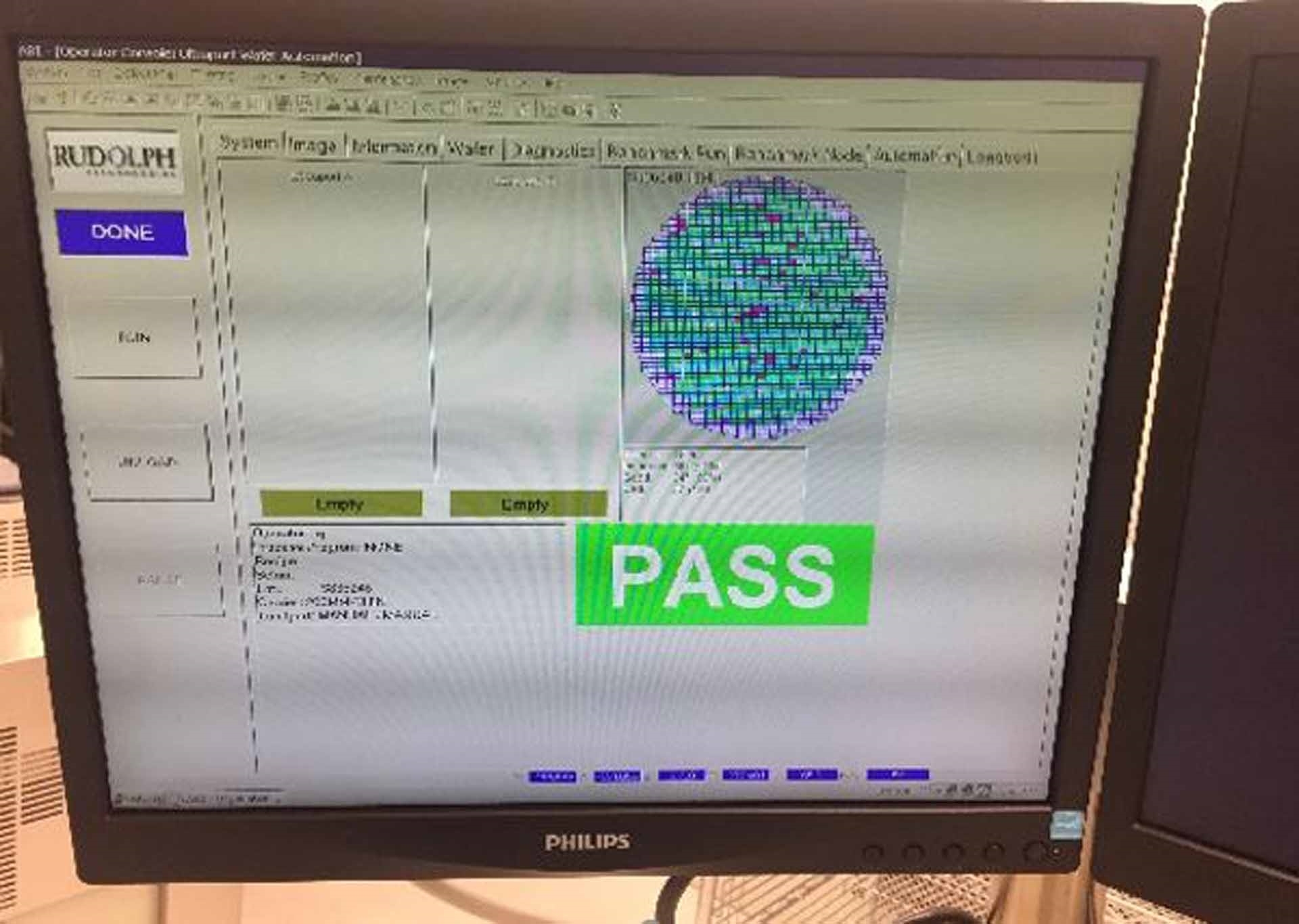

Operating system: Windows XP

Automatic data collection & reporting

High speed laser focus

Optics: 1x, 2x, 5x, 10x, 20x

Whole wafers: 1"-12"

Min defect: 0.5 um

Pneumatic inker.

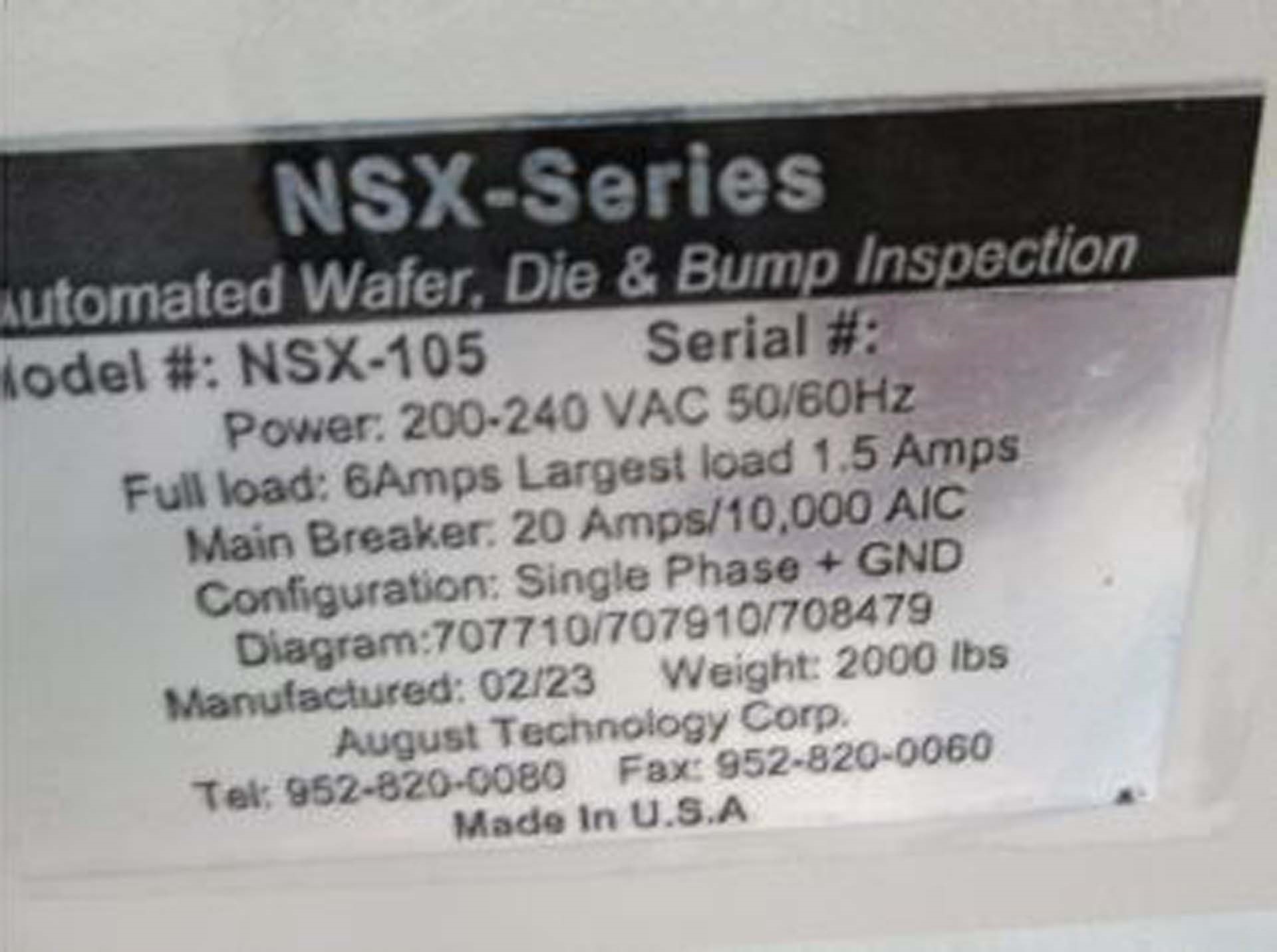

RUDOLPH / AUGUST NSX 105 is a fully automated mask & wafer inspection equipment developed and manufactured by AUGUST Technologies, Inc. AUGUST NSX-105 offers a complete mask & wafer inspection solution in a single platform that meets both quality and productivity requirements. RUDOLPH NSX 105 inspection system utilizes innovative 2D and 3D imaging technologies to inspect wafer defects with a high level of precision and accuracy. The image capture unit includes a series of high-resolution cameras that capture quality images in a variety of formats, including color, monochrome and bilevel. The wafer inspection module is capable of detecting and measuring defects on silicone and aluminum oxide masks, along with detecting voids, pinholes, scratches and other irregularities on wafers. NSX 105 is equipped with a variety of tools that allow the user to customize the machine. The tool includes an intuitive user interface that provides easy access to the full range of mask & wafer inspection parameters. The user can adjust the inspection parameters, including the size and shape of the defects to be detected and the threshold value for edge and noise effects. In addition, the user can set up multiple inspection modes to quickly and easily check for specific defects. The wafer inspection module is designed to provide fast, accurate, and repeatable inspections, with repeatability of greater than 95%. The asset can inspect up to 700 wafers per hour and features a high-speed calibration function to ensure accuracy and repeatability. NSX-105 is a fully automated inspection model that is easy to operate and maintain. The equipment is highly efficient and cost effective, making it ideal for semiconductor mask and wafer inspection applications. With its innovative 2D and 3D imaging technology and intuitive user interface, NSX 105 provides a reliable and efficient mask and wafer inspection solution.

There are no reviews yet