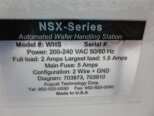

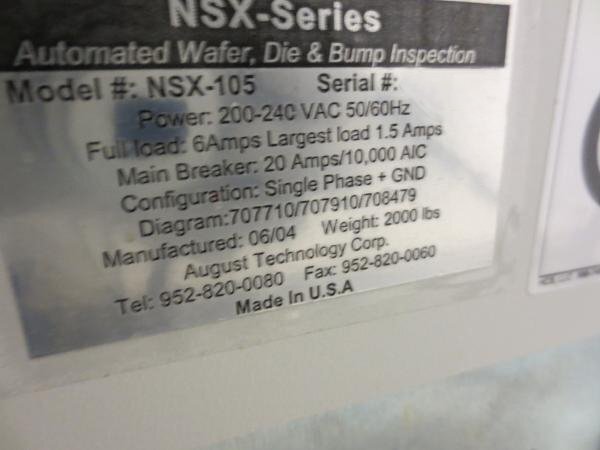

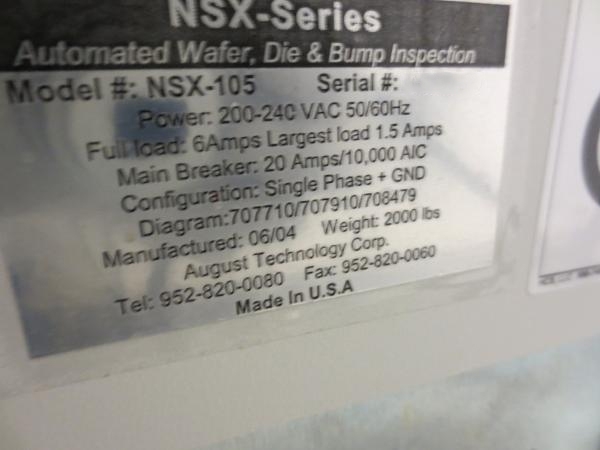

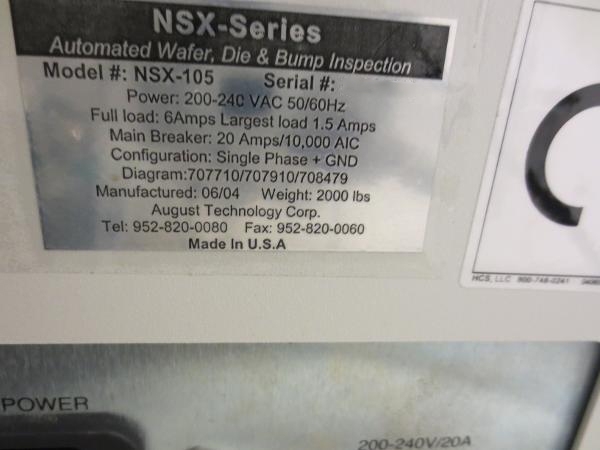

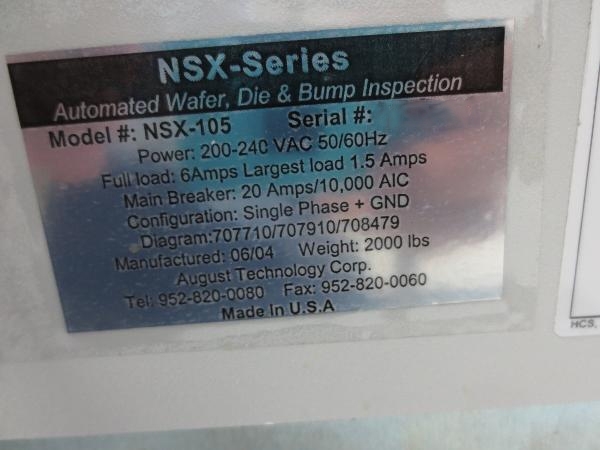

Used RUDOLPH / AUGUST NSX 105 #9274495 for sale

URL successfully copied!

Tap to zoom

ID: 9274495

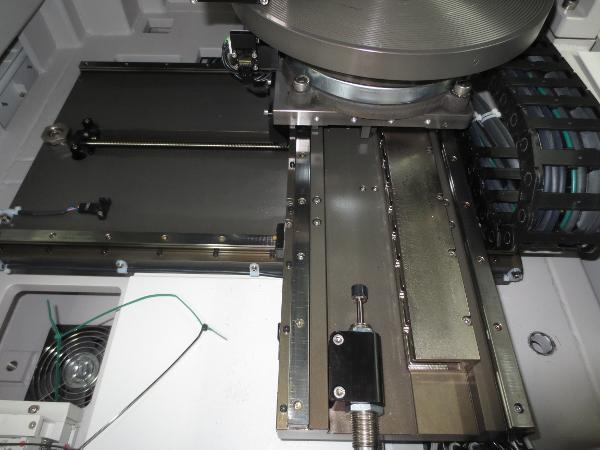

Wafer Size: 8"

Vintage: 2003

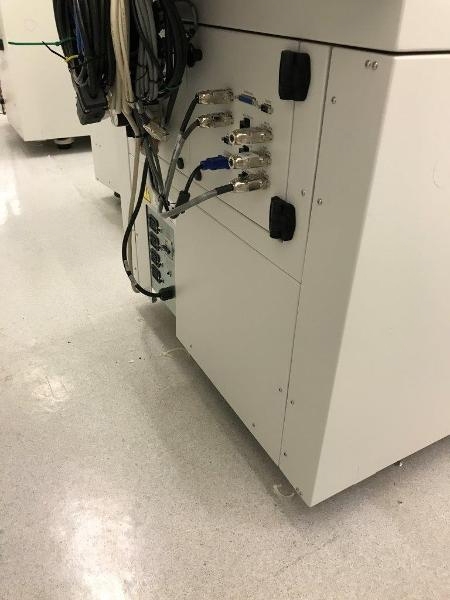

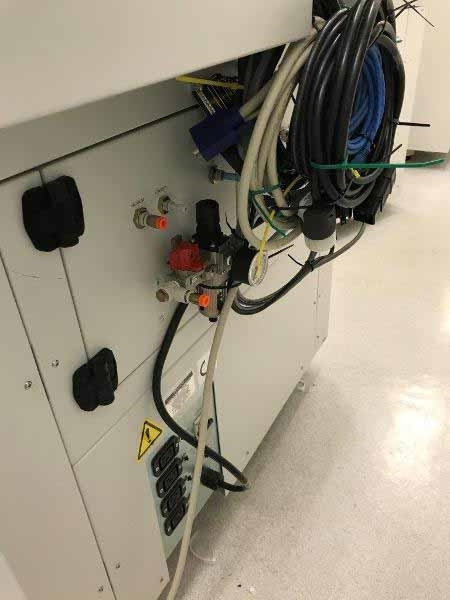

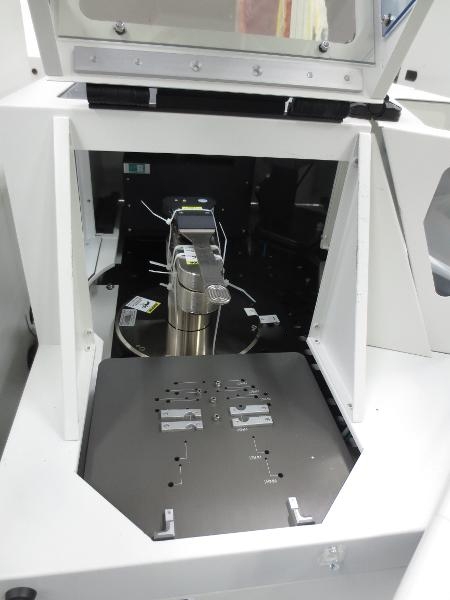

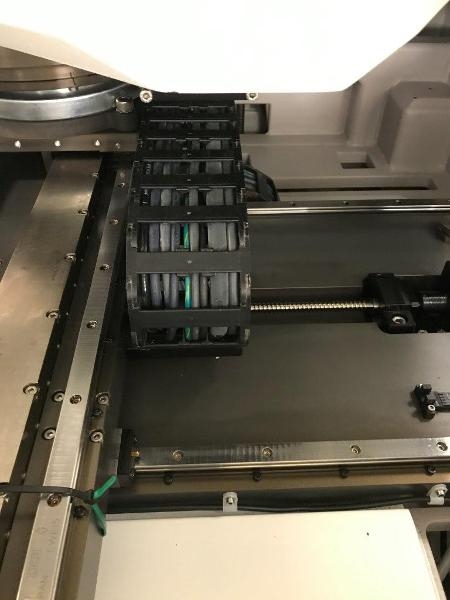

Automated defect inspection system, 8"

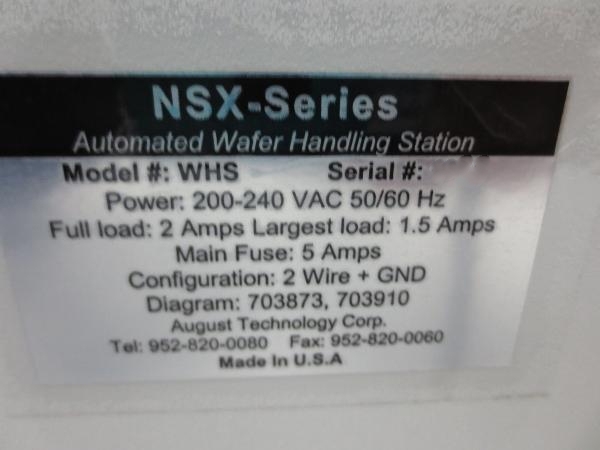

(2) Load ports, 6"-8"

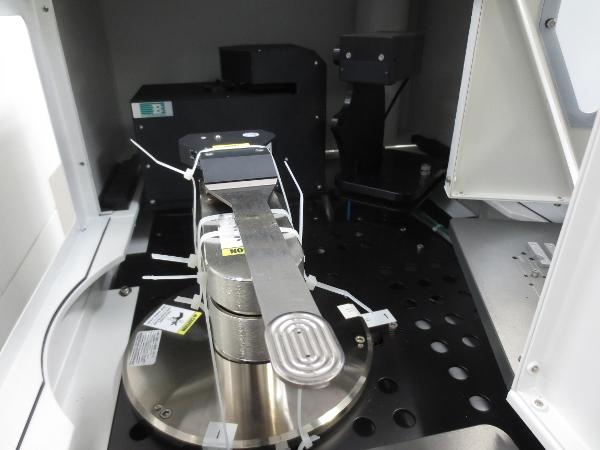

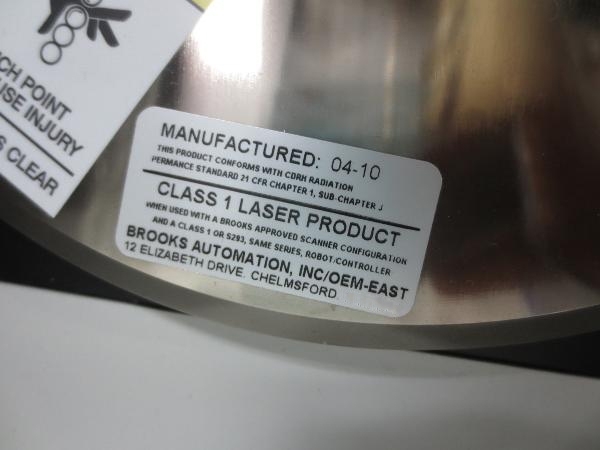

BROOKS (Robot and aligner)

Wafer stage, 12"

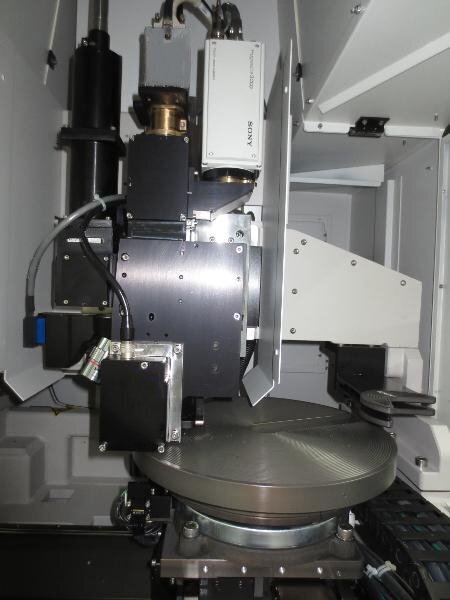

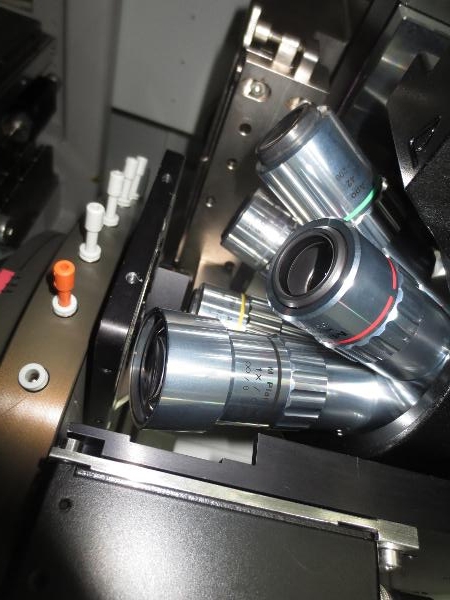

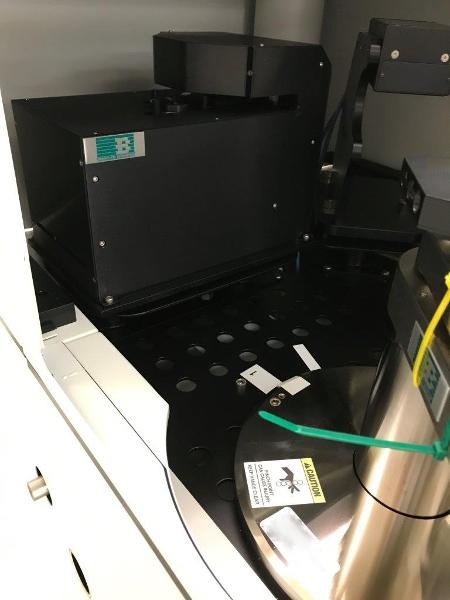

(5) Optic lens

With CCD 3D camera (SONY)

2003 vintage.

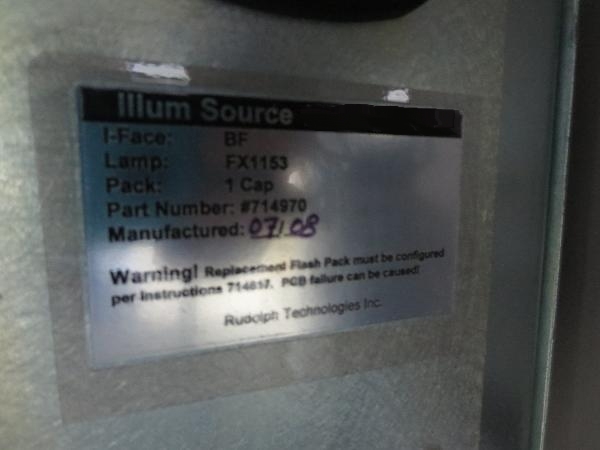

RUDOLPH / AUGUST NSX 105 is a mask and wafer inspection equipment designed for efficient, high-accuracy wafer, substrate, and reticle inspection and metrology. The system boasts several advanced features such as optical alignment calibration, multi-sensor monitoring, and high resolution imaging. AUGUST NSX-105 is an intuitive platform designed for ease of use. It provides a range of parameter settings for wafer and mask inspection, allowing the user to optimize their process. The unit also offers a range of selectable graph output options, enabling users to export results in various formats. The multi-sensor monitoring function ensures optimal front-side exposure conditions that improve inspection accuracy and yields. Additionally, the machine is equipped with algorithmic-based defect detection, allowing accurate defect detection in both full-chip and partial-chip images. The tool features six megapixel optical sensors, providing high accuracy optical alignment calibration and enhanced image quality. The image processing capabilities of the asset are enhanced by the use of high-grade optics and sensors, offering imaging performance and accuracy that are significantly better than conventional metrology equipment. The viewfinder and live image feature of the model allows the operator to acquire real-time images of the wafer construction, assisting the user in quickly analyzing and correcting any issues. The unprecedented accuracy and capabilities of the equipment are further complemented by the ability of the system to store multiple inspection profiles. This allows the user to quickly switch between different inspection profiles and parameters. As the unit also has a full suite of automated metrology functions, users are able to measure critical structural components with ease. RUDOLPH NSX 105 is an ideal machine for detailed wafer and mask inspection and metrology. From single view to multi-view interaction, it is suitable for a wide range of application requirements, offering a cost-effective solution to the demands of the most advanced analytical projects. The tool features robust features, advanced functionality, and an intuitive user-interface that are essential in meeting the requirements of the semiconductor industry. With its advanced features and capabilities, NSX 105 asset is sure to deliver unrivalled precision, speed, and accuracy in wafer and reticle inspection.

There are no reviews yet