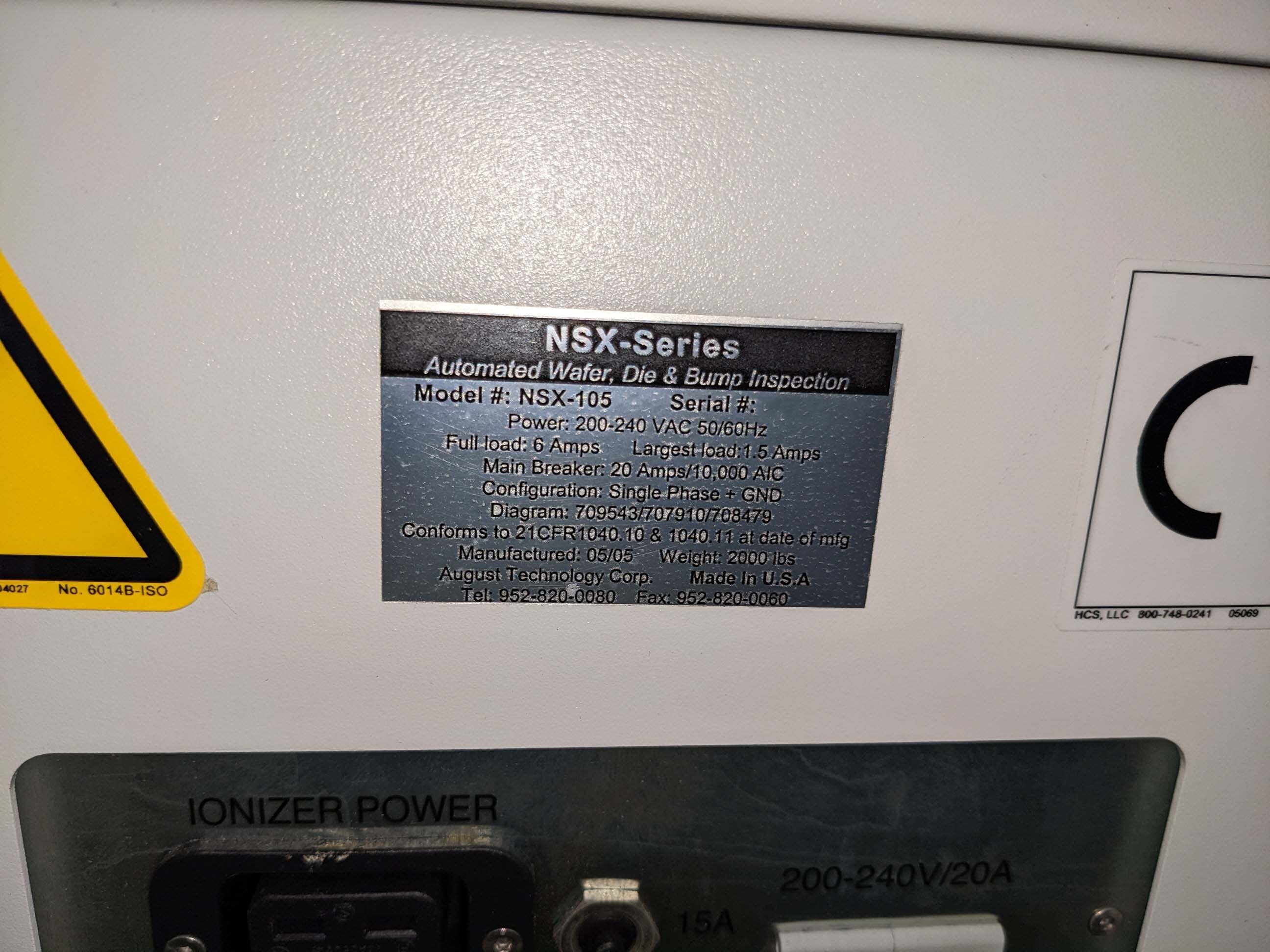

Used RUDOLPH / AUGUST NSX 105 #9276182 for sale

URL successfully copied!

Tap to zoom

ID: 9276182

Wafer Size: 8"

Vintage: 2005

Wafer inspection system, 8"

Standalone

Main body

EFEM

Main UI

Protection bar

Manual type

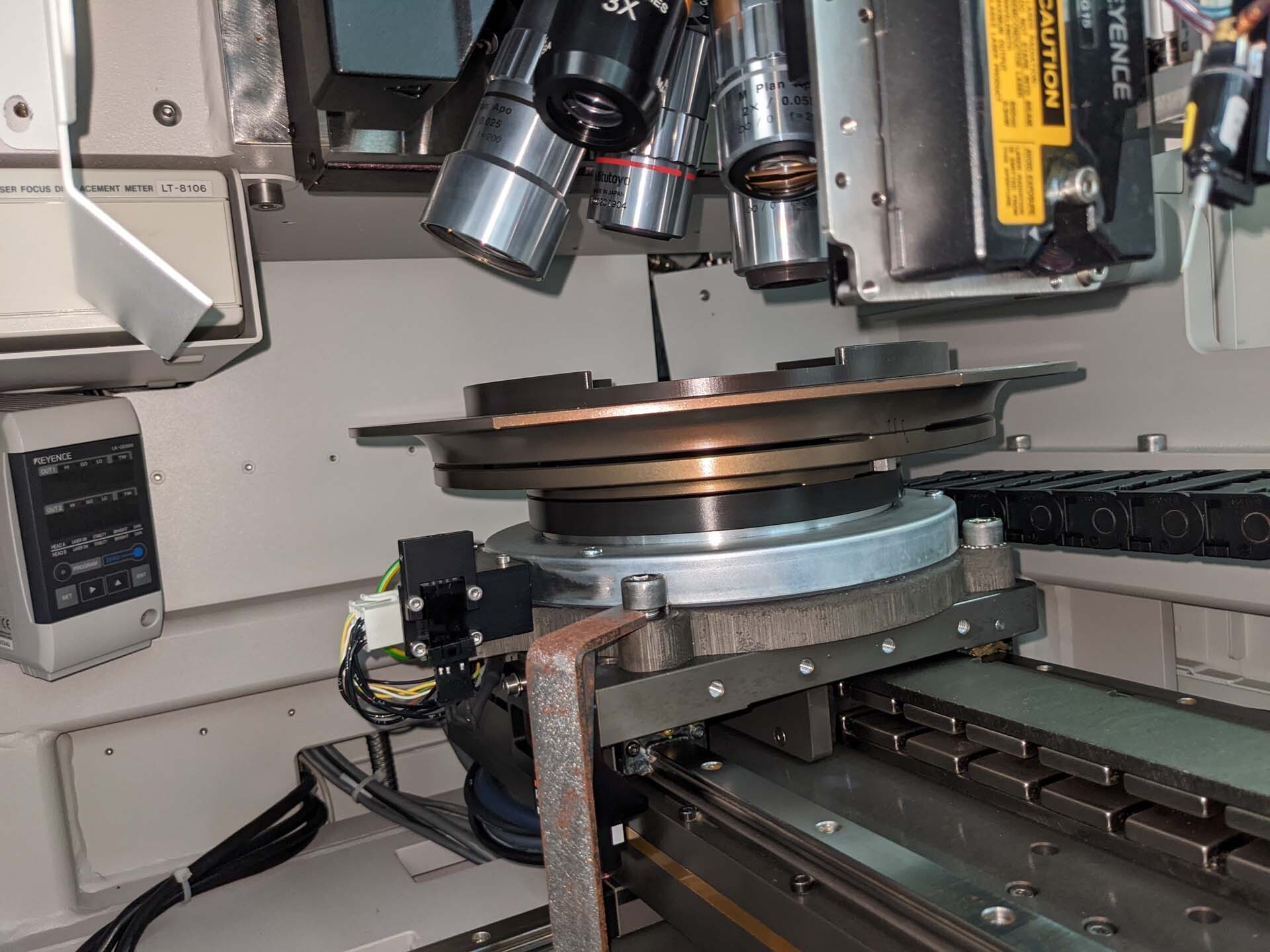

Inspection edge contact chuck

Platform for 8"

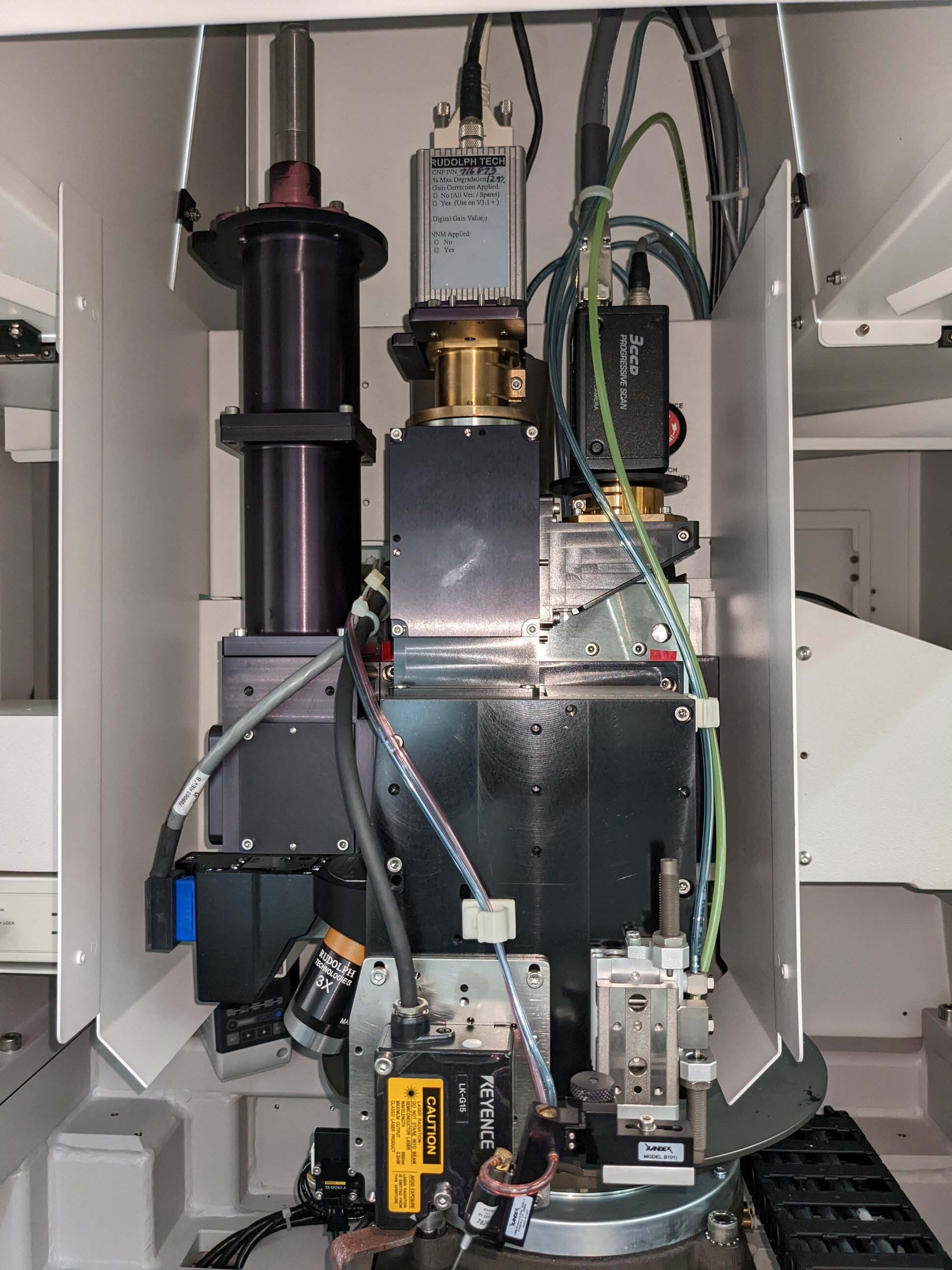

Matrox 4M

GENESIS Board

Inker

KEYENCE LK-G15 Focus sensor

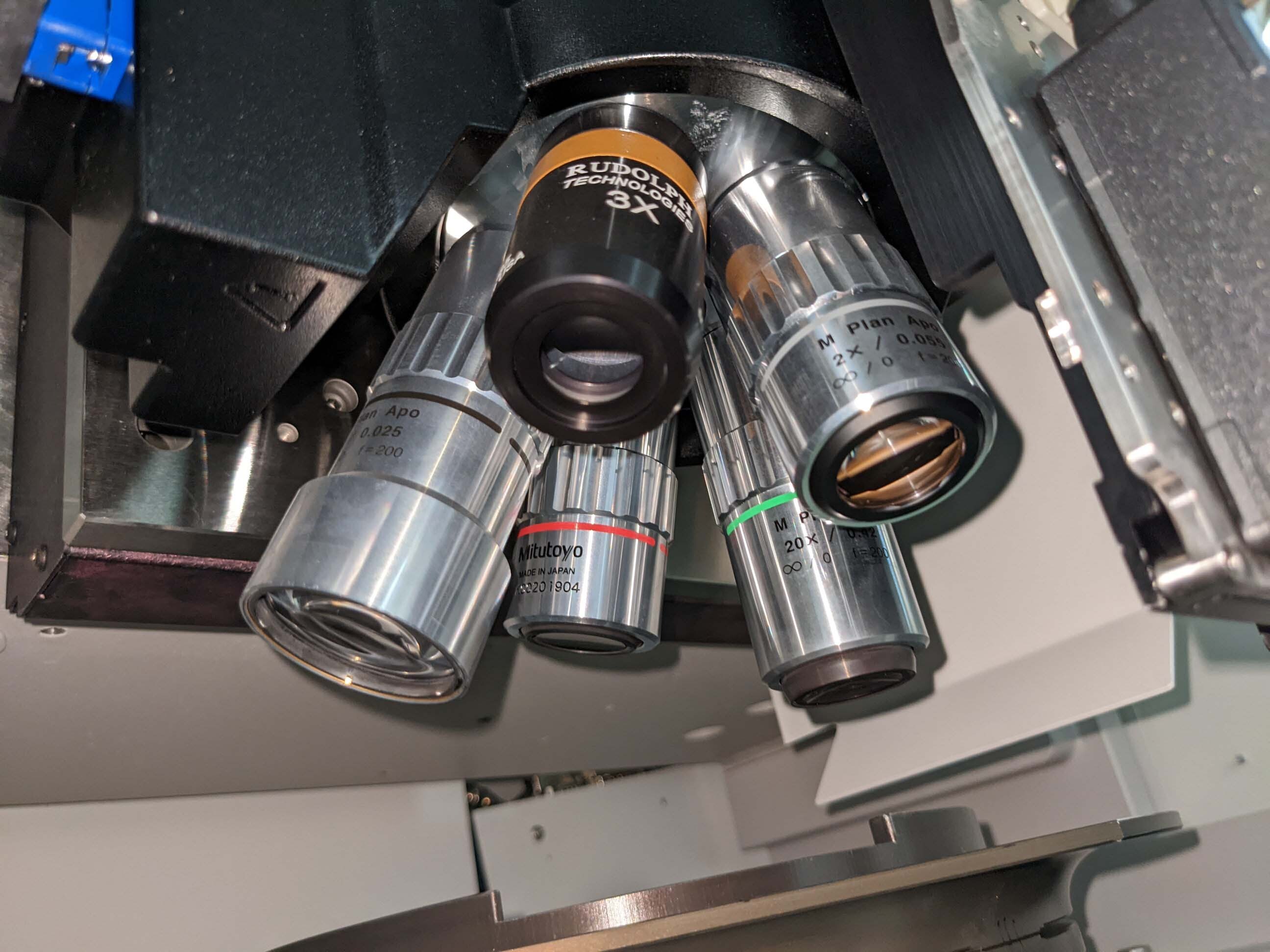

Objectives: 1x, 2x, 3x, 5x and 20x

Camera type: ADIMEC 1600M (7.4 um/pixel)

Ring light (Dark file illumination)

Without robot handling module

2005 vintage.

RUDOLPH / AUGUST NSX 105 Mask & Wafer Inspection Equipment is a specialized industrial equipment designed to inspect a wide range of masks and wafers with extremely high precision and accuracy. This system combines the latest in advanced CMOS imaging technology with an advanced optical design, which provides superior image quality of inspection samples. The unique design of AUGUST NSX-105 Mask & Wafer Inspection Unit ensures fast and accurate automatic measurement of masks, wafers, and reticles for defects, making it ideal for use in the most stringent quality control and testing standards. RUDOLPH NSX 105 Mask & Wafer Inspection Machine has a patented Ultra Contrast Hypersensitive (UCH) imaging module built into the tool, which is capable of enhancing the image contrast of an inspection sample for increased clarity and resolution. In addition, the asset has a high-resolution imaging tool, which is capable of conducting in-line inspection of mask and wafer images. Furthermore, NSX 105 Mask & Wafer Inspection Model is equipped with a micro-dispensing equipment, which is capable of automatically distributing photosensitive materials to the sample surface in a controlled manner. This micro-dispensing system ensures that samples of large size and various shapes can be quickly and accurately inspected. RUDOLPH / AUGUST NSX-105 Mask & Wafer Inspection Unit also incorporates advanced image processing and software algorithms for high-density defect detection and analysis. These algorithms are based on Fourier analysis and other modern measurement techniques that are capable of capturing the most minute variations in inspections to the highest degree of accuracy. In addition, the machine is also capable of detecting and correcting errors such as misalignment of pattern or geometric distortions. Furthermore, RUDOLPH / AUGUST NSX 105 Mask & Wafer Inspection Tool is designed for use in extreme environmental conditions such as low or high temperatures, humidity, and debris. It is also capable of performing defect inspection at high speeds and is equipped with a wide range of optical filters and illumination sources for extreme environmental conditions. The asset also features an integrated report generation tool for creating a detailed report of defect inspections, along with a graphical user interface (GUI) for easy operation. The model is designed to be highly cost-effective and provides low operating costs, while delivering superior performance and reliable results. Overall, RUDOLPH NSX 105 Mask & Wafer Inspection Equipment is a powerful and reliable tool for conducting high-precision mask and wafer inspection in various industries. It is a must-have for any enterprise that values accuracy, precision and productivity in their inspection processes.

There are no reviews yet