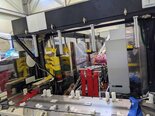

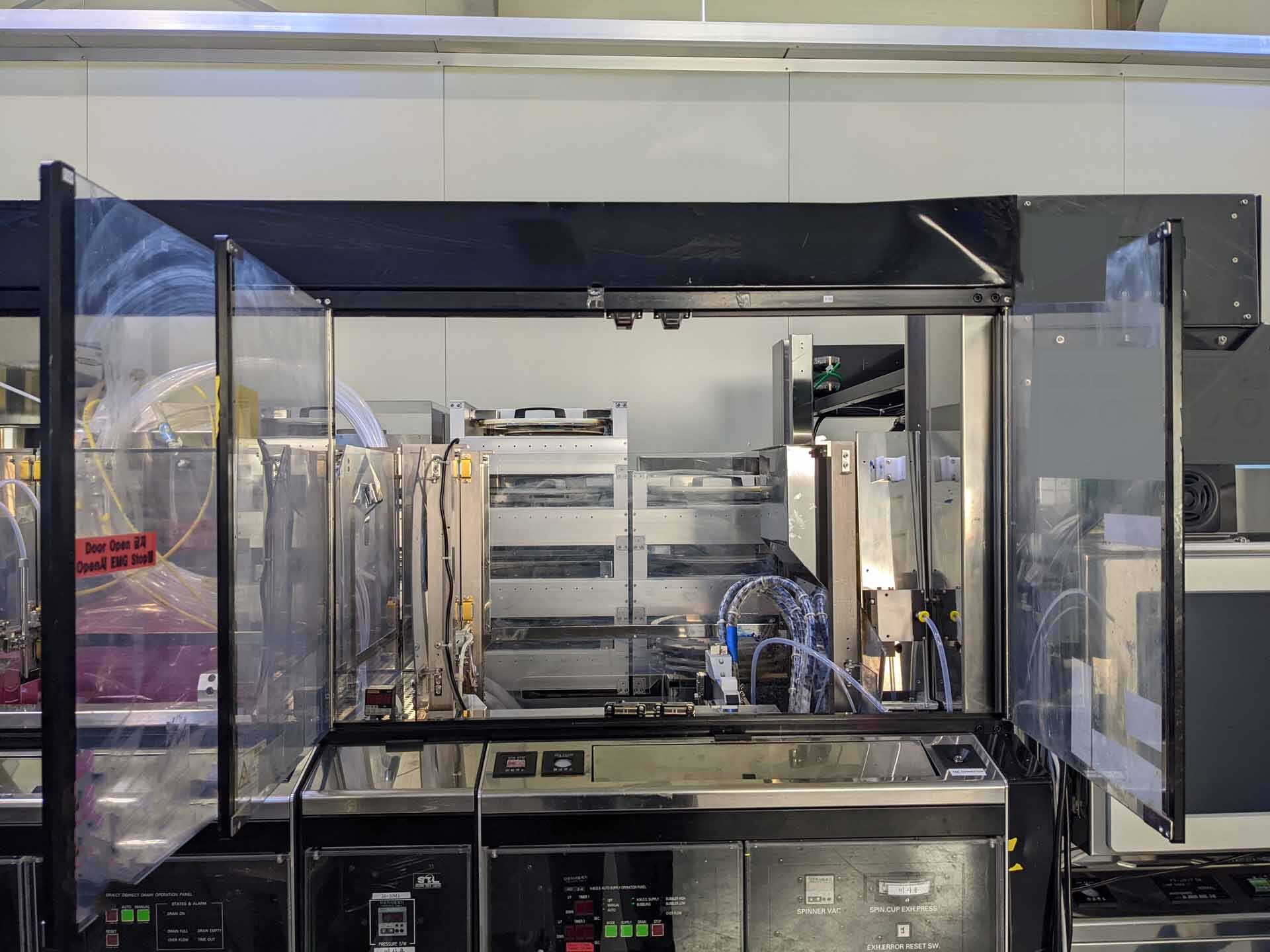

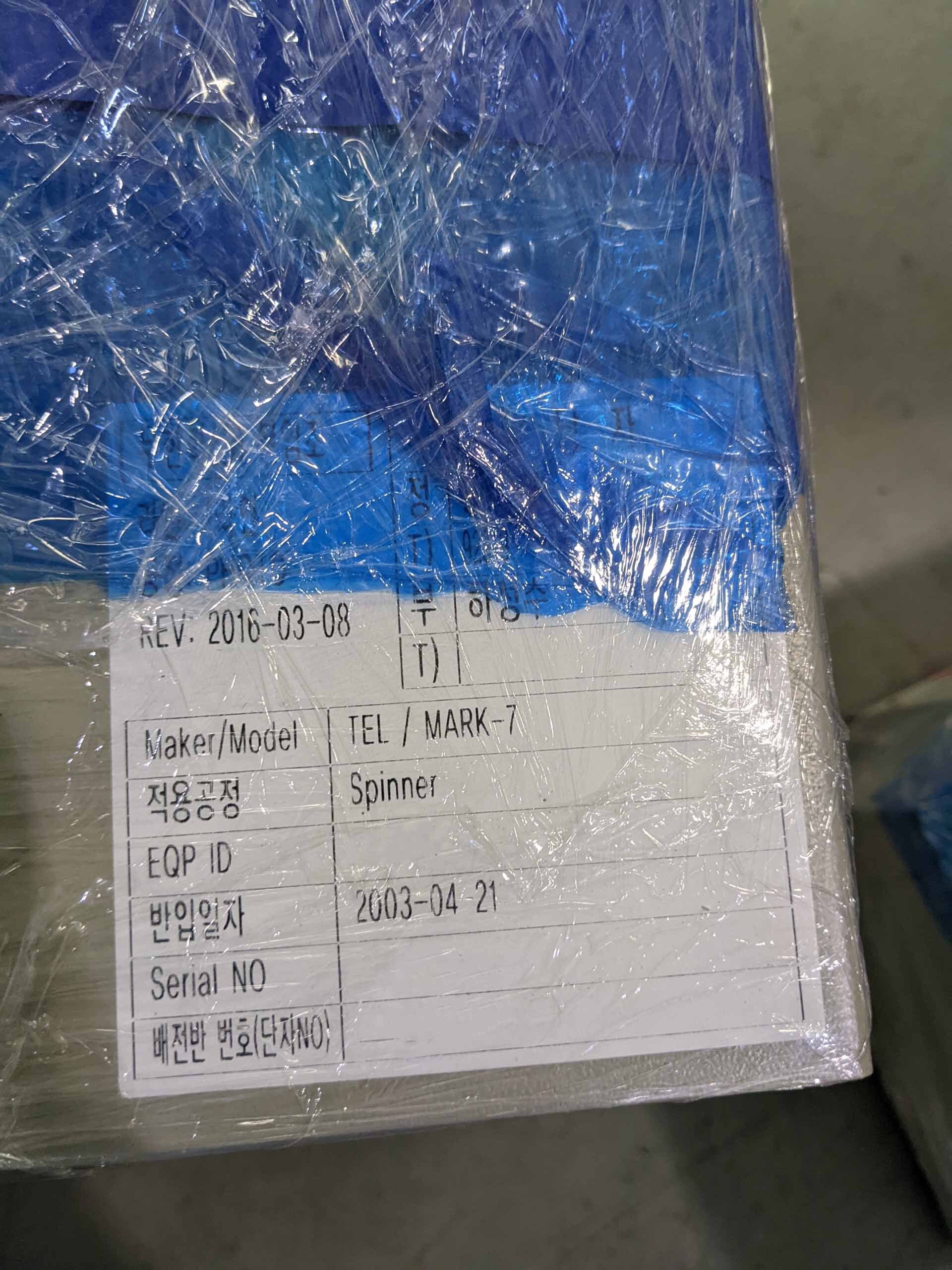

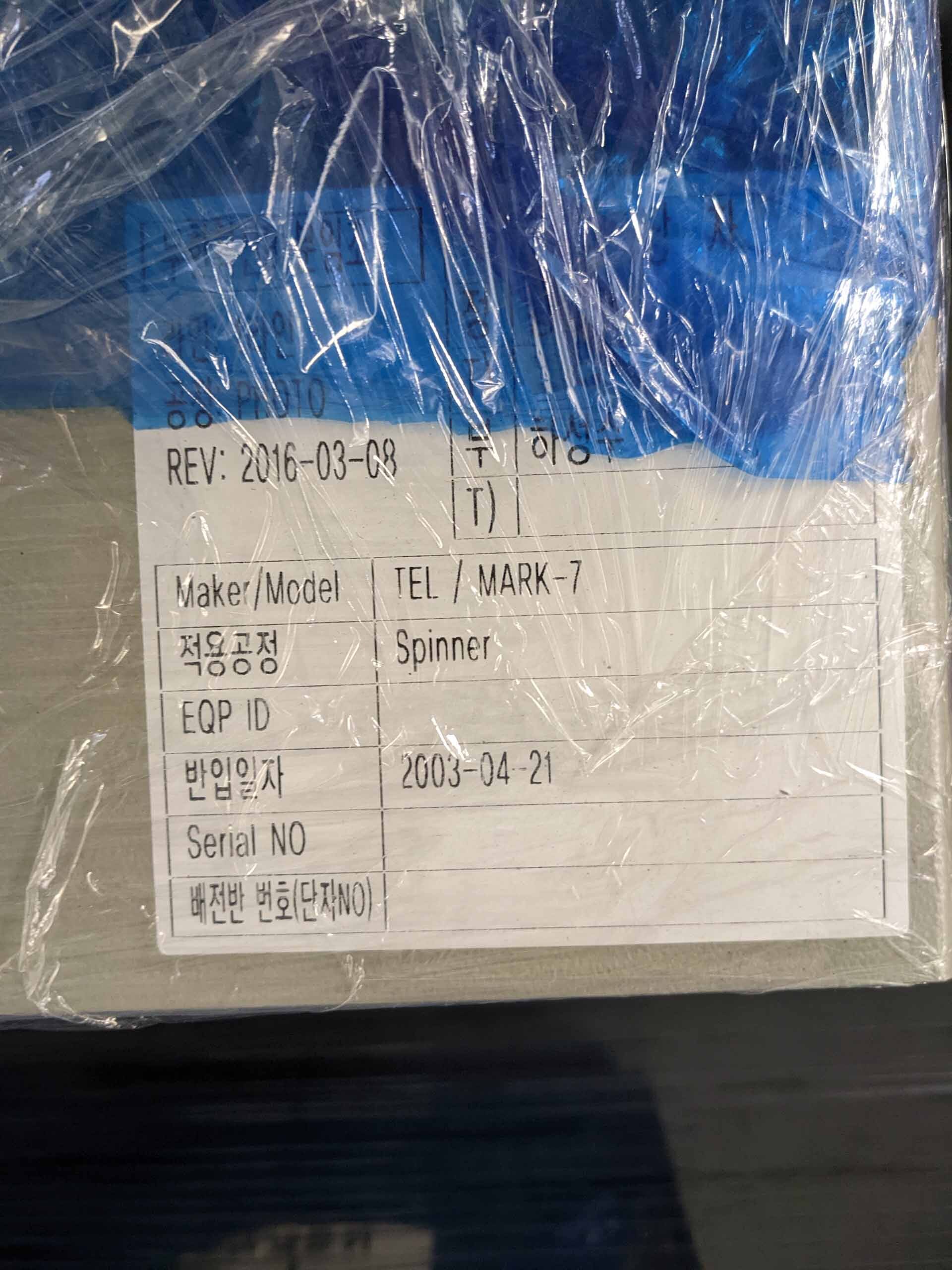

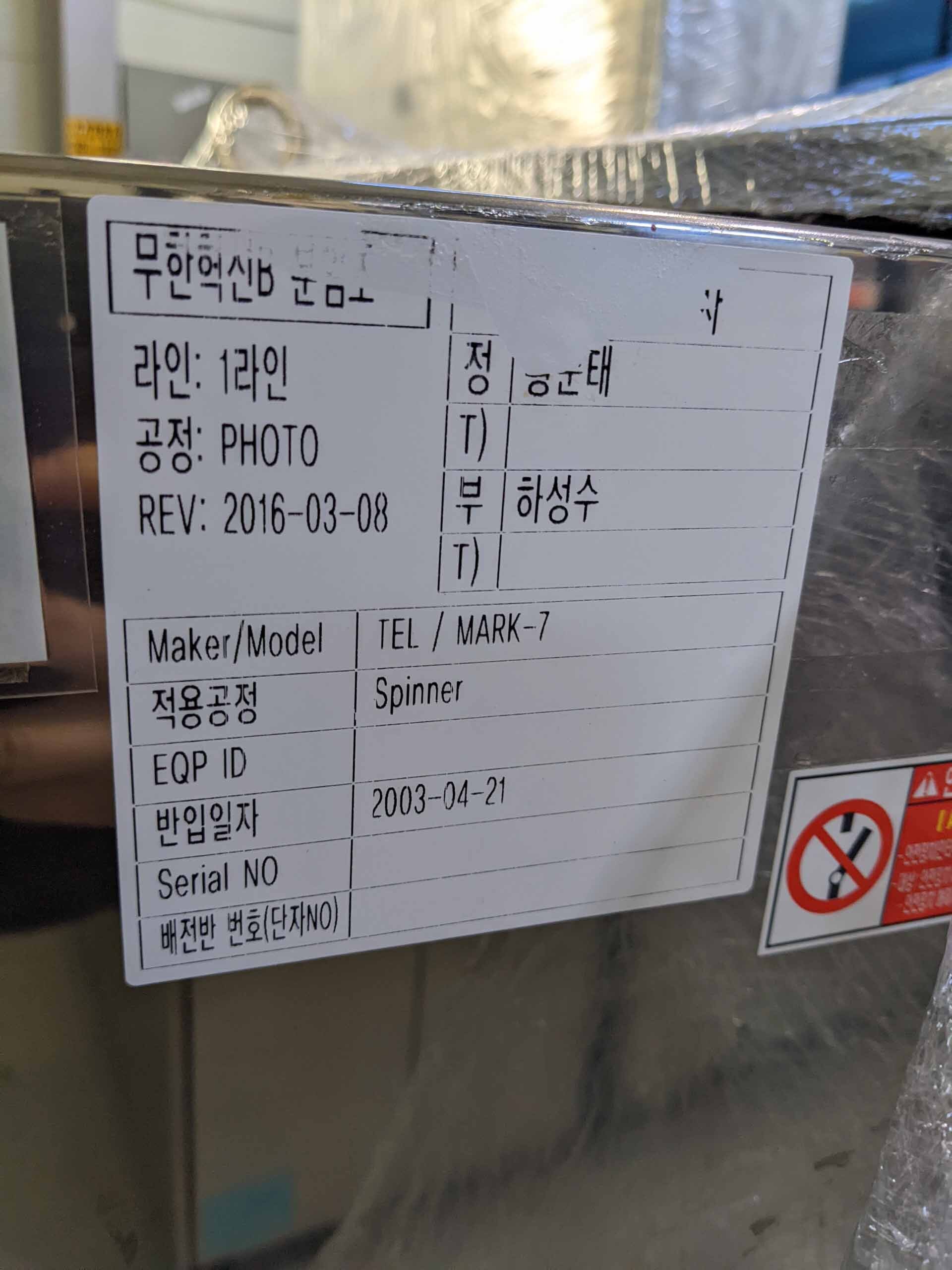

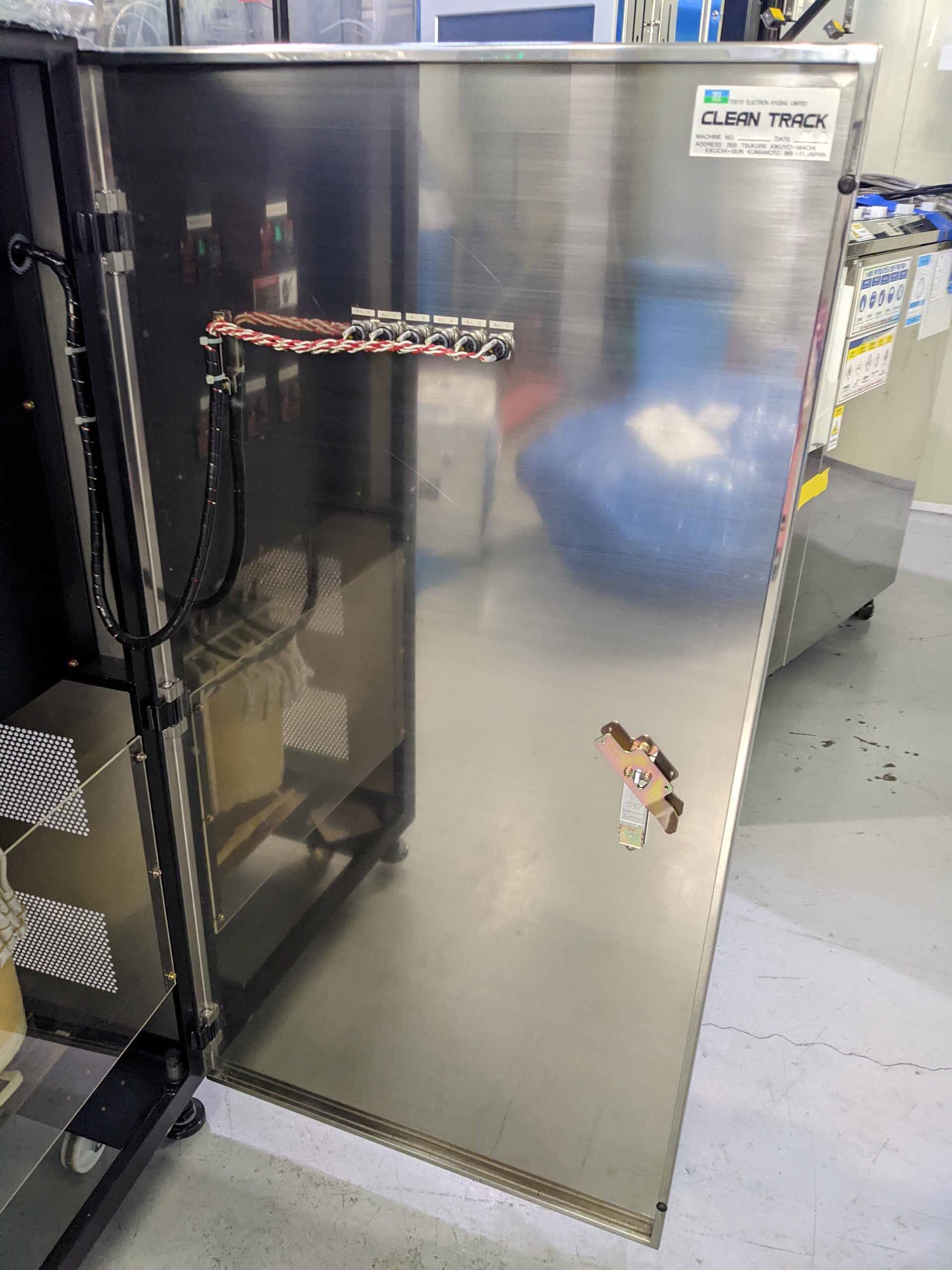

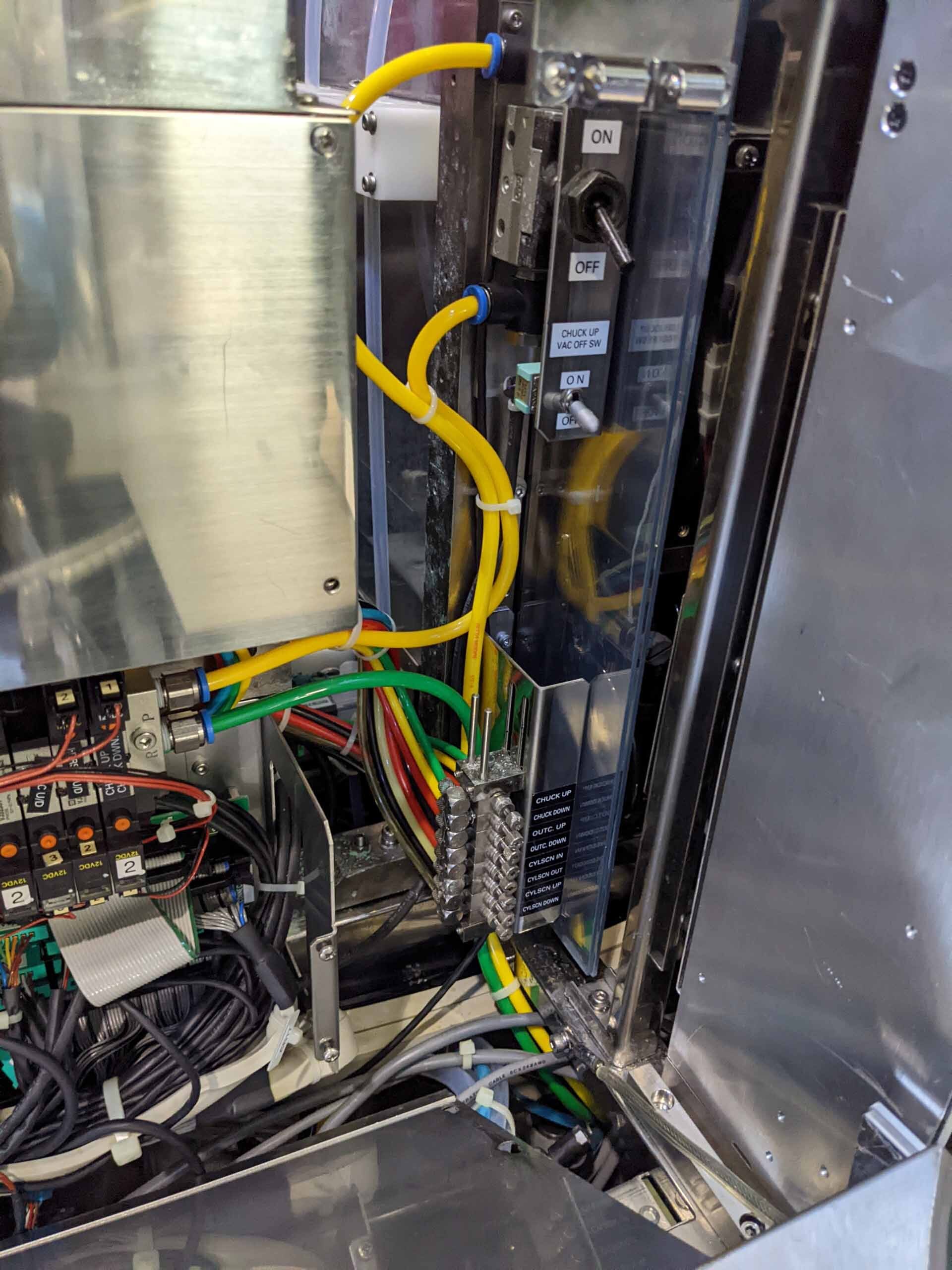

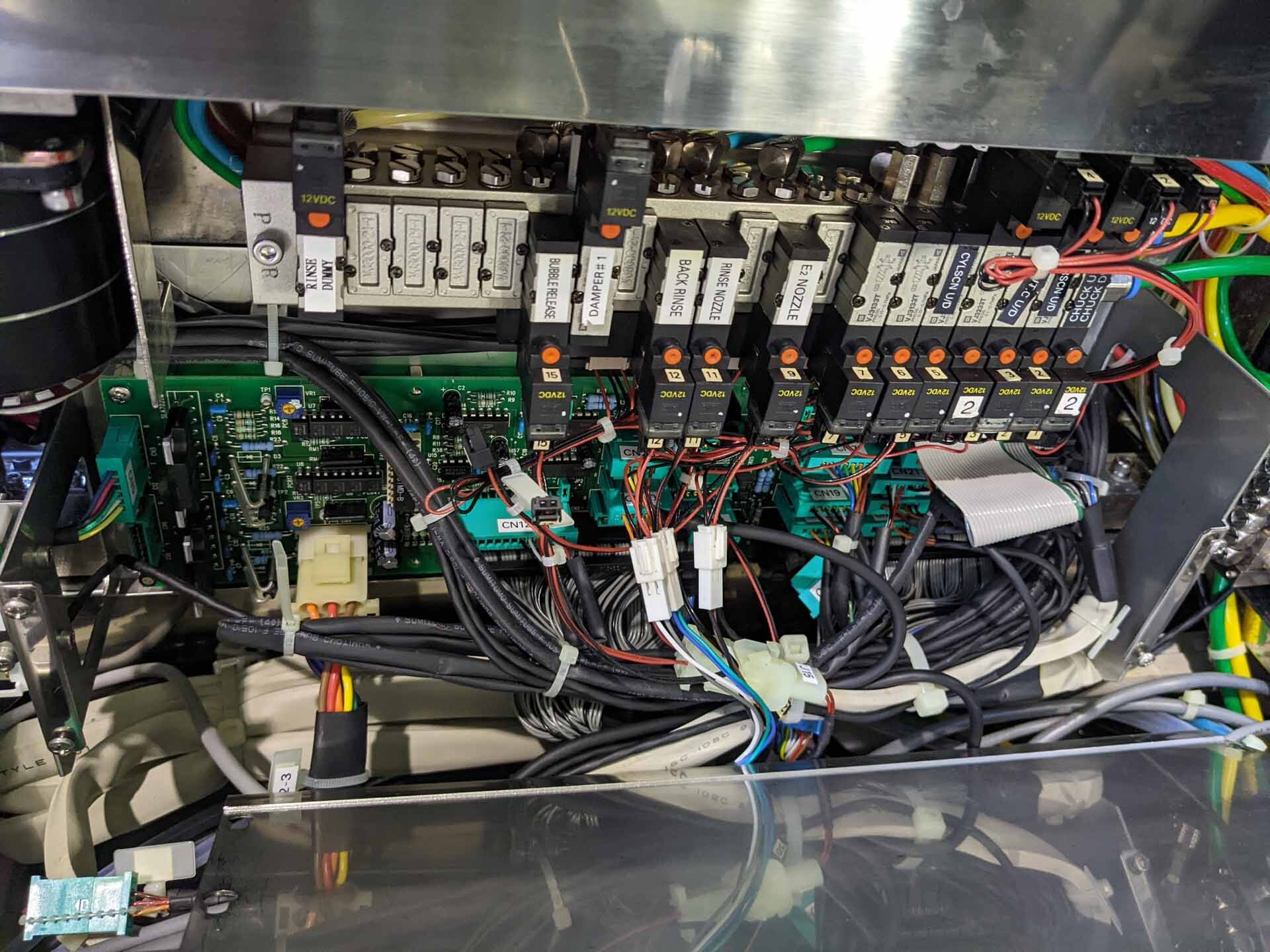

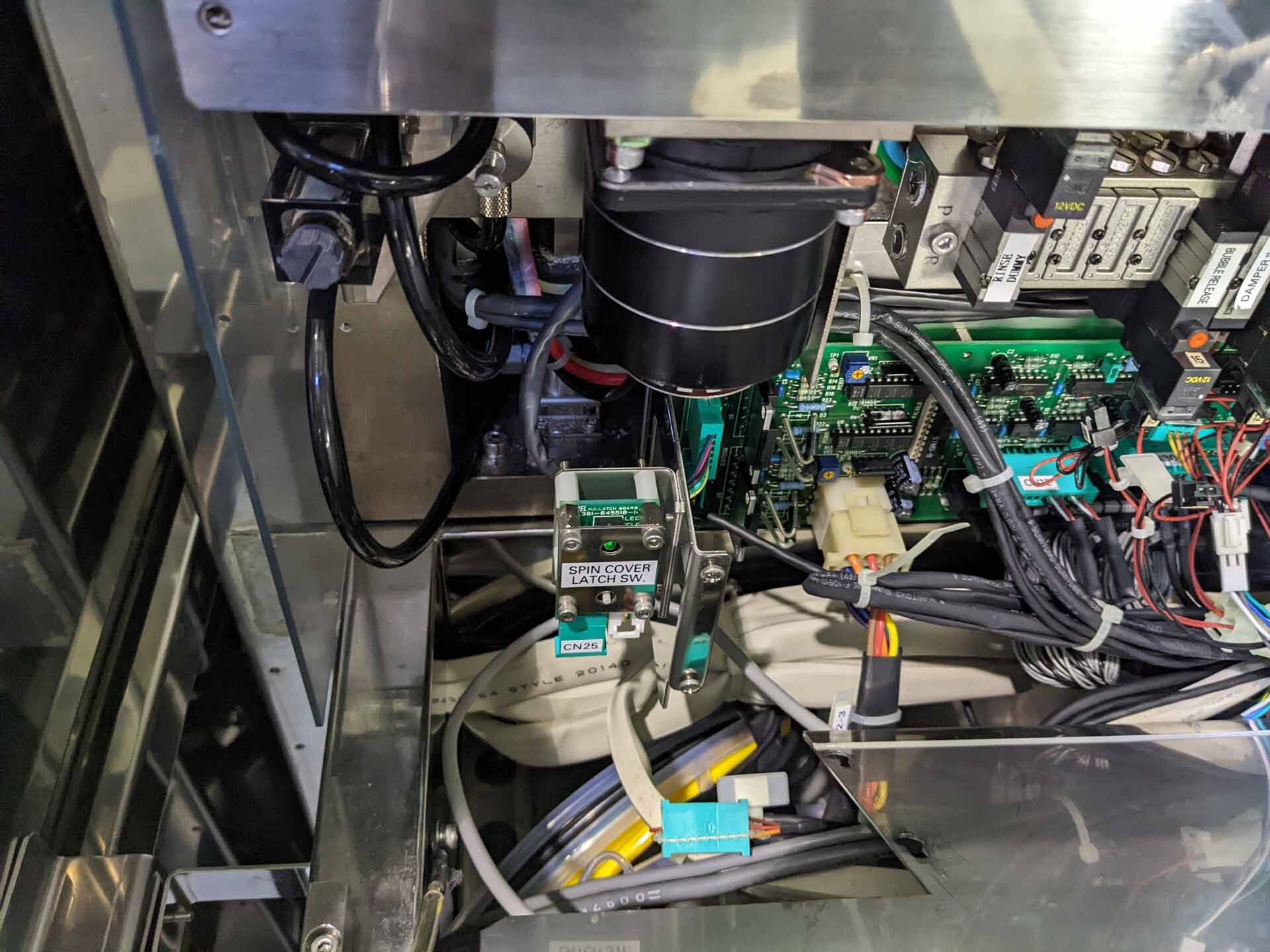

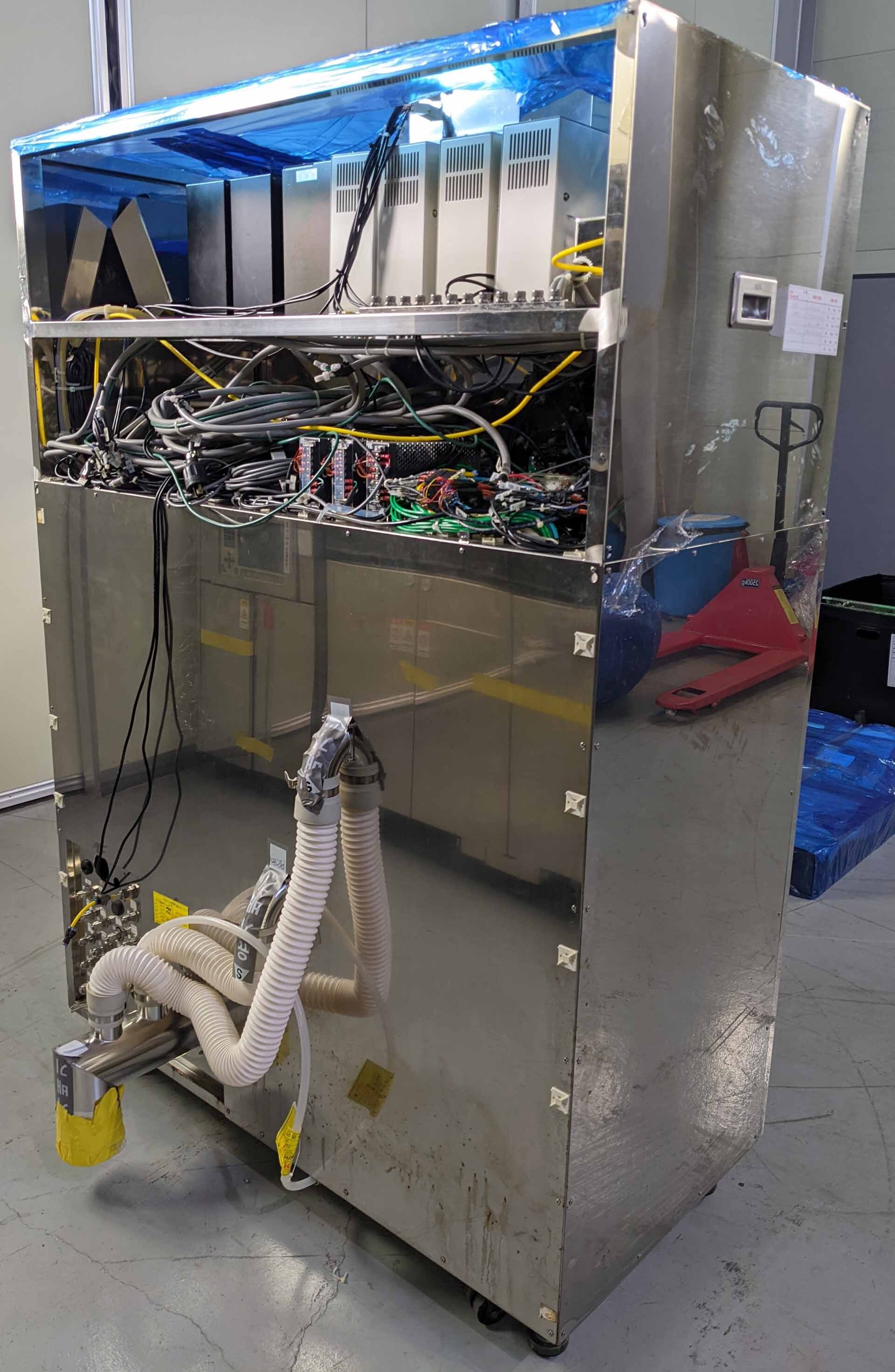

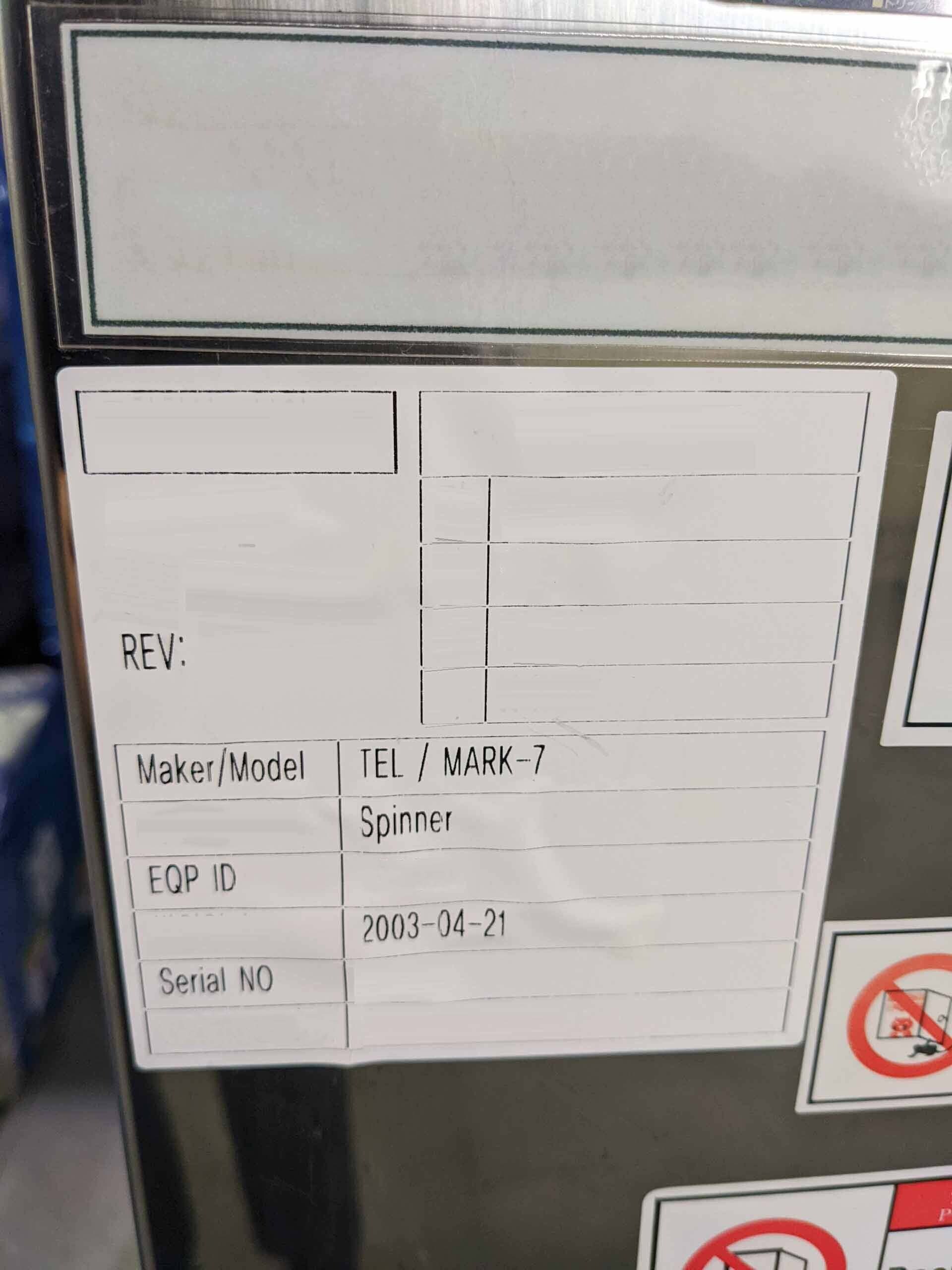

Used TEL / TOKYO ELECTRON Clean Track Mark 7 #293632604 for sale

URL successfully copied!

Tap to zoom

ID: 293632604

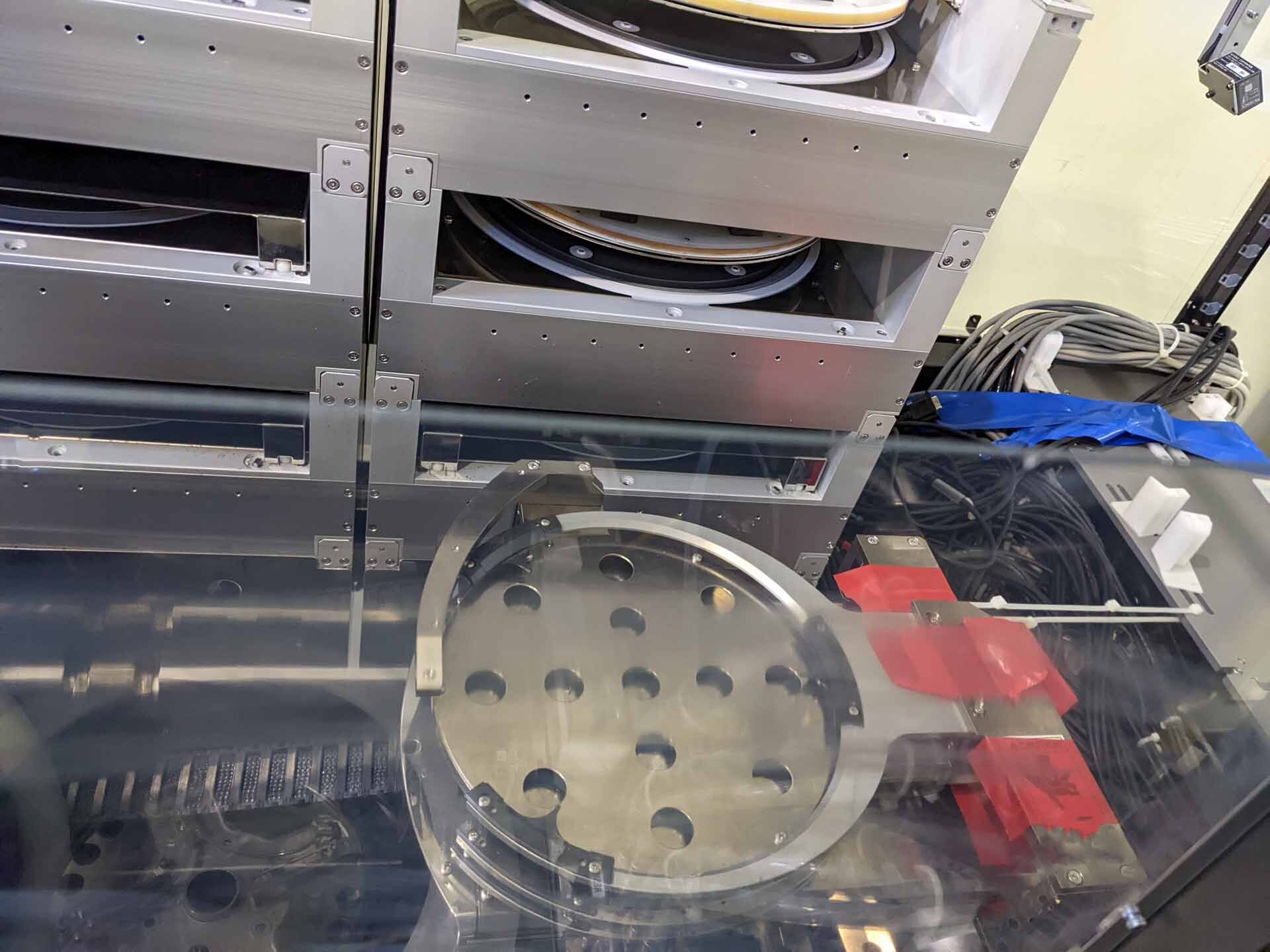

Wafer Size: 8"

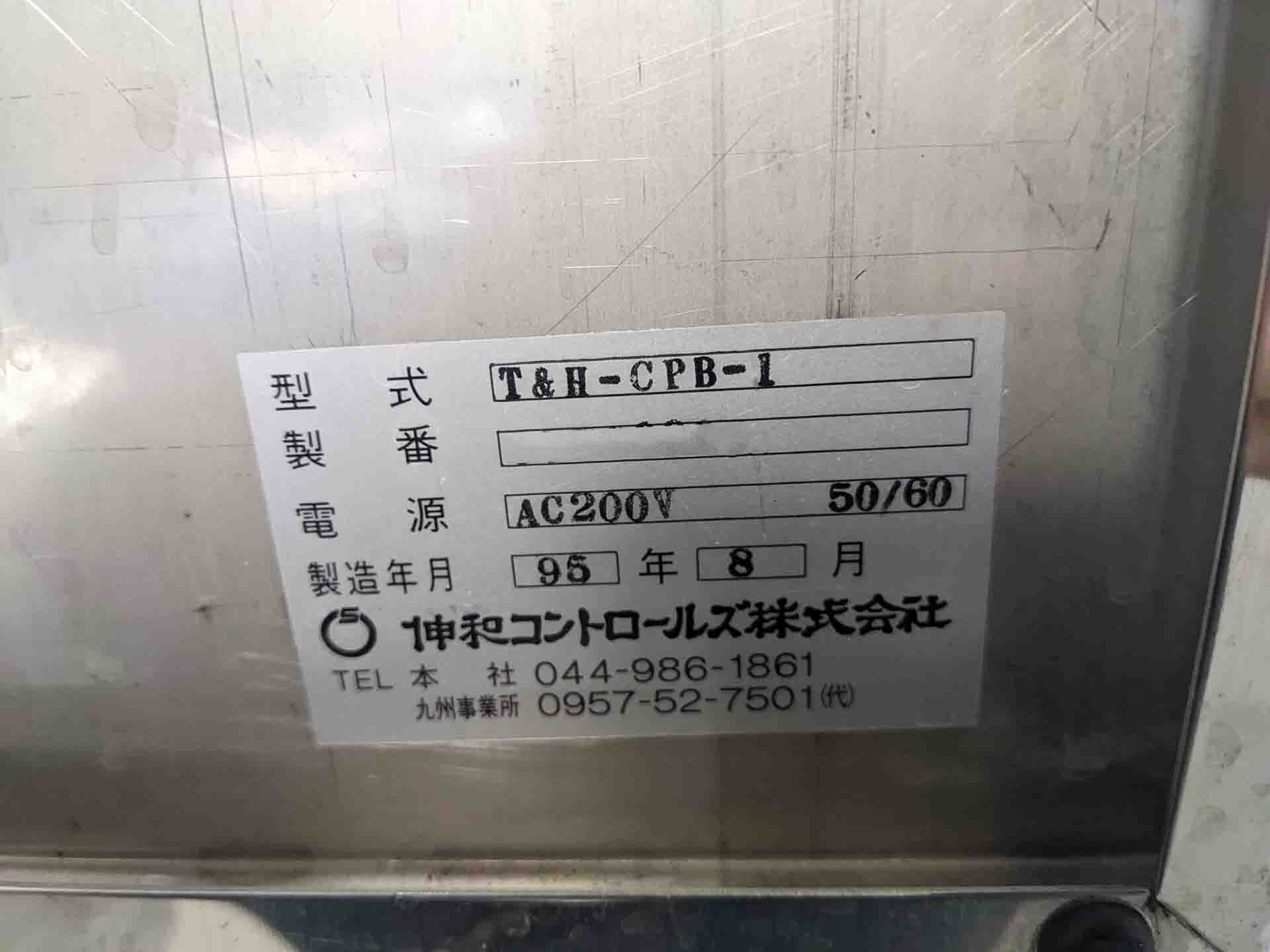

Vintage: 1995

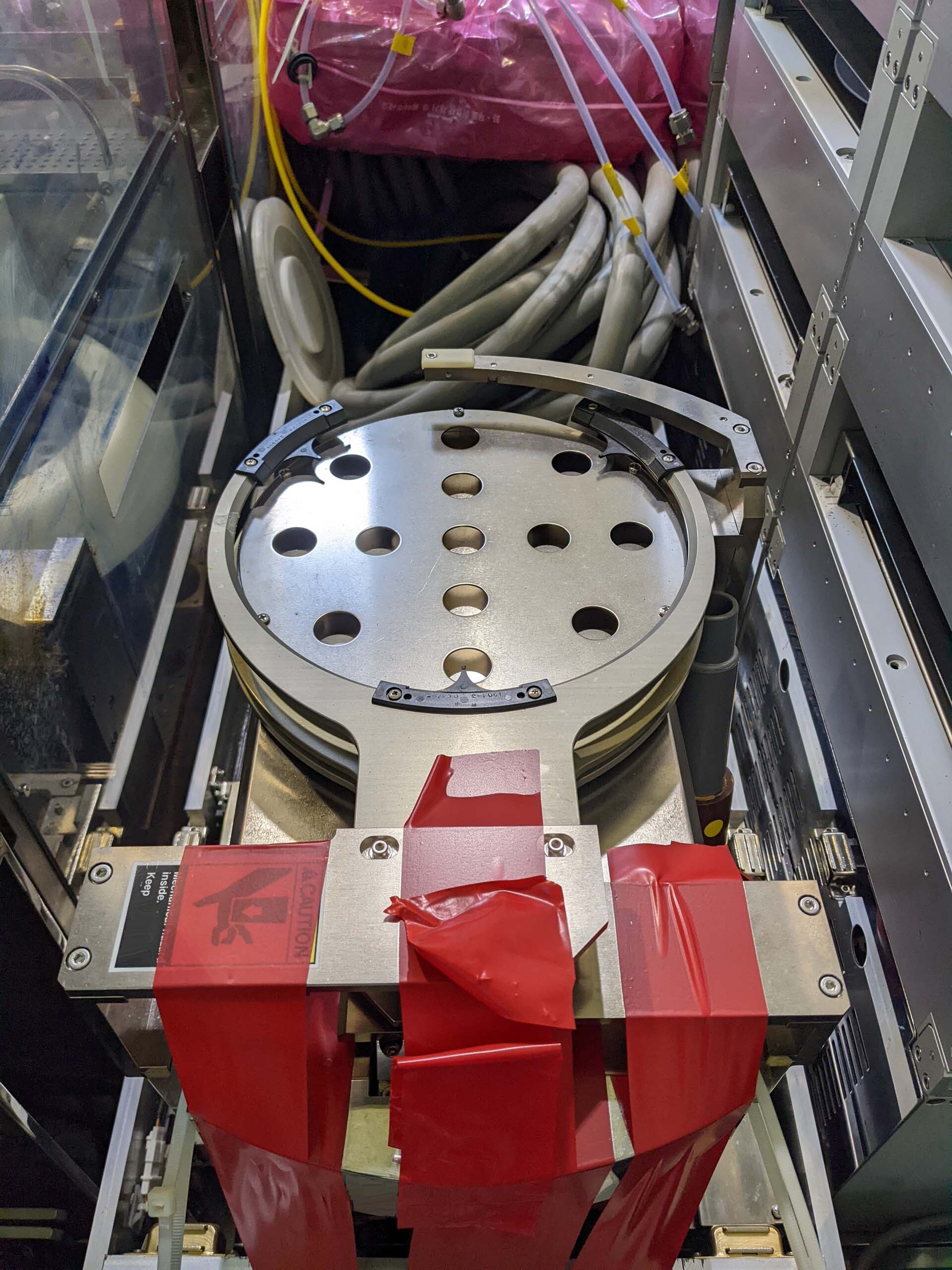

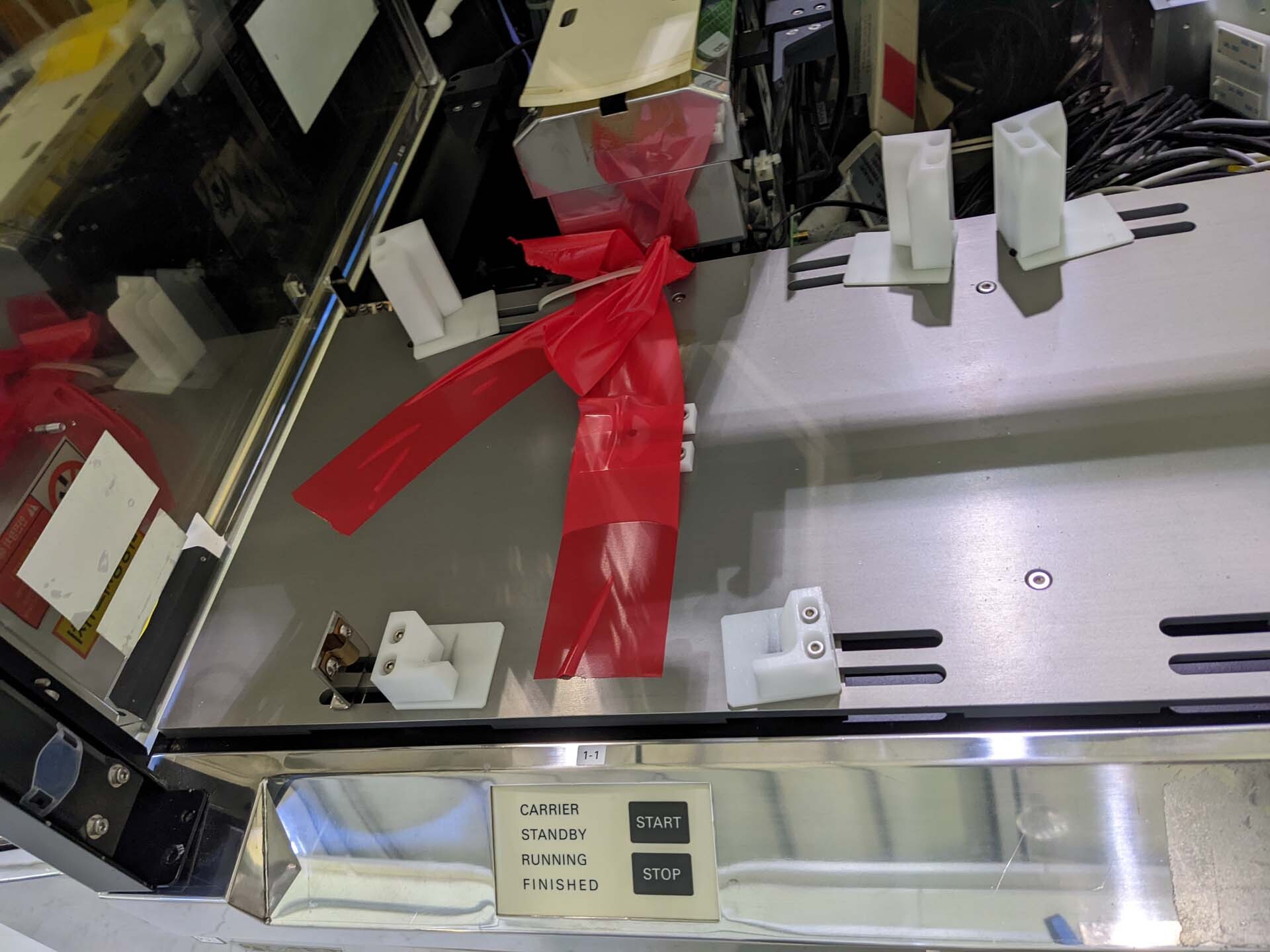

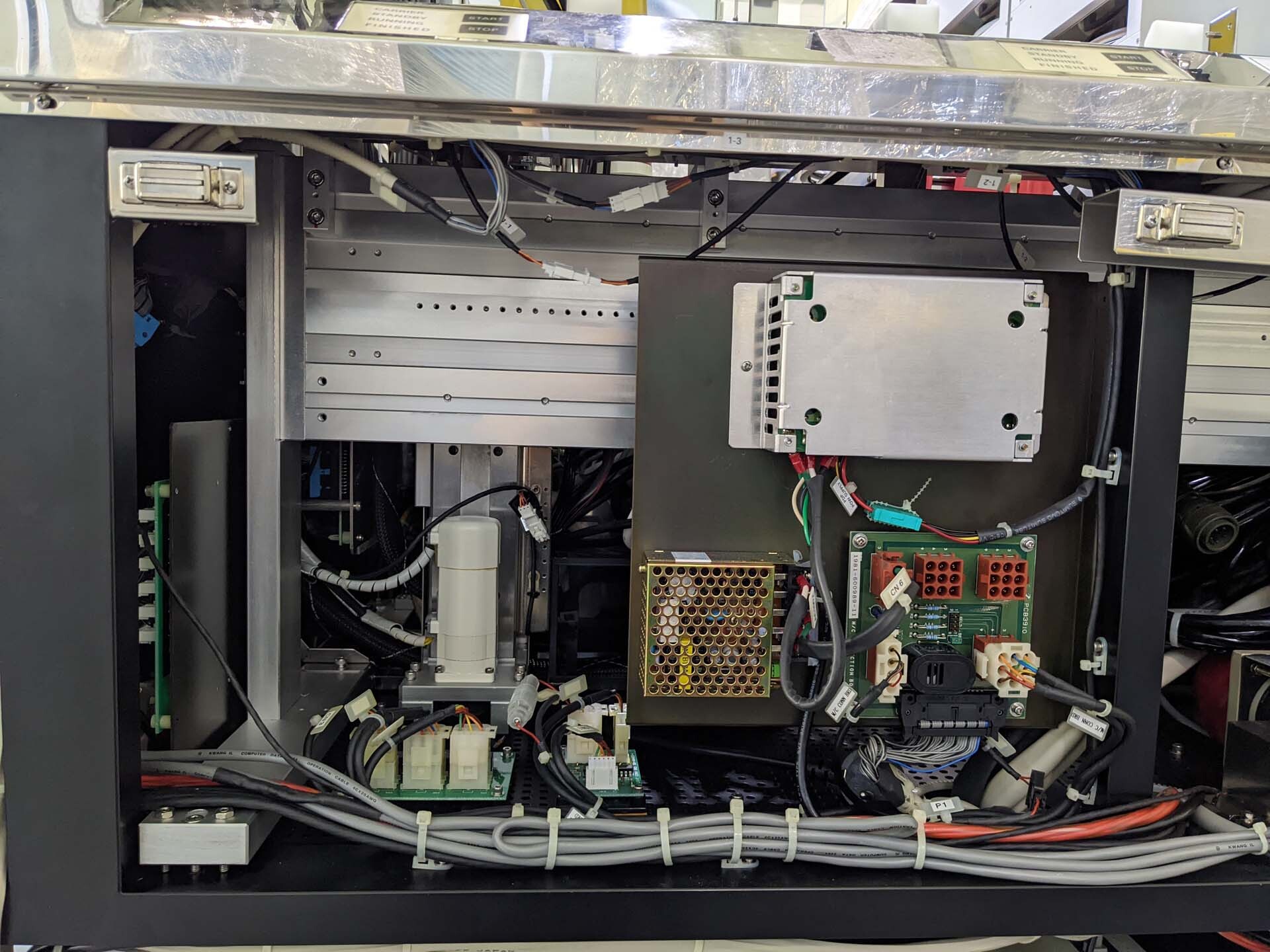

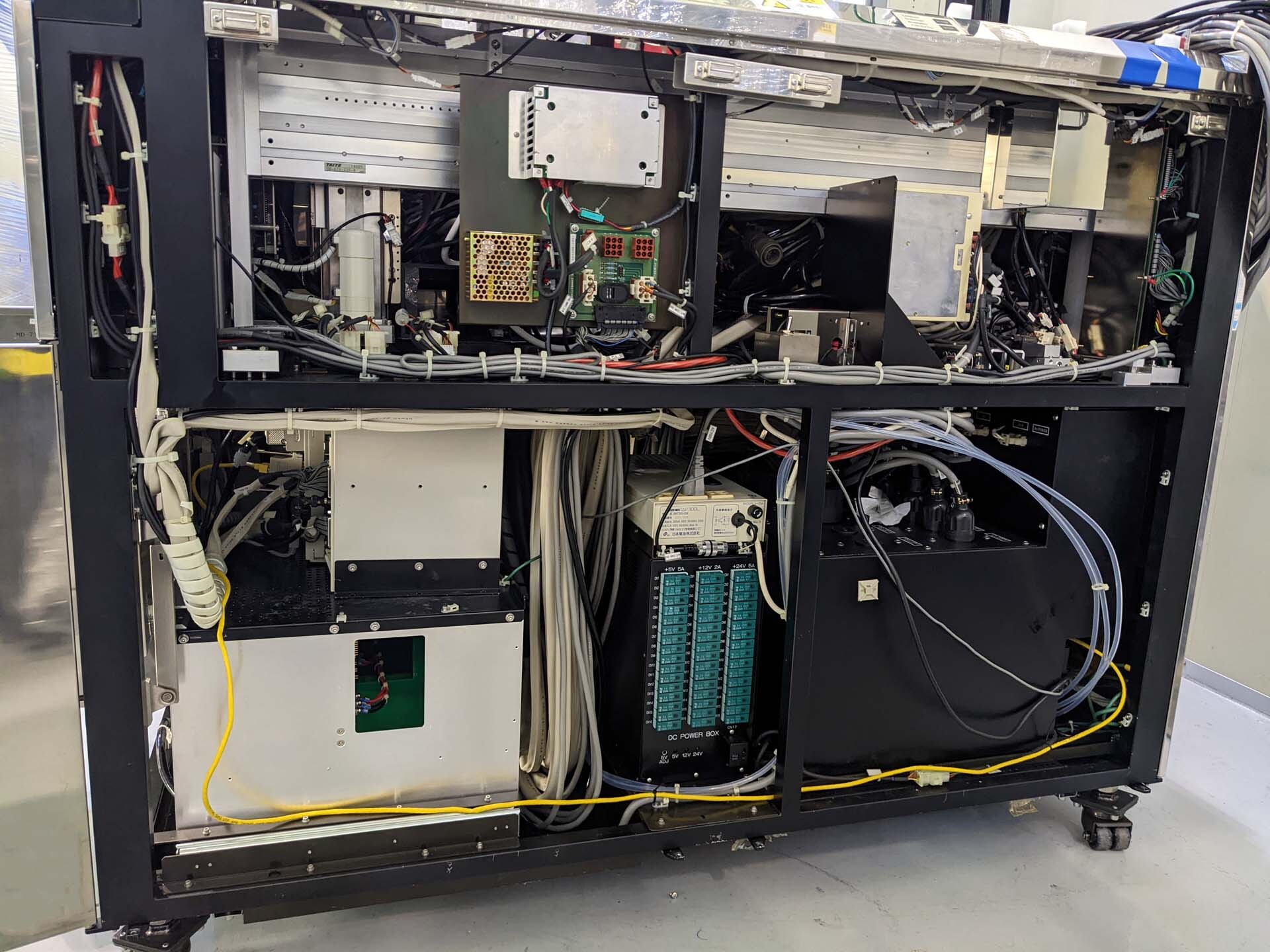

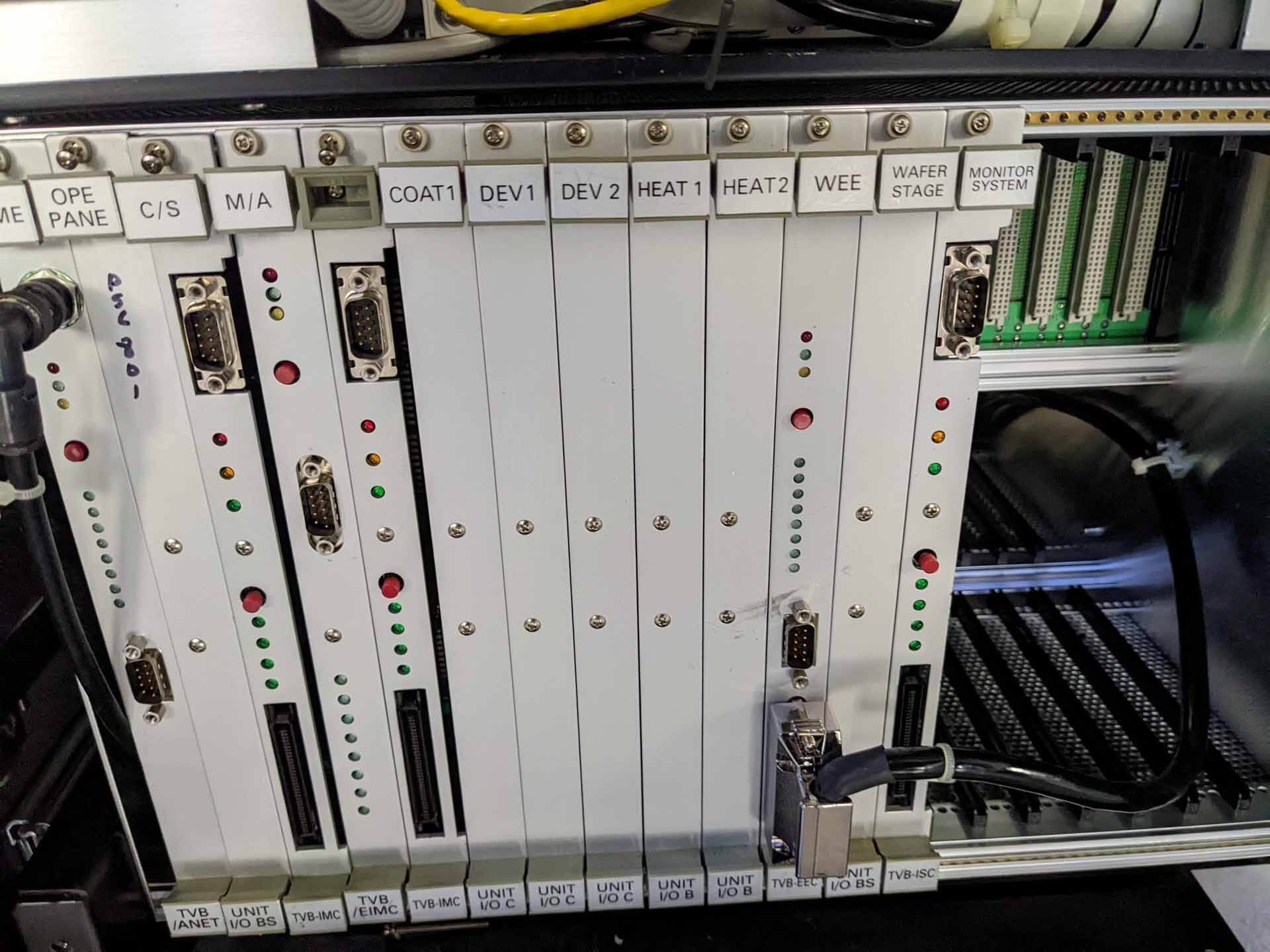

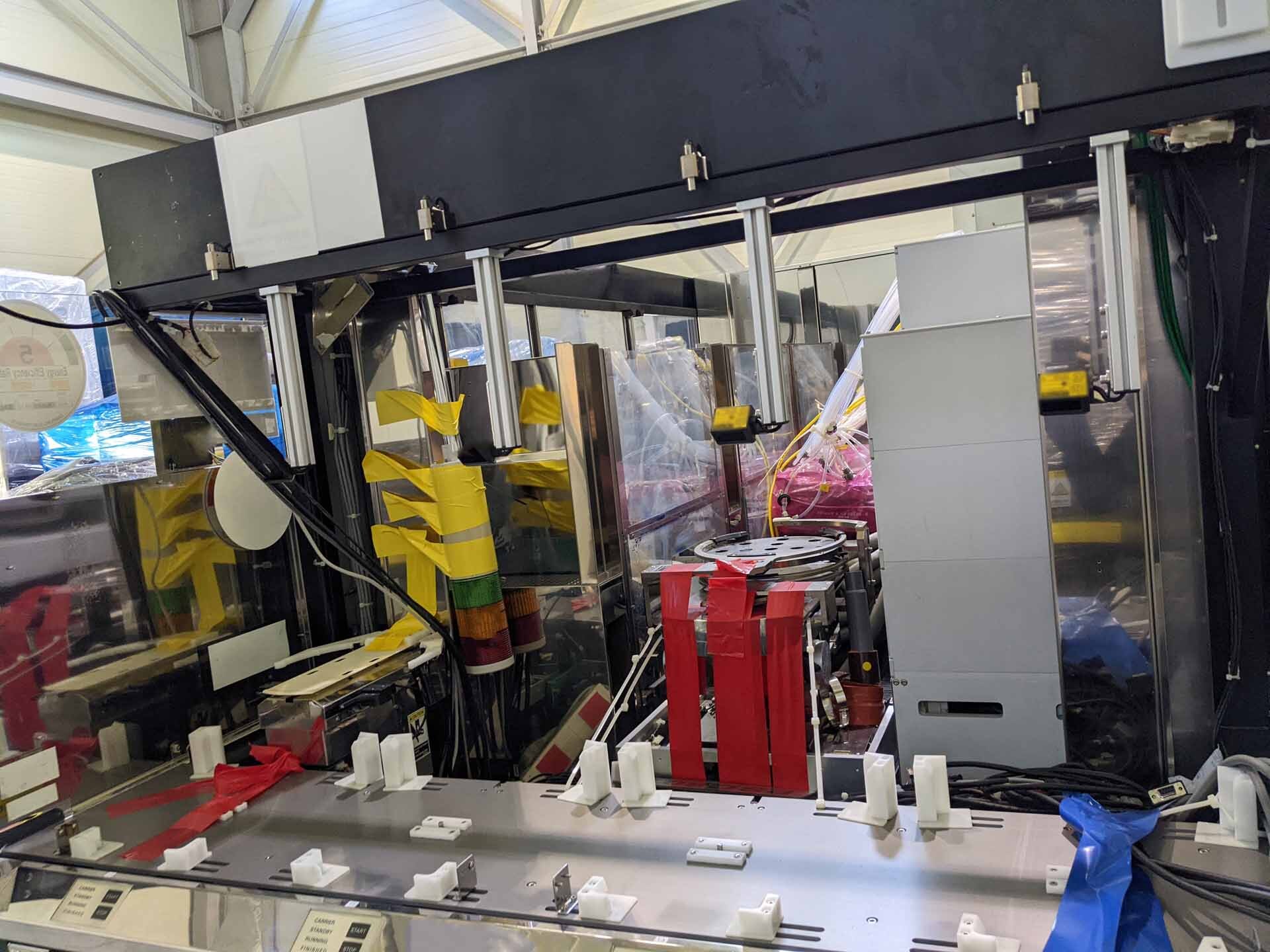

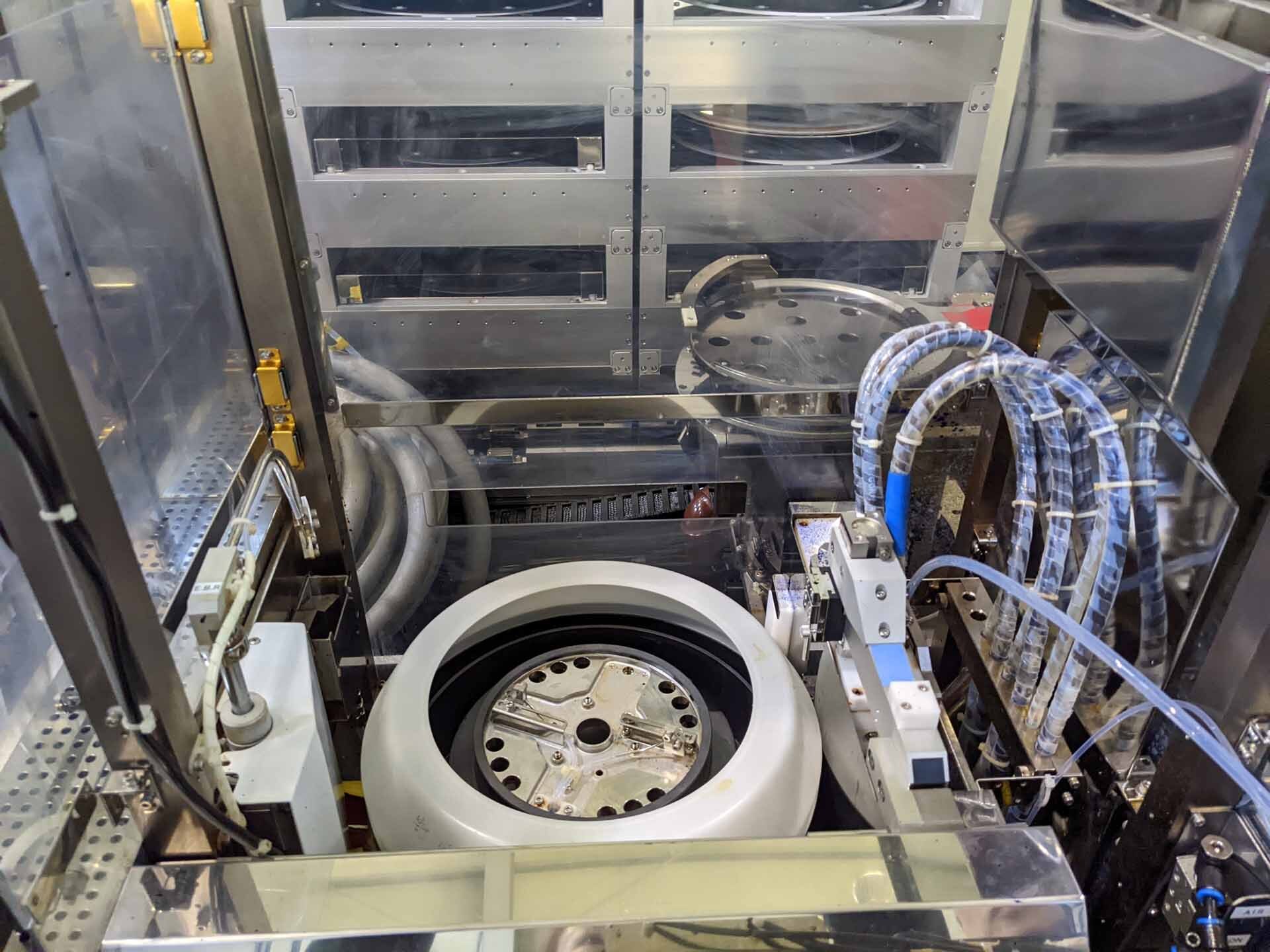

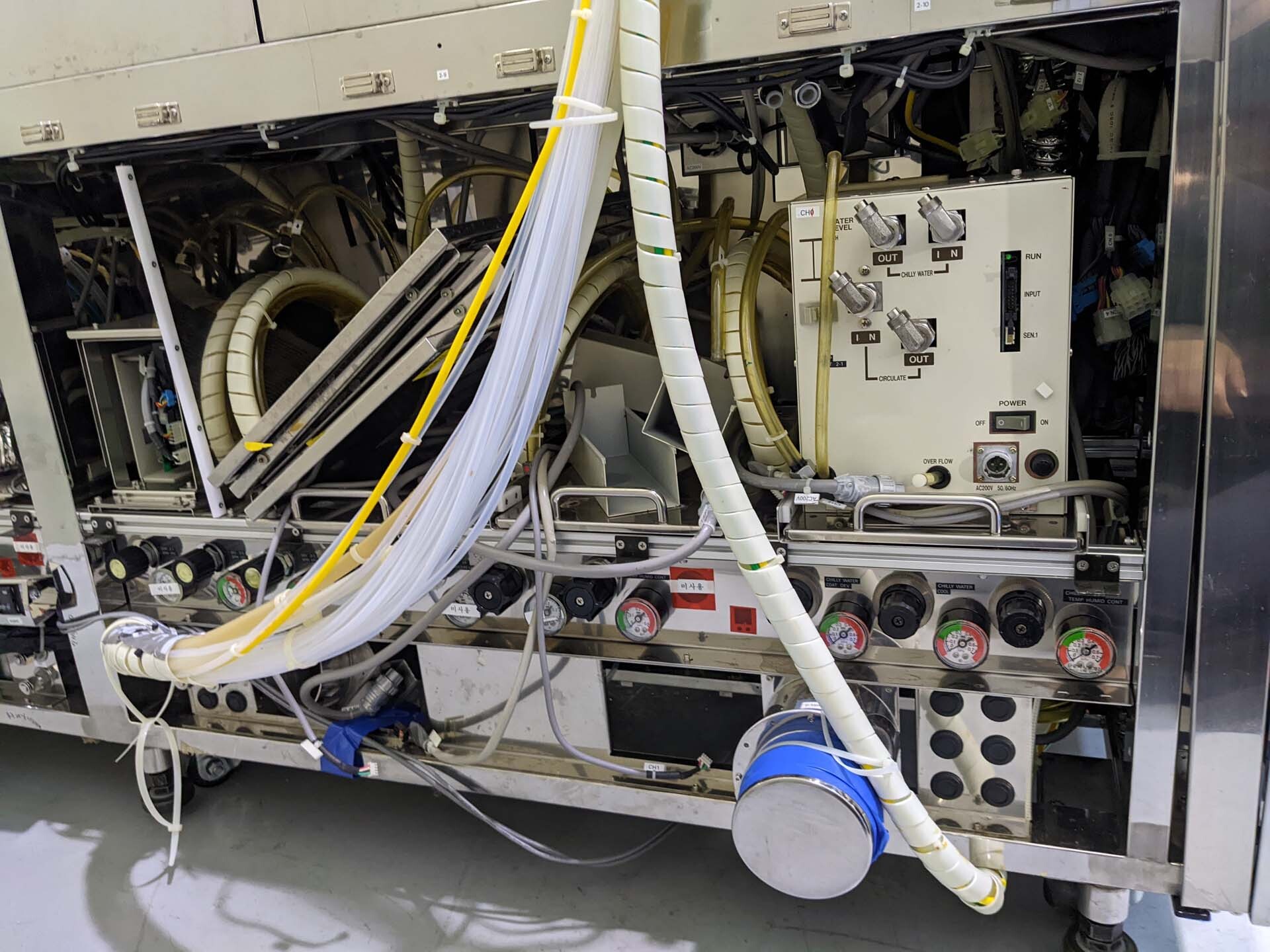

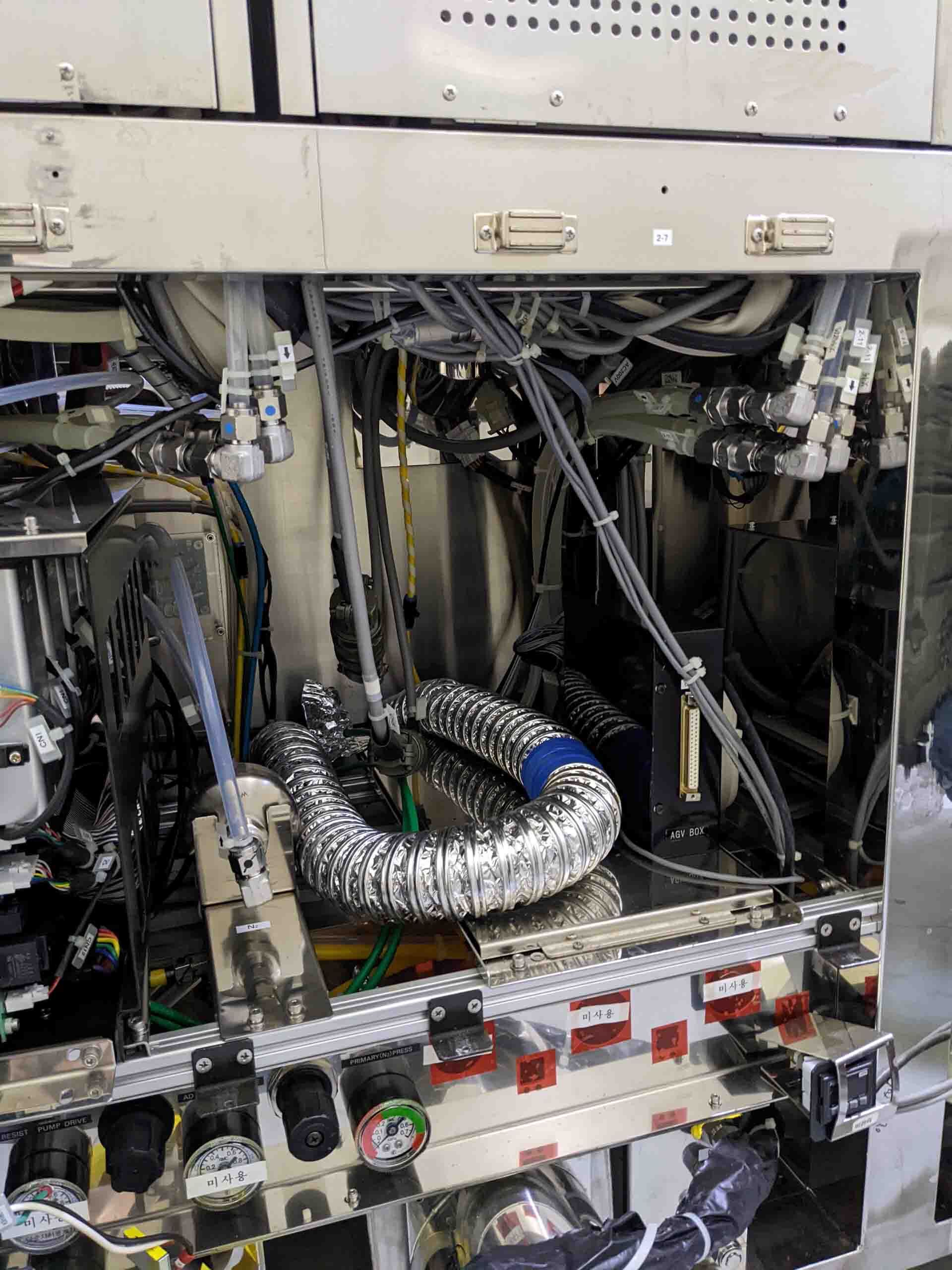

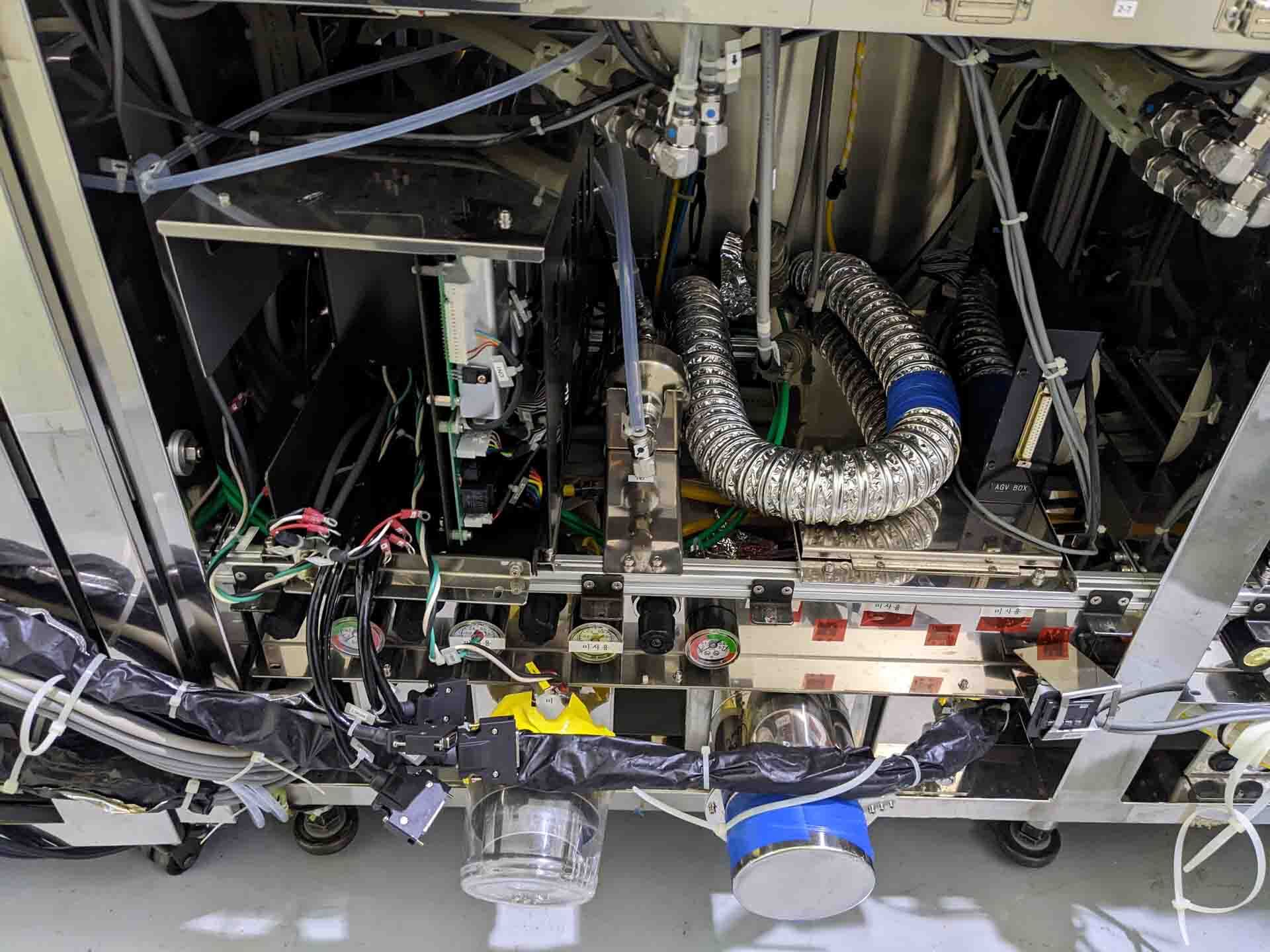

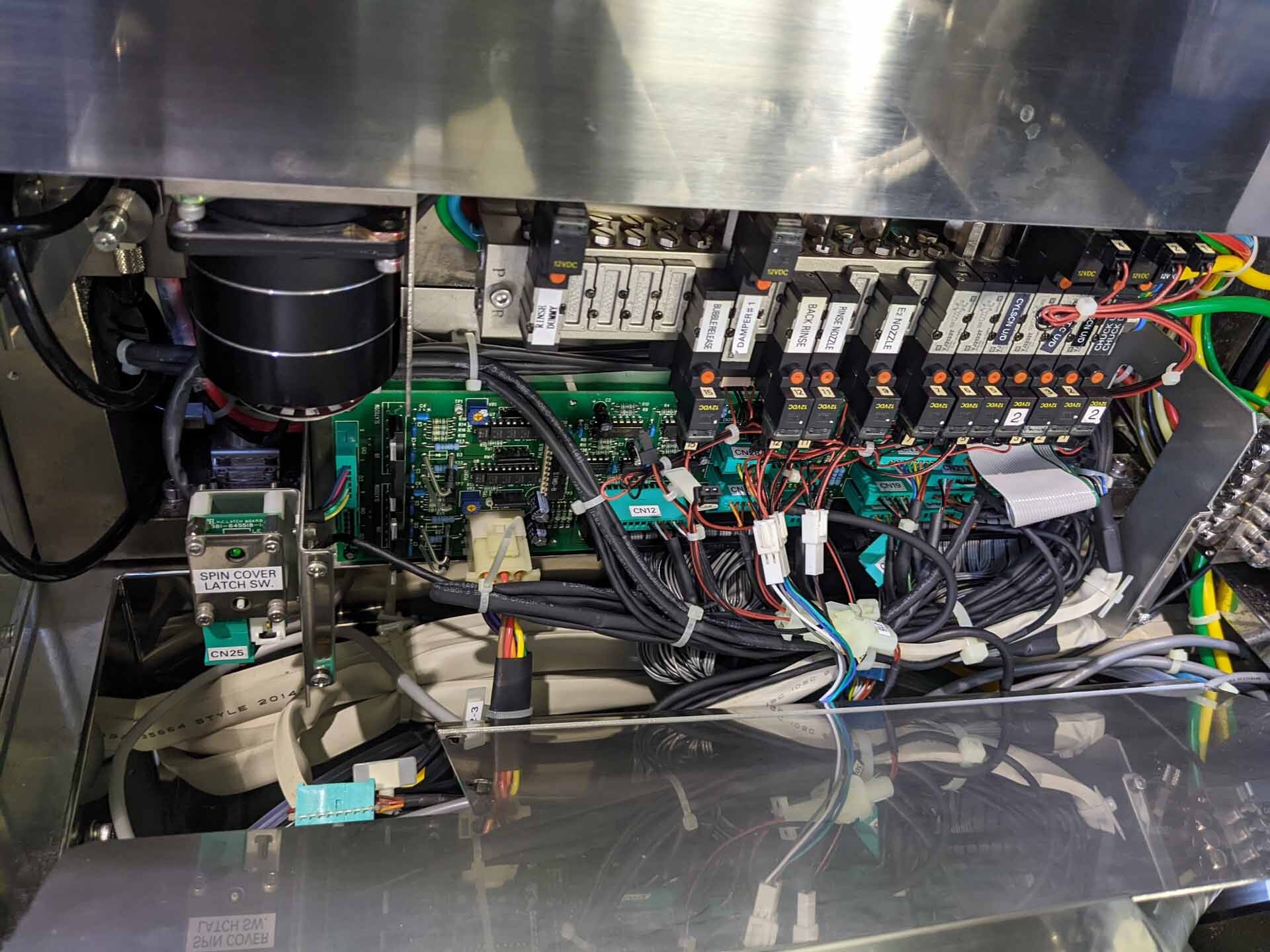

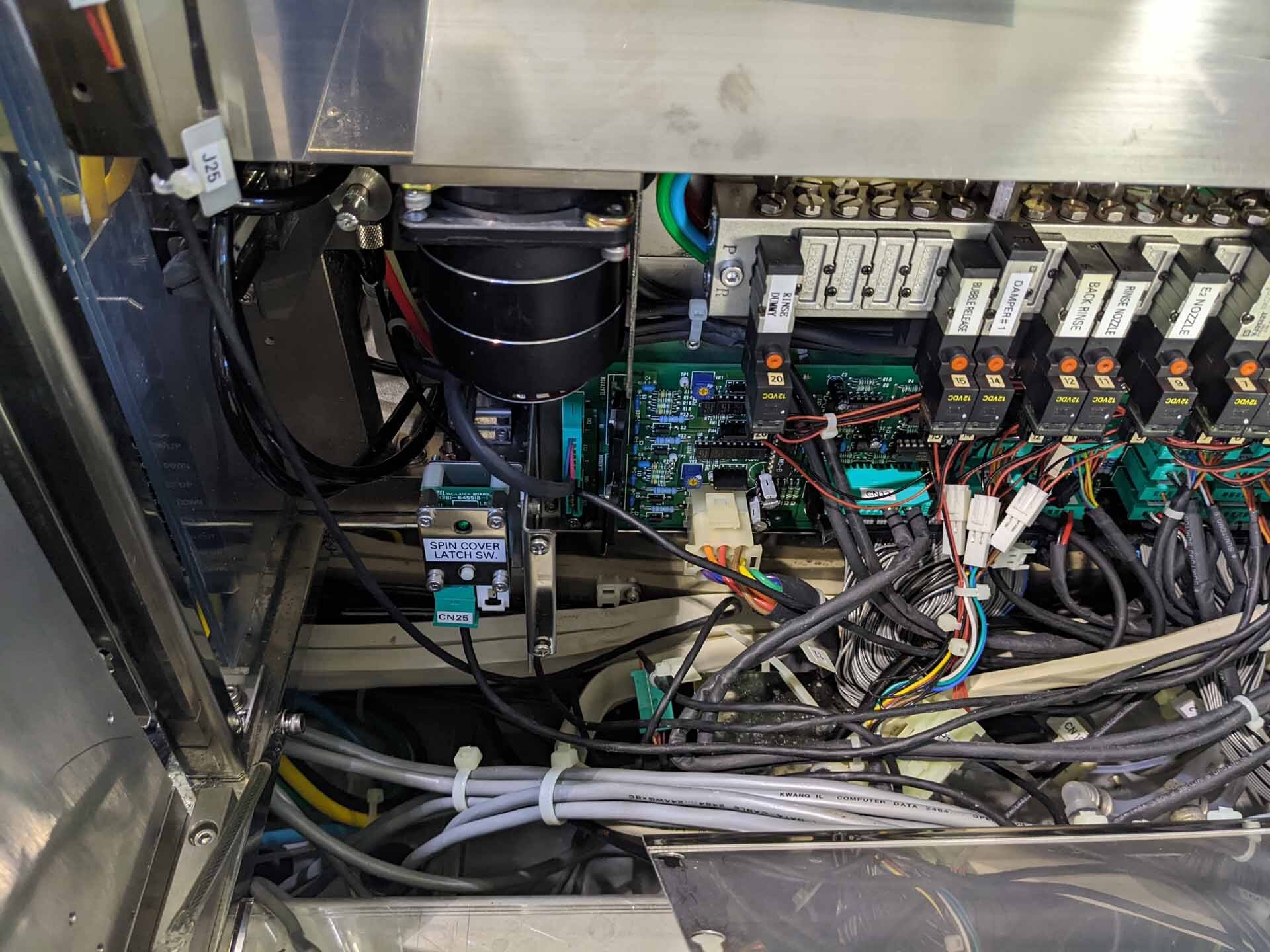

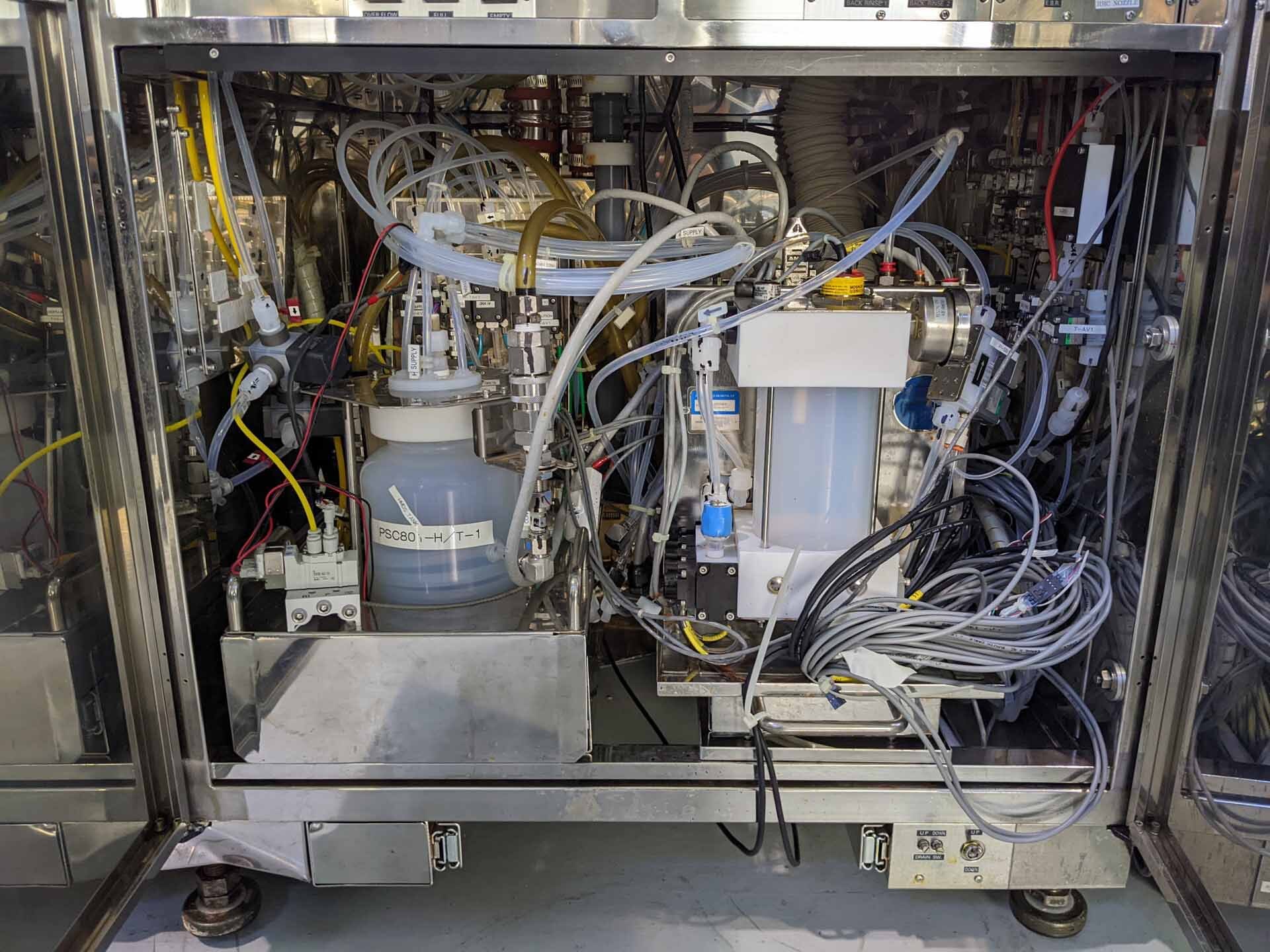

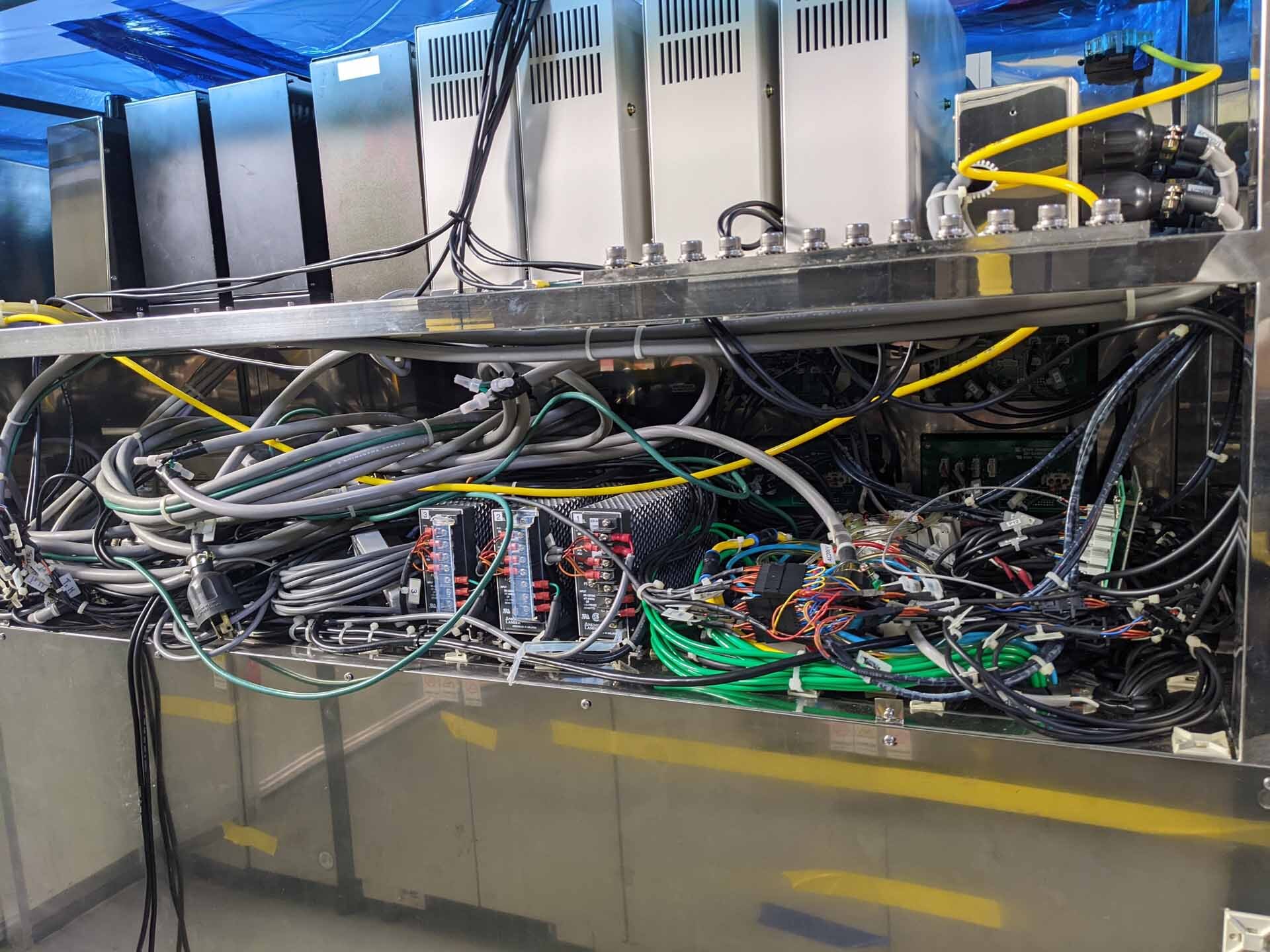

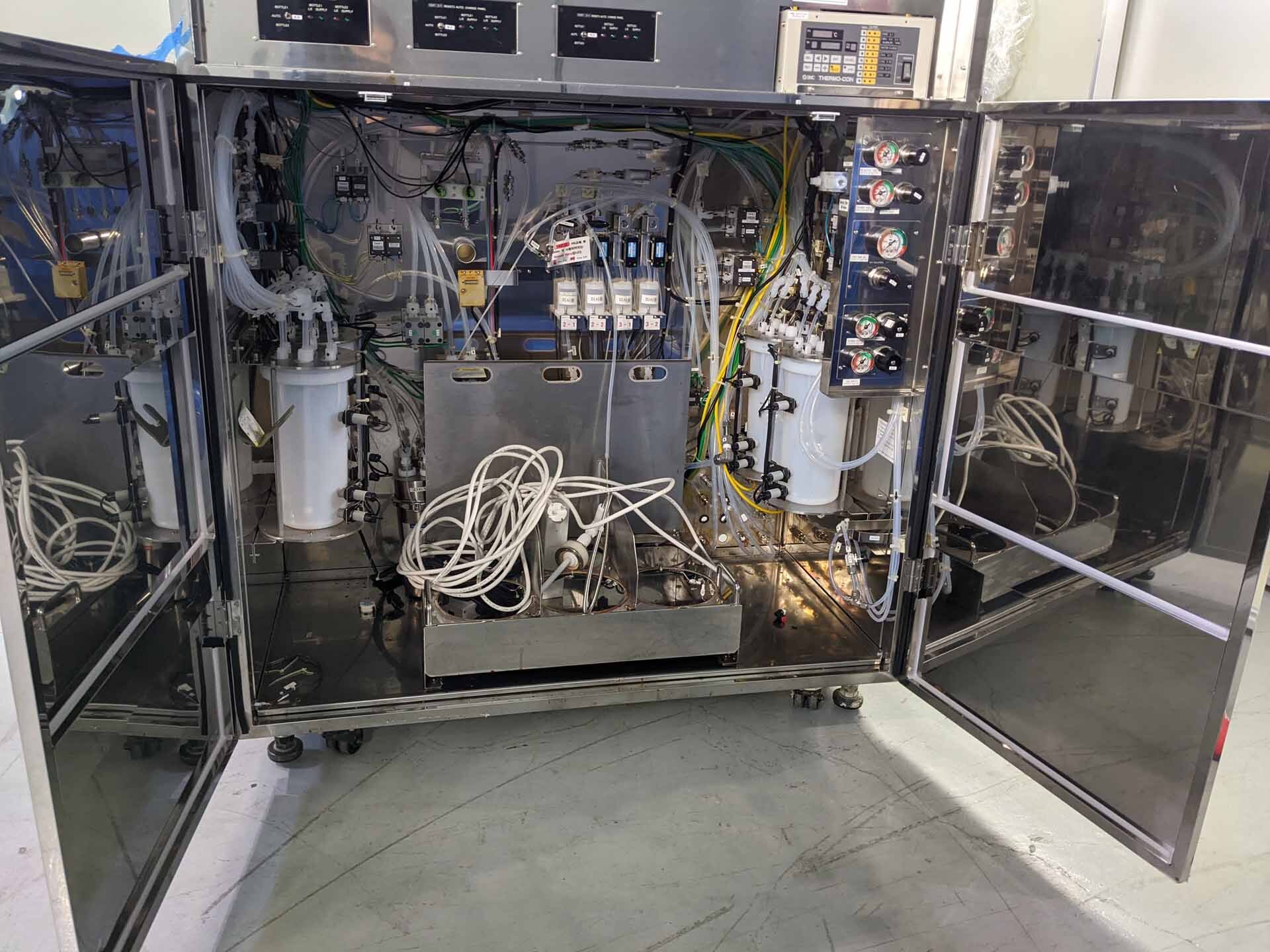

(1) Coater / (2) Developer system, 8"

Silicon wafer

Wafer flow: Right to left

Single block

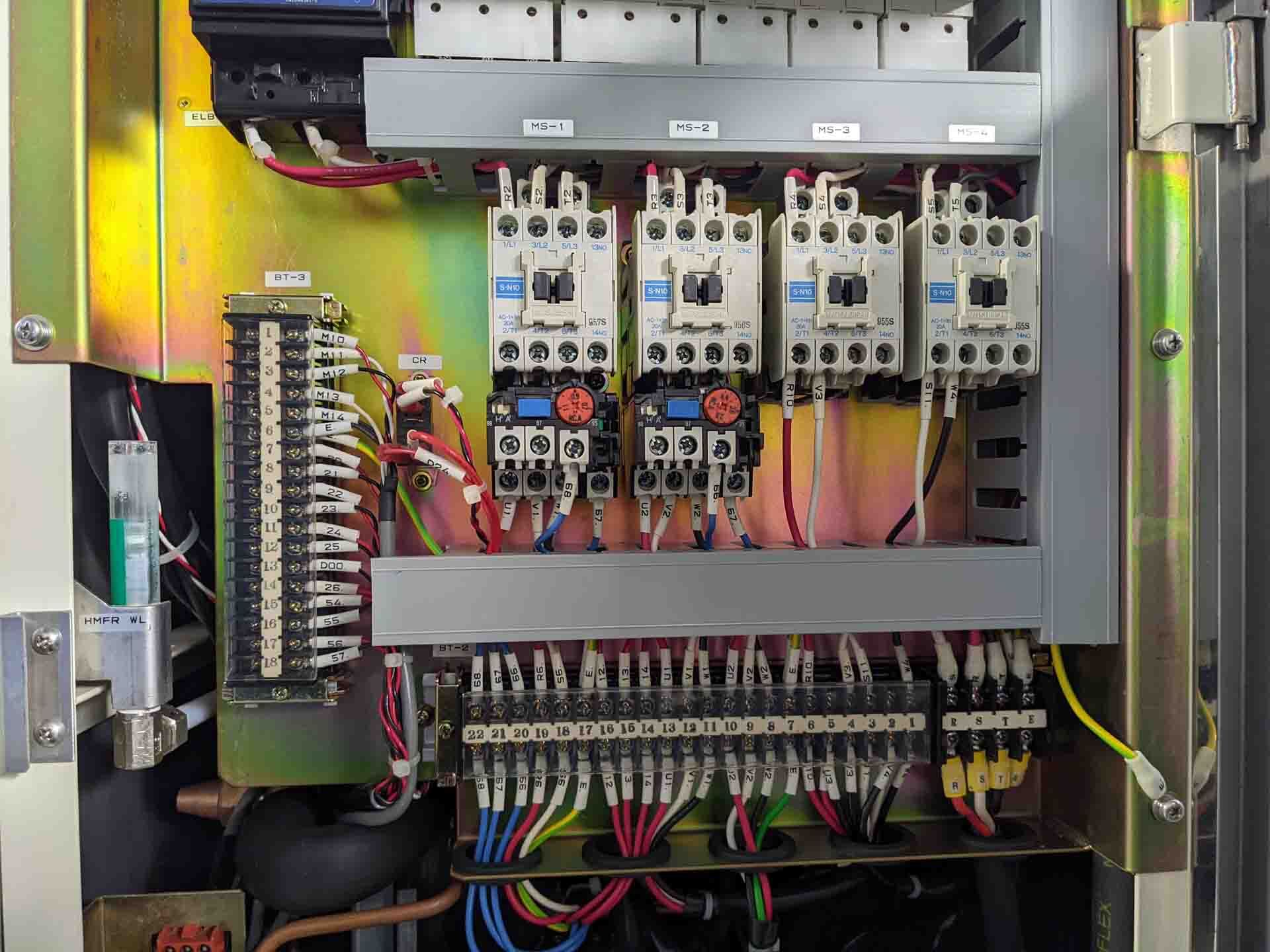

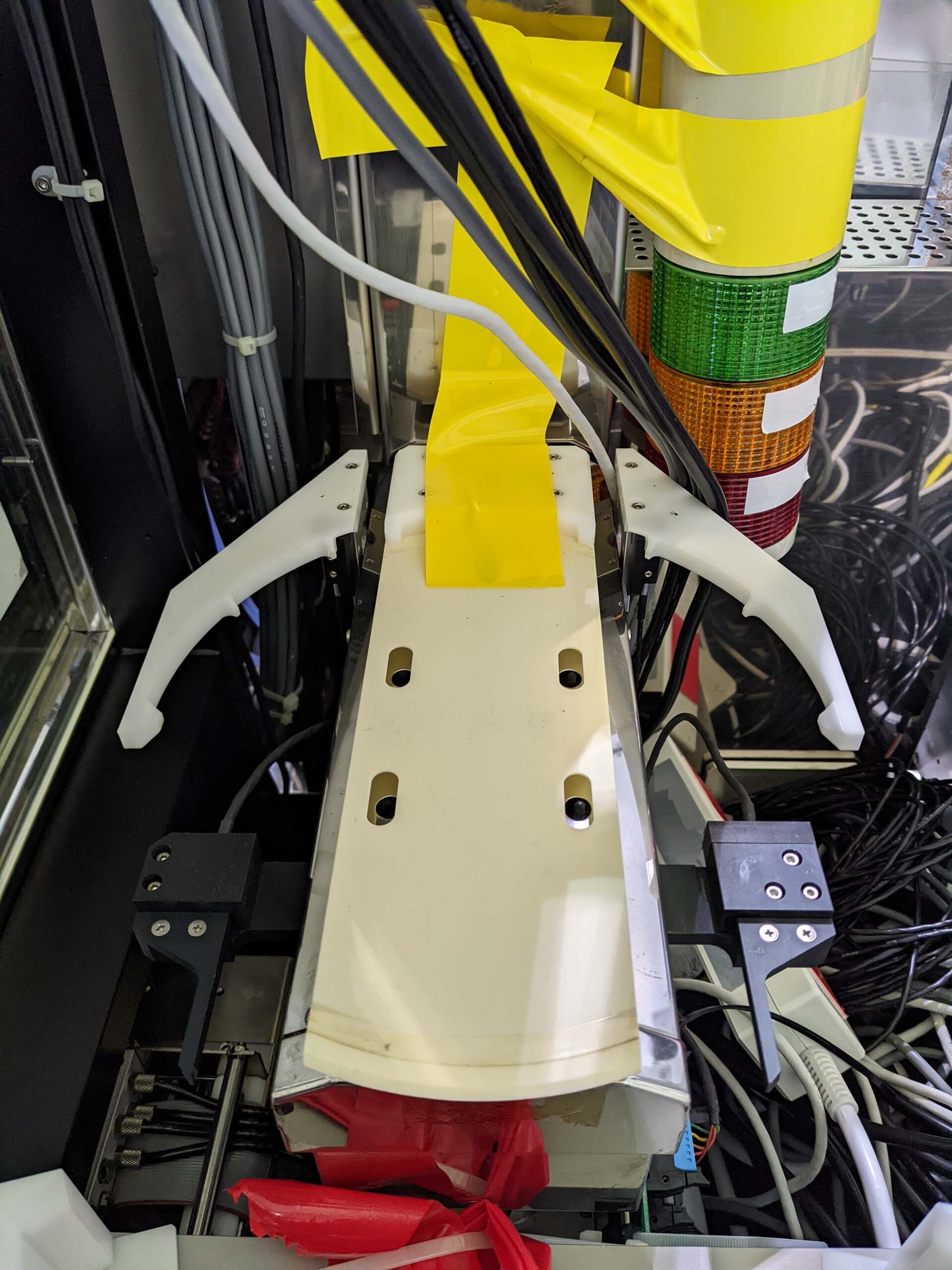

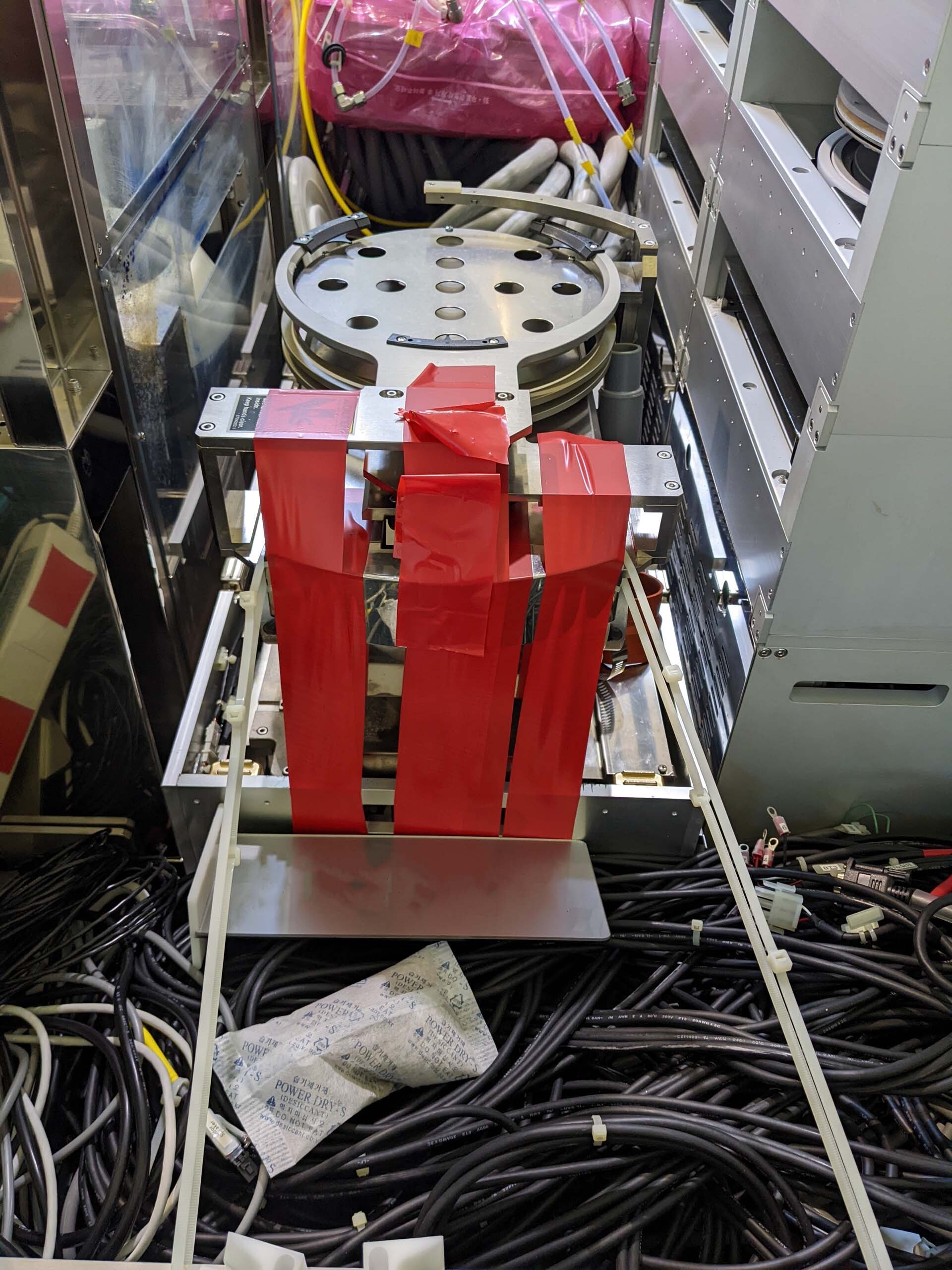

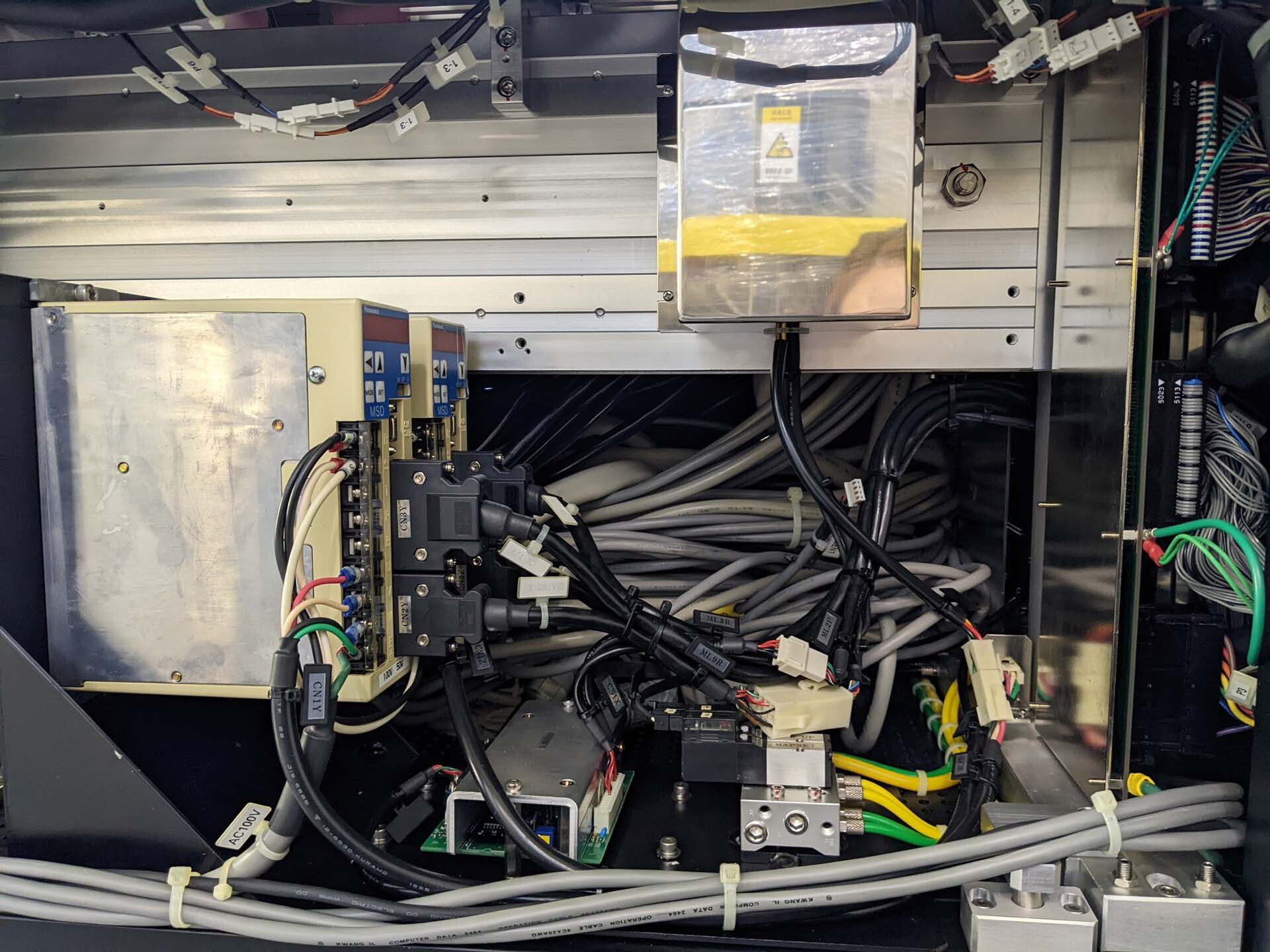

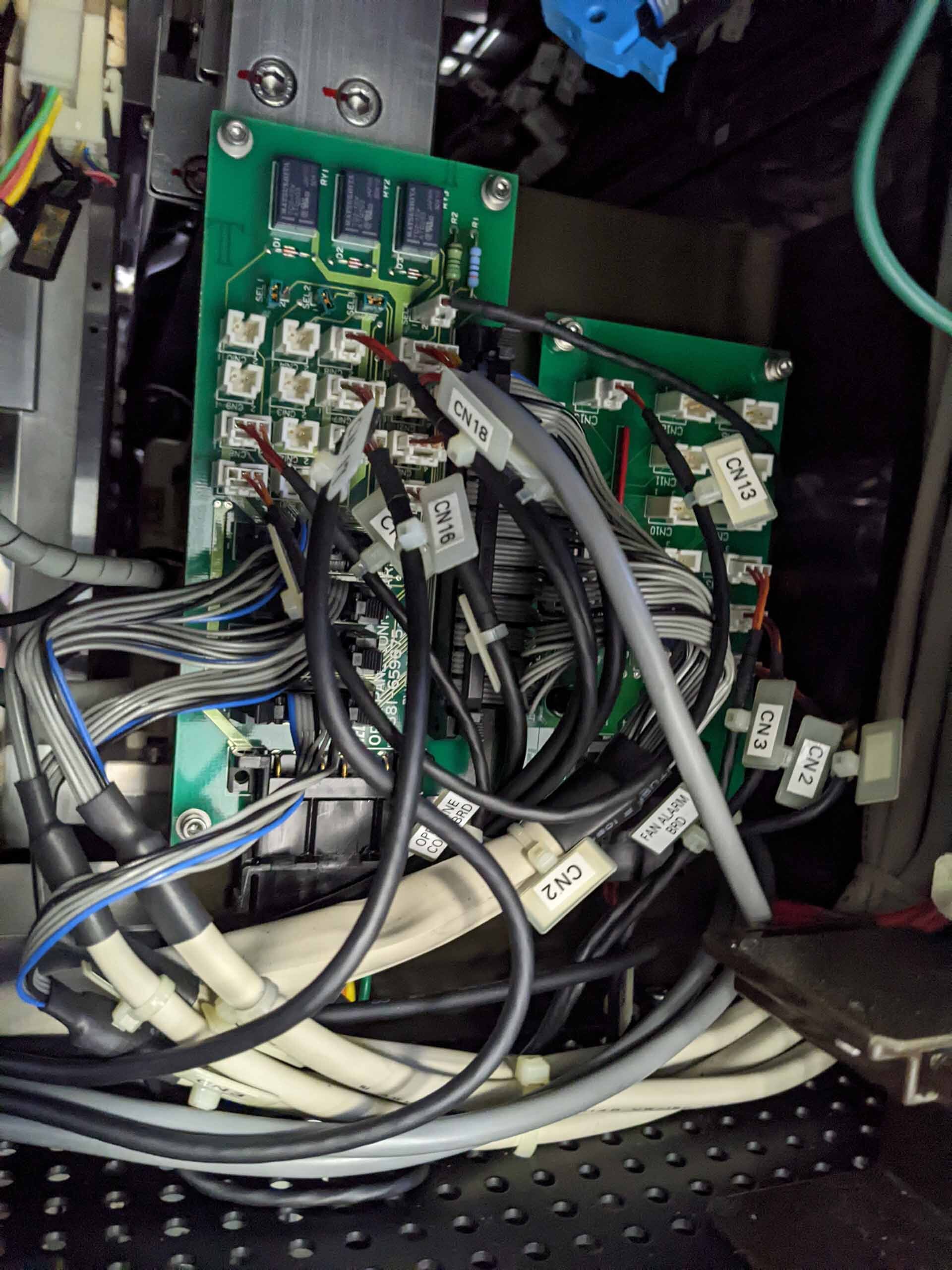

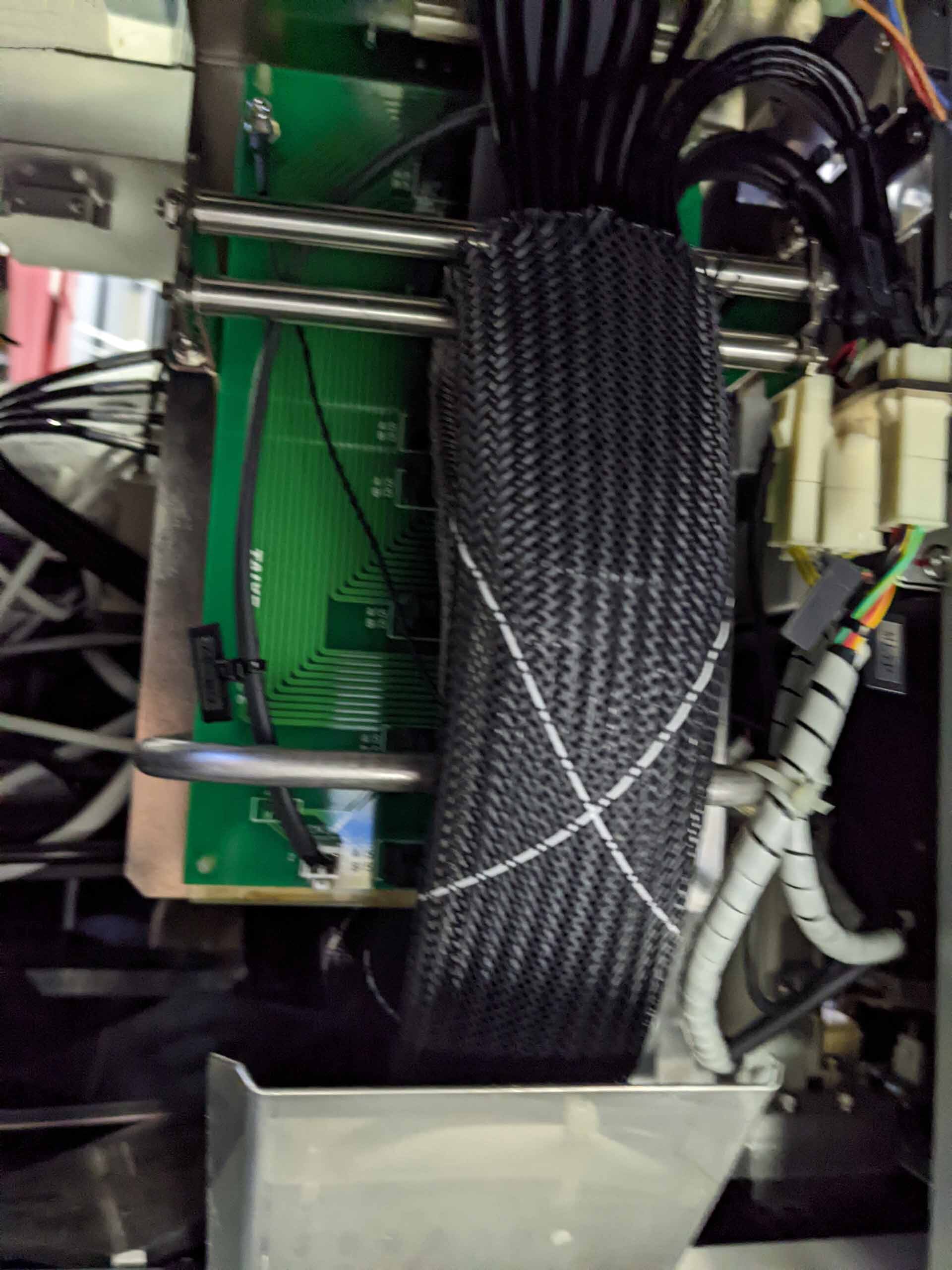

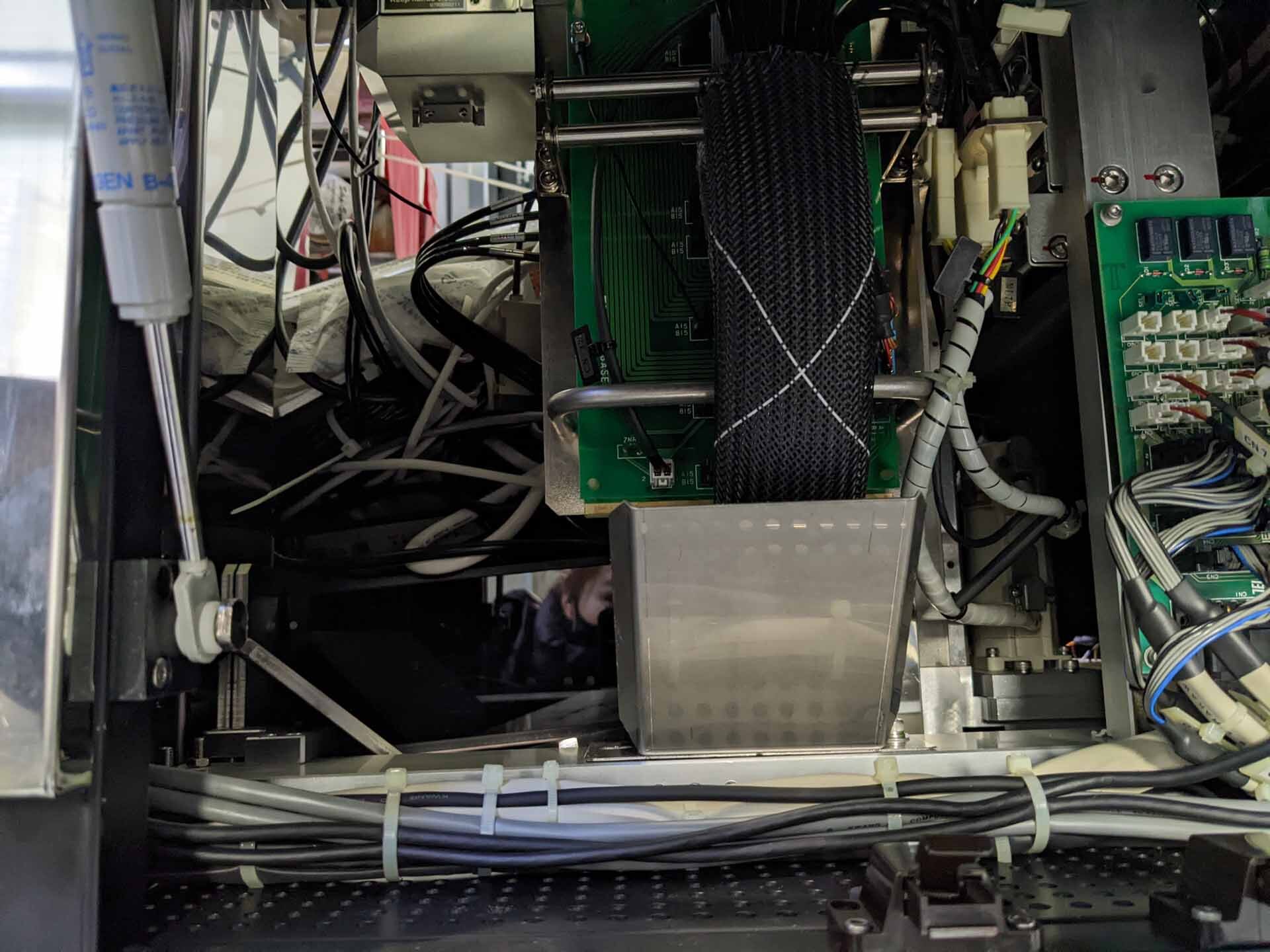

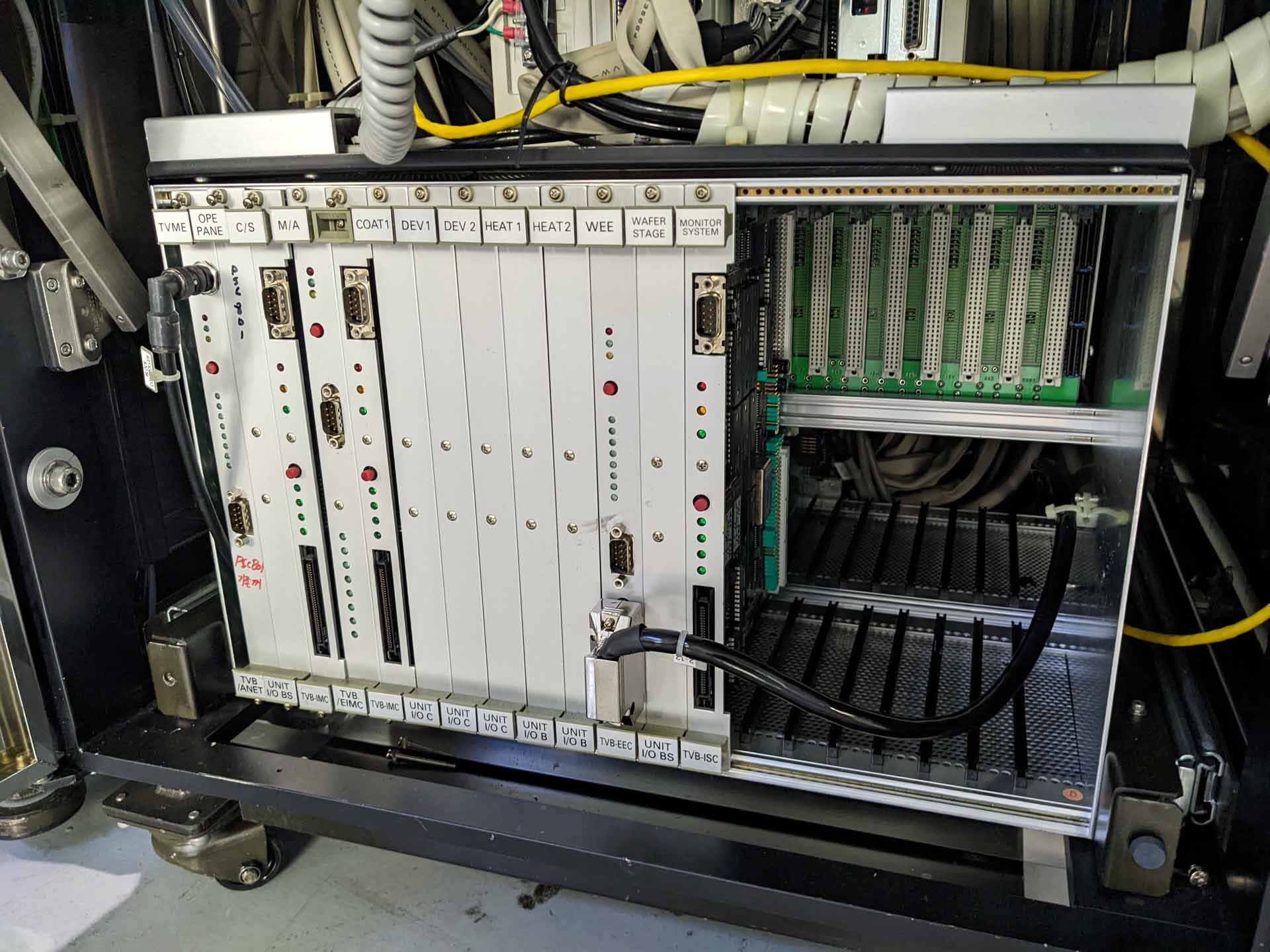

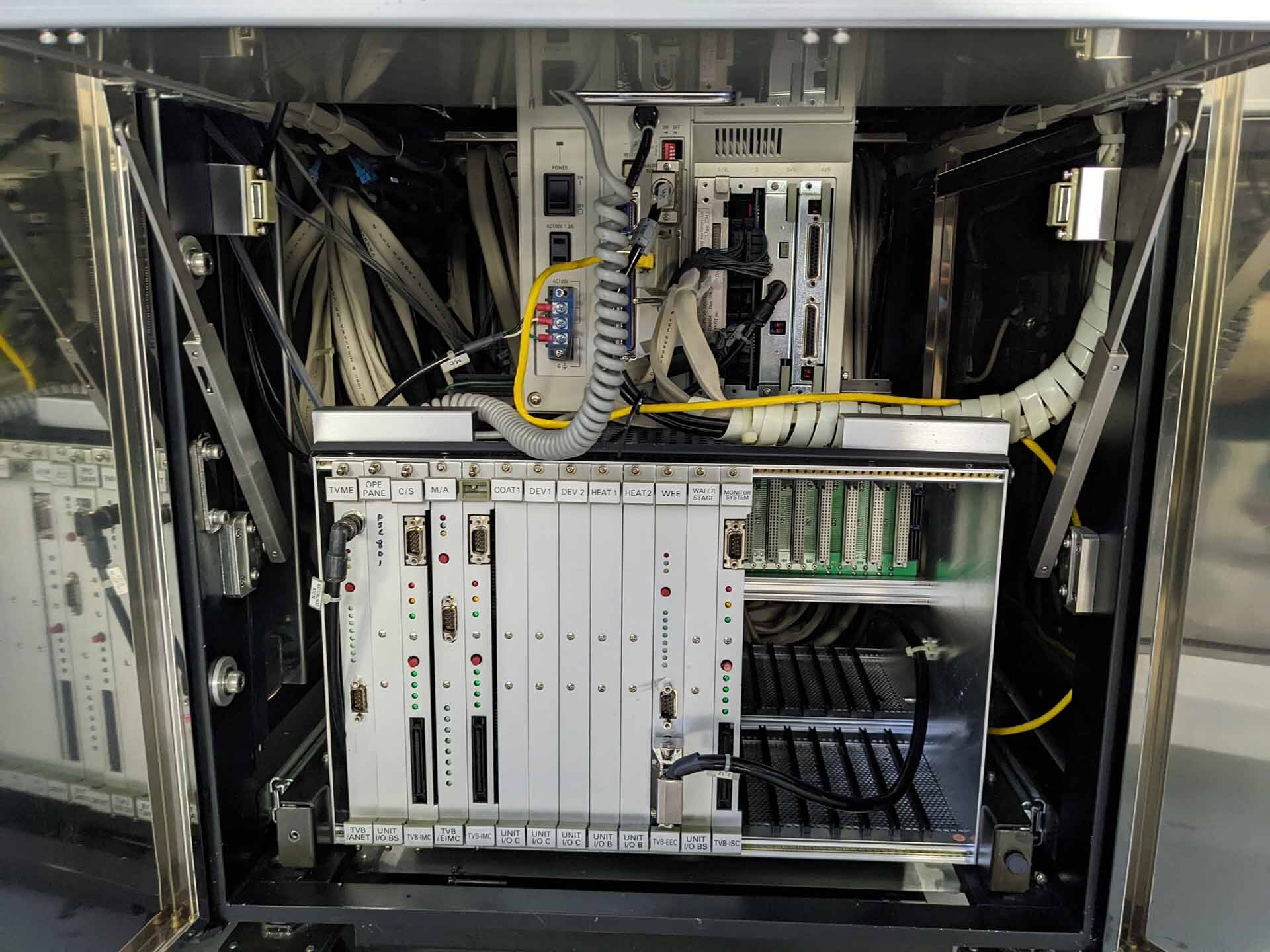

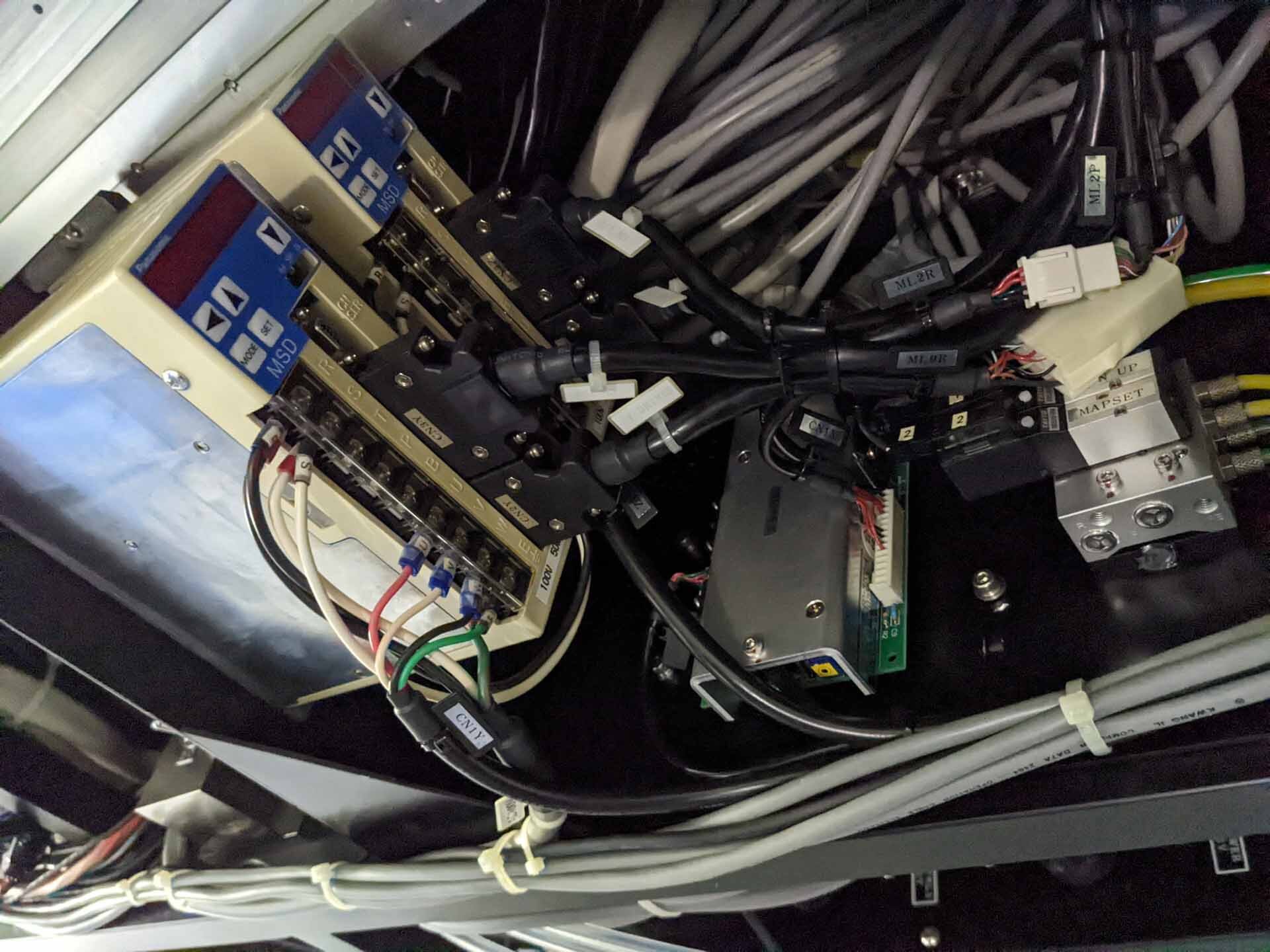

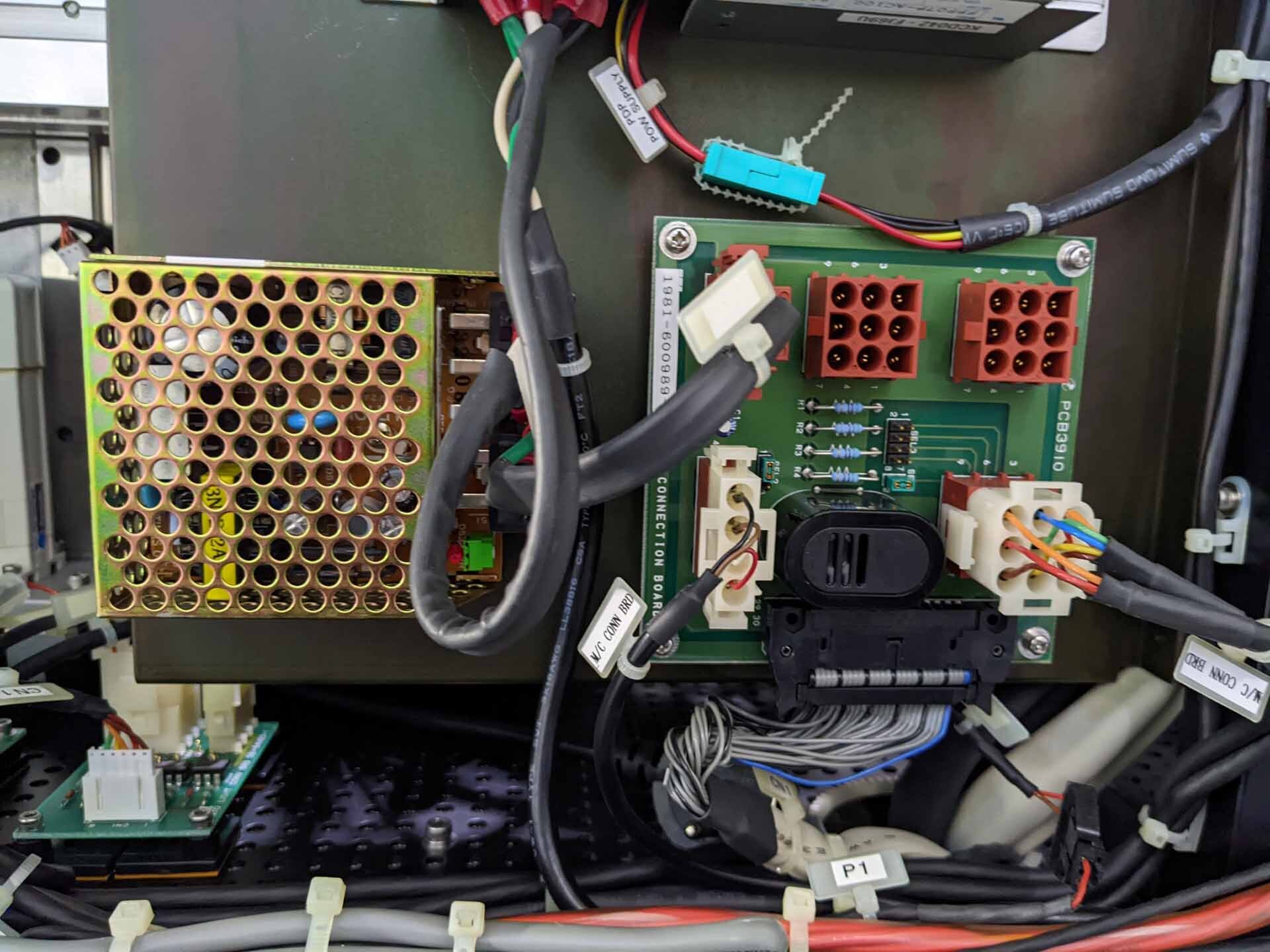

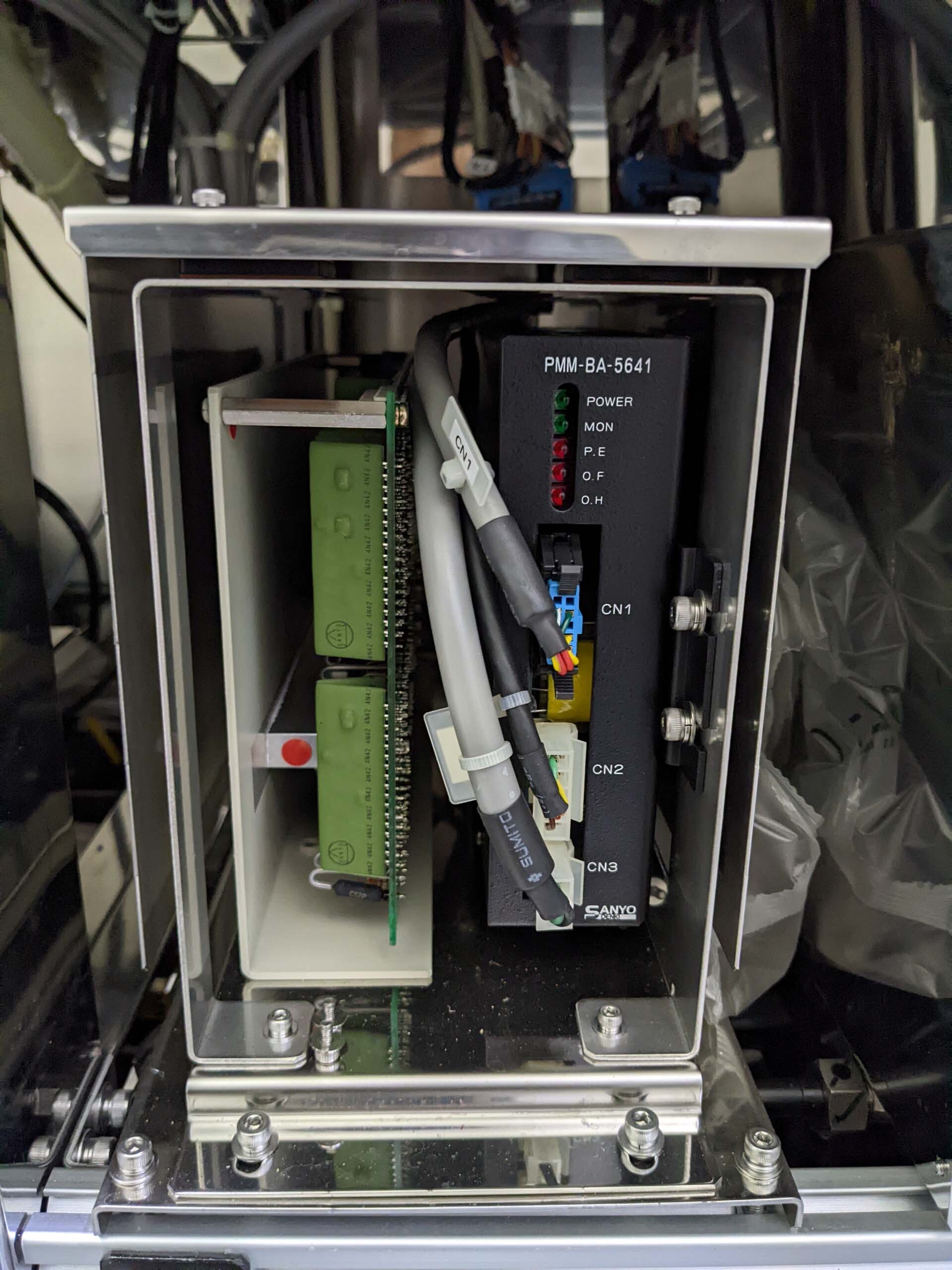

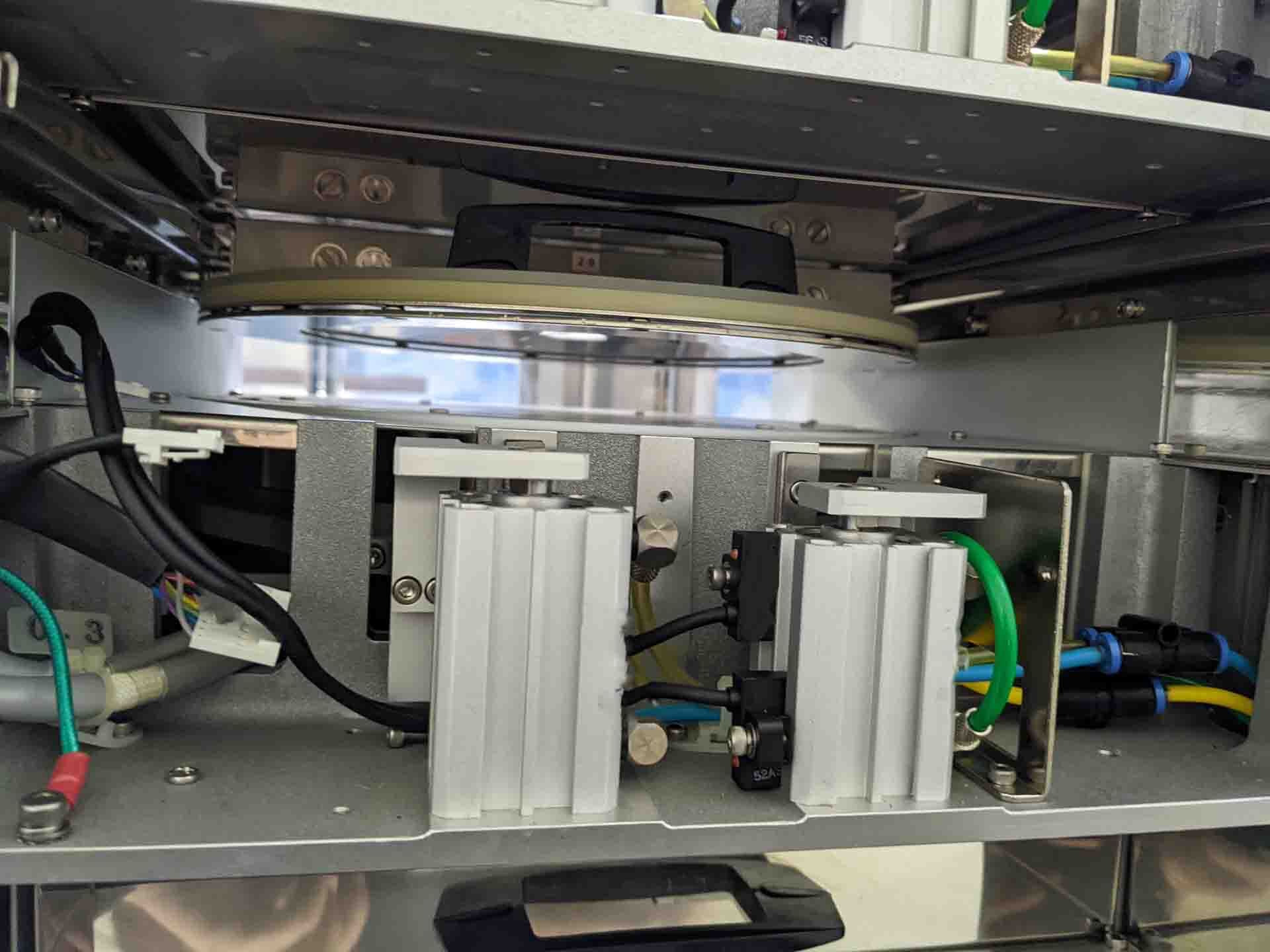

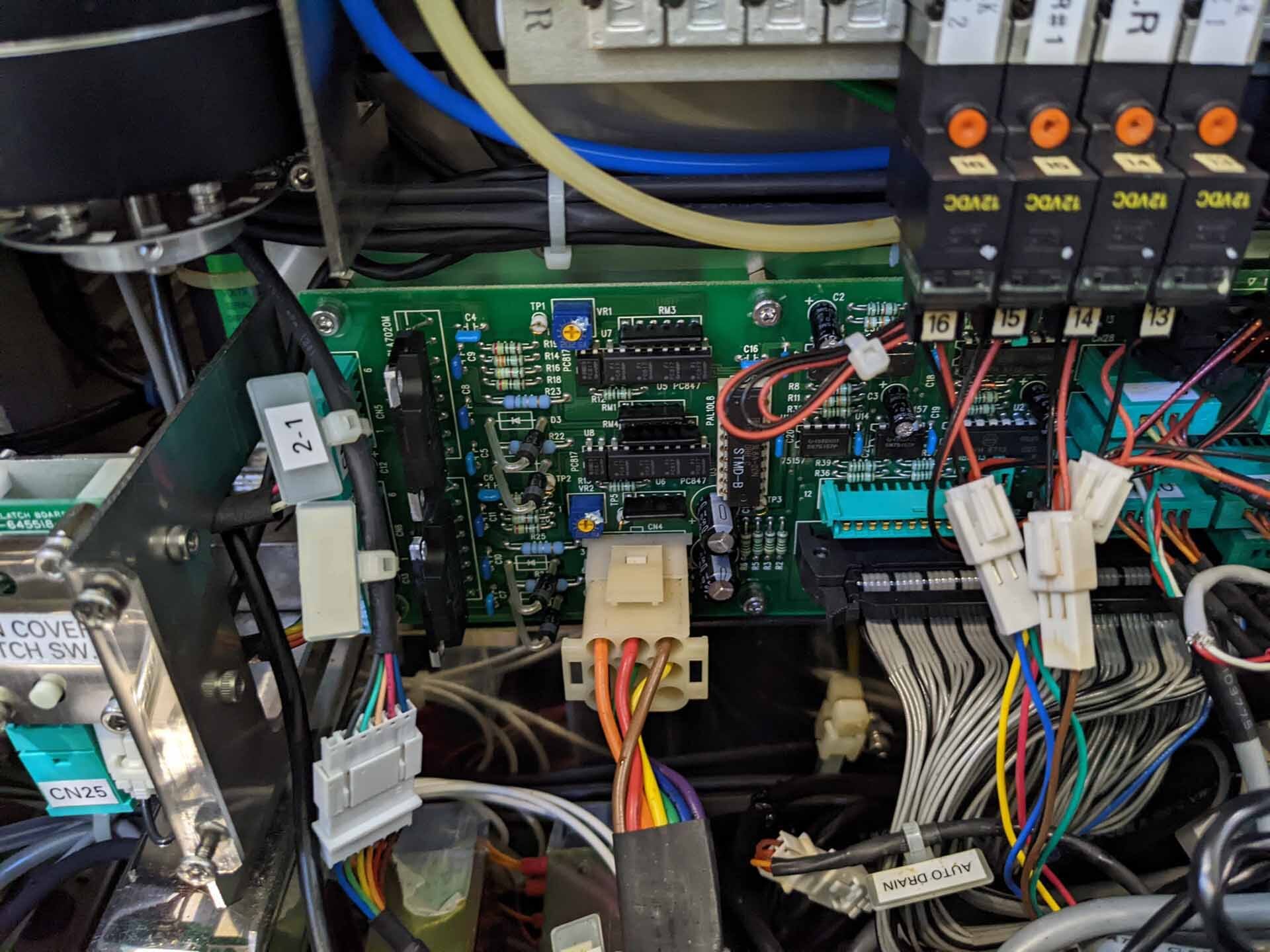

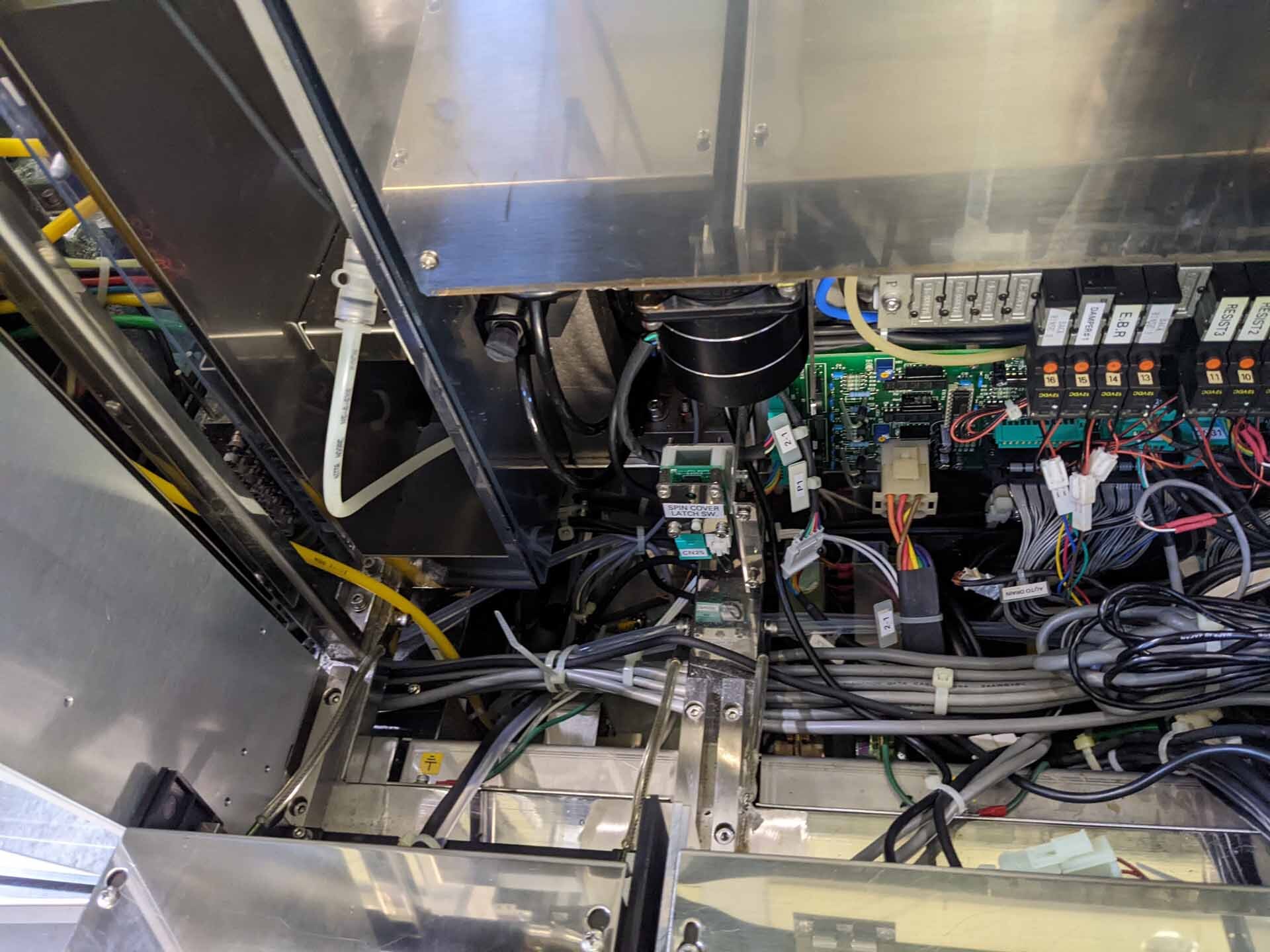

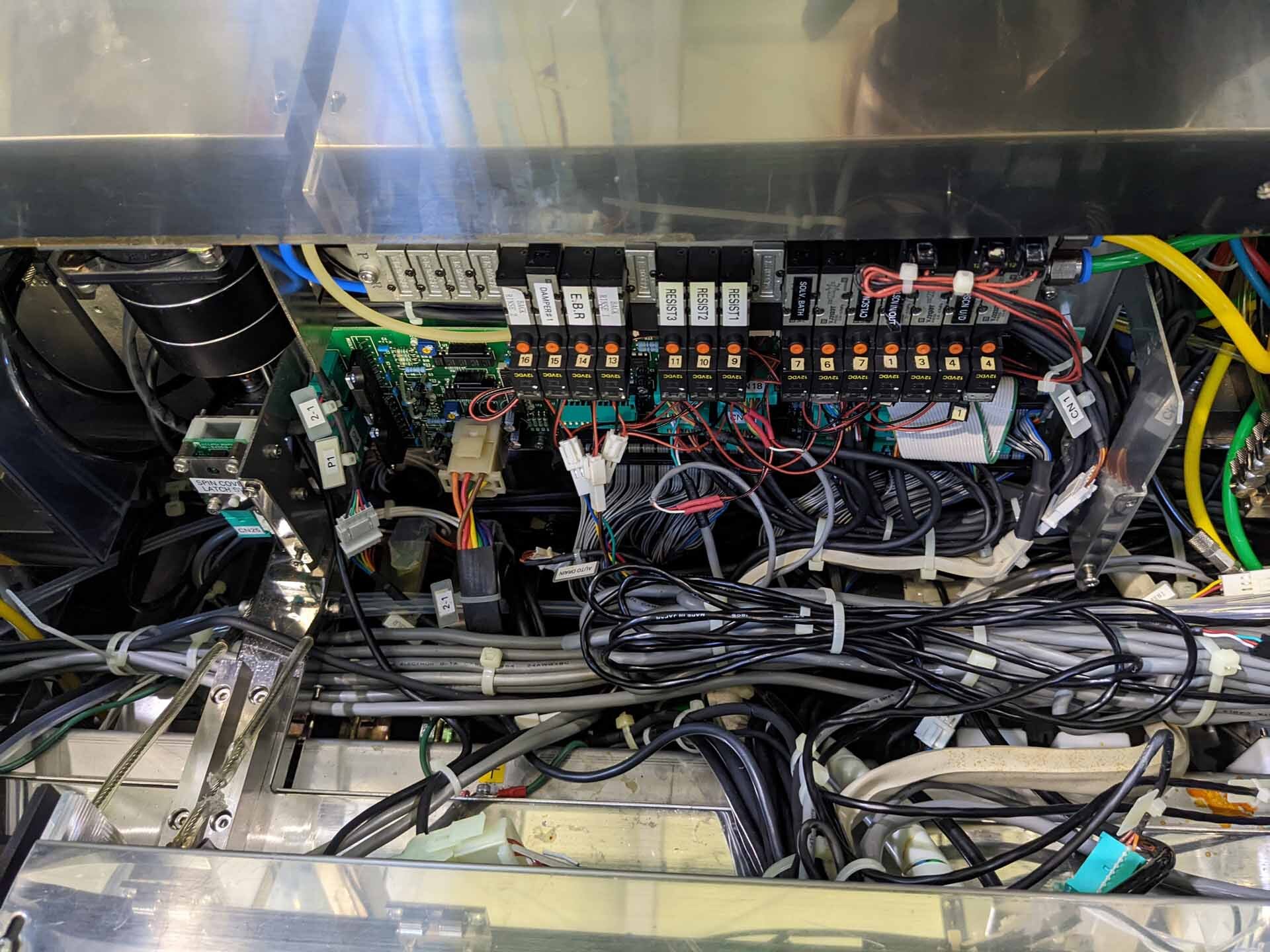

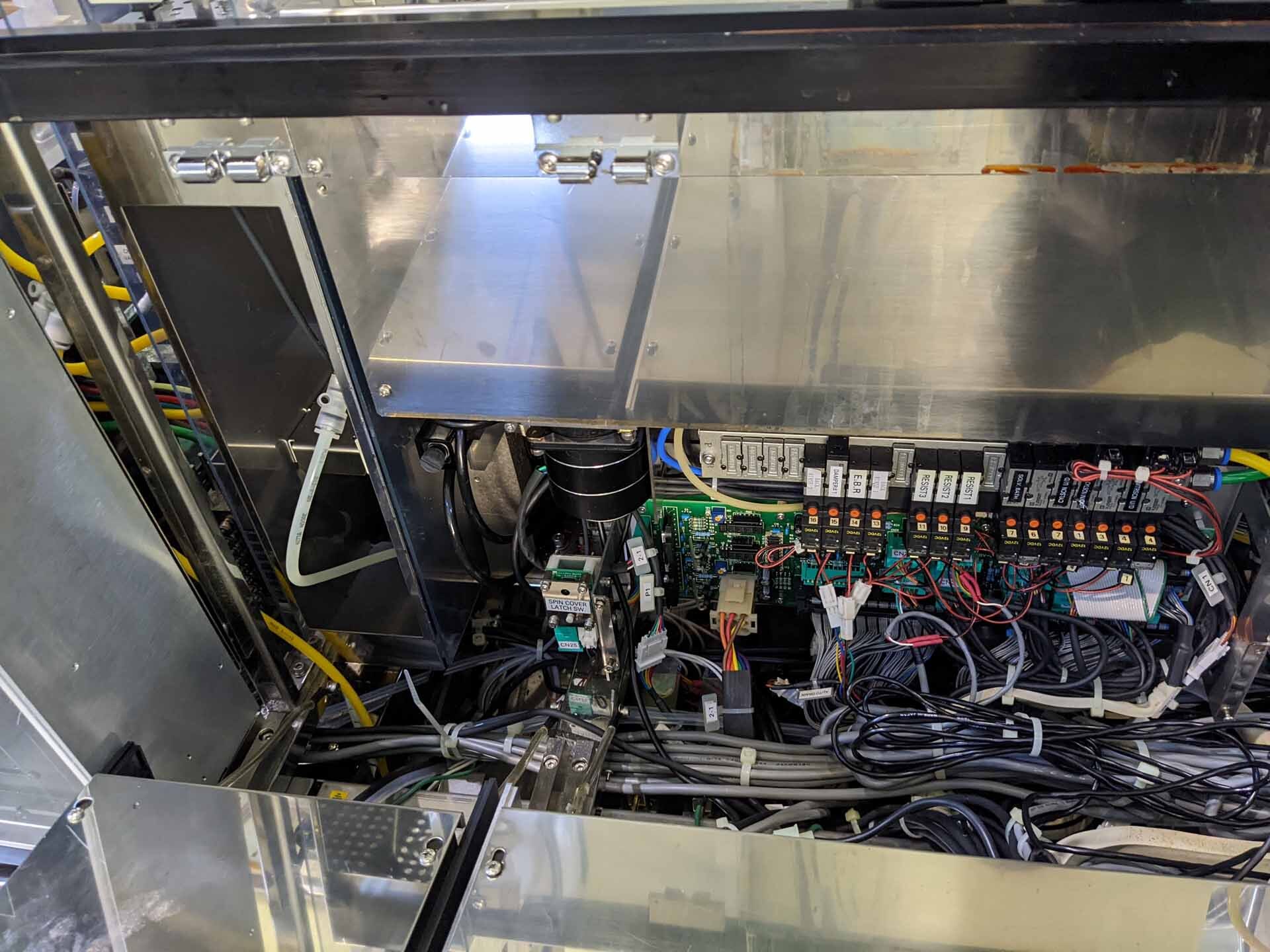

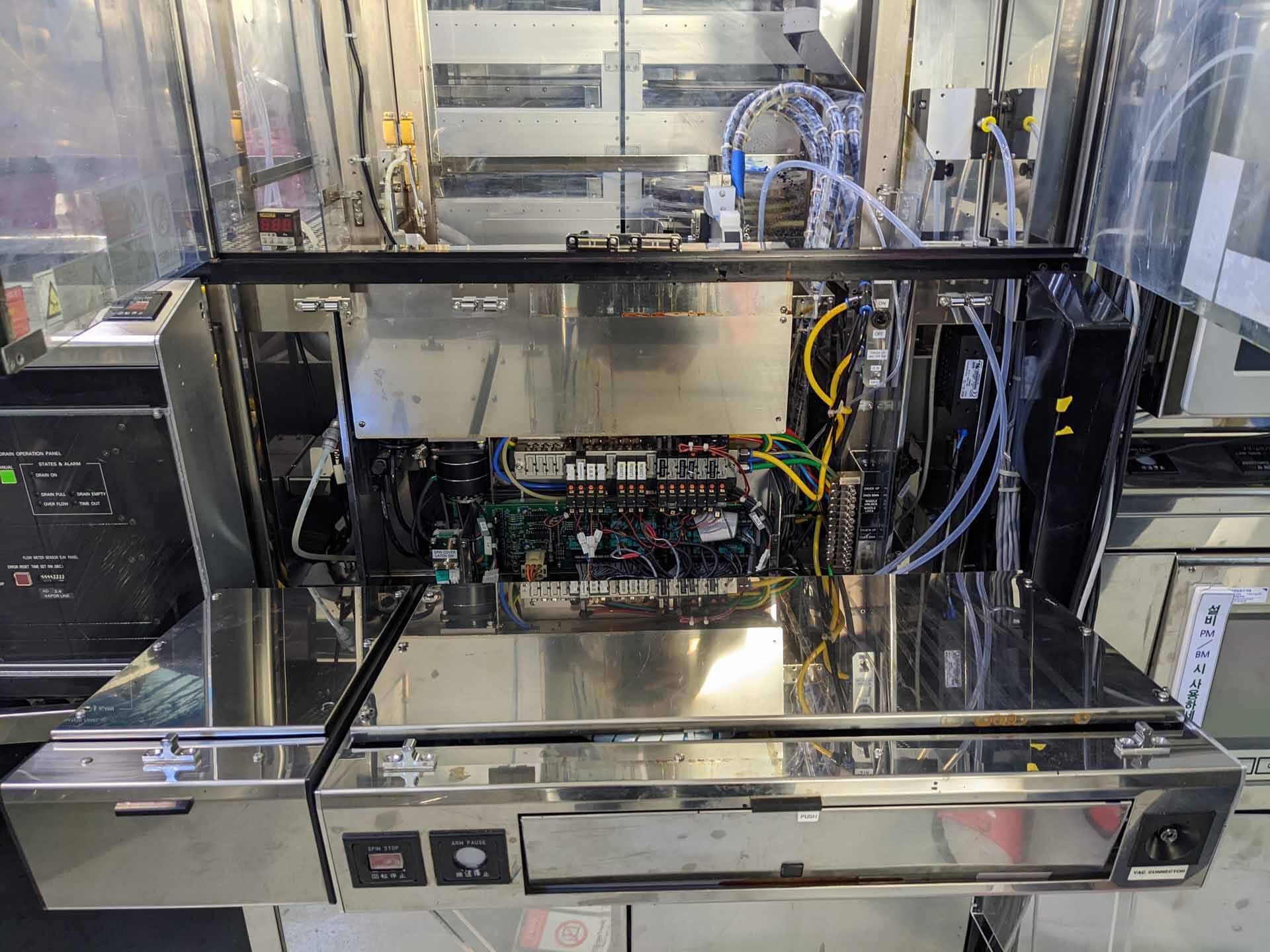

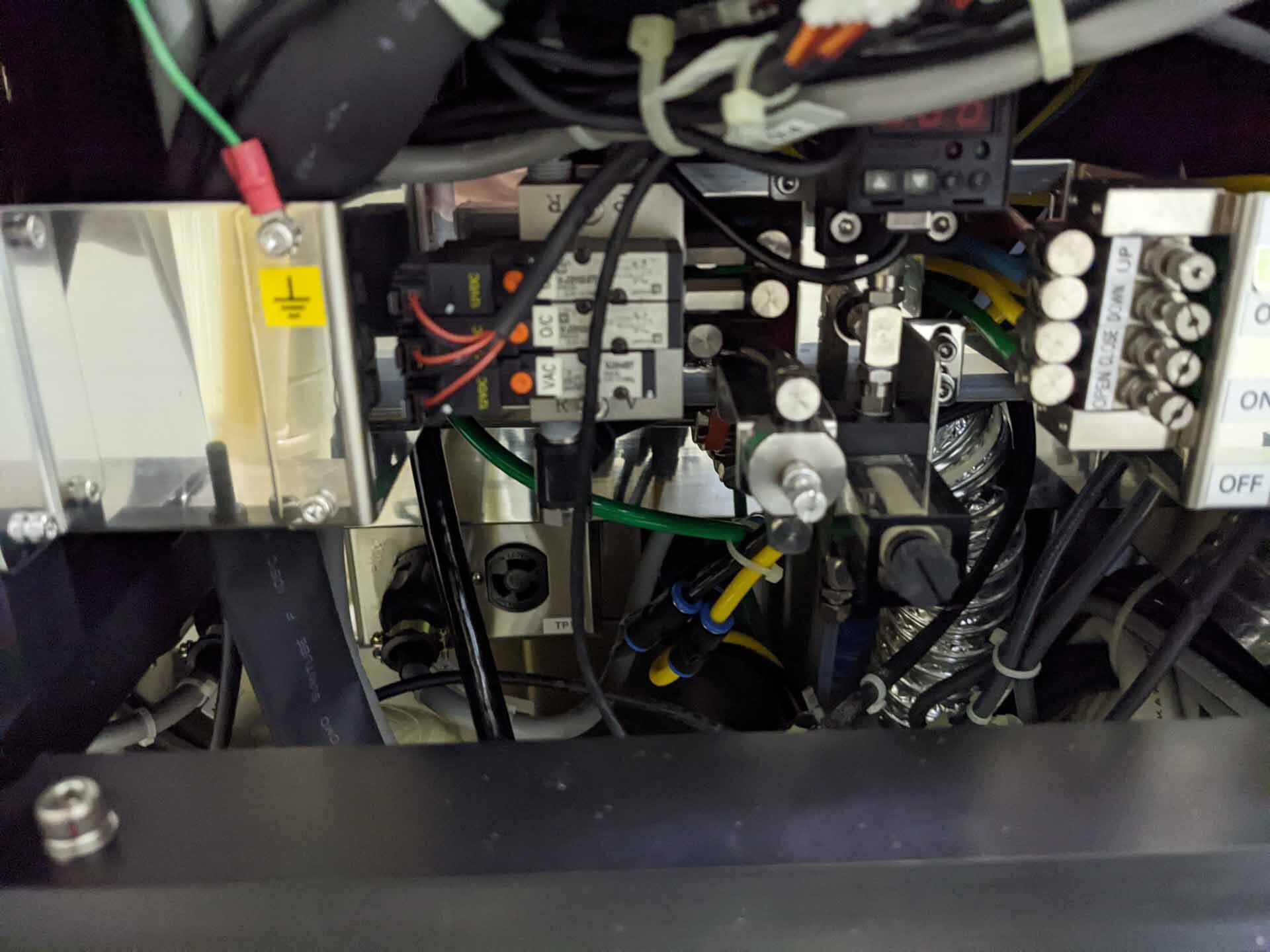

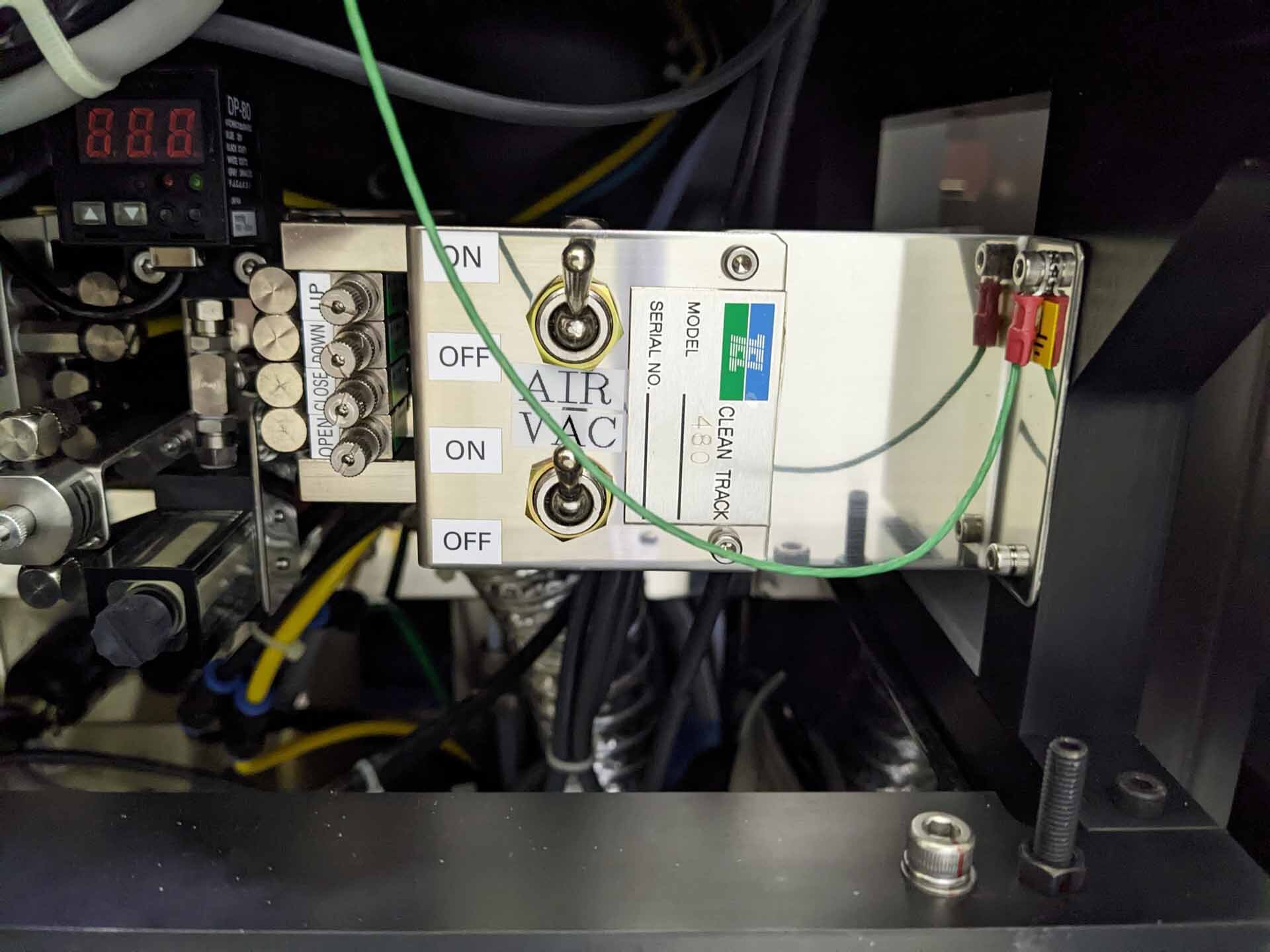

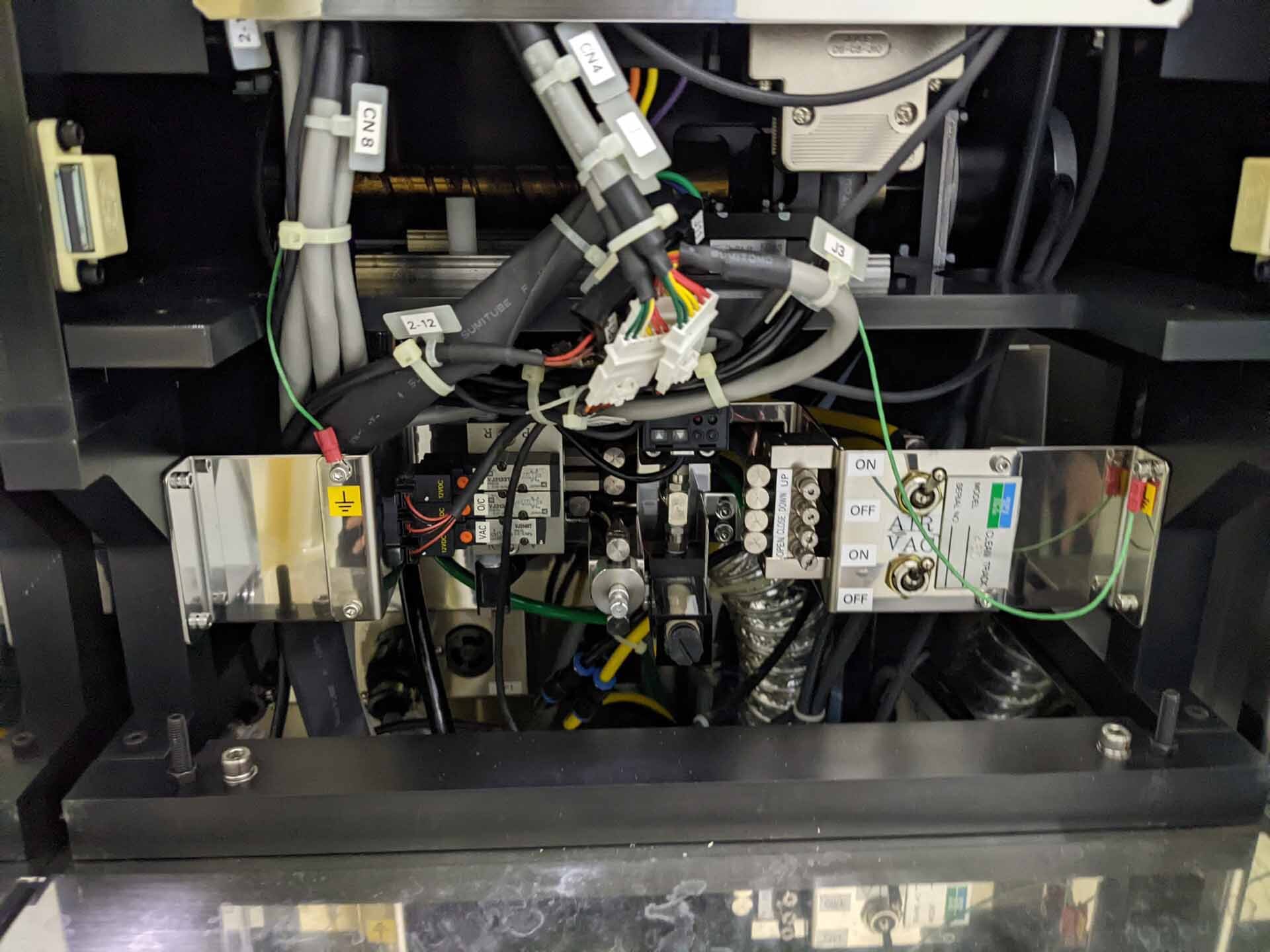

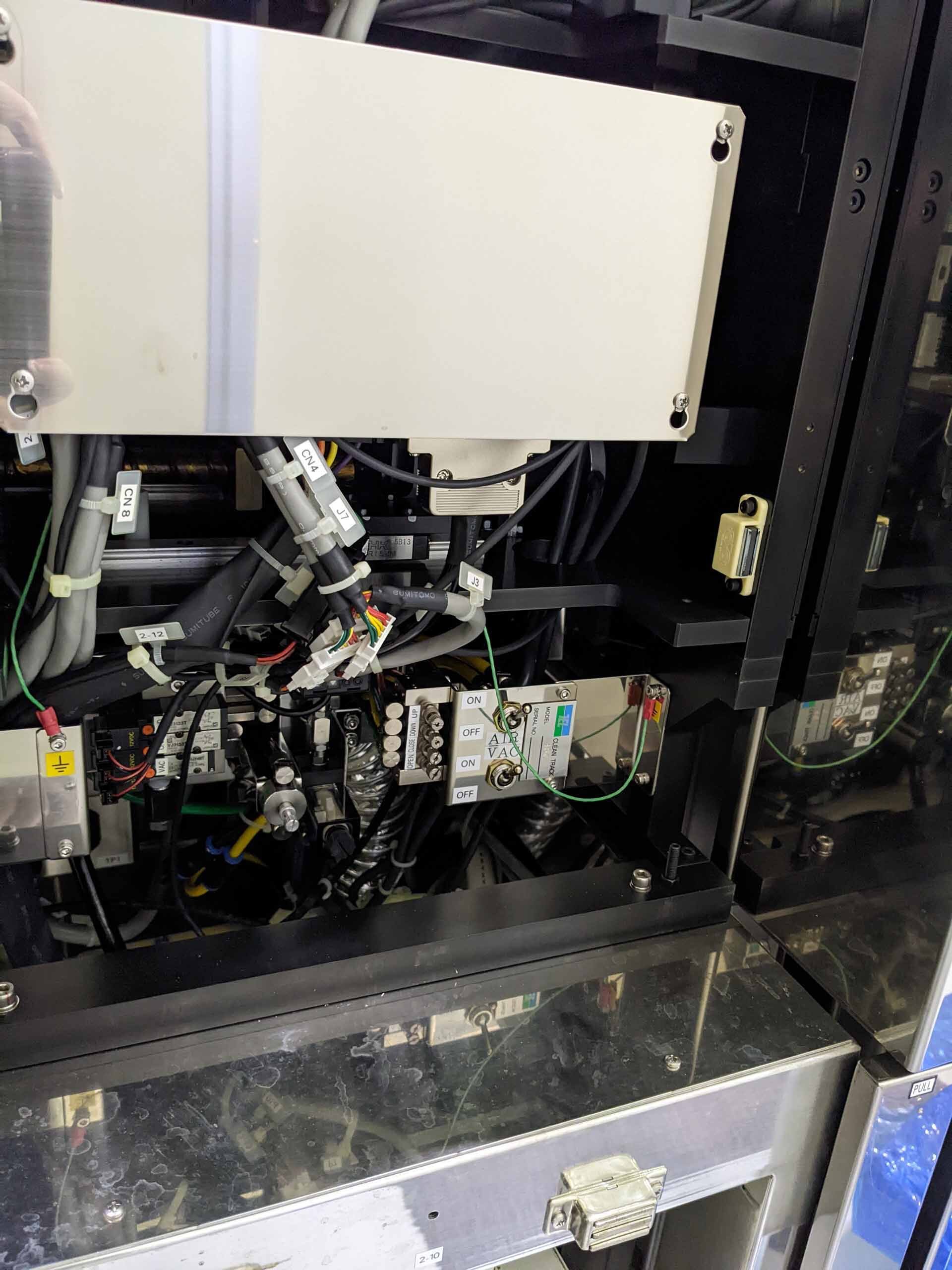

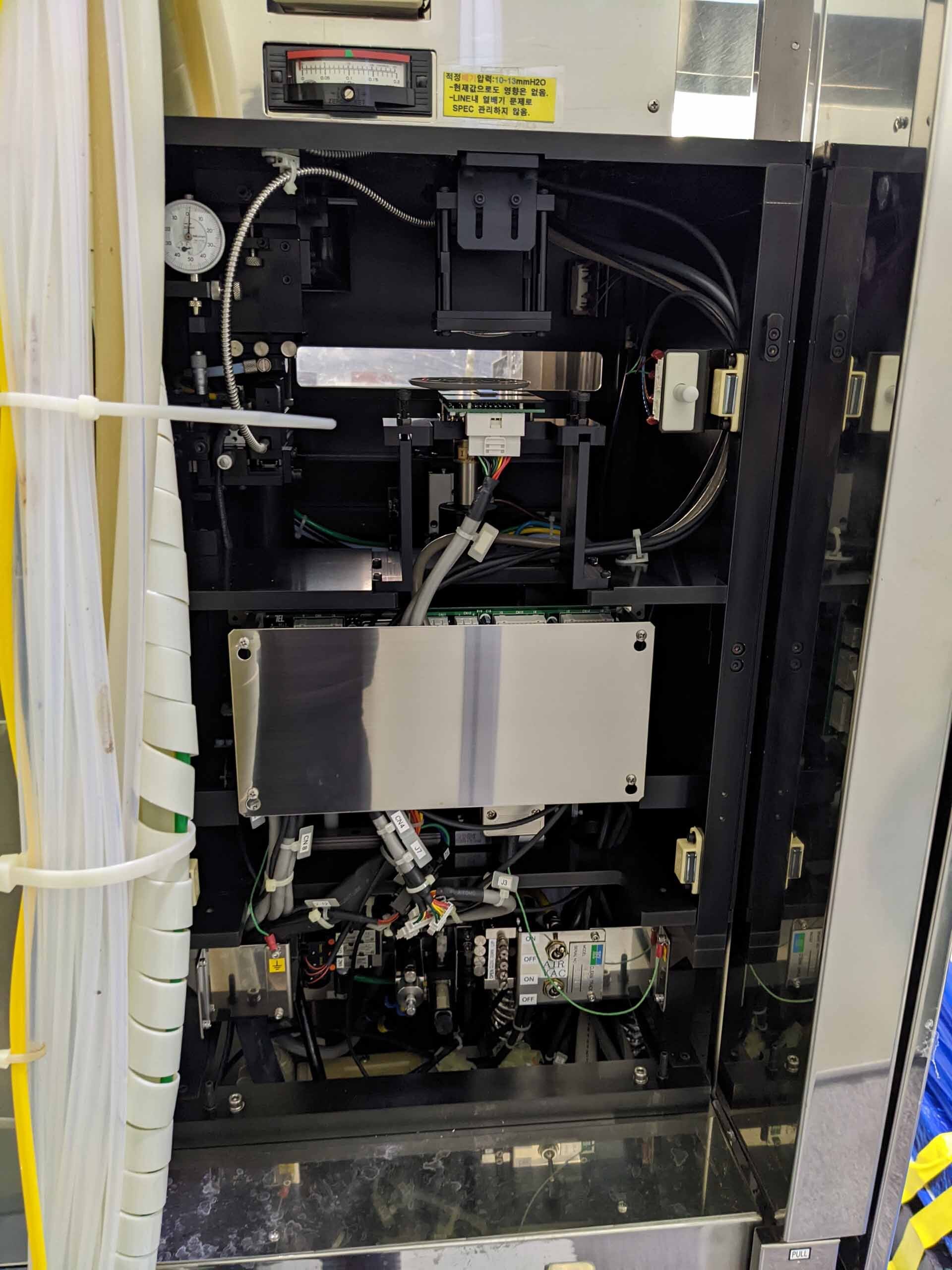

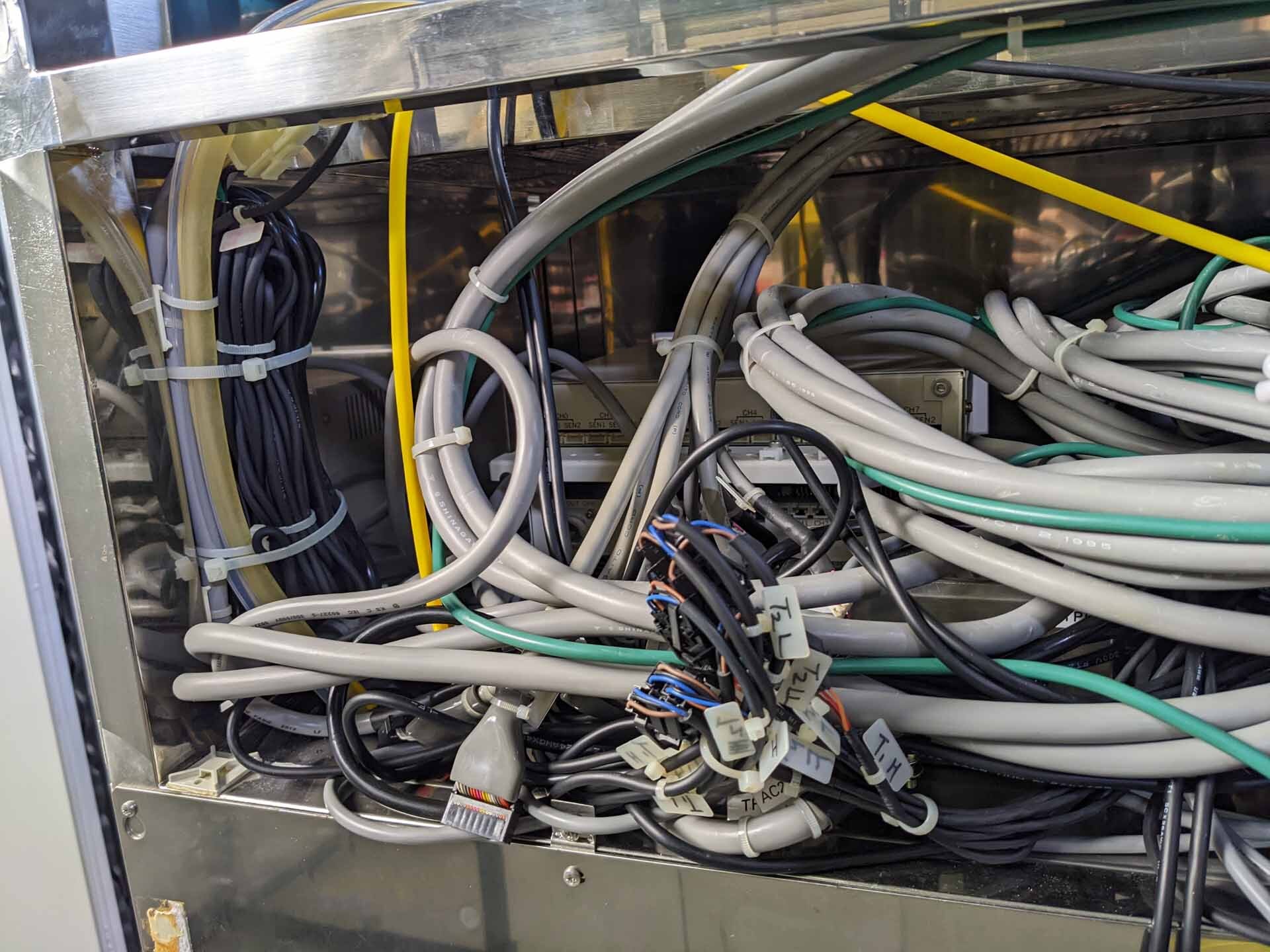

Process station (PSB): Process block robotic arm (PRA)

ADH

(4) LHP

(3) CPL

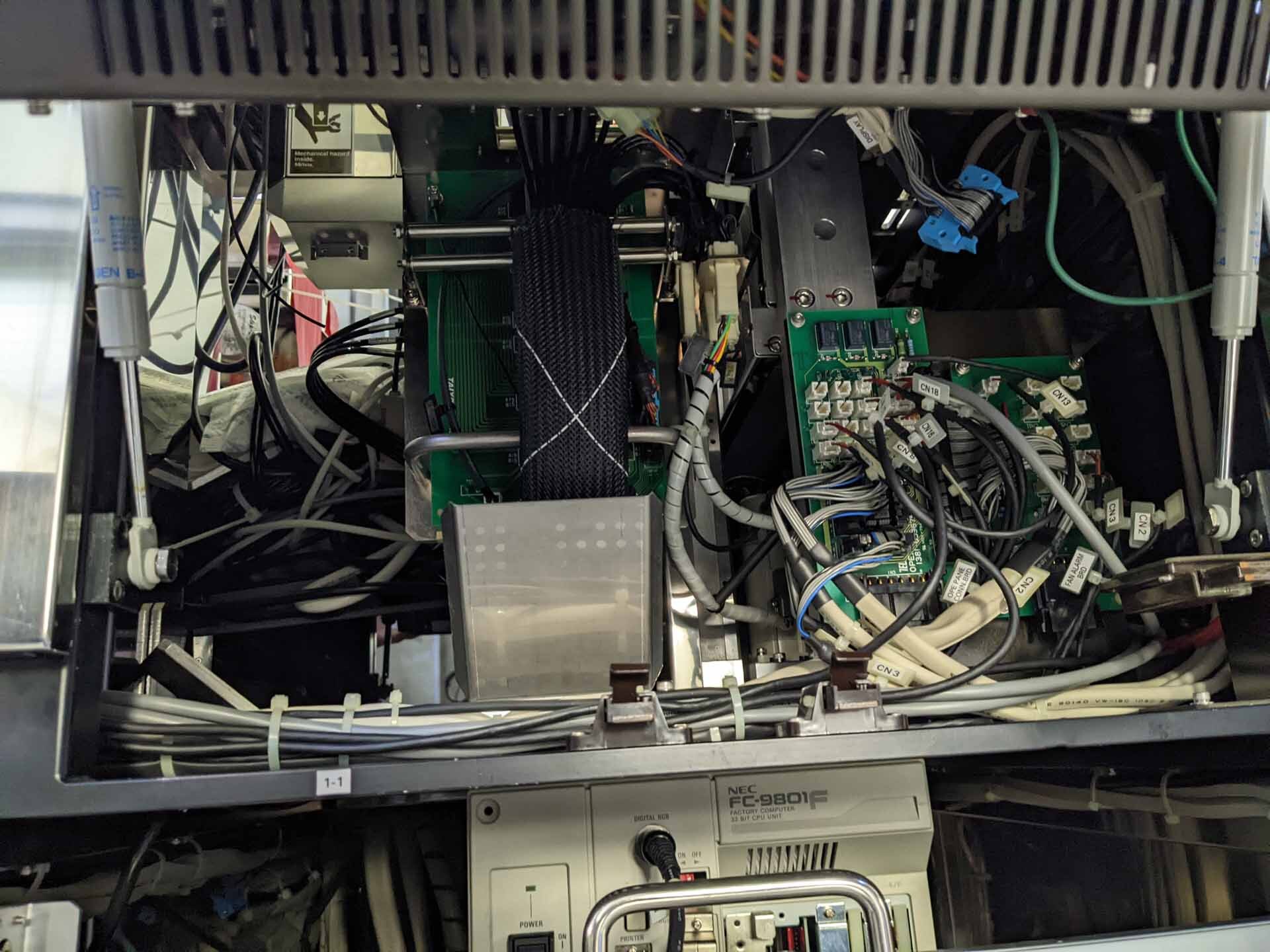

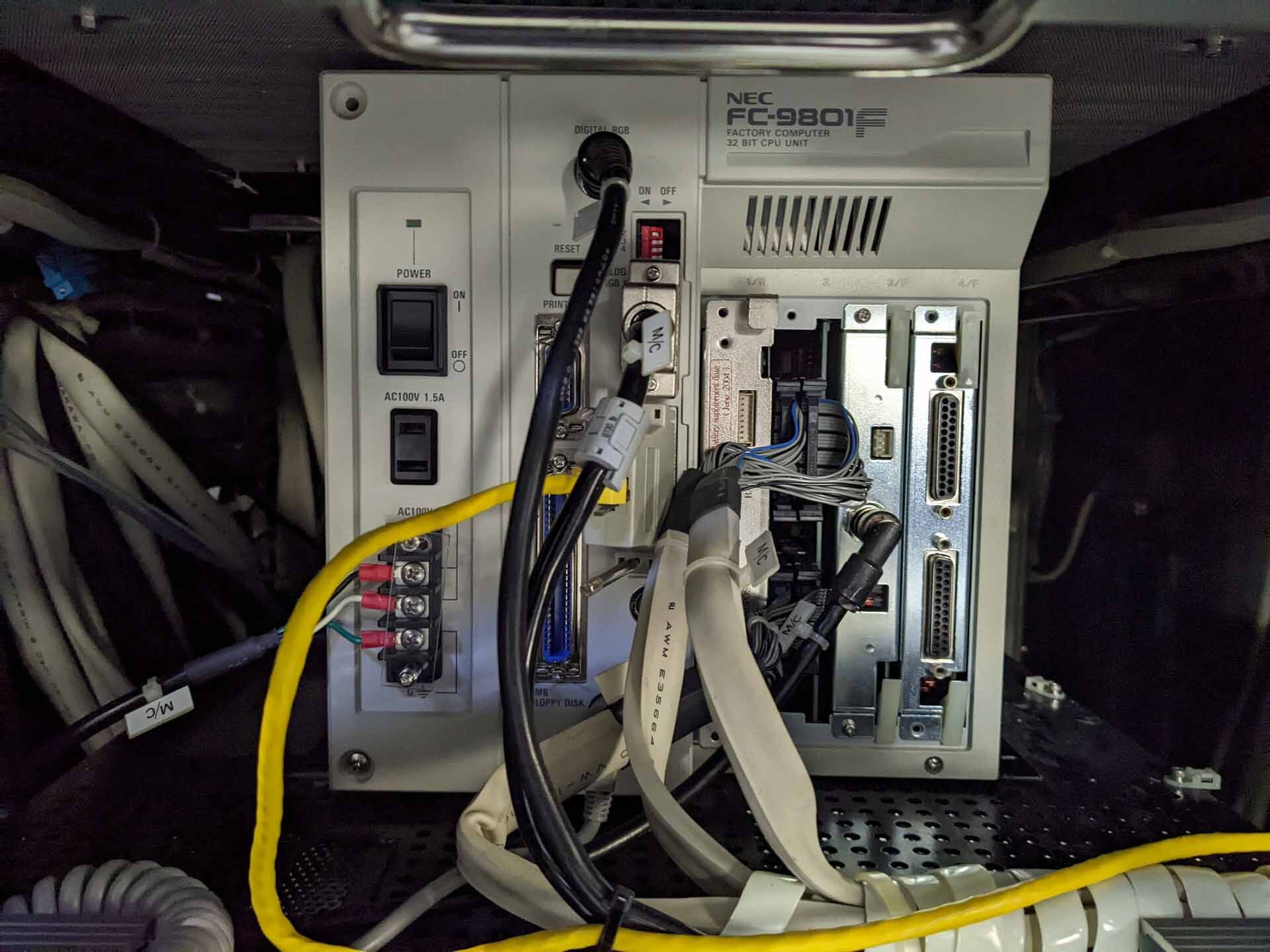

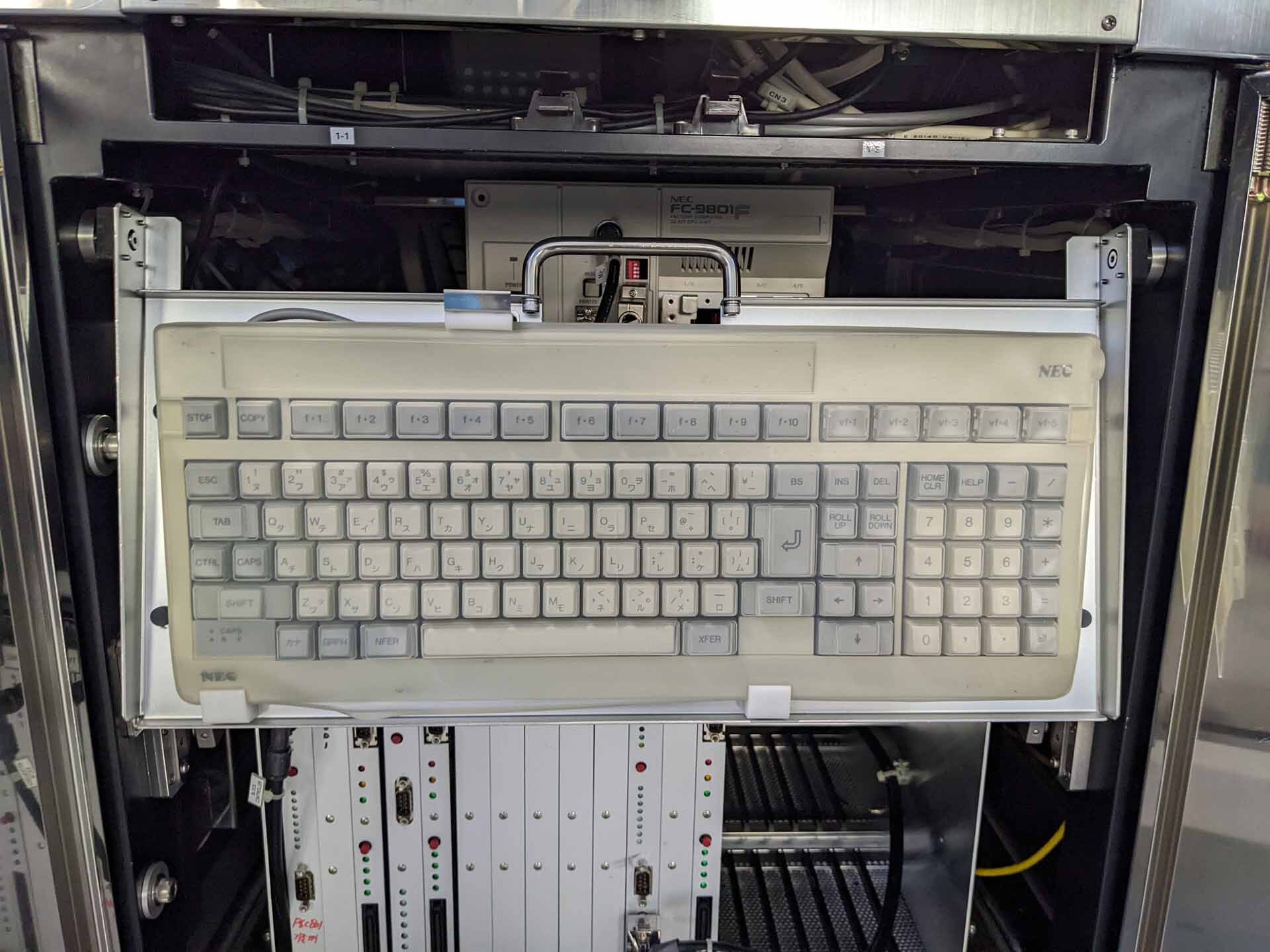

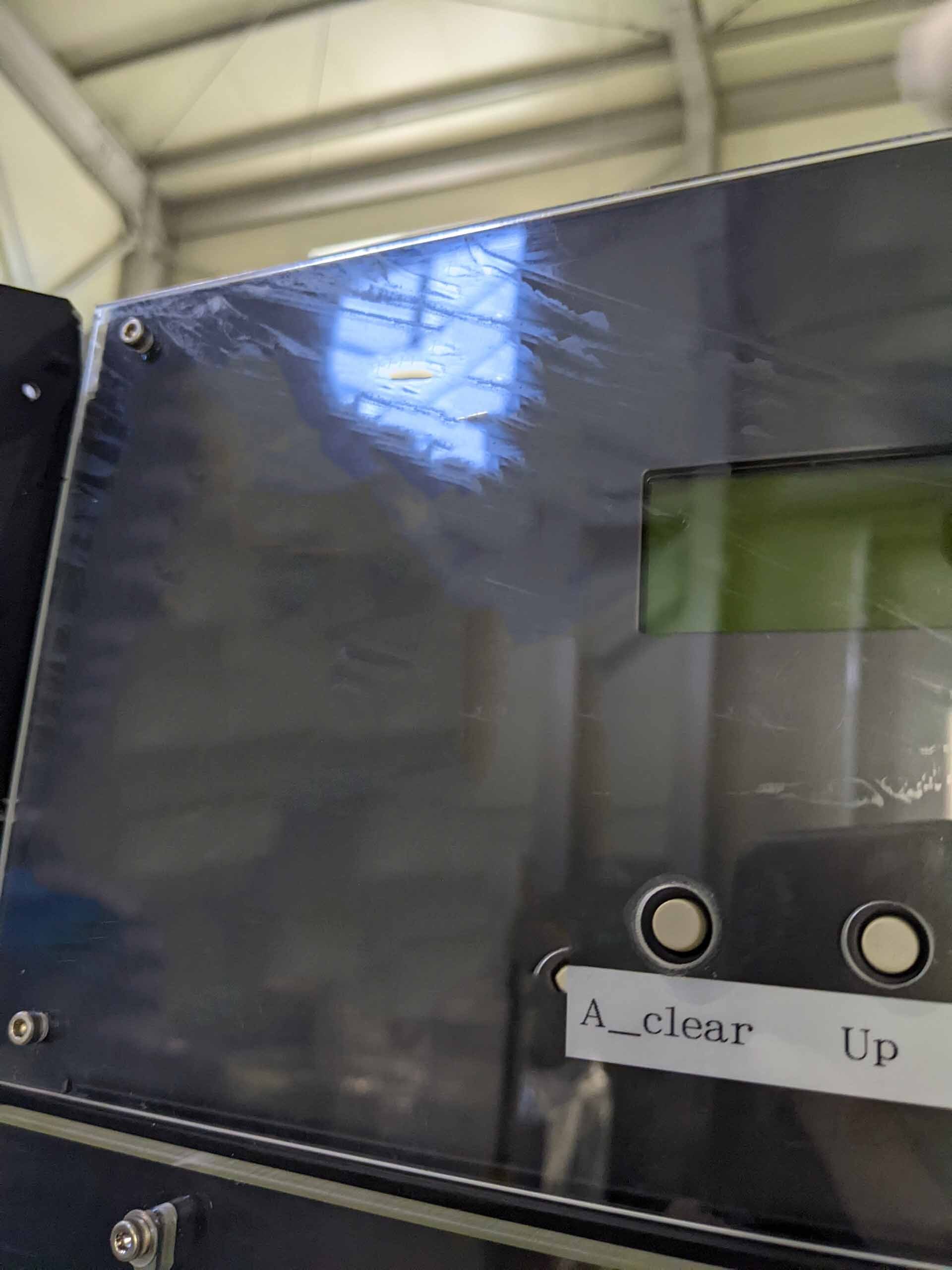

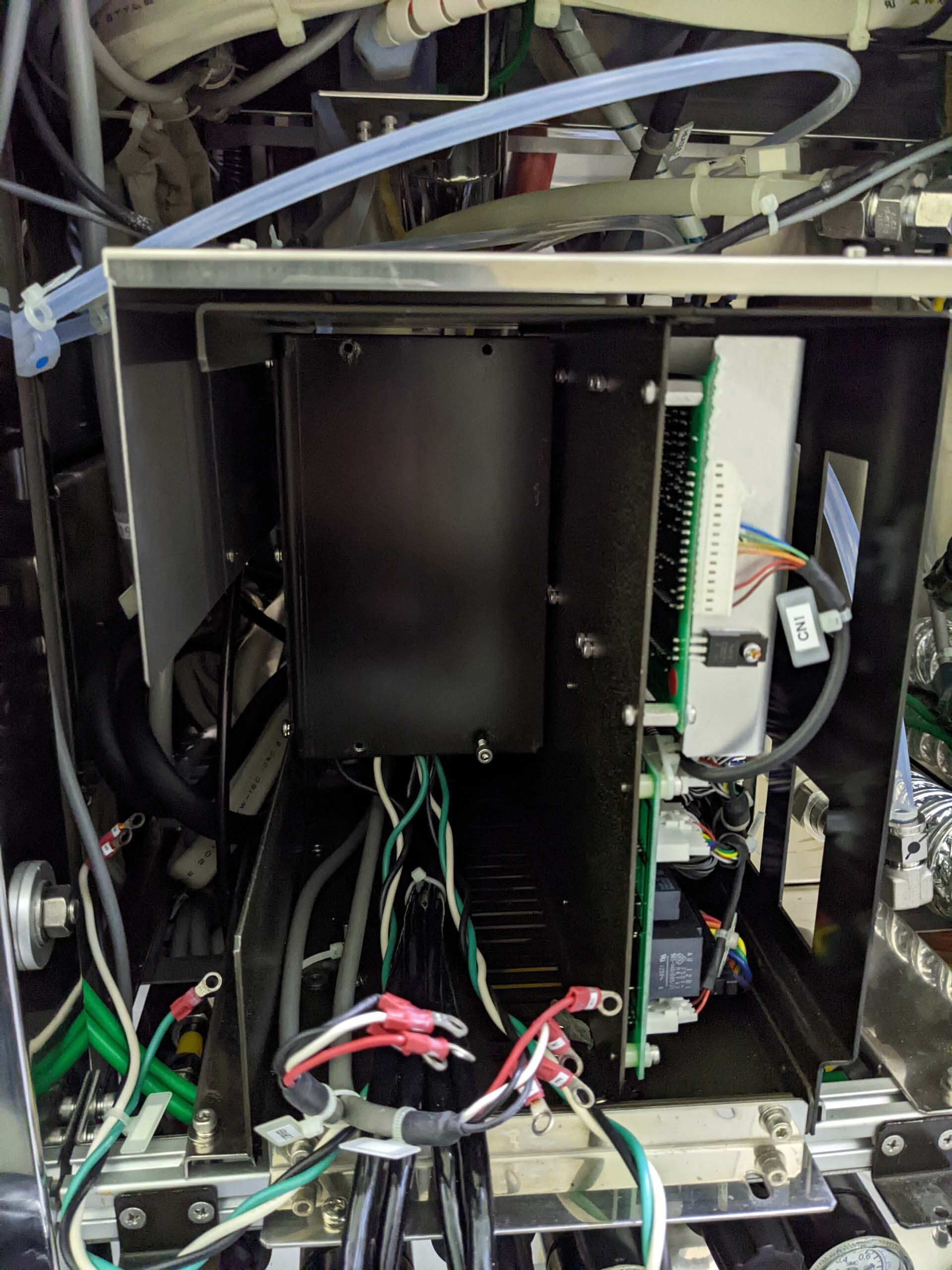

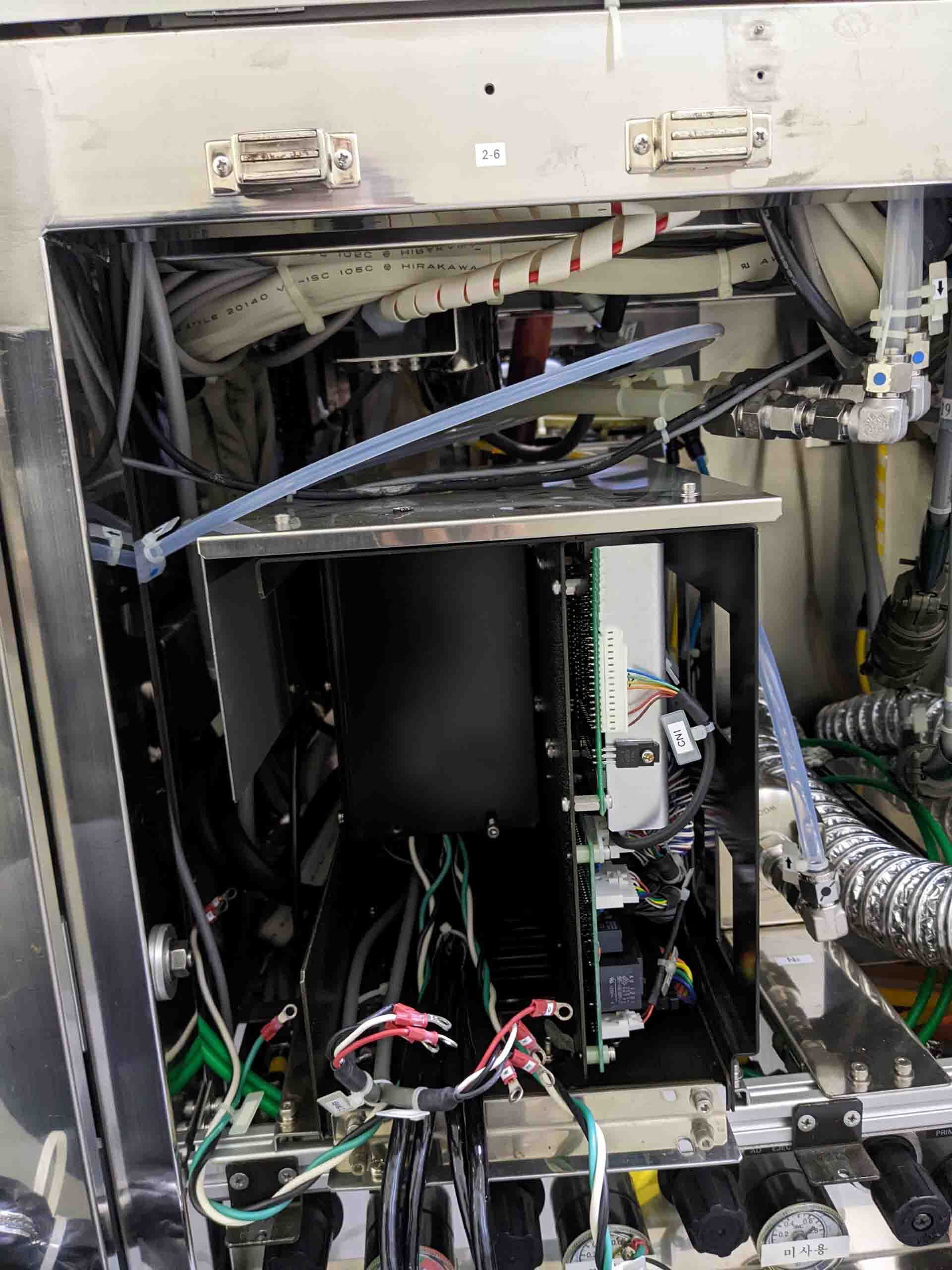

FC-9801 F Controller

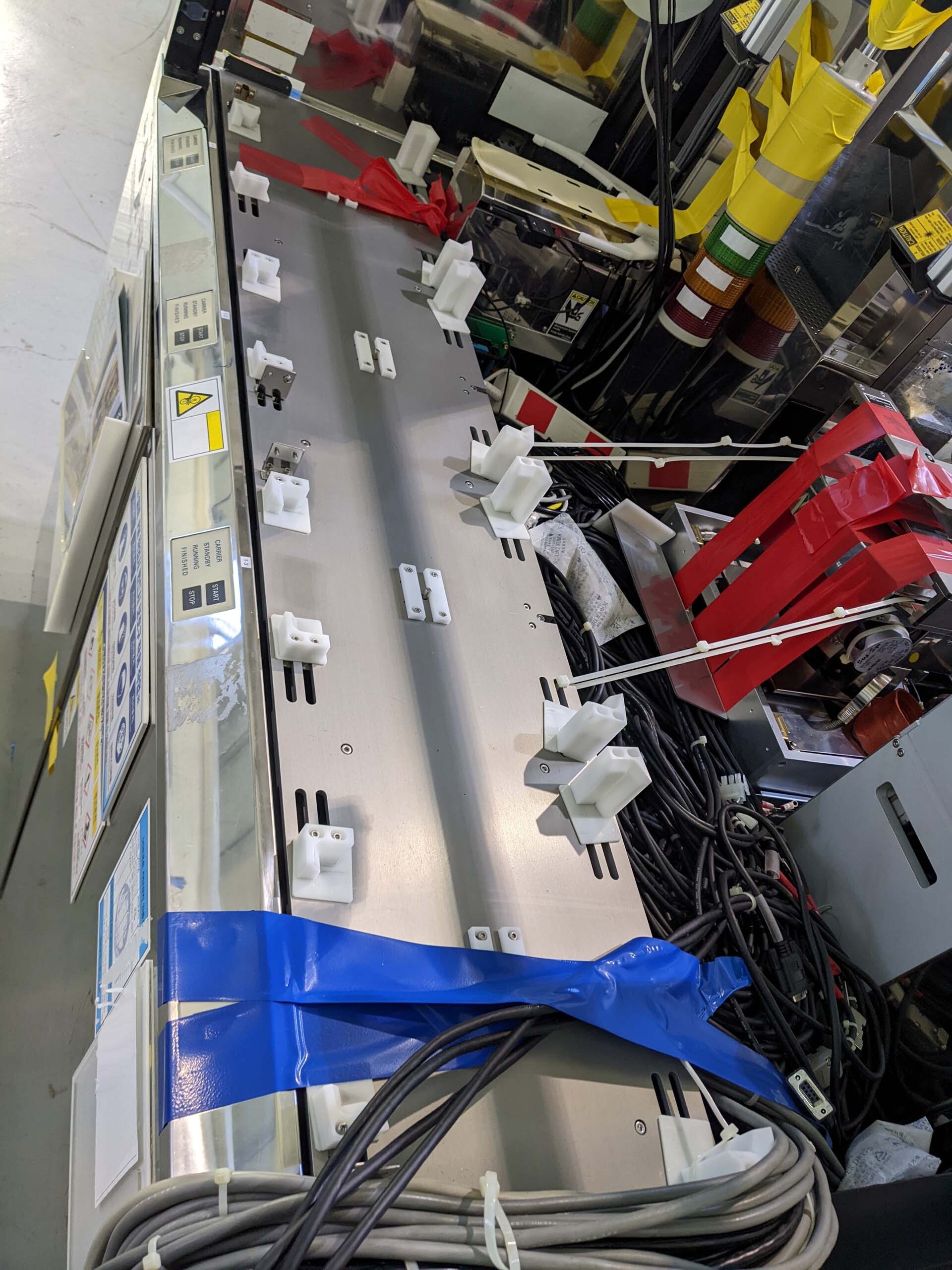

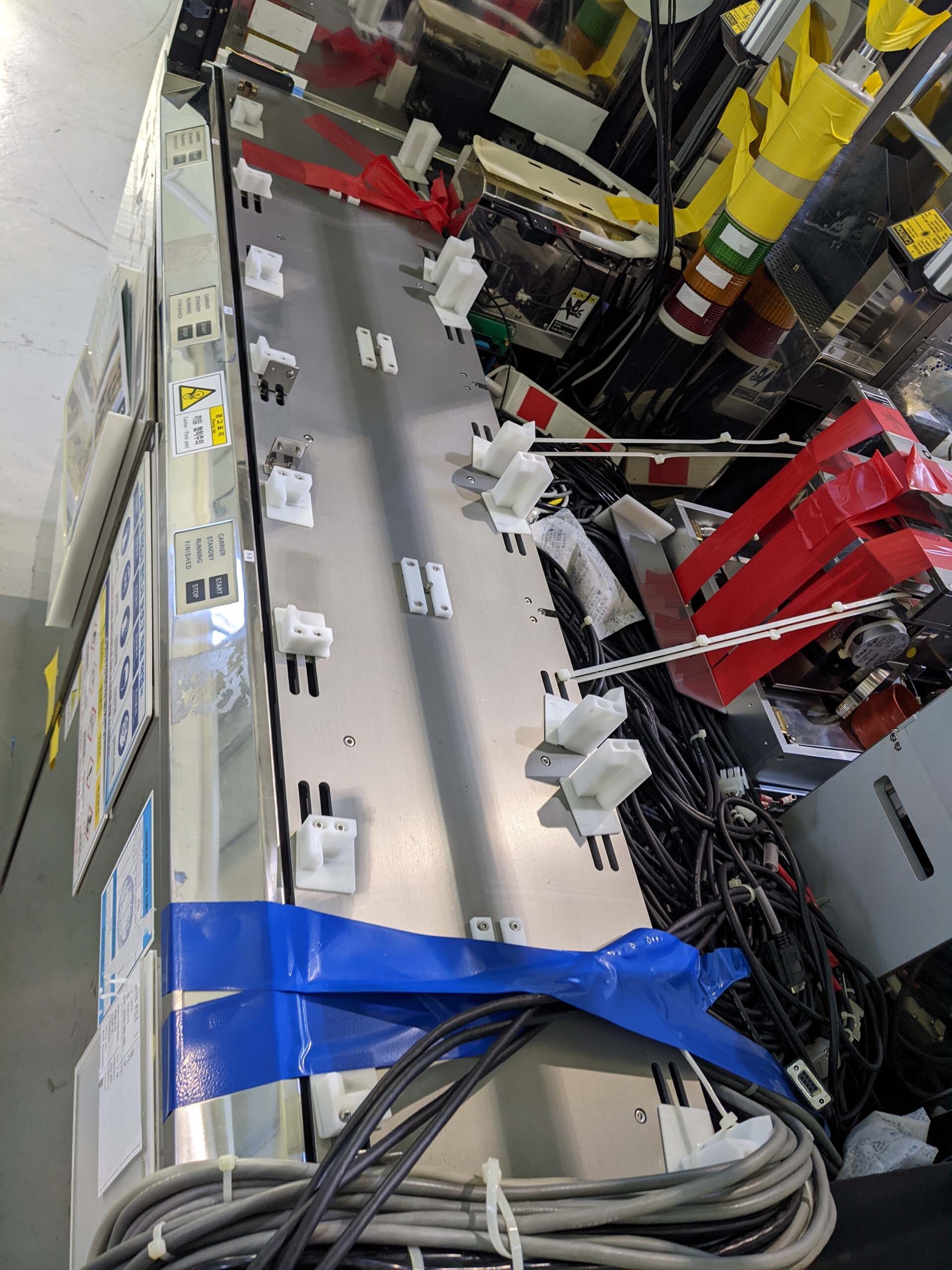

Stage: Cassette stage

Indexer: Open CSB

CRA

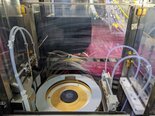

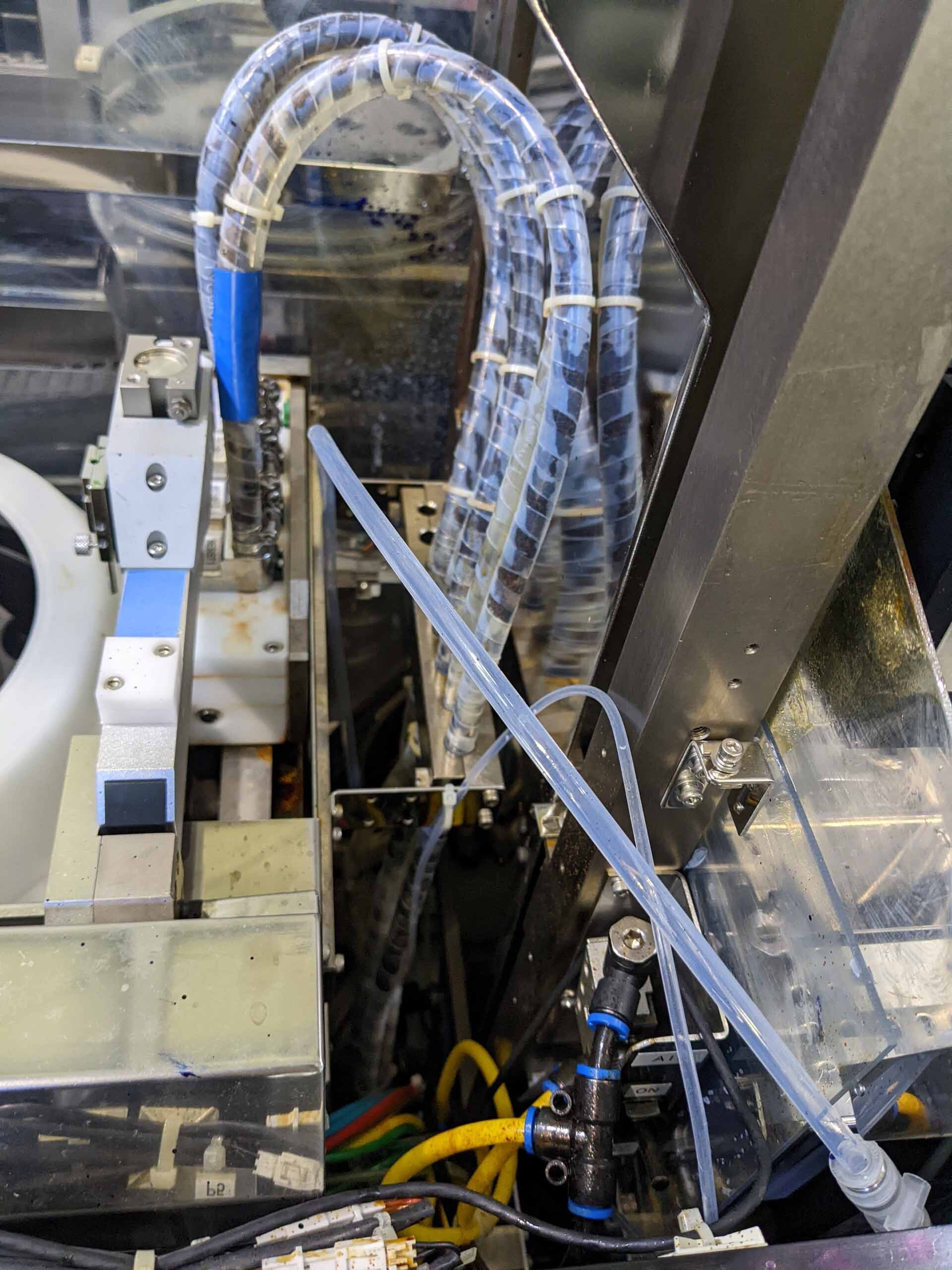

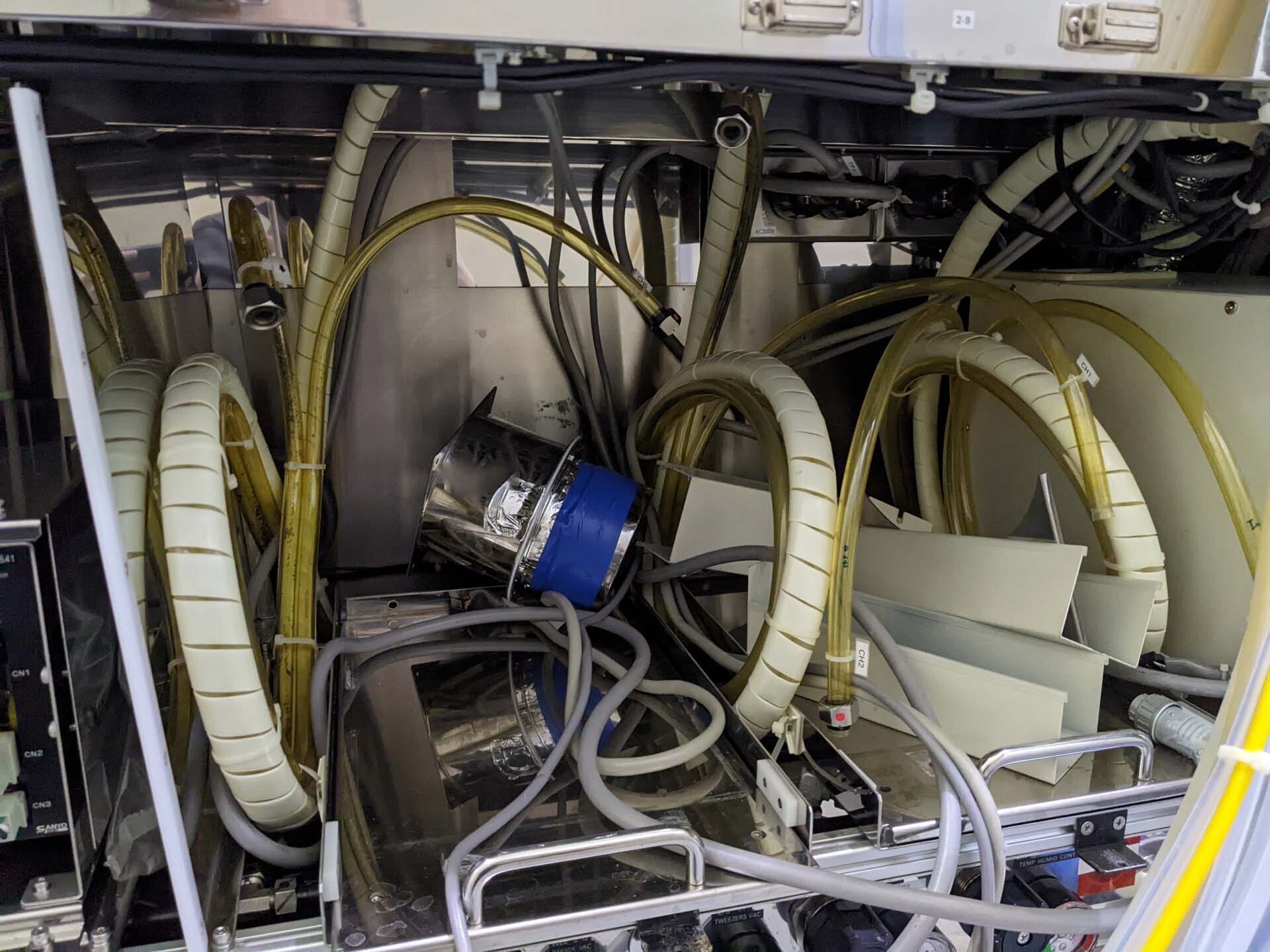

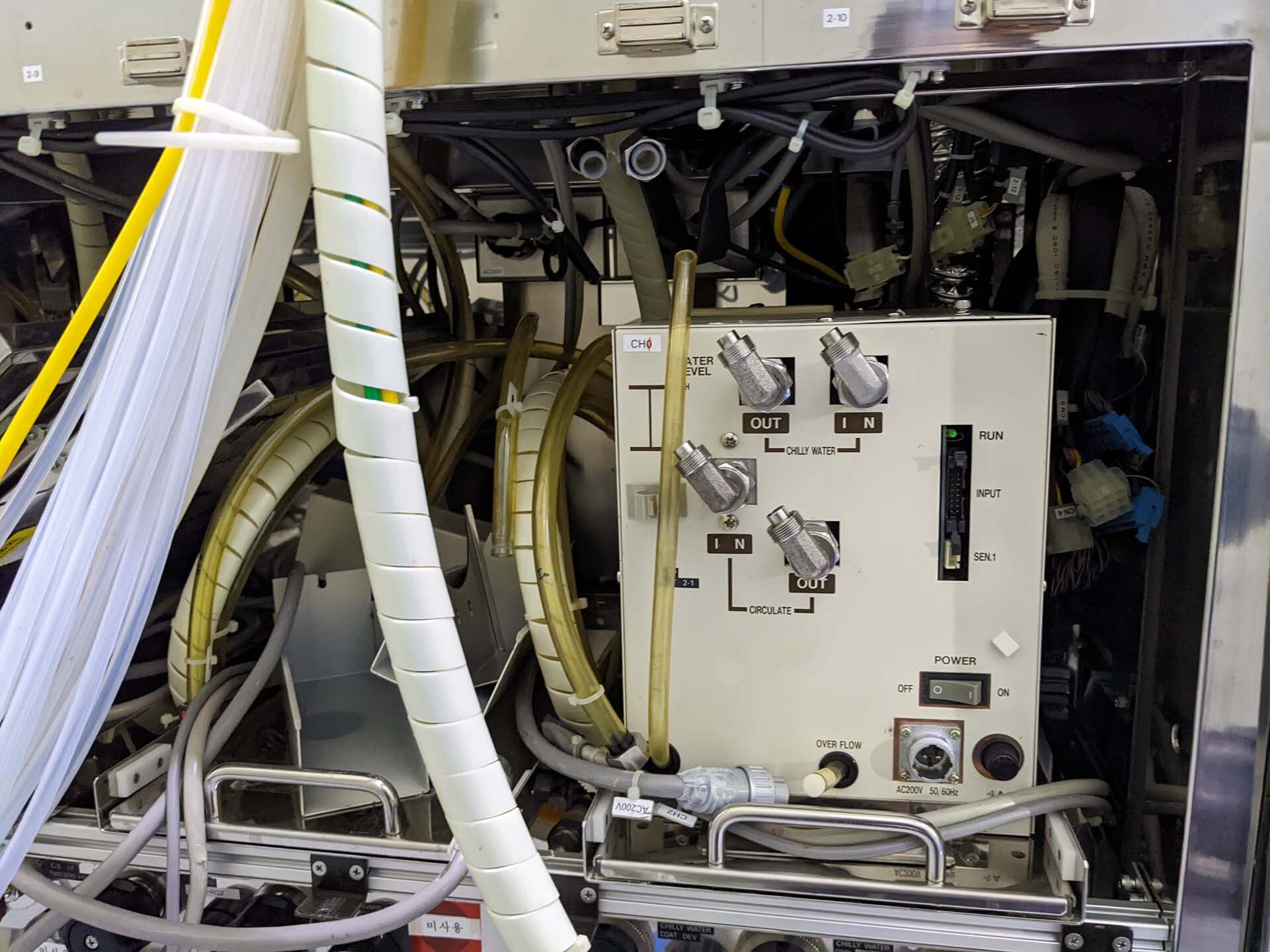

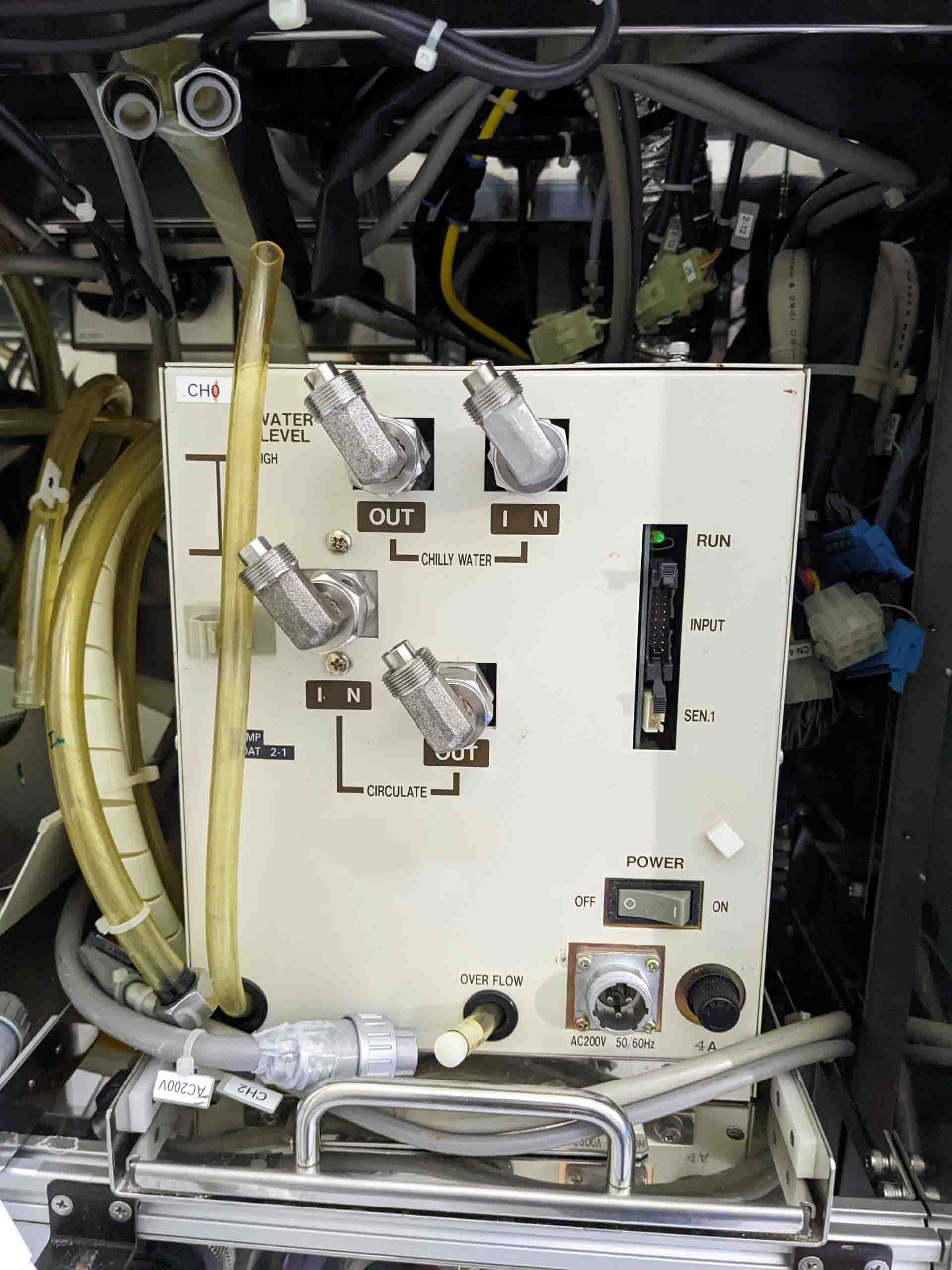

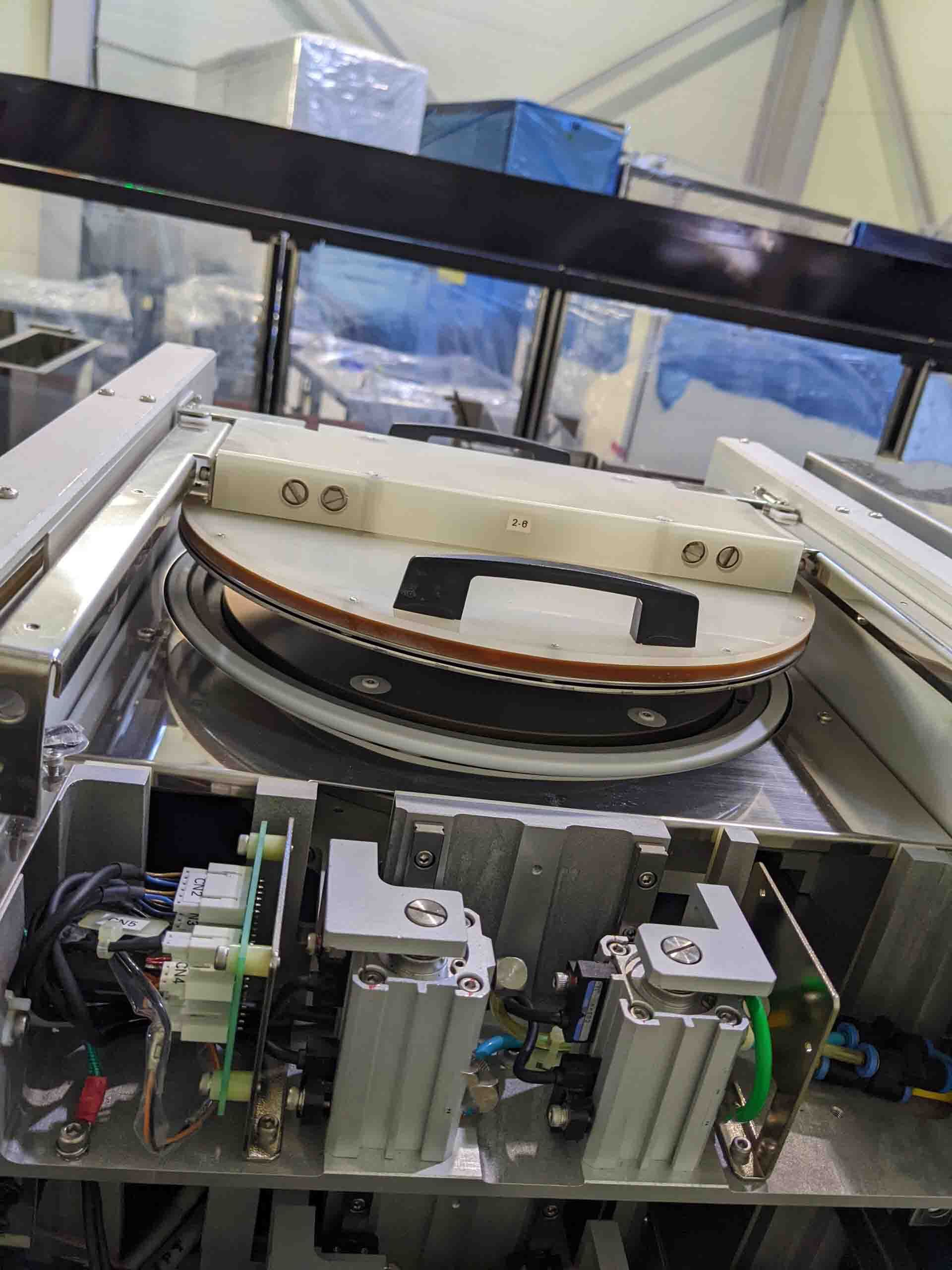

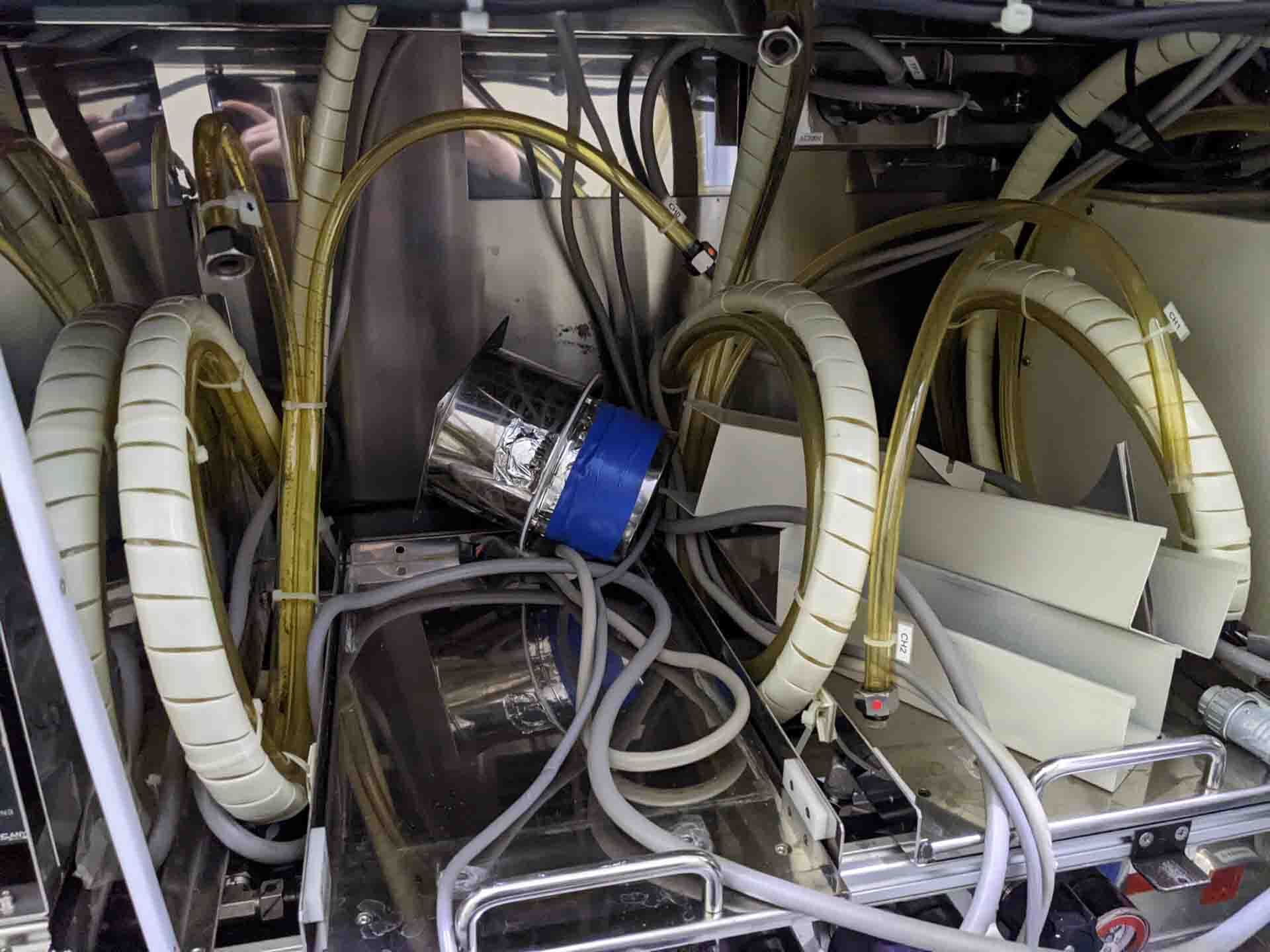

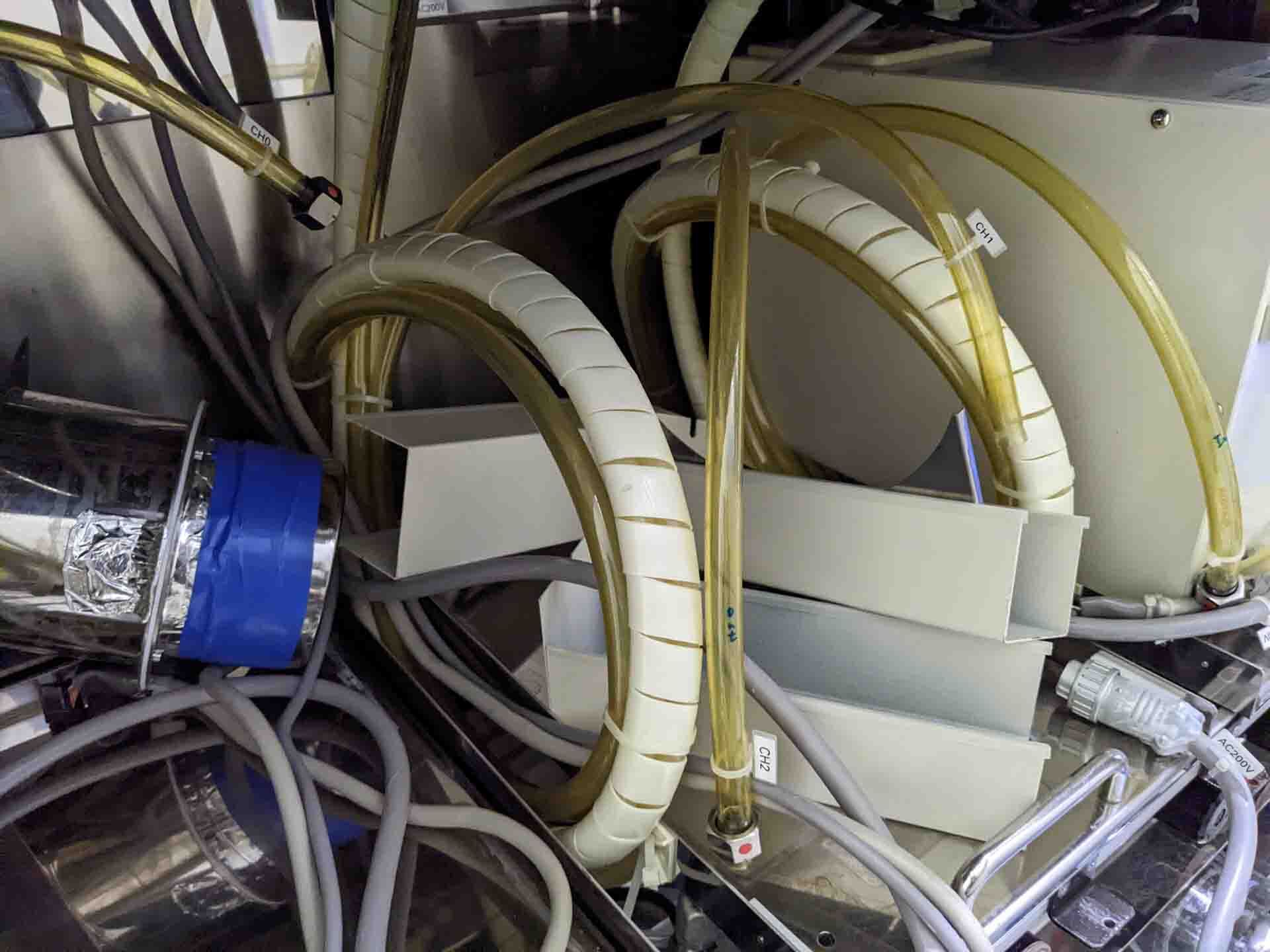

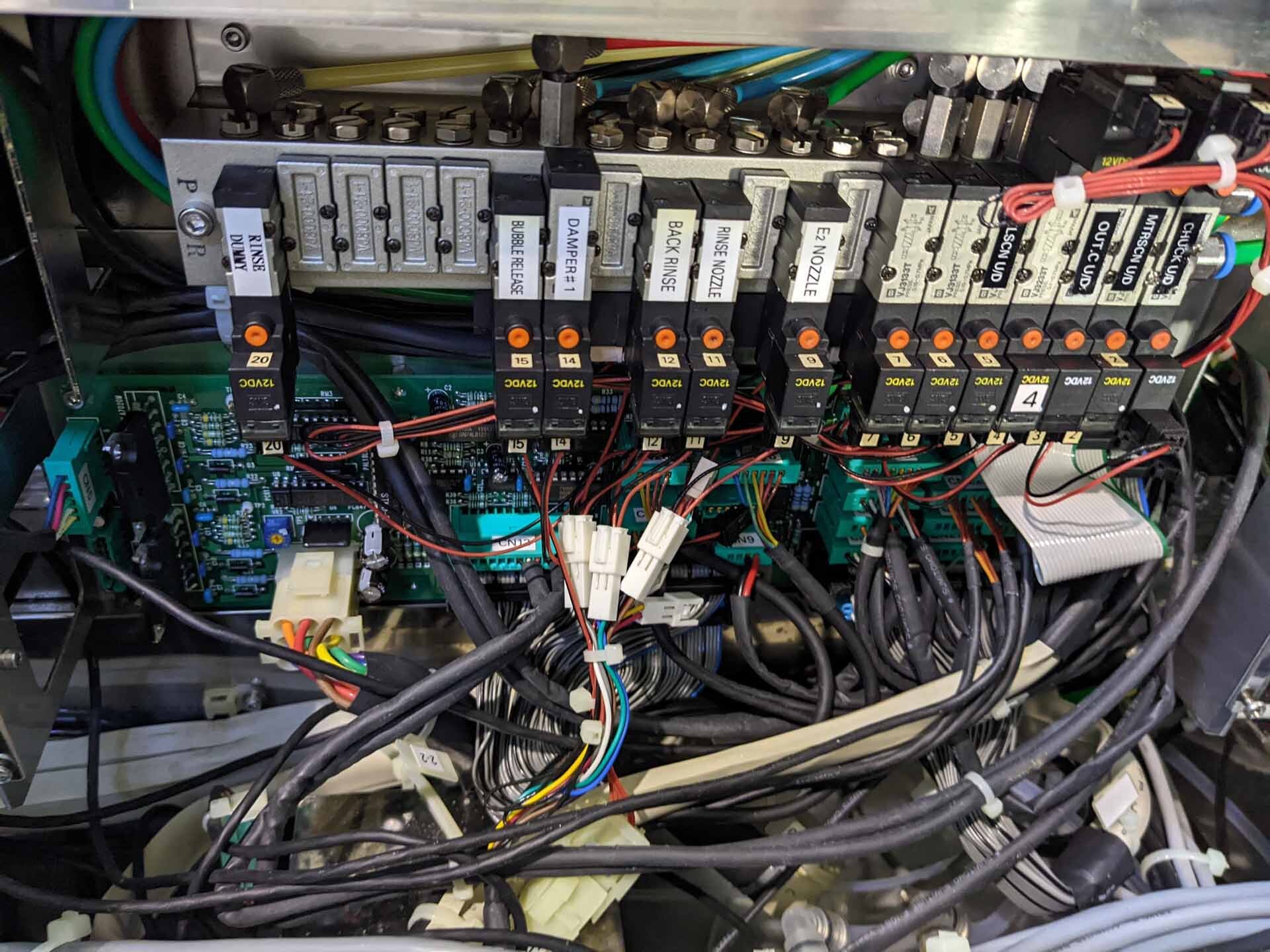

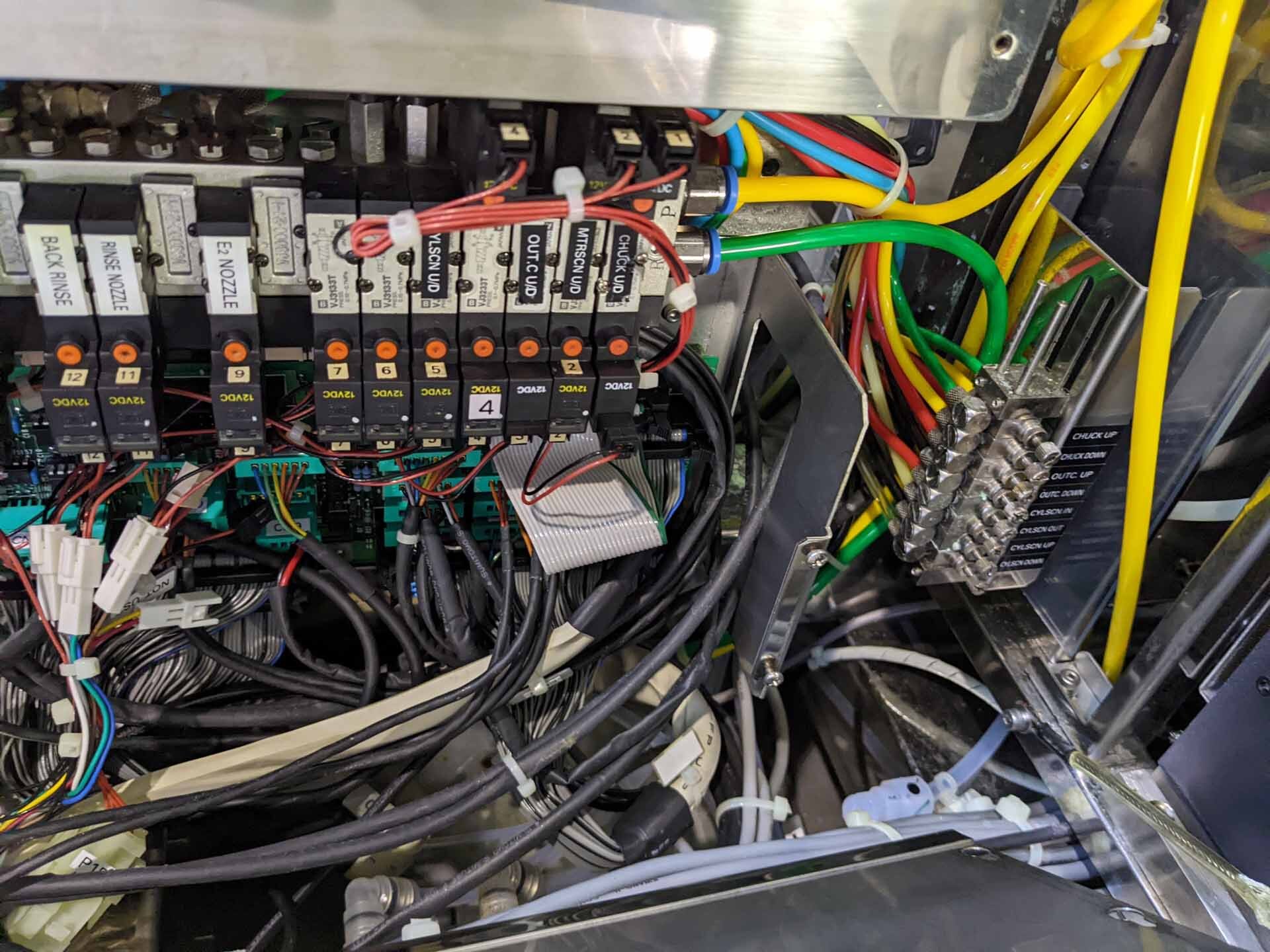

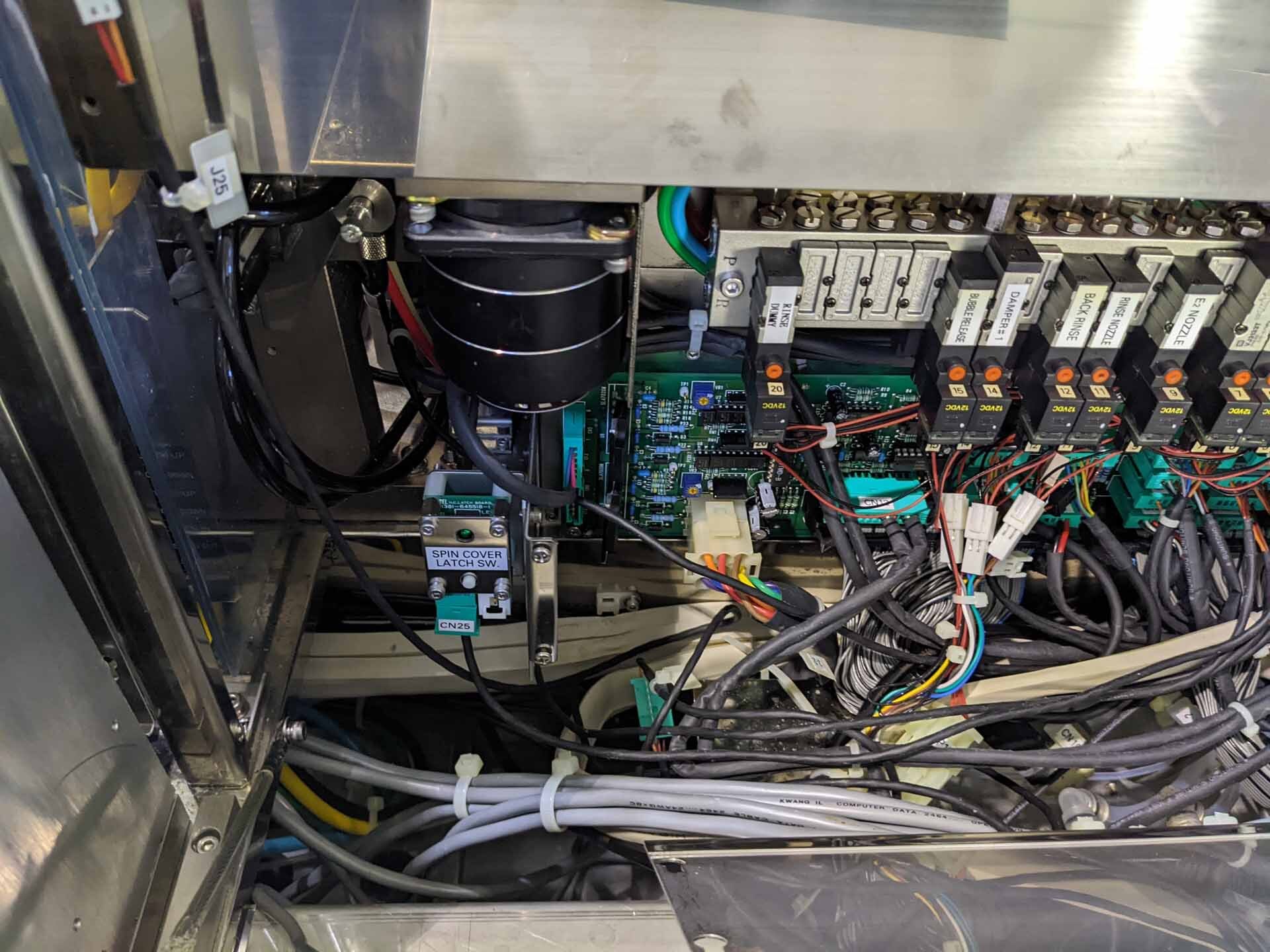

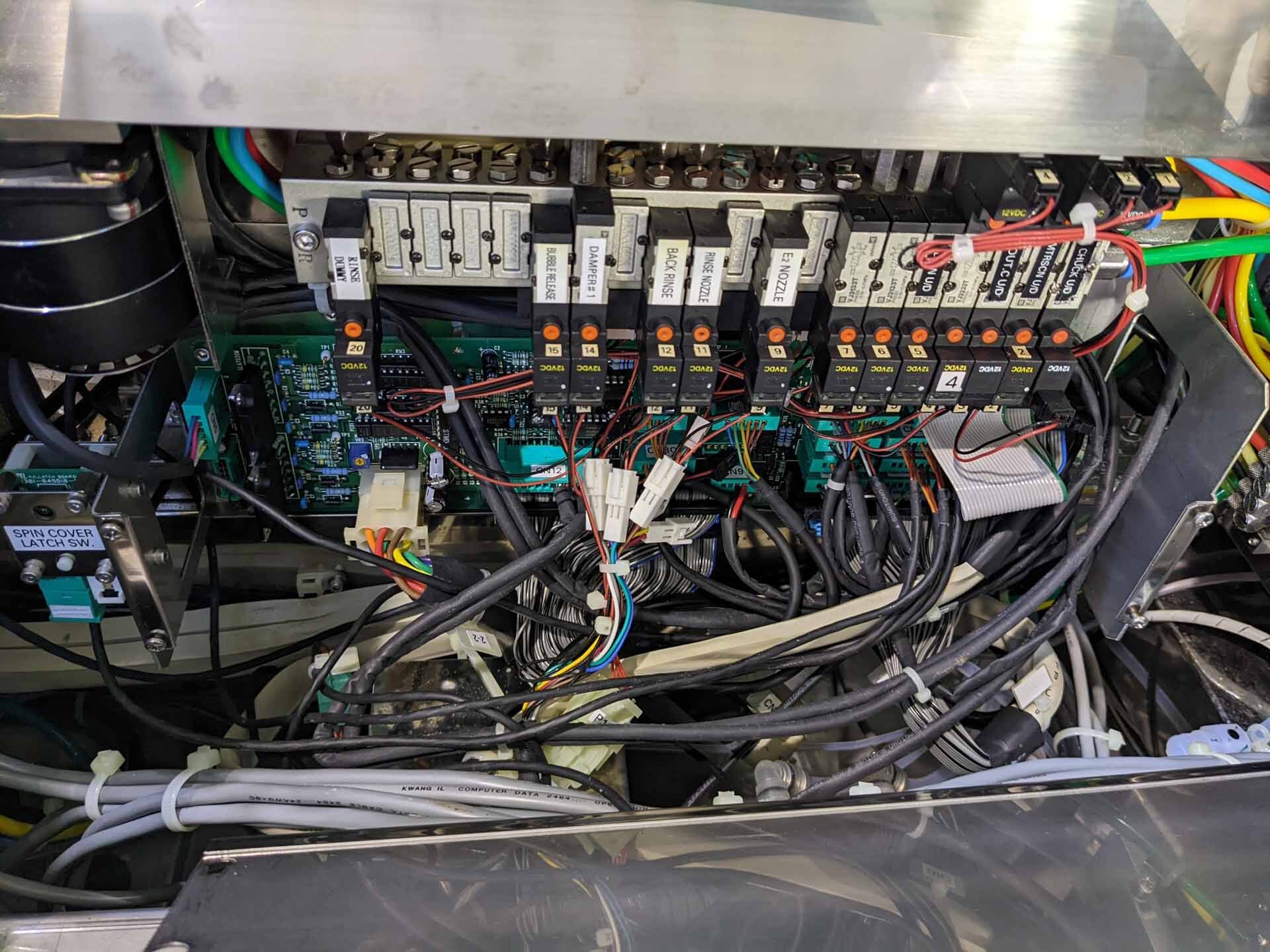

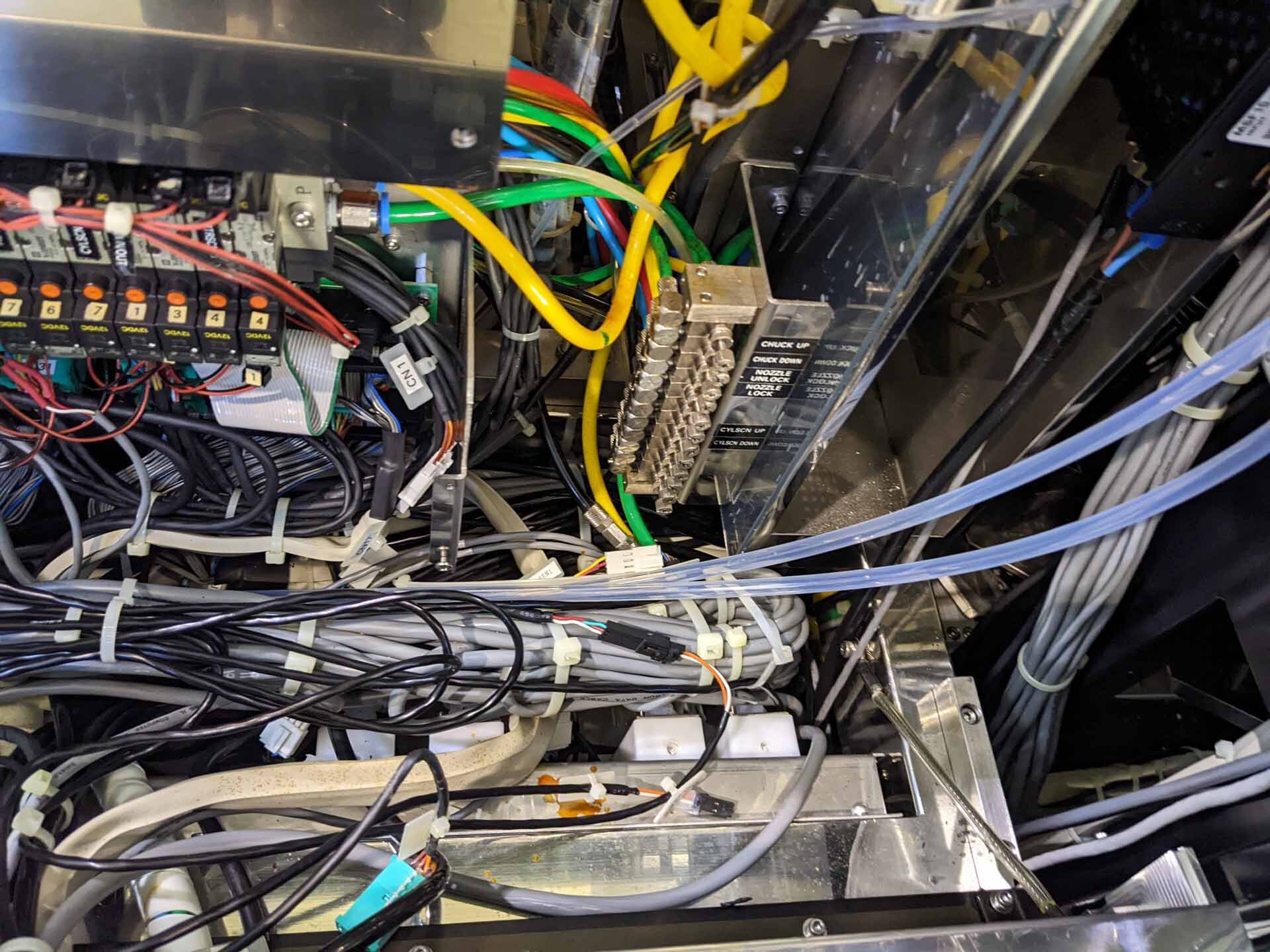

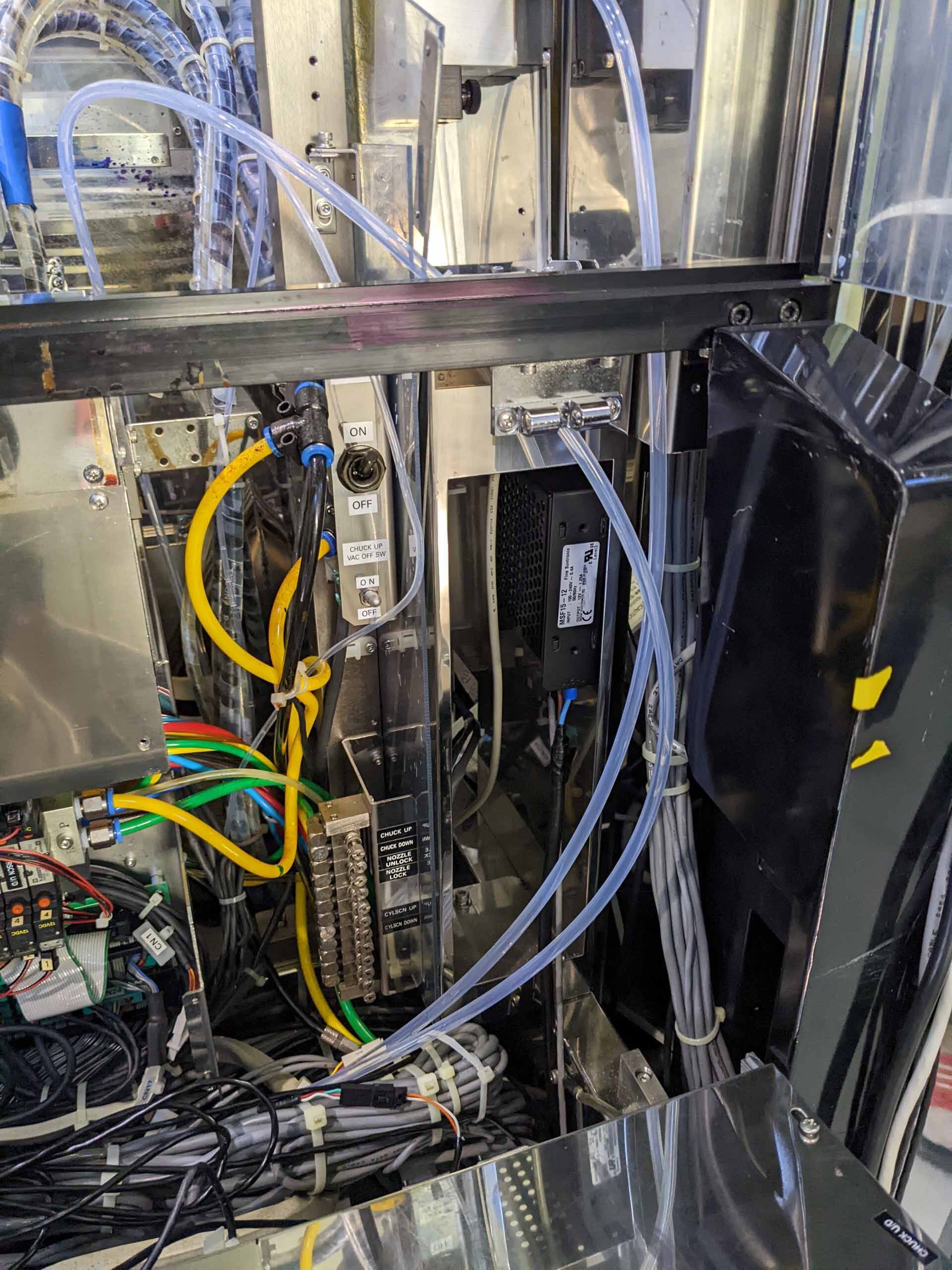

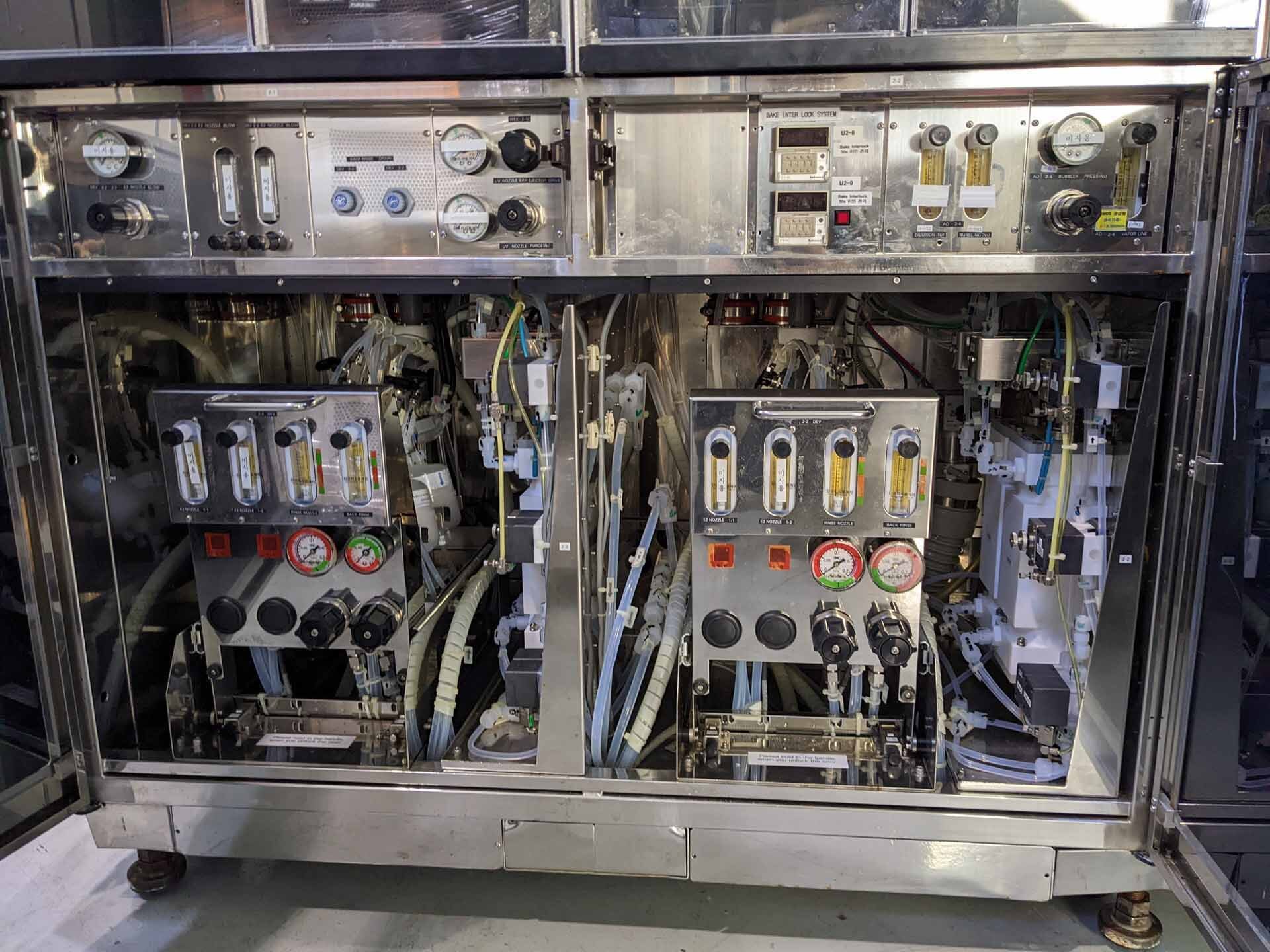

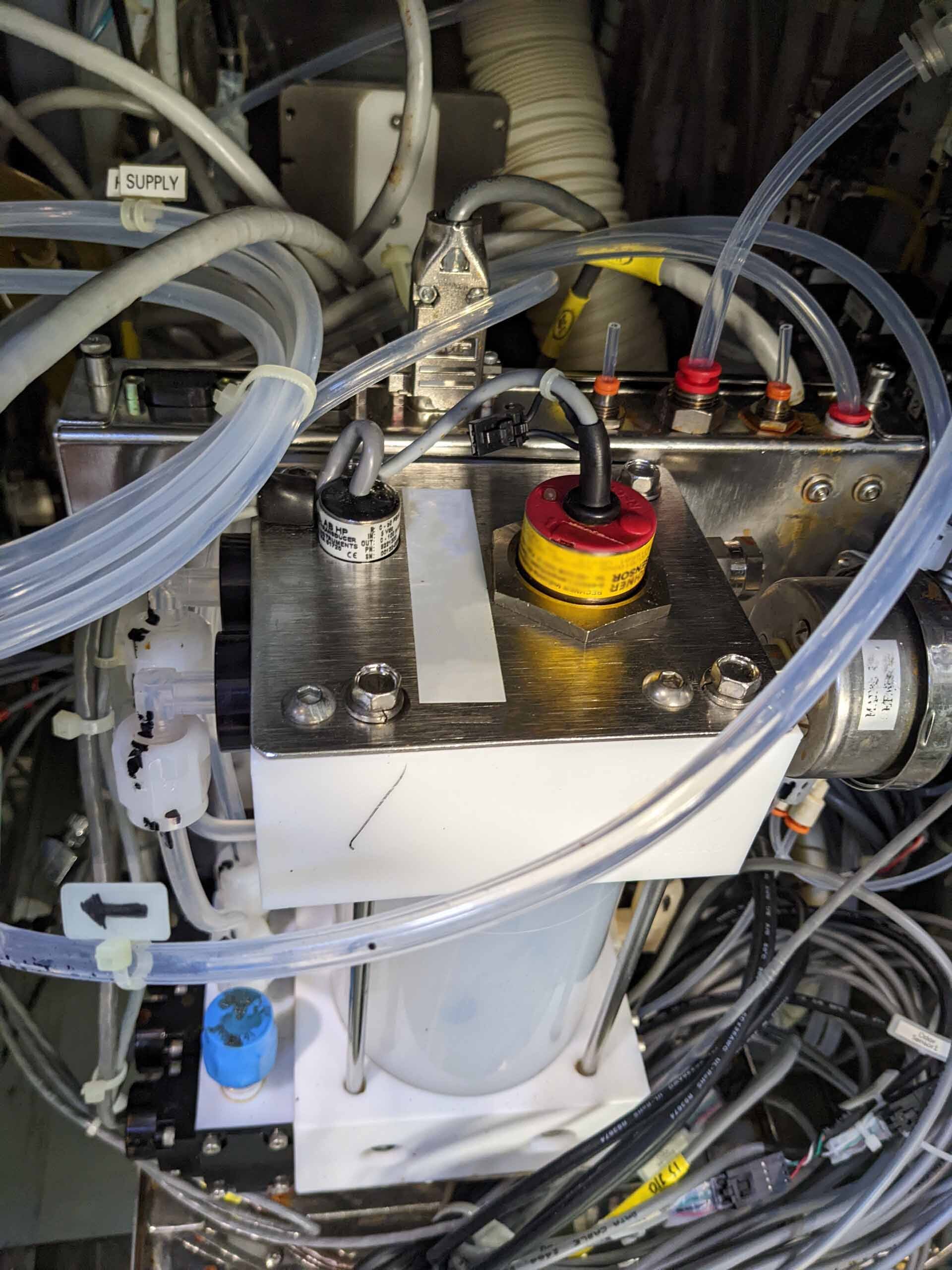

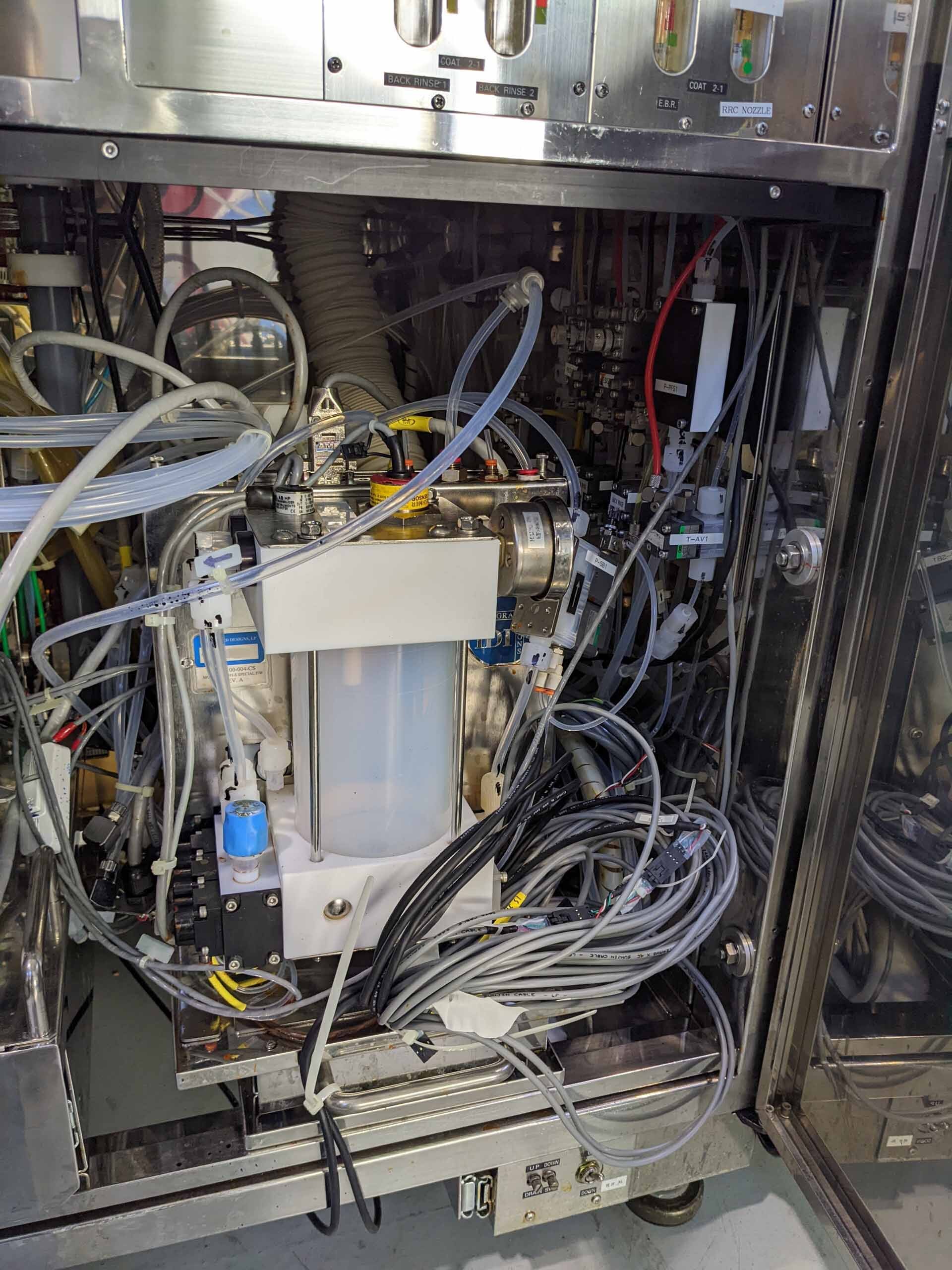

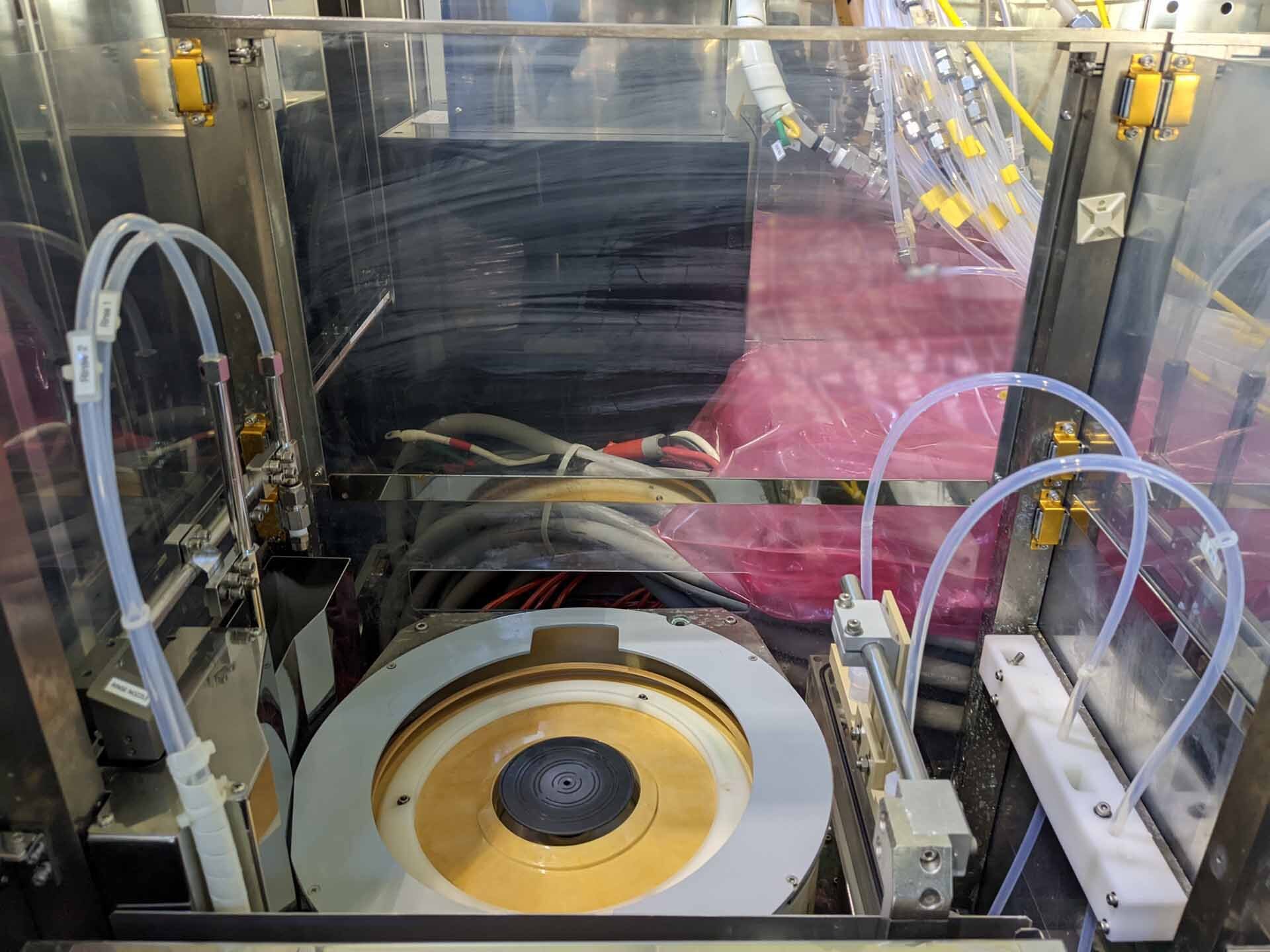

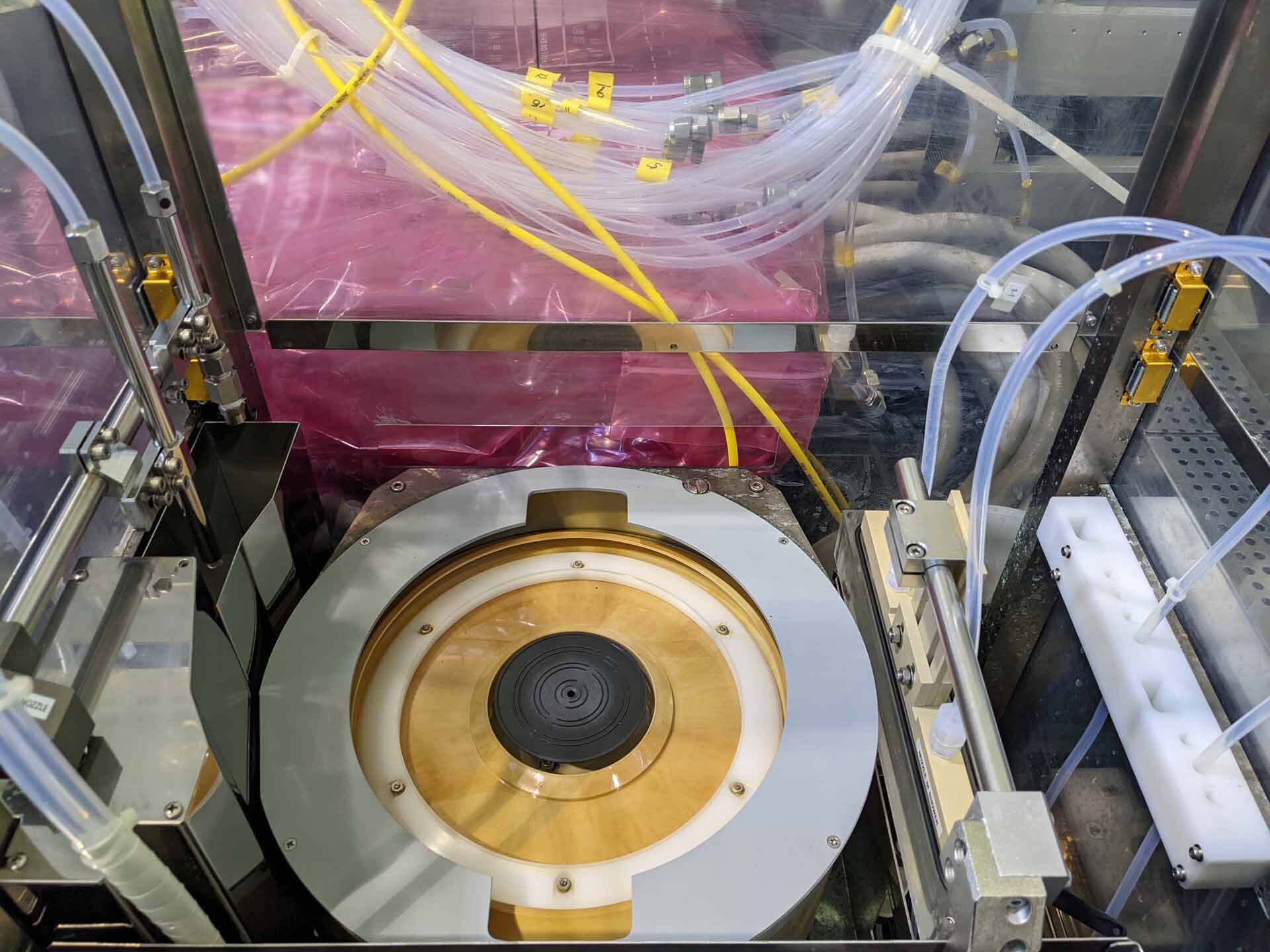

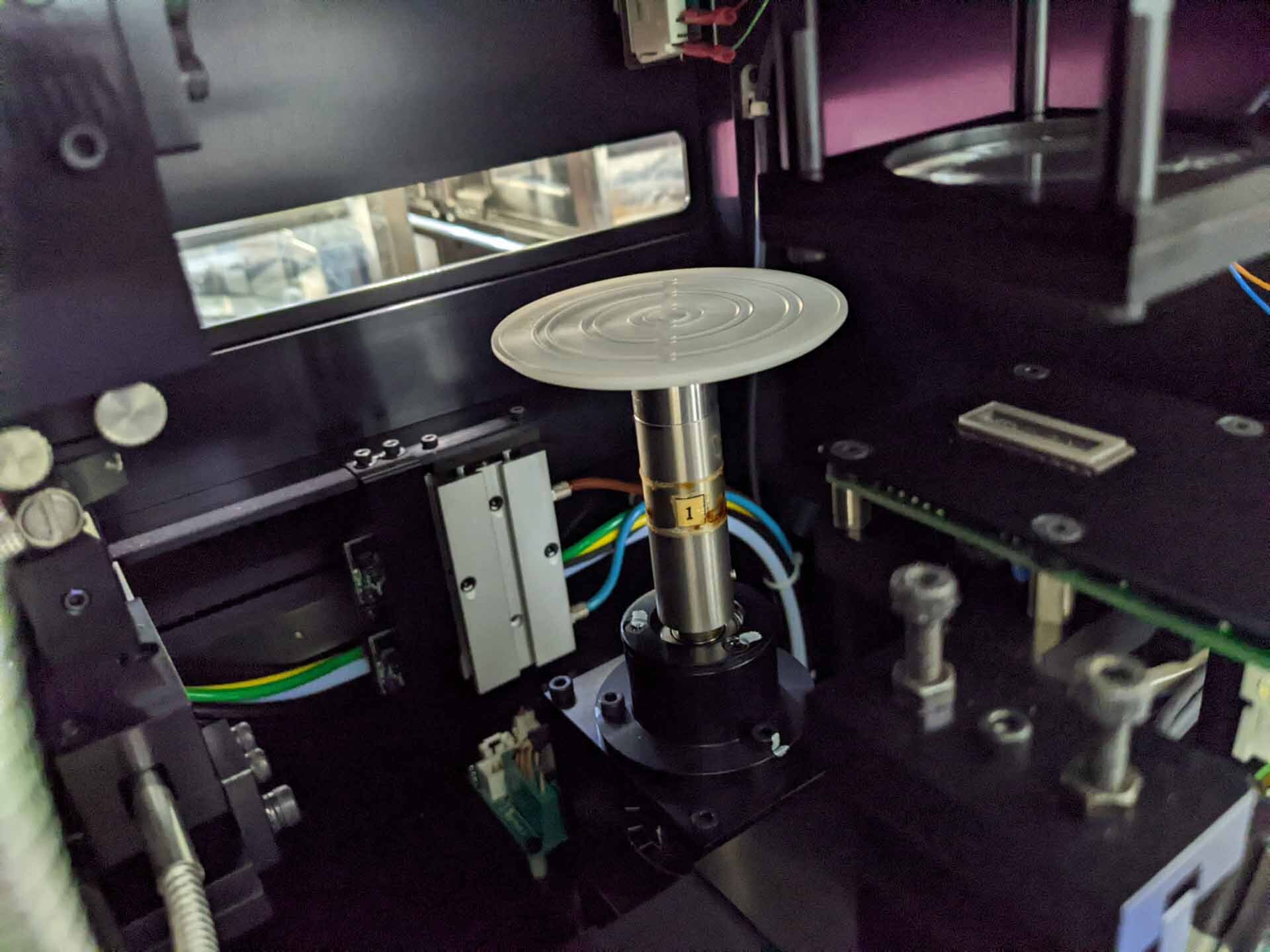

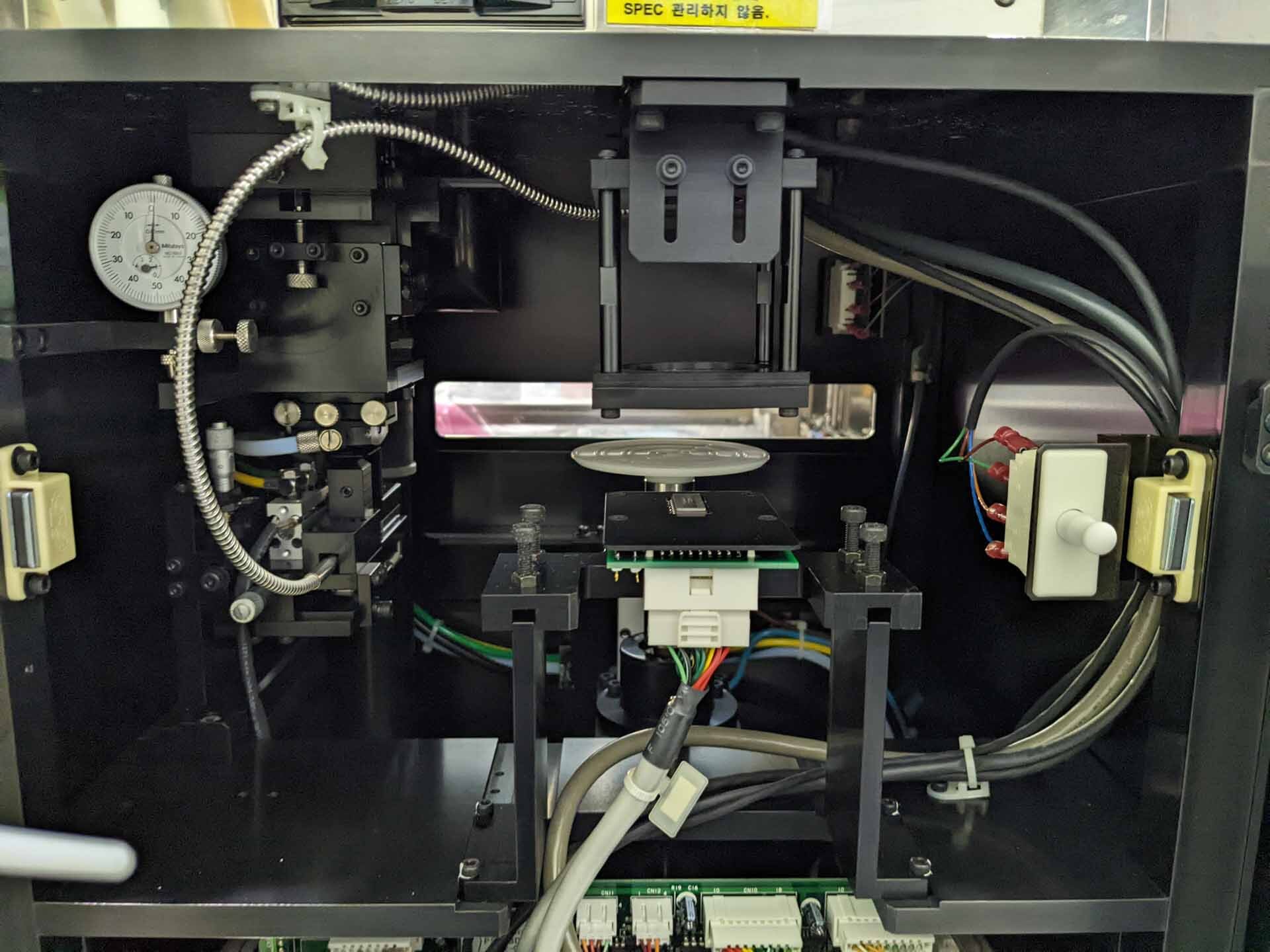

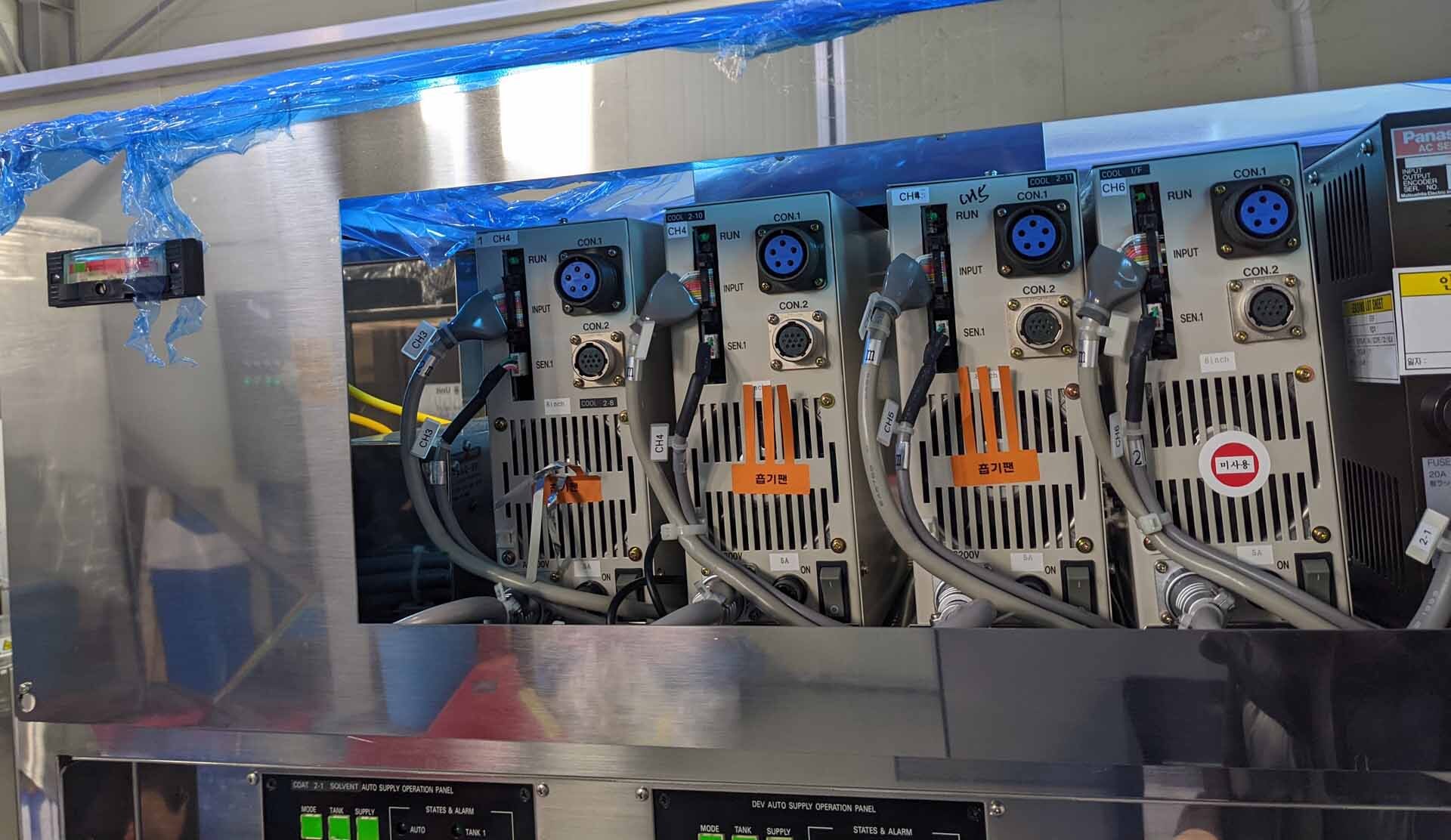

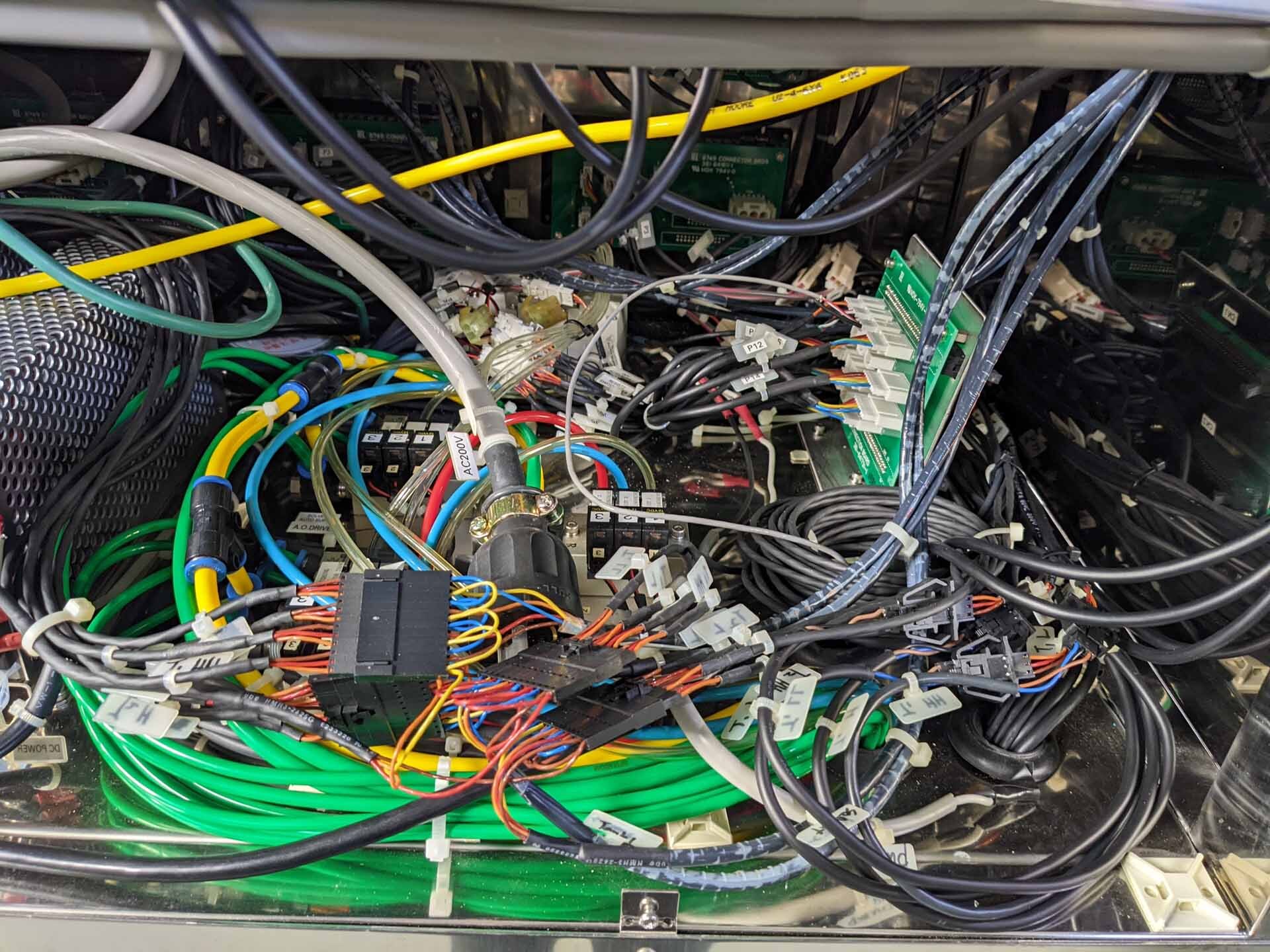

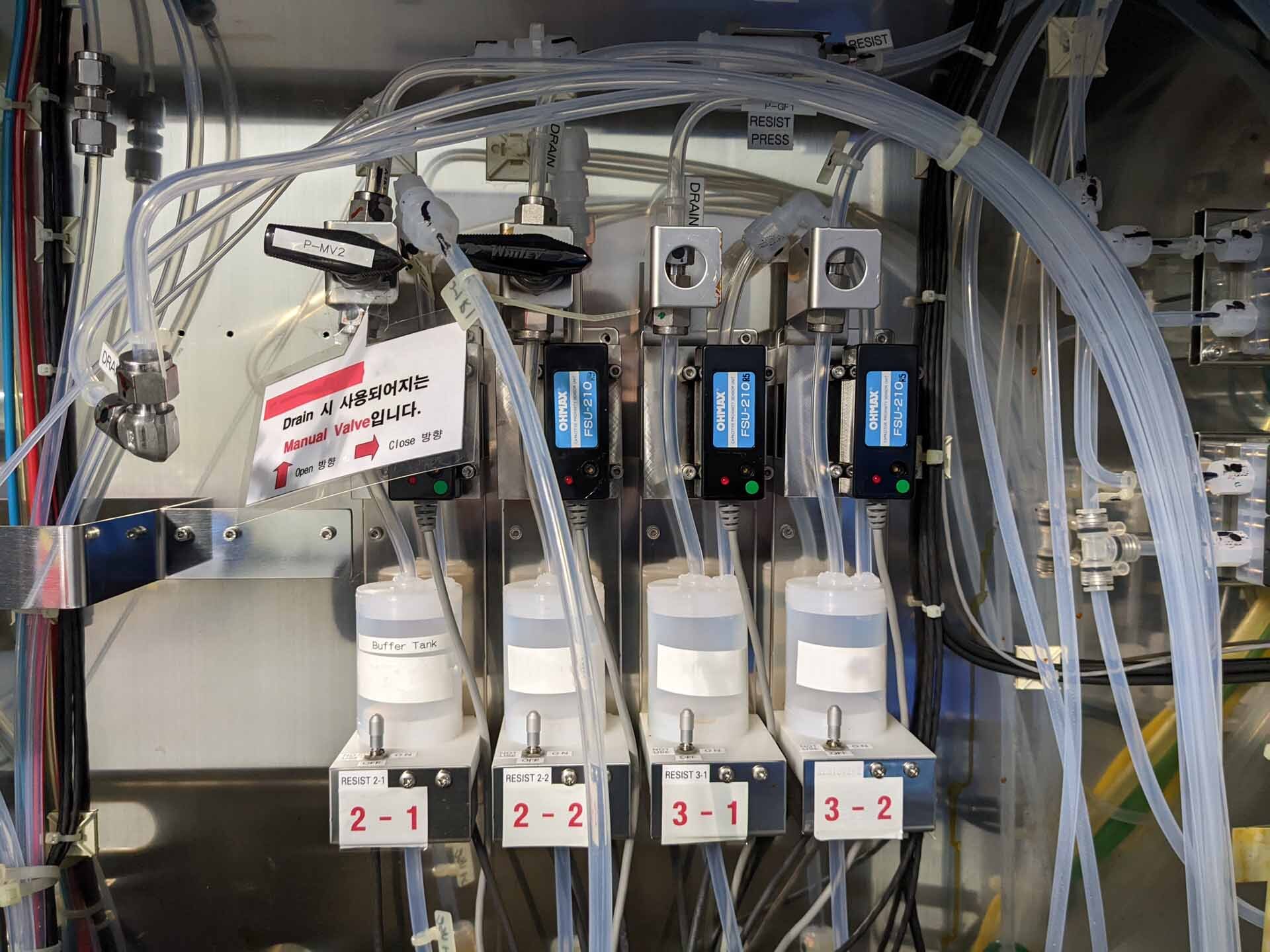

2-1 COT unit:

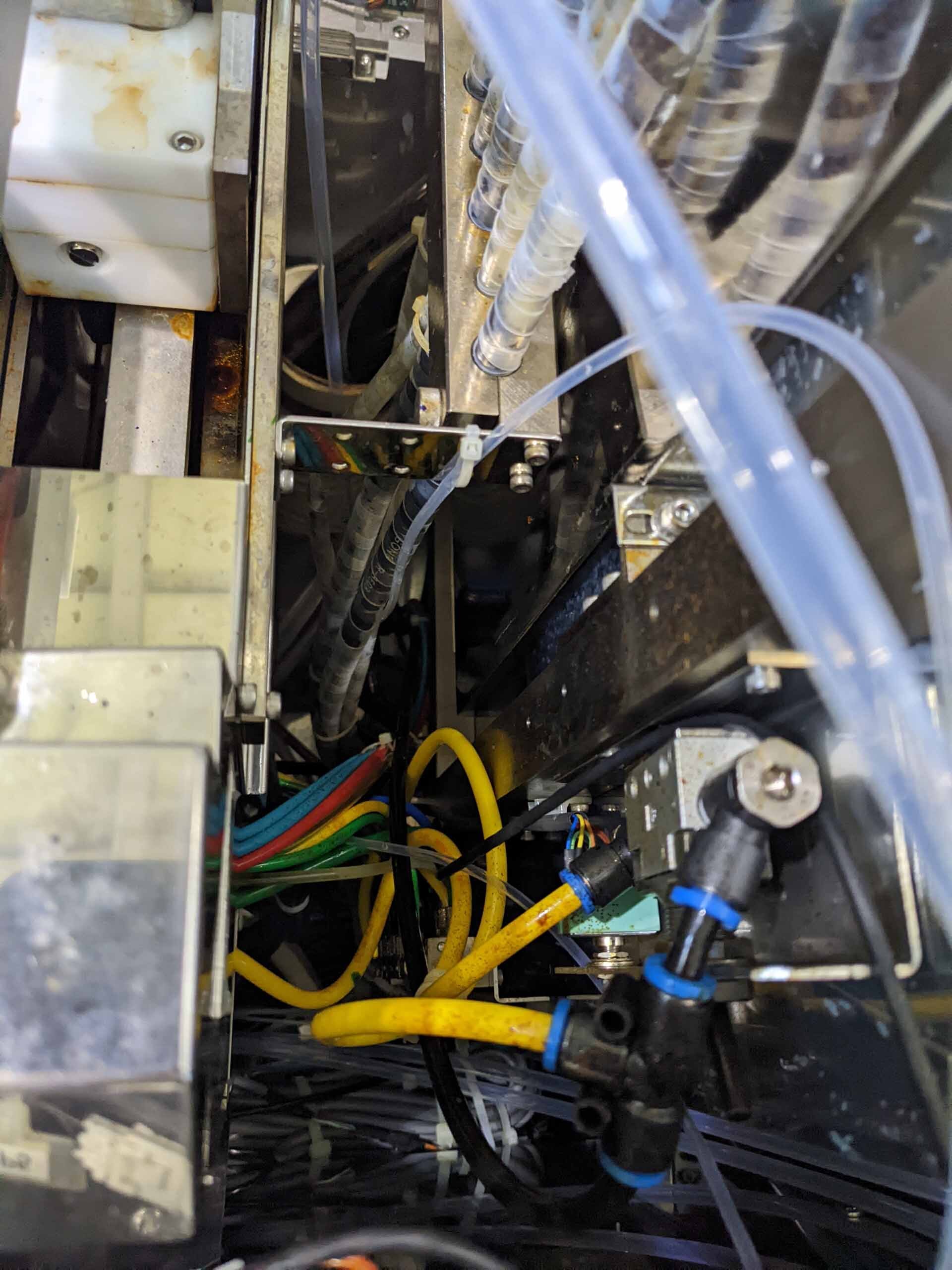

Resist dispense nozzle with HV pump

Side rinse nozzle

Dual back rinse nozzles

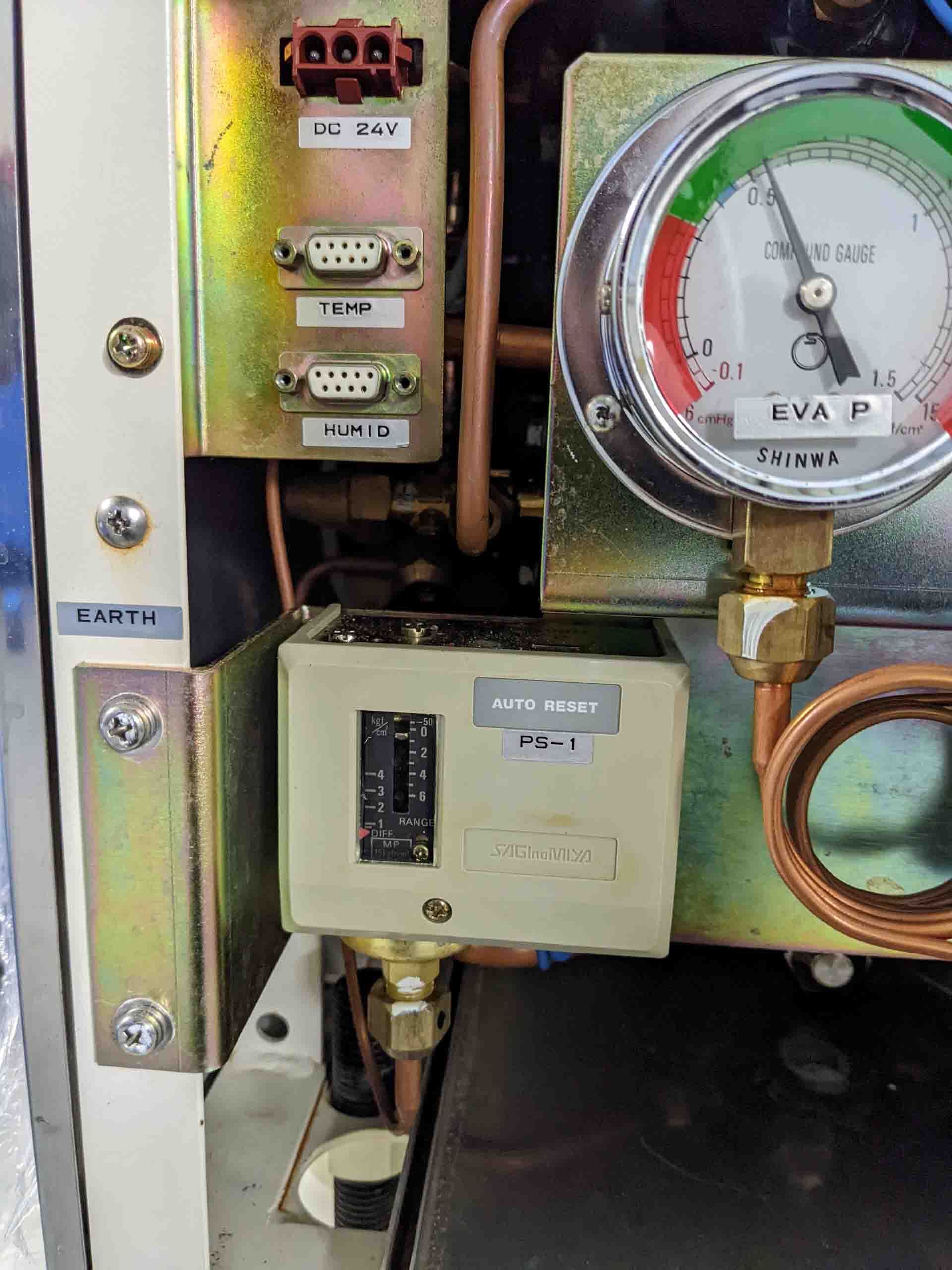

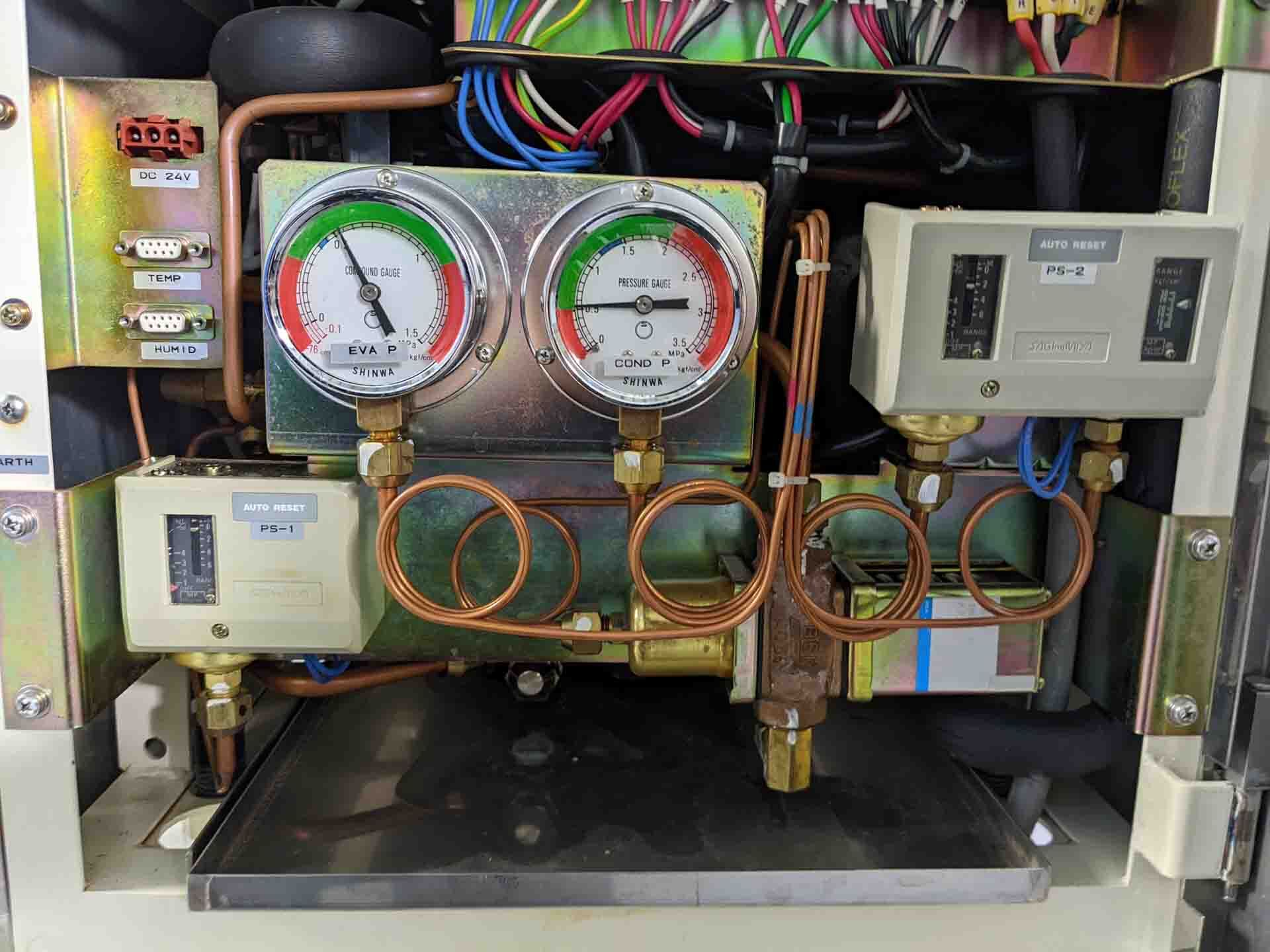

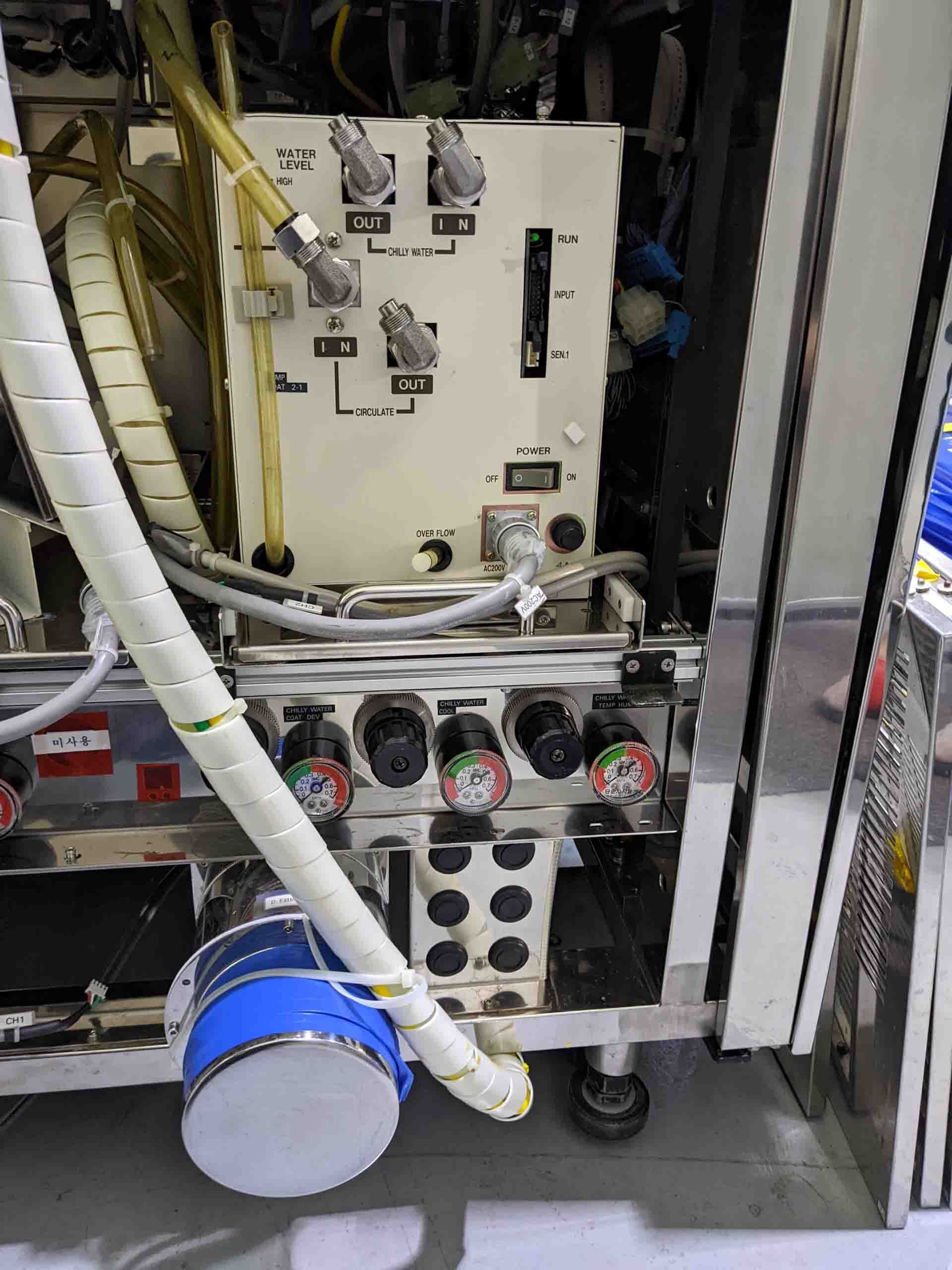

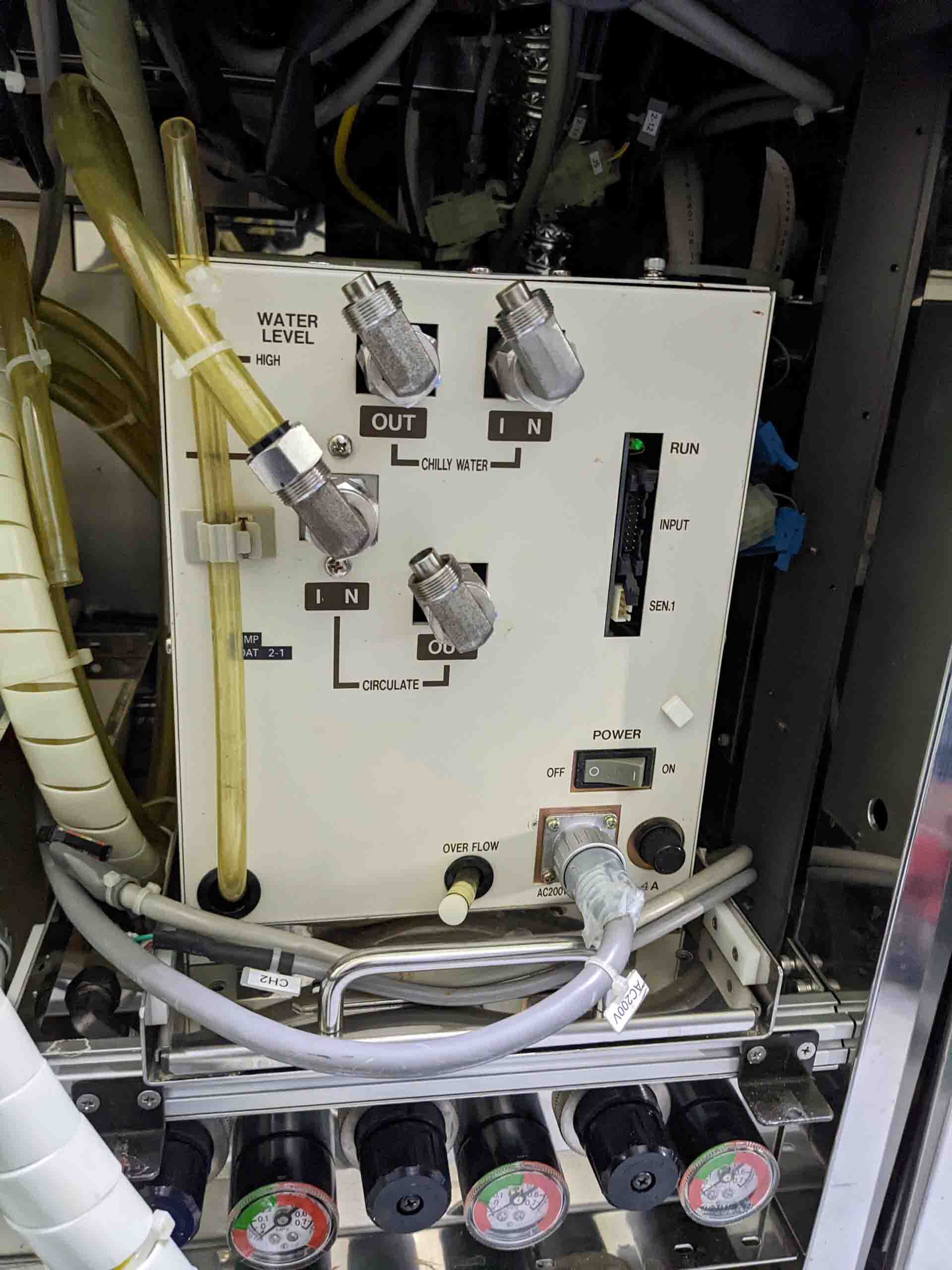

Photoresist temperature controller

Motor flange temperature controller

Direct gravity drain type

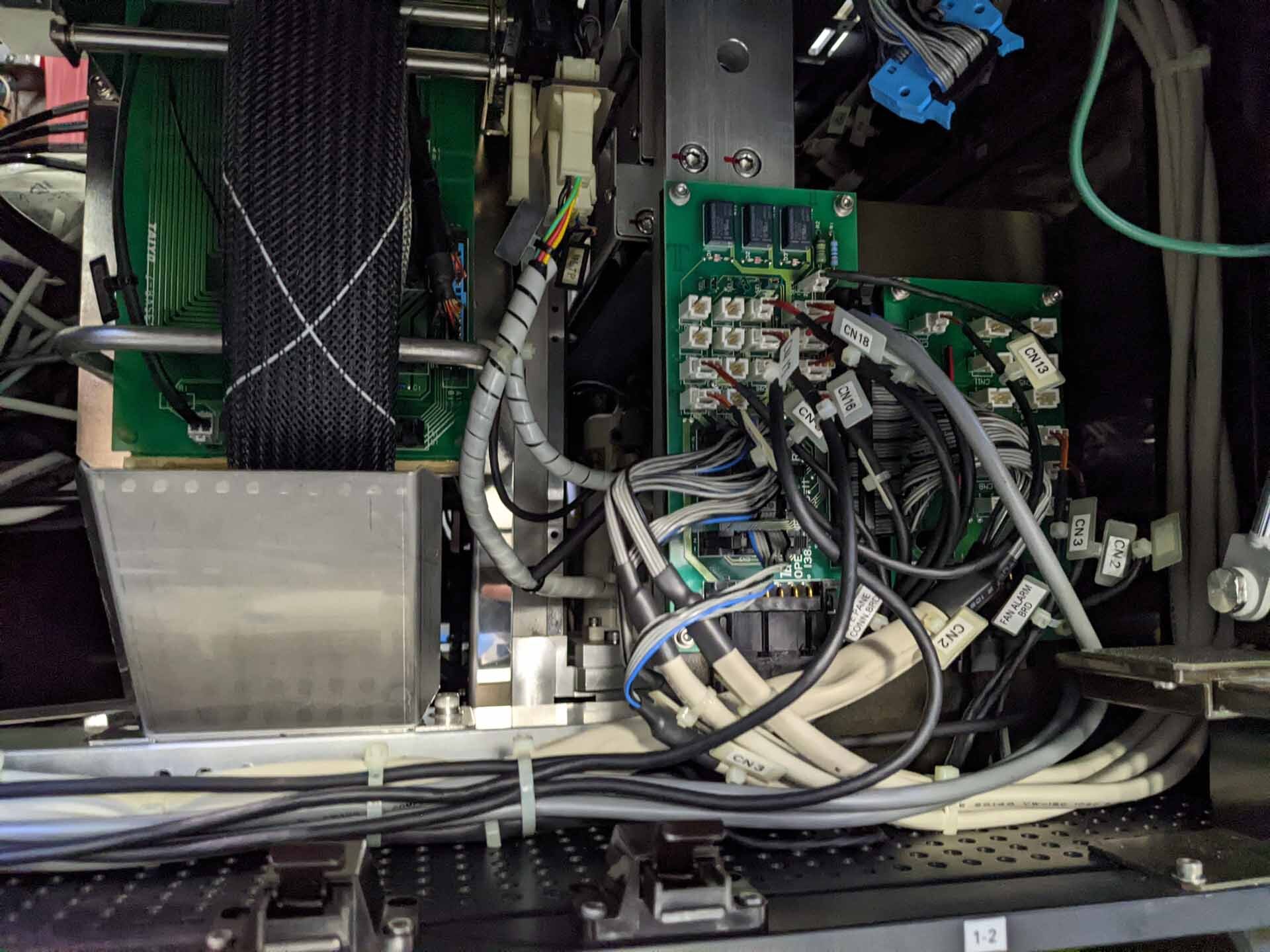

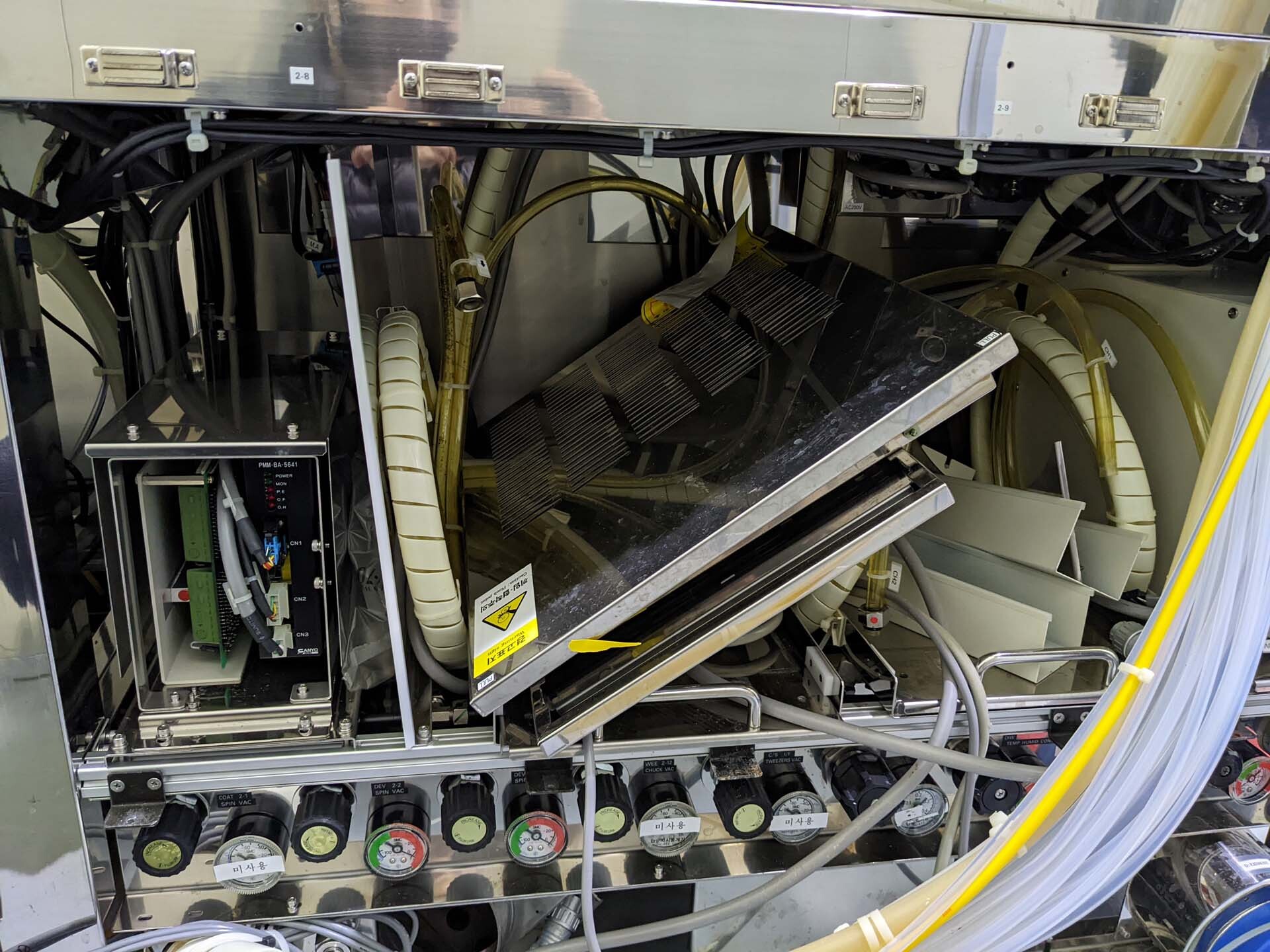

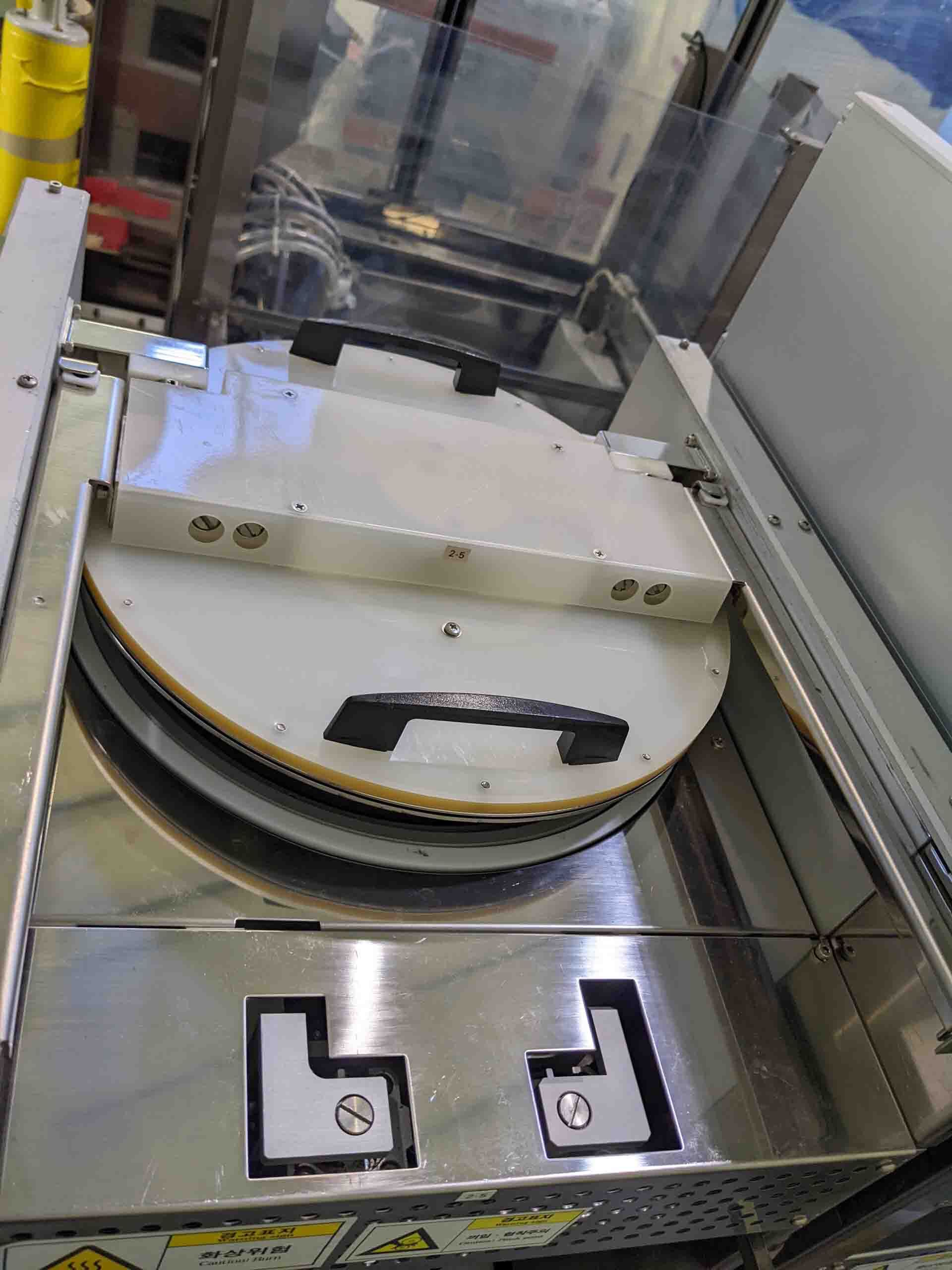

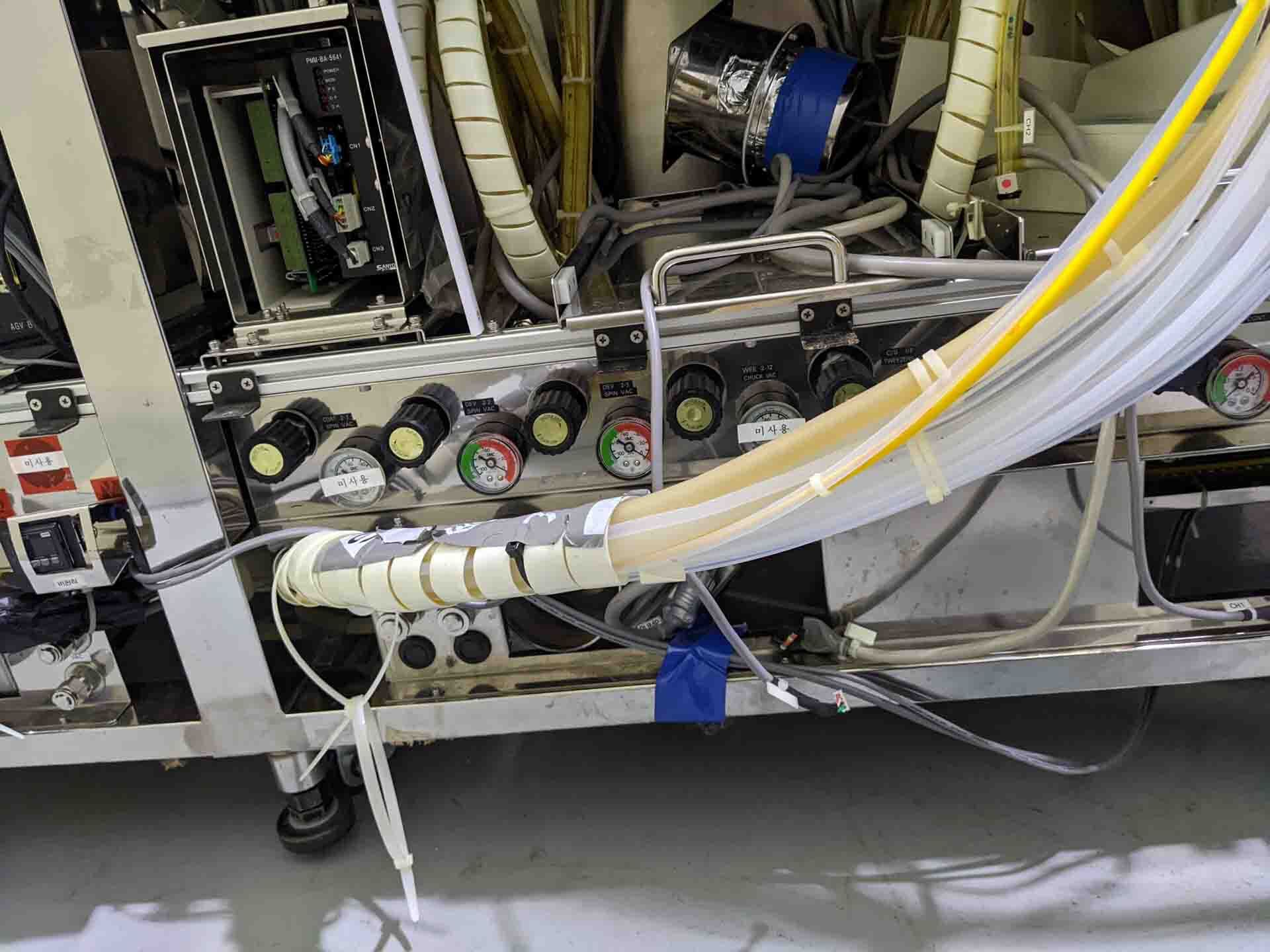

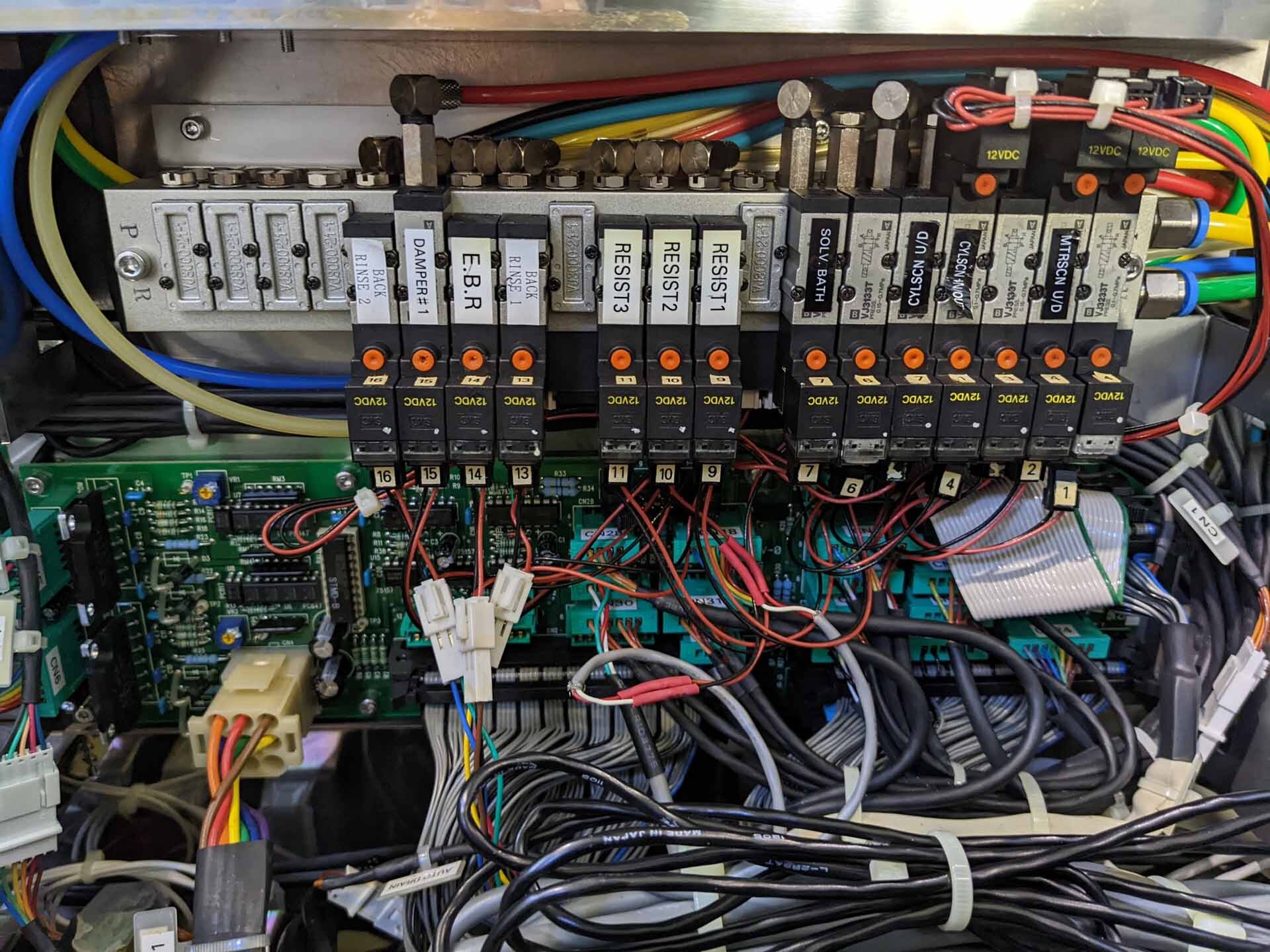

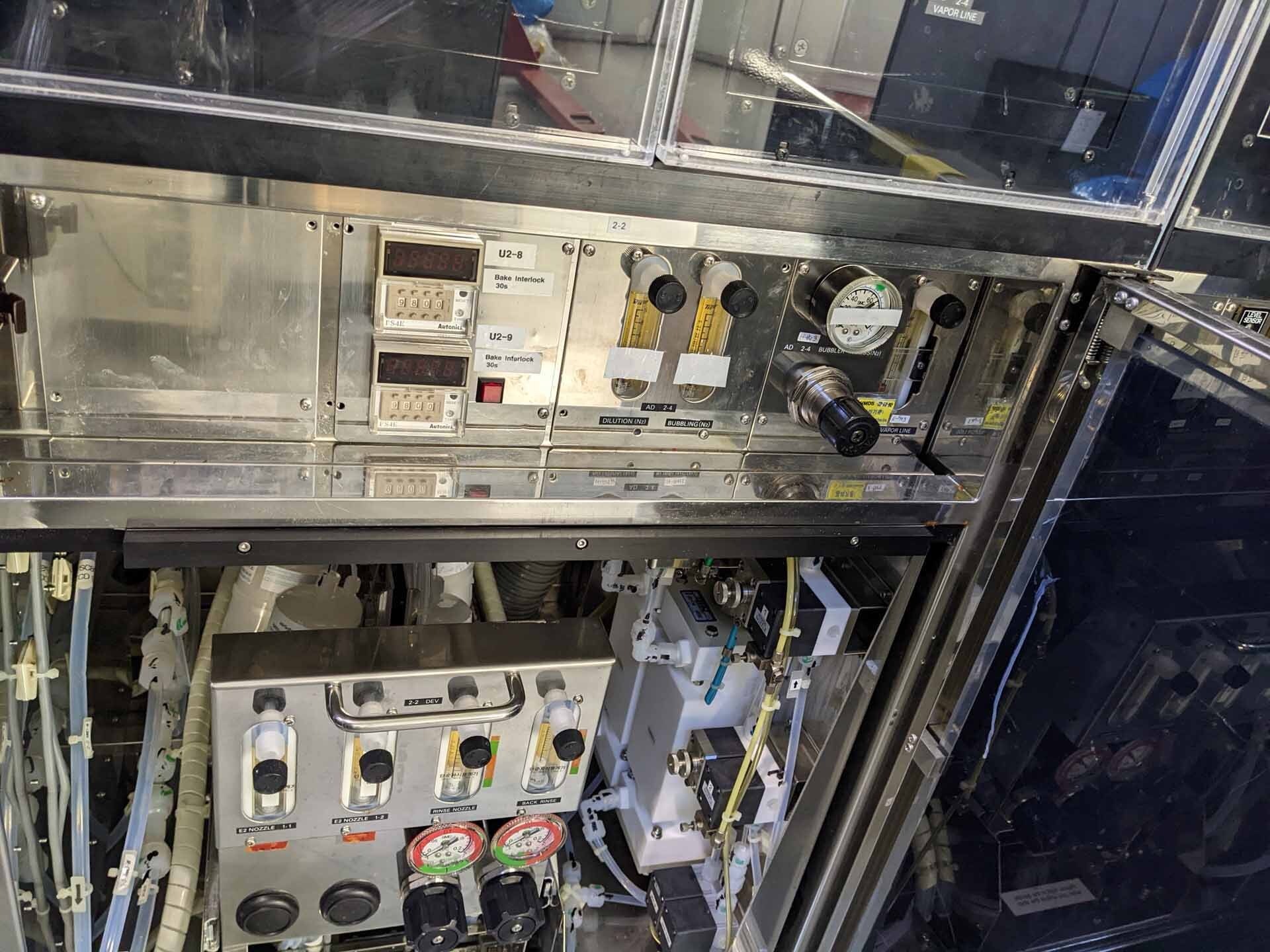

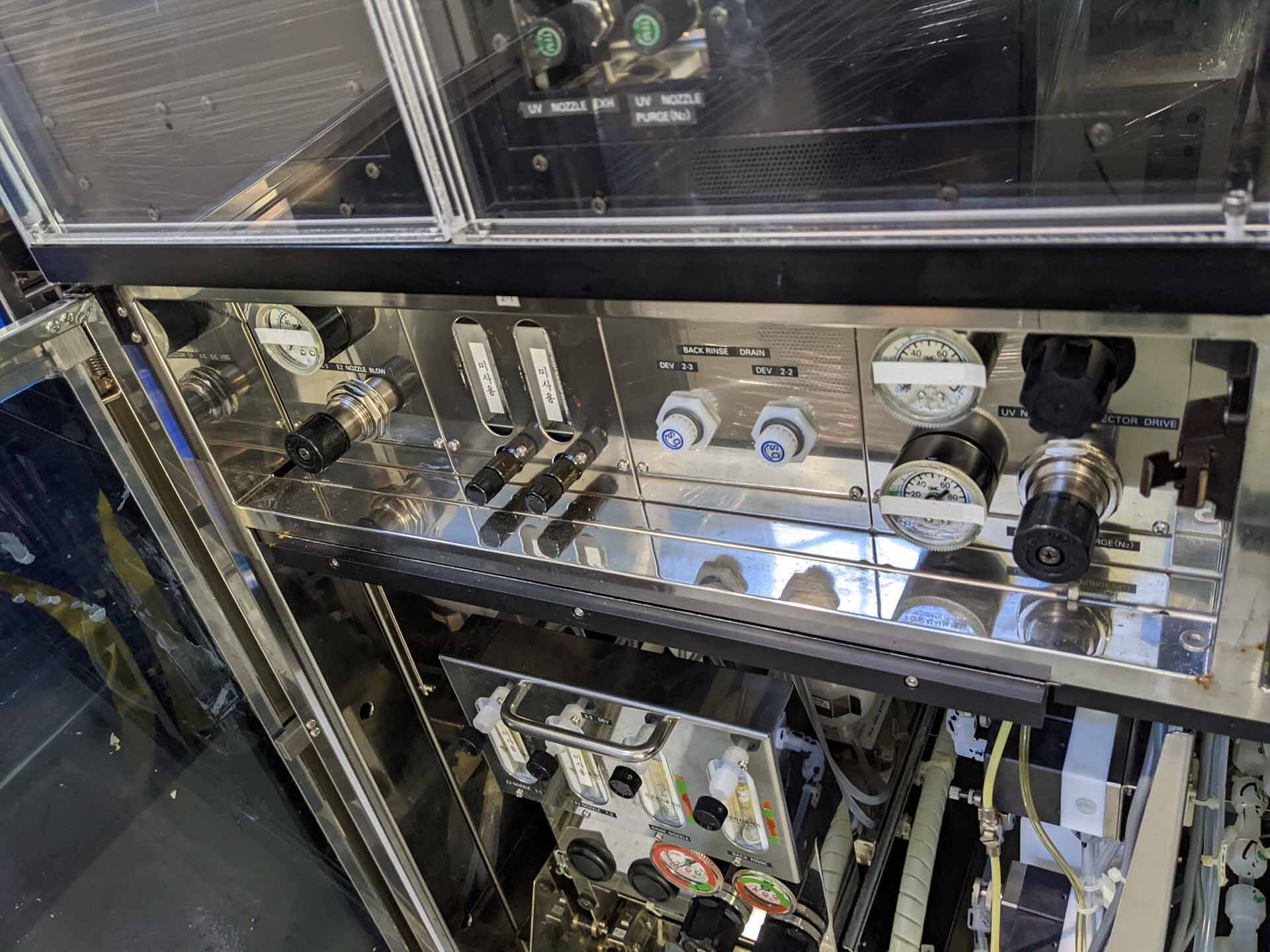

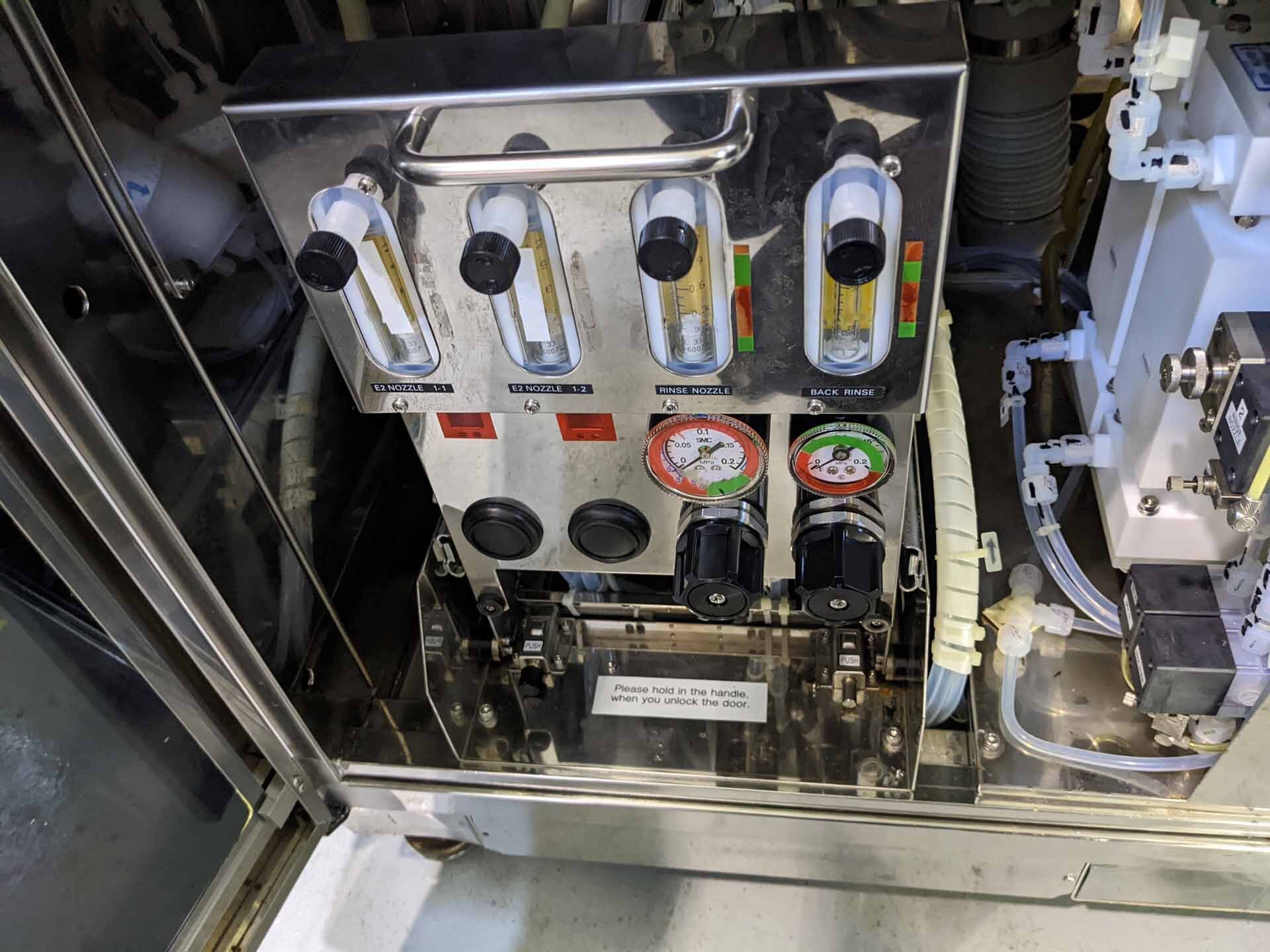

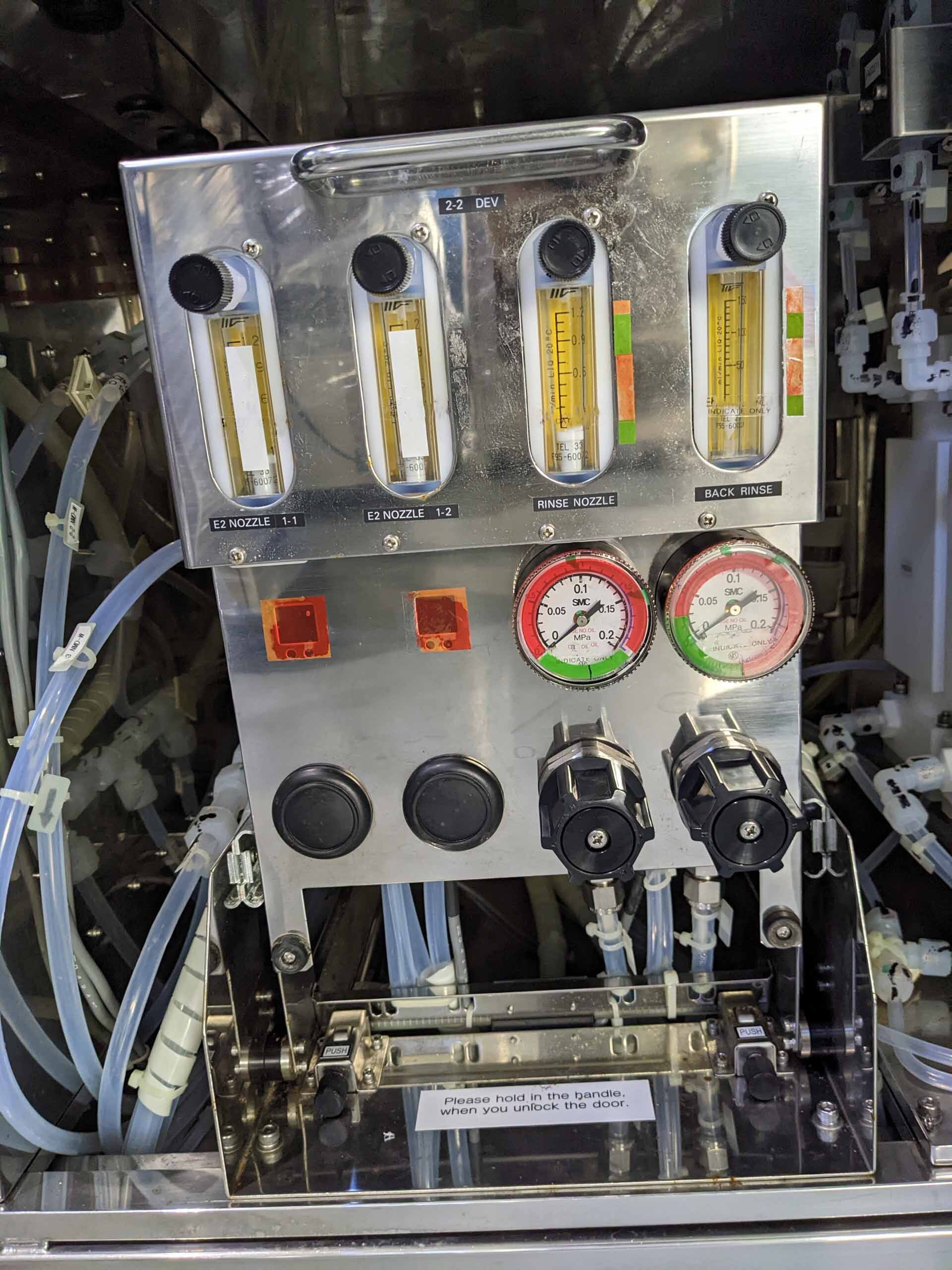

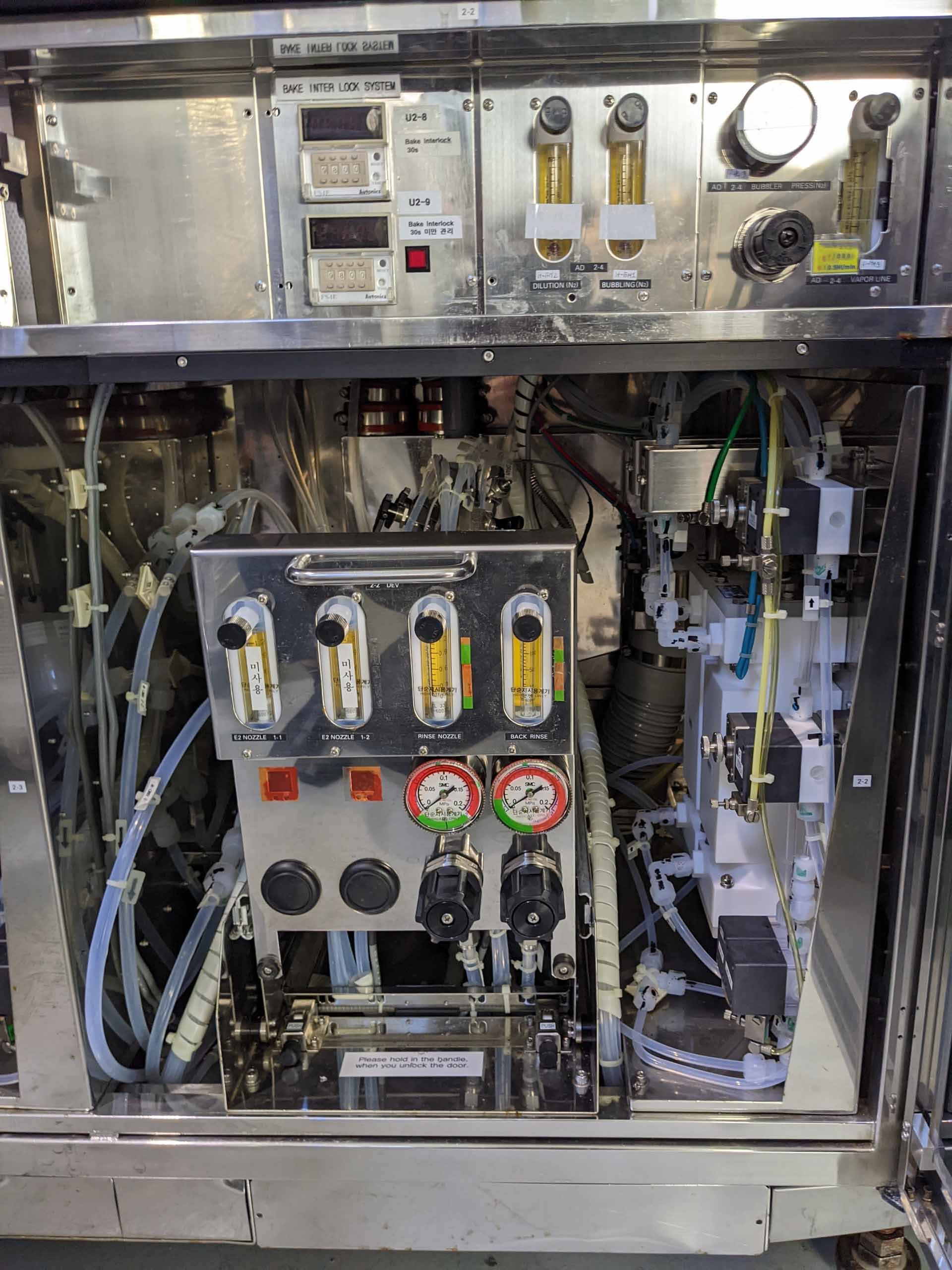

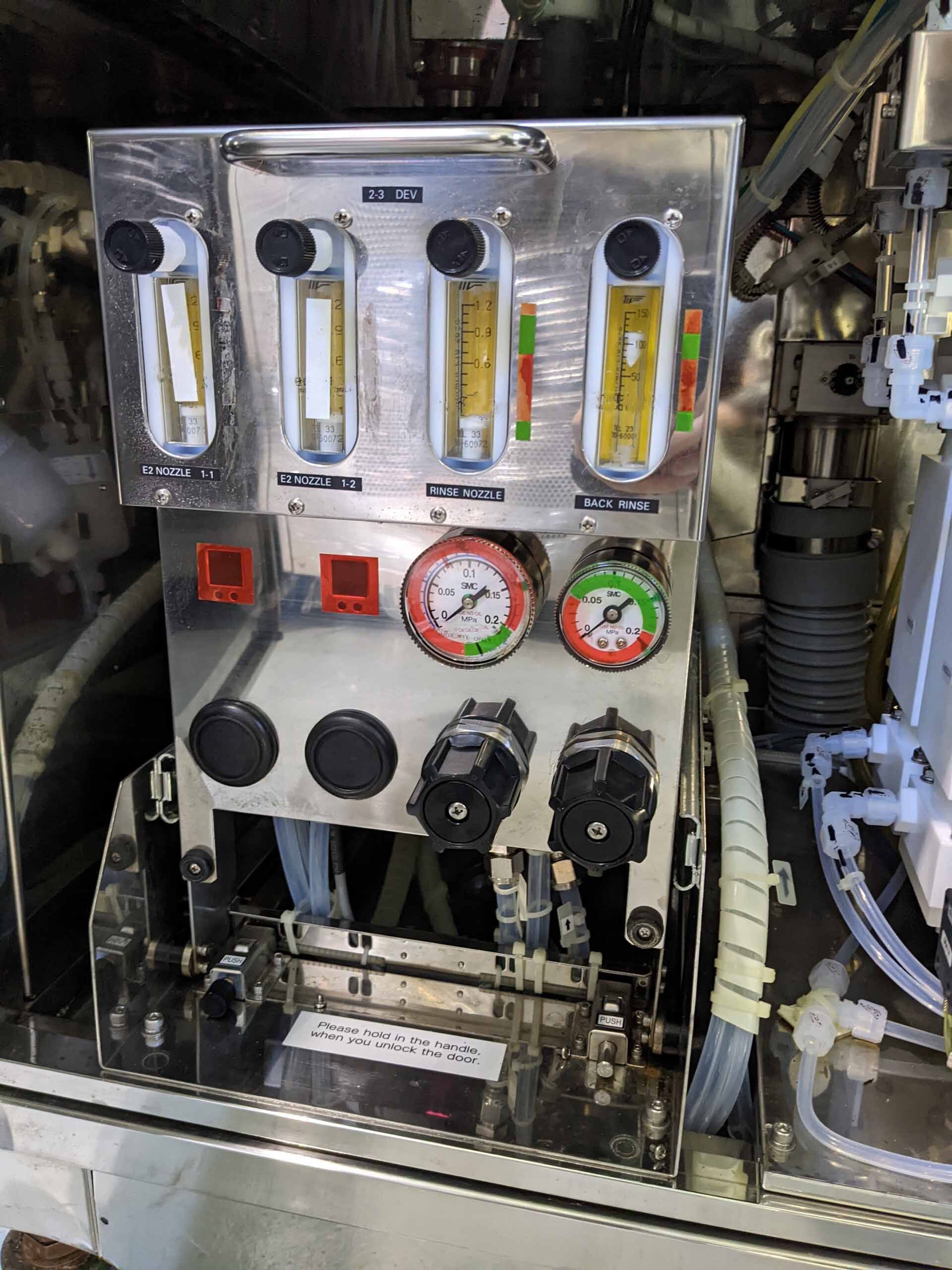

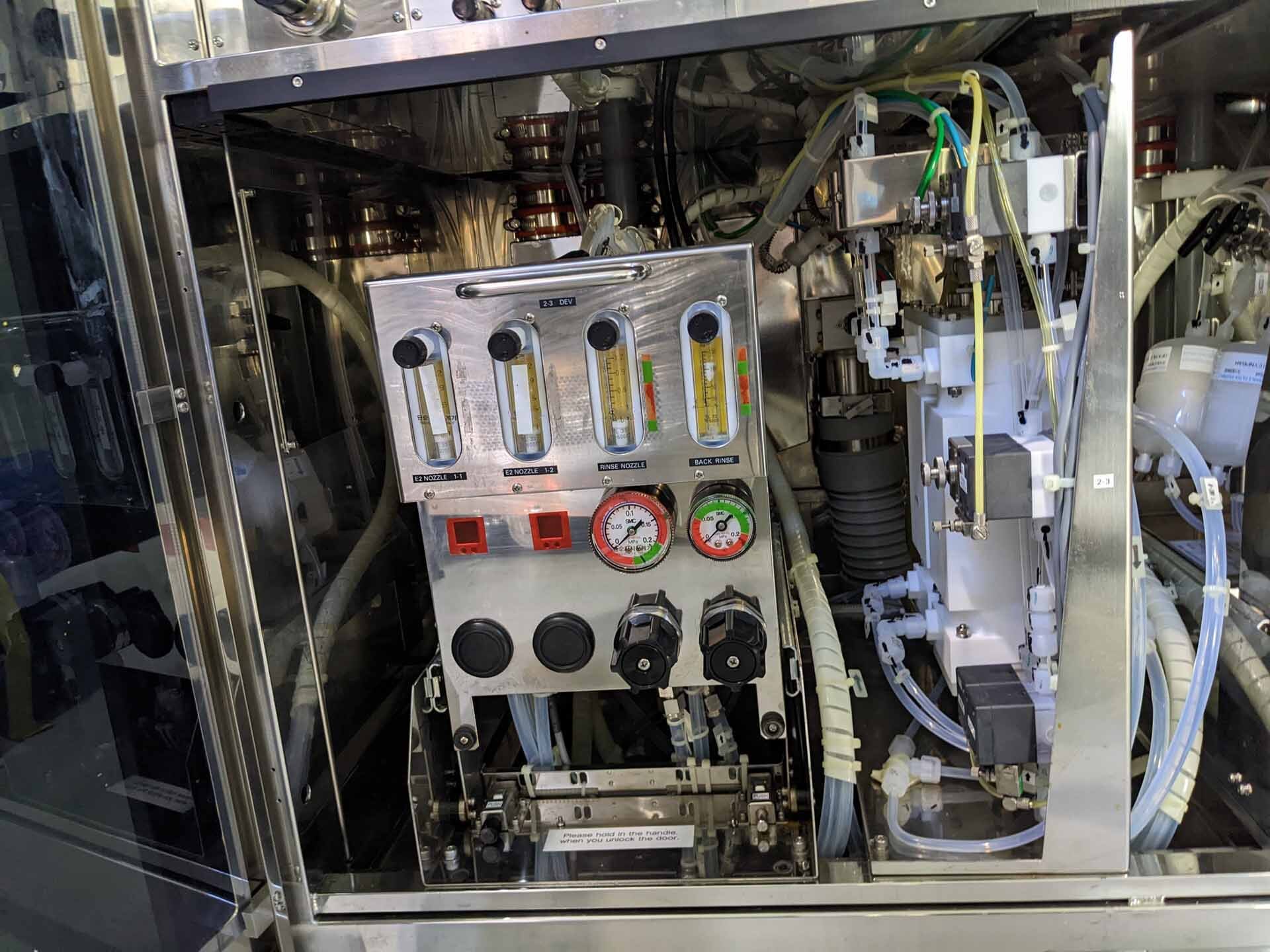

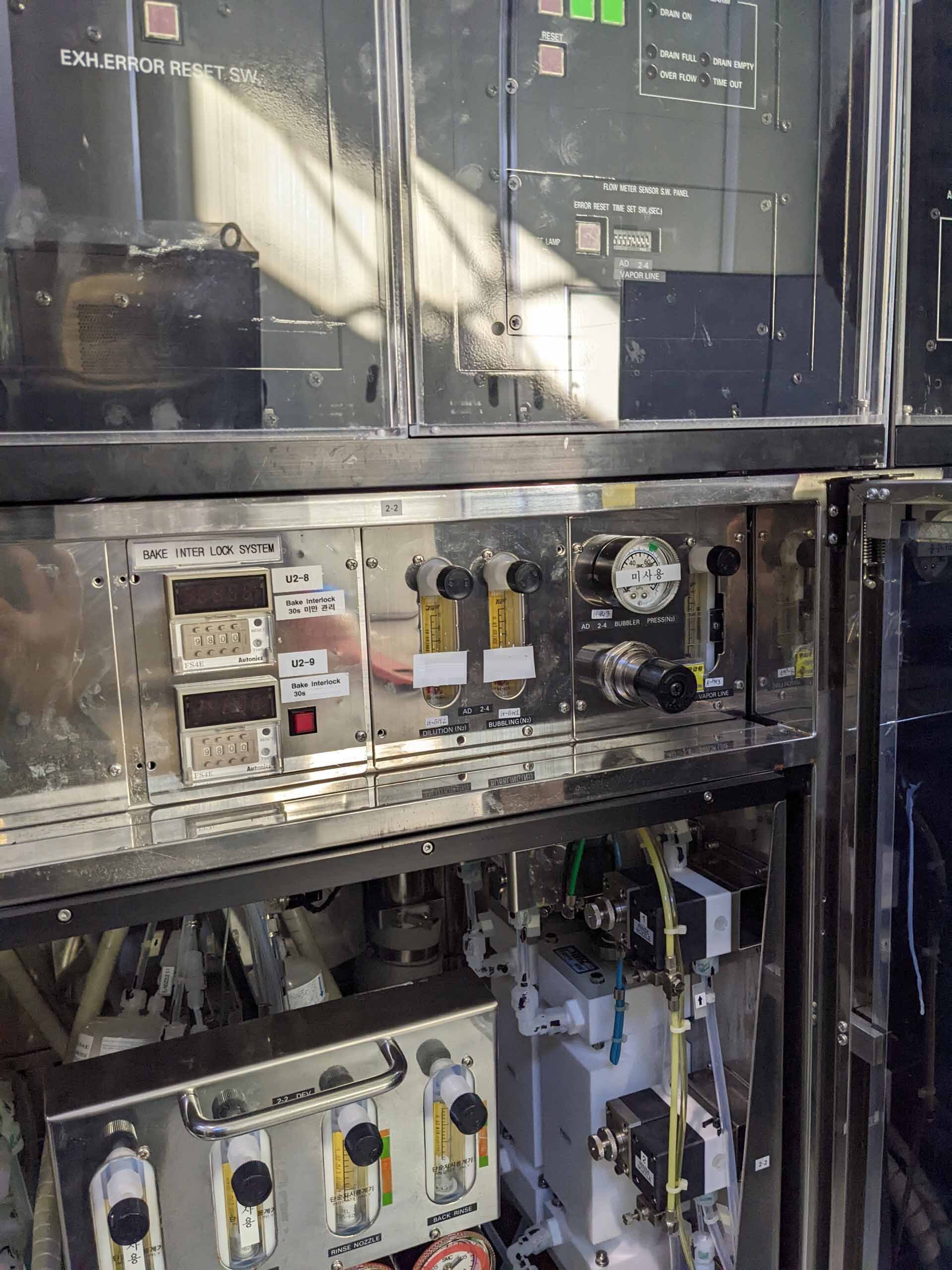

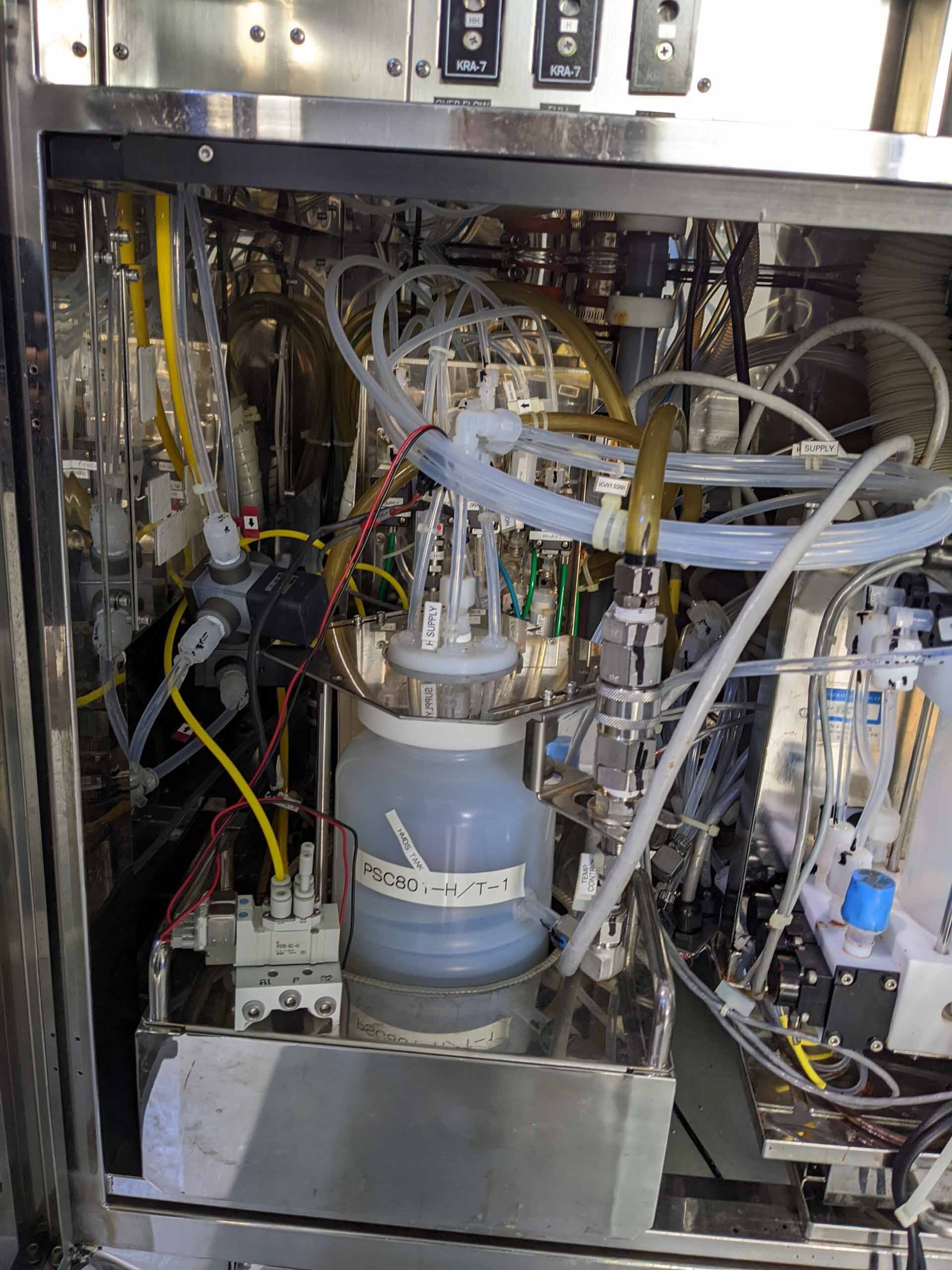

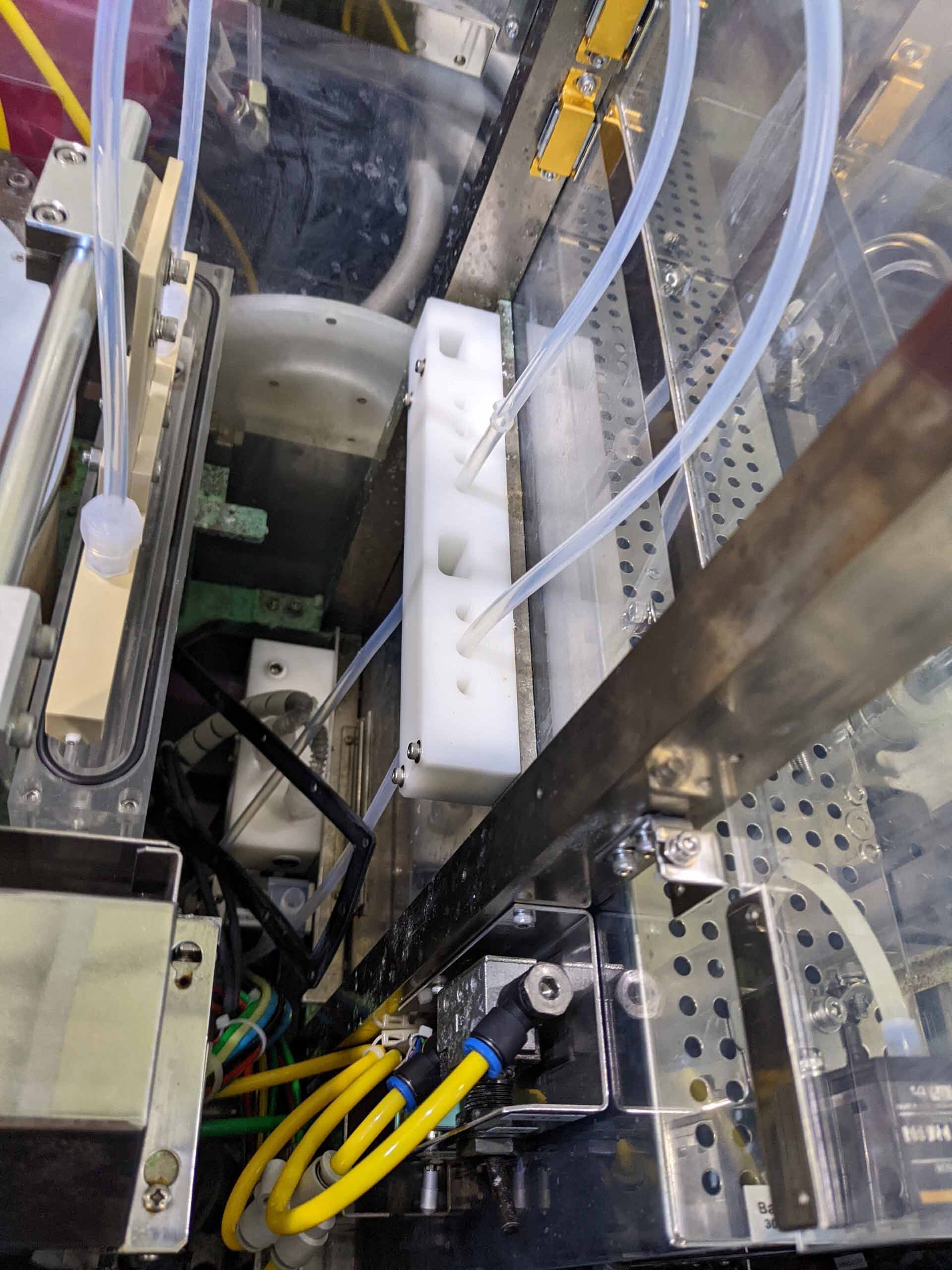

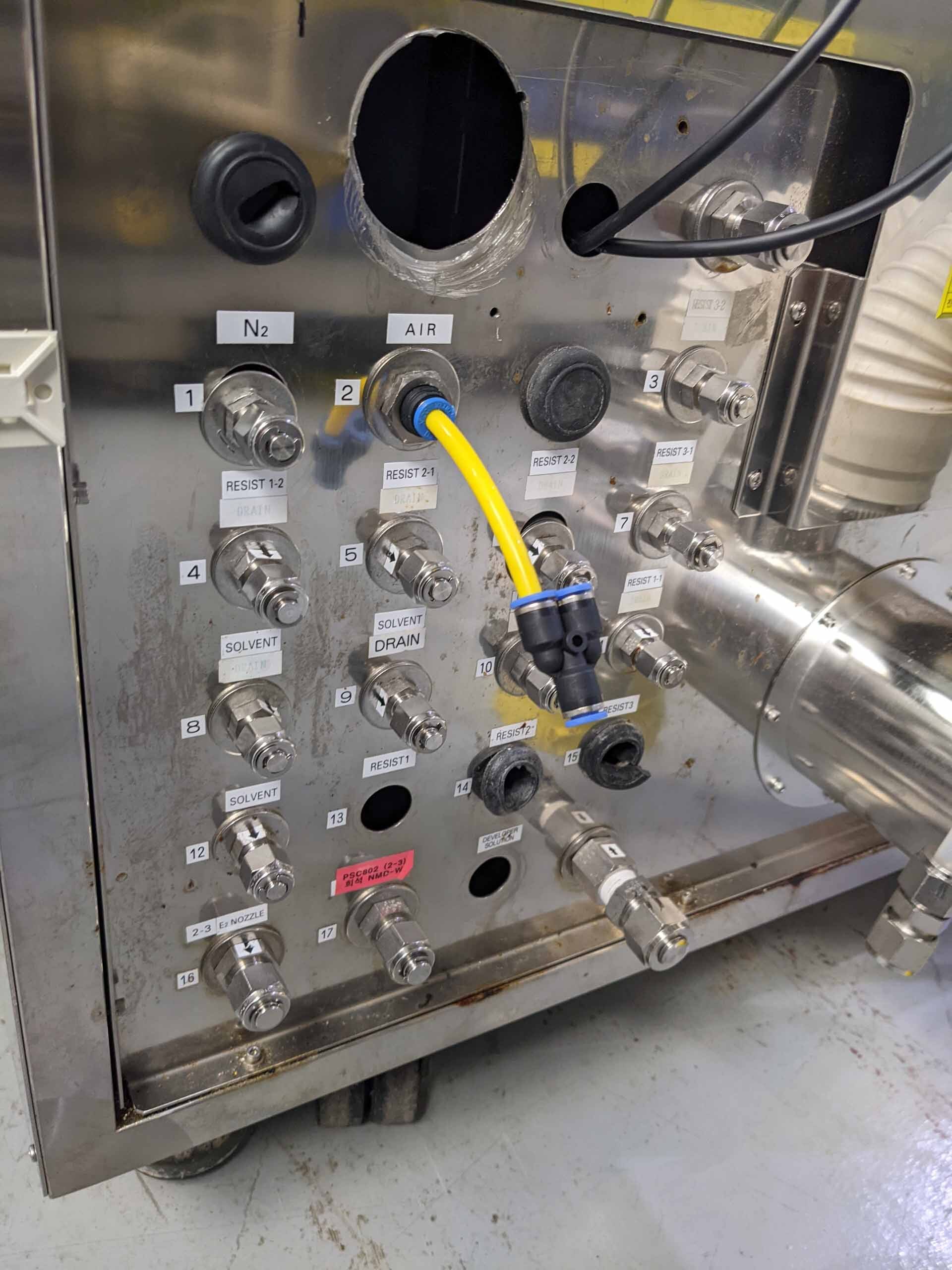

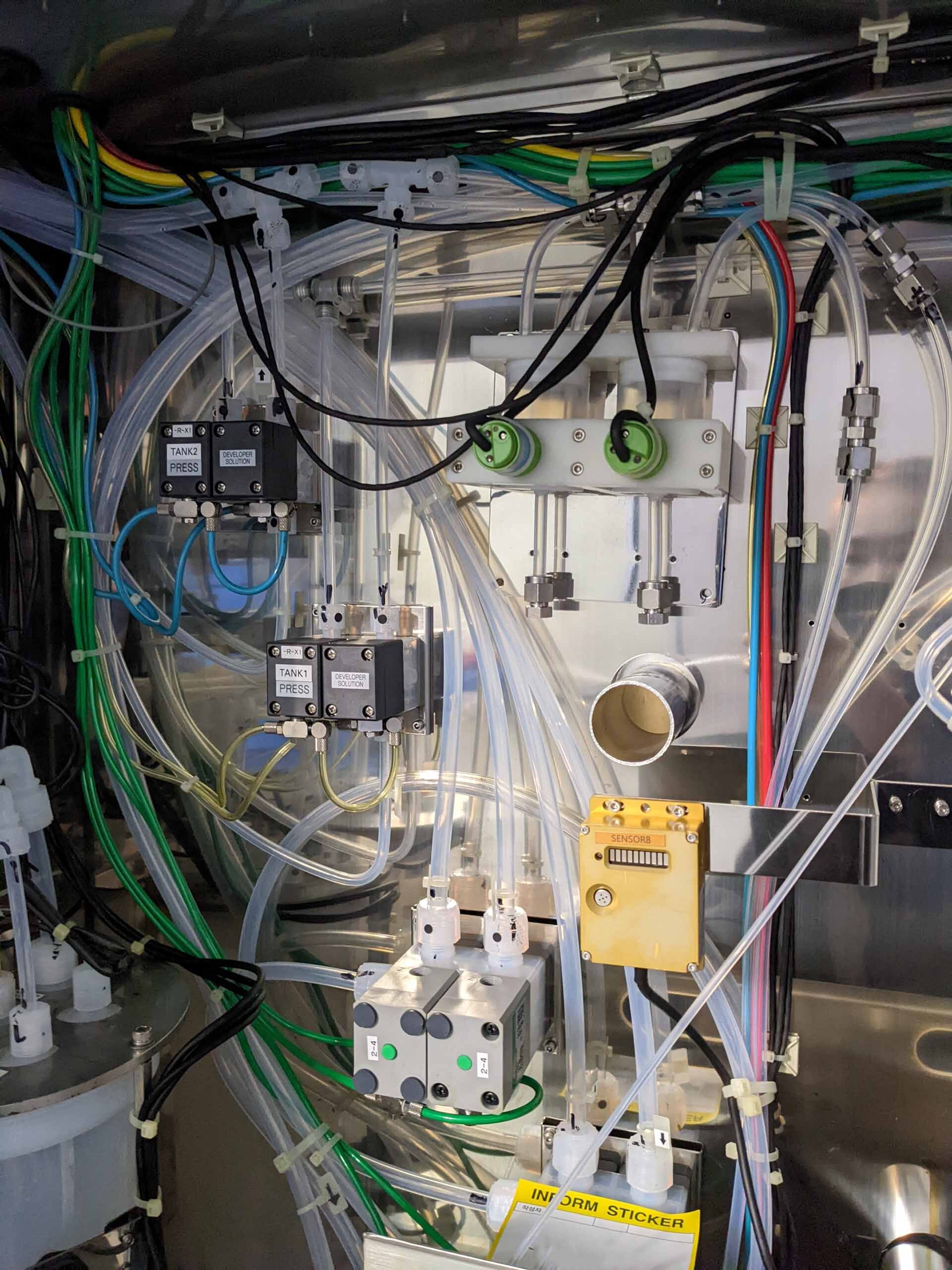

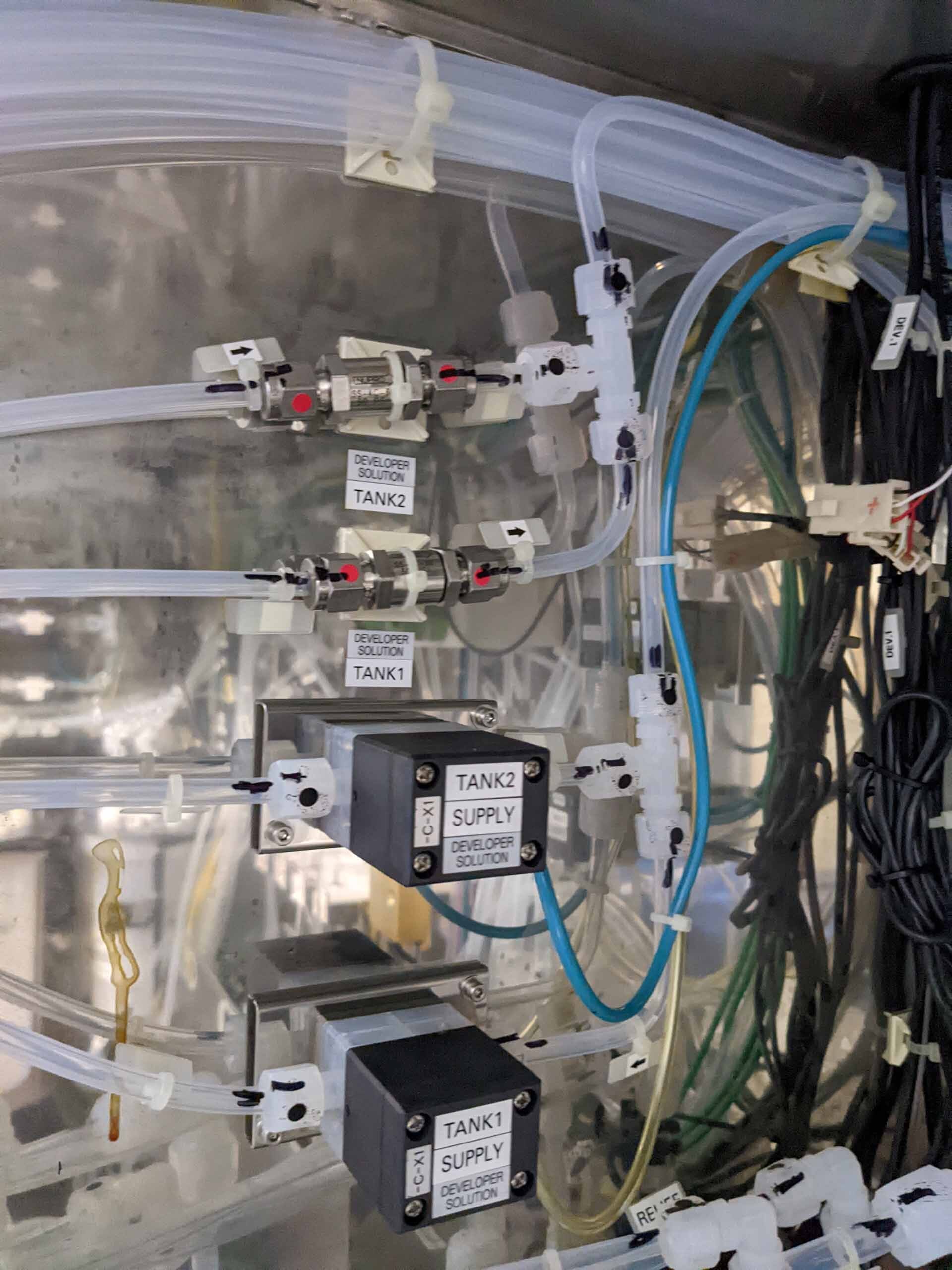

2-2 / 2-3 DEV unit:

Stream nozzle

Dual D.I top rinse nozzle

Dual back rinse nozzles

Motor flange temperature controller

Direct gravity drain type

Auto damper

Auto dummy dispenser

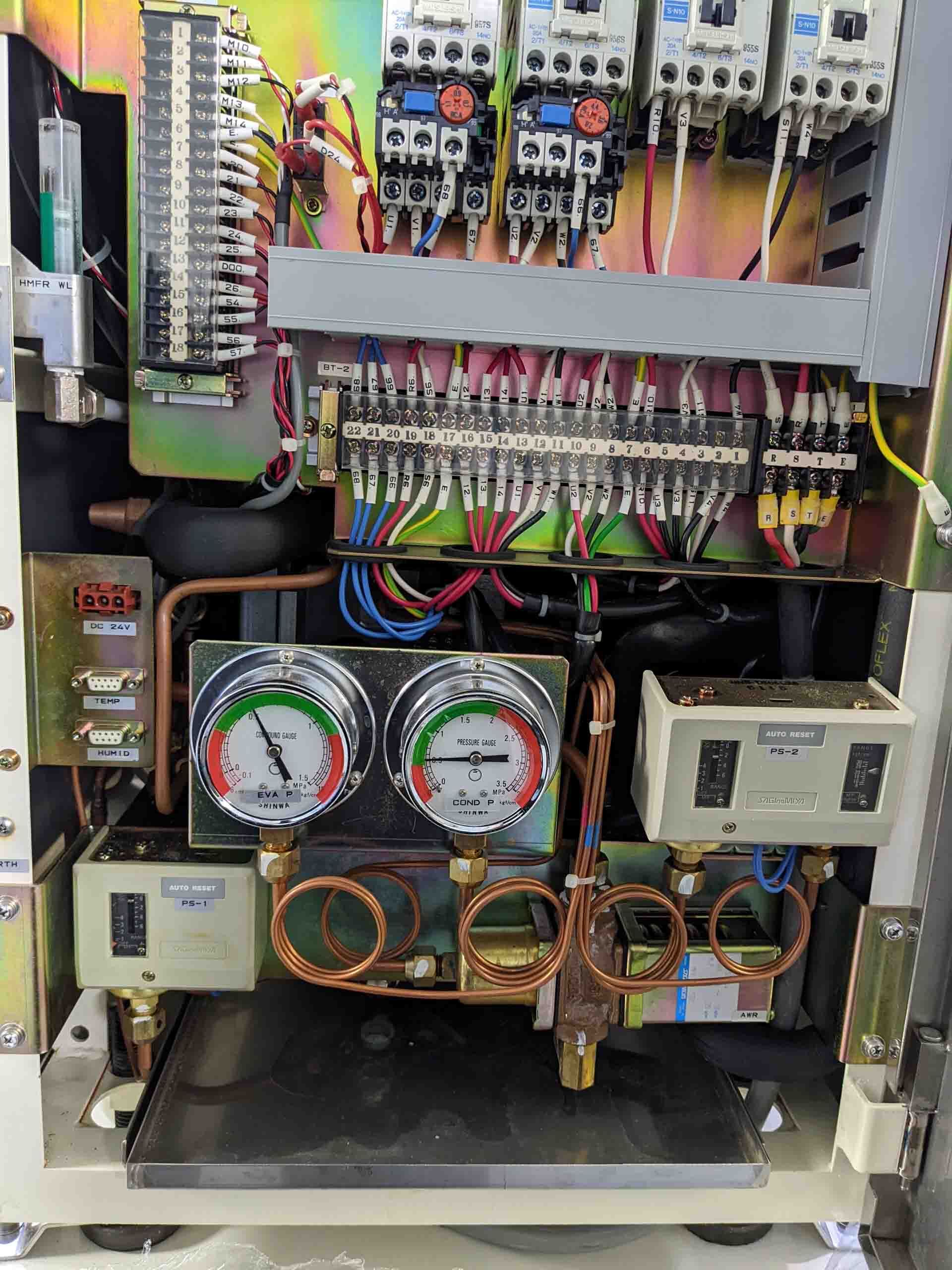

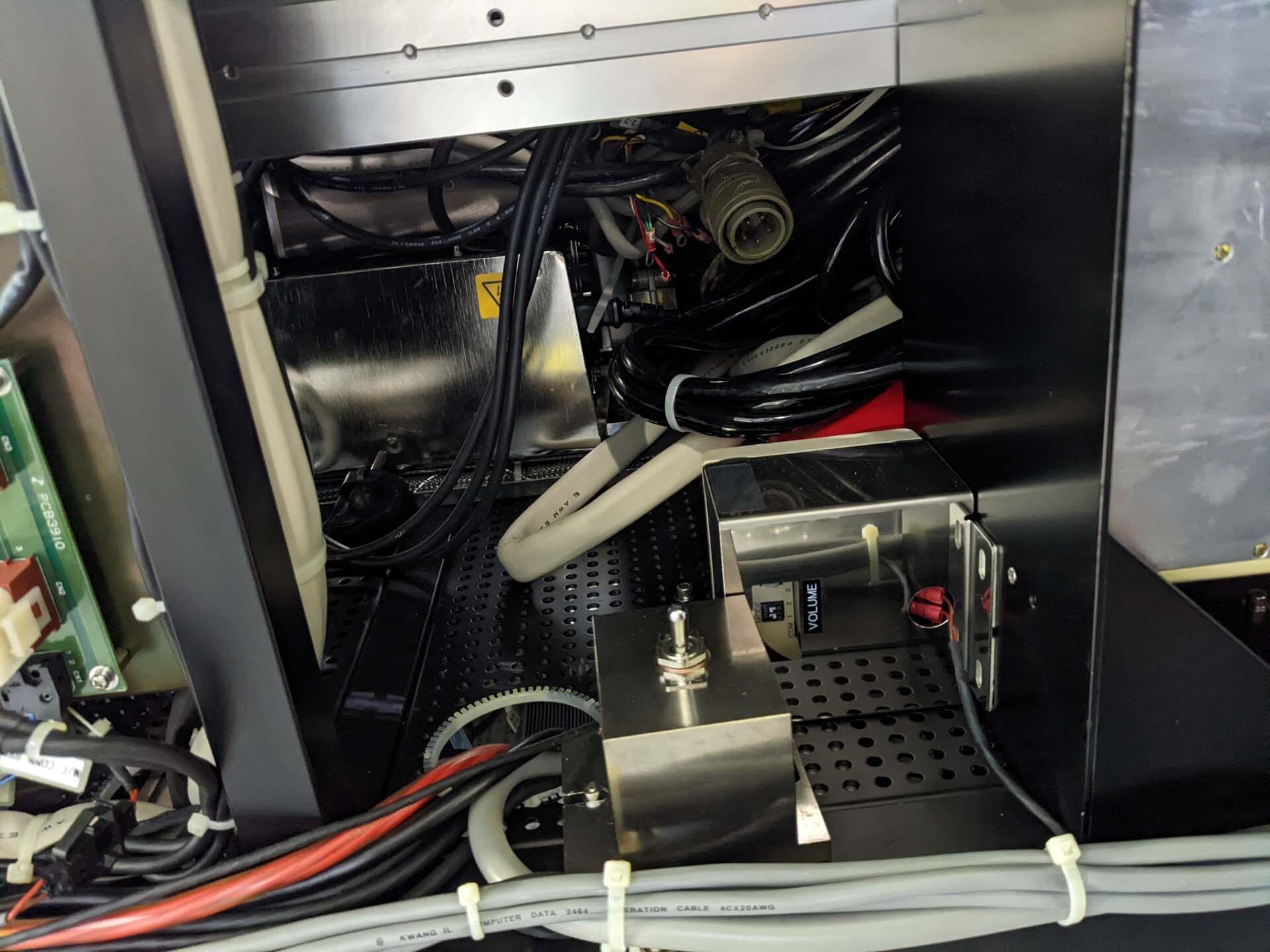

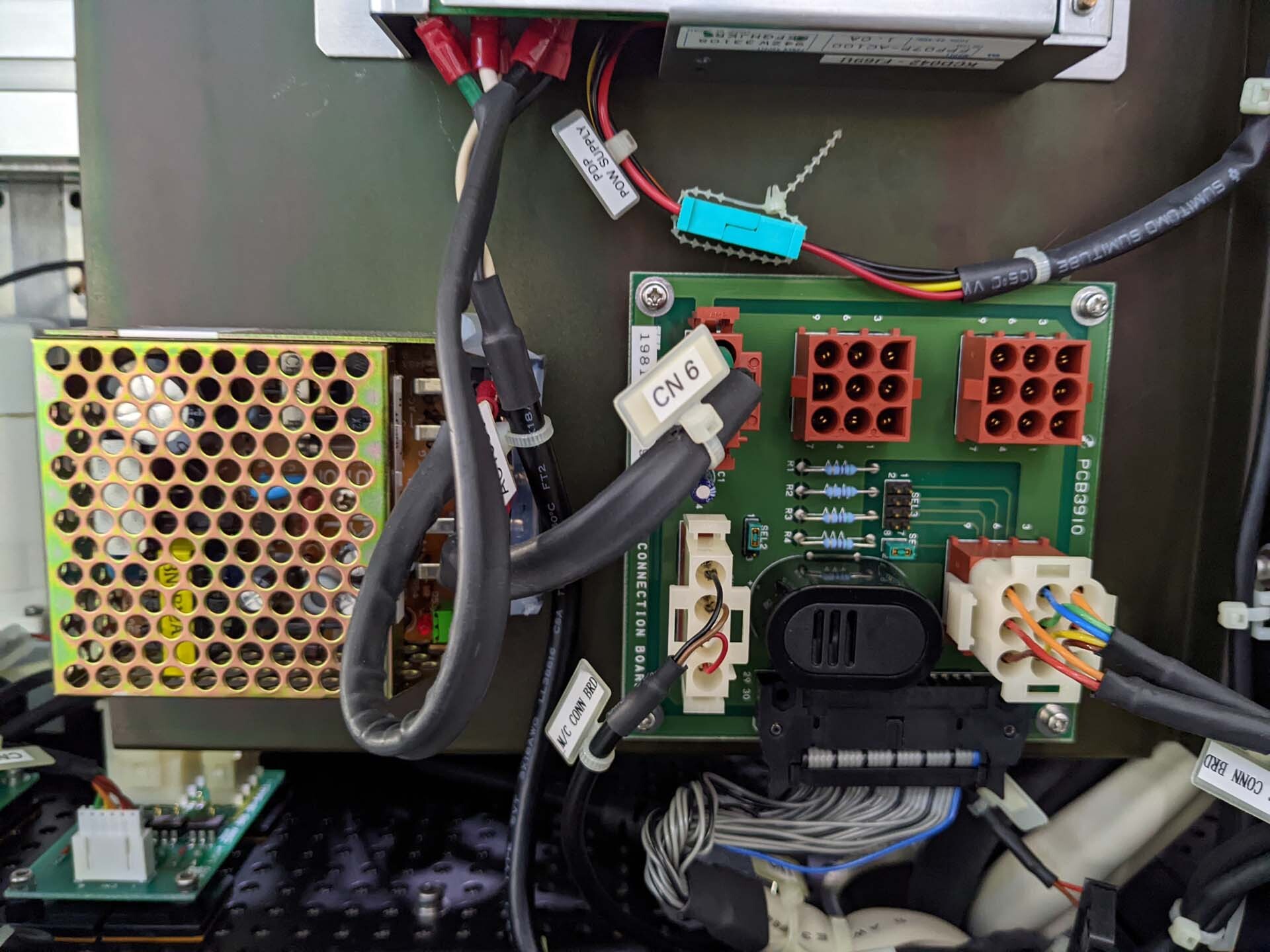

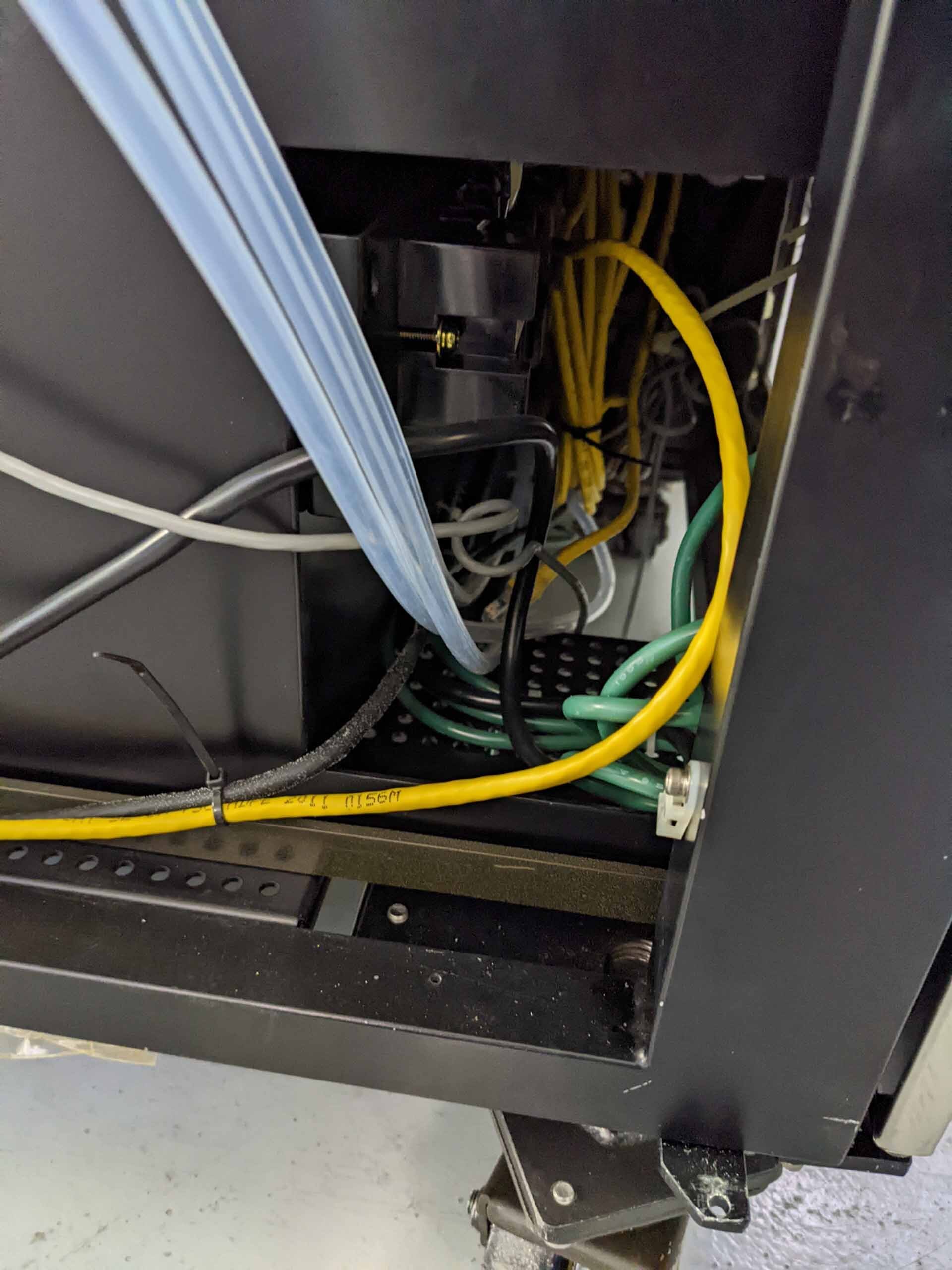

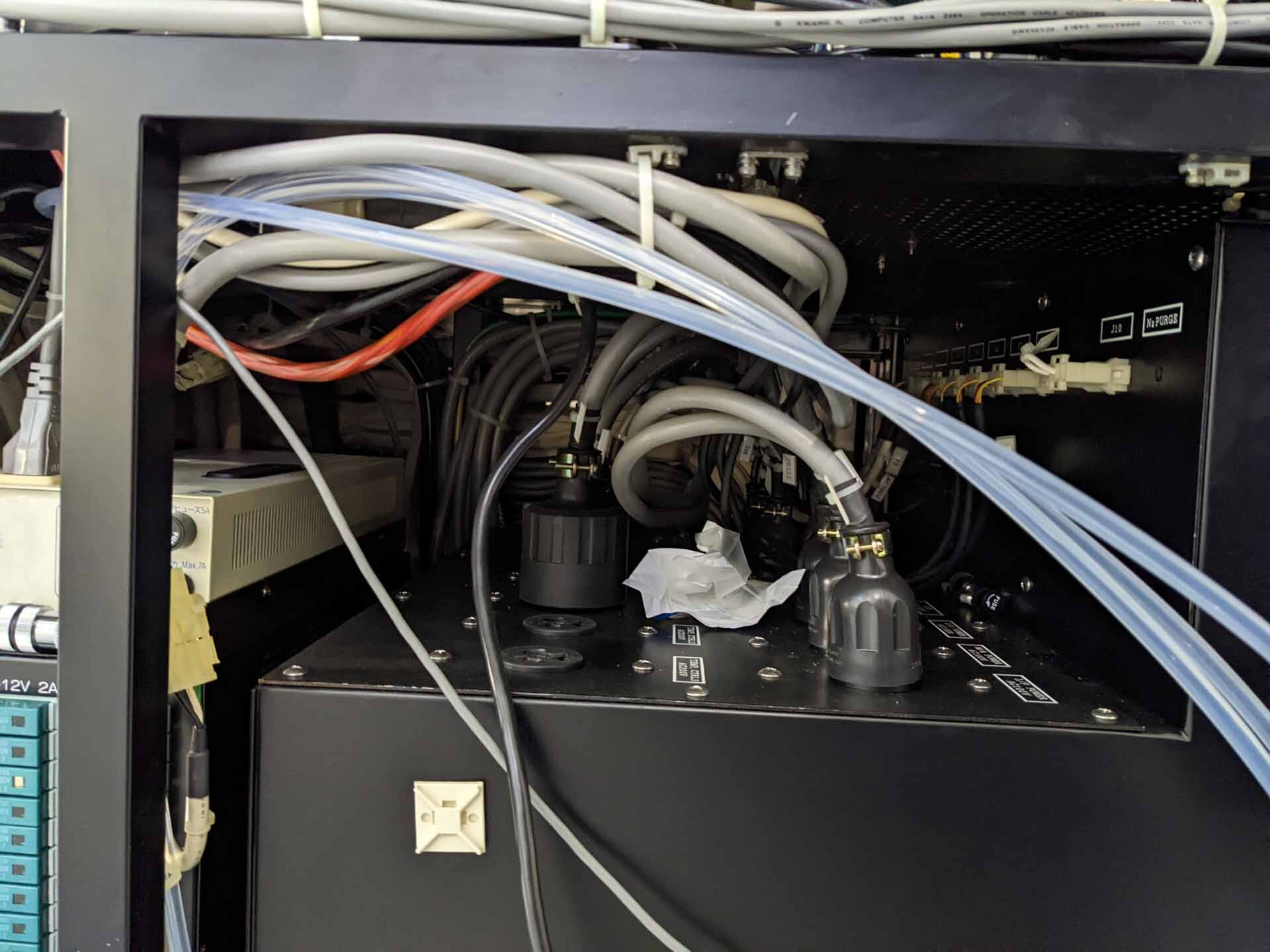

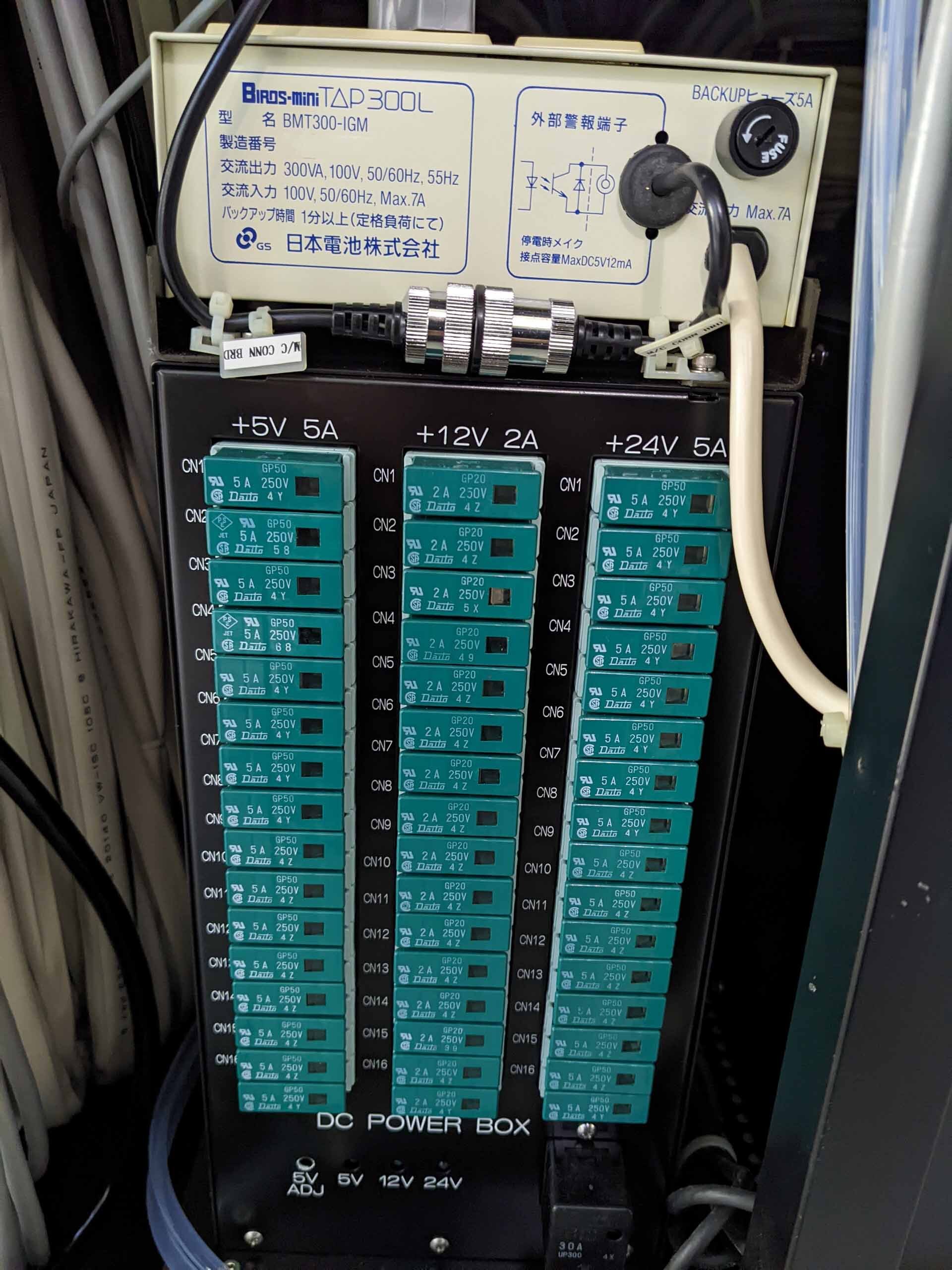

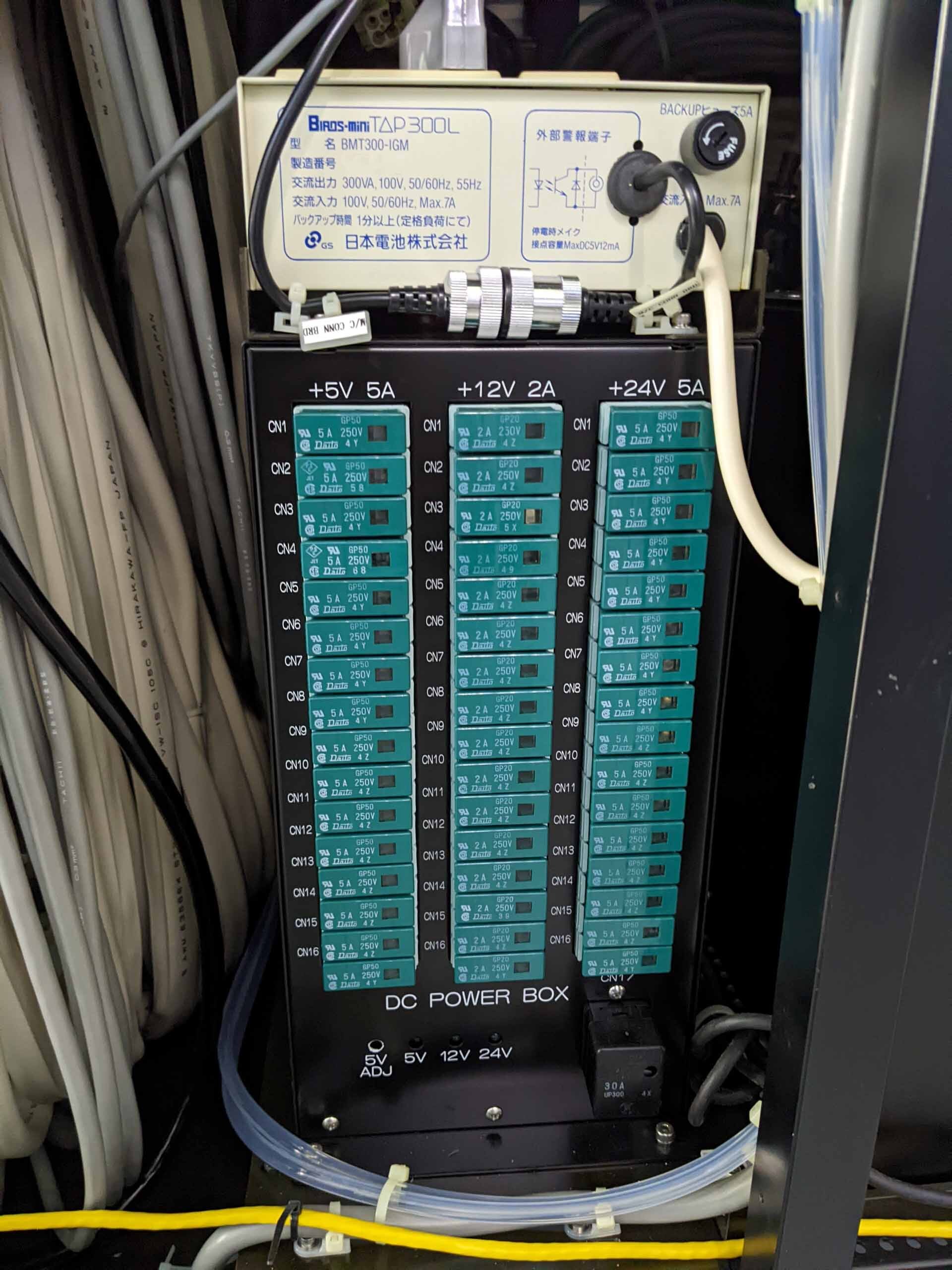

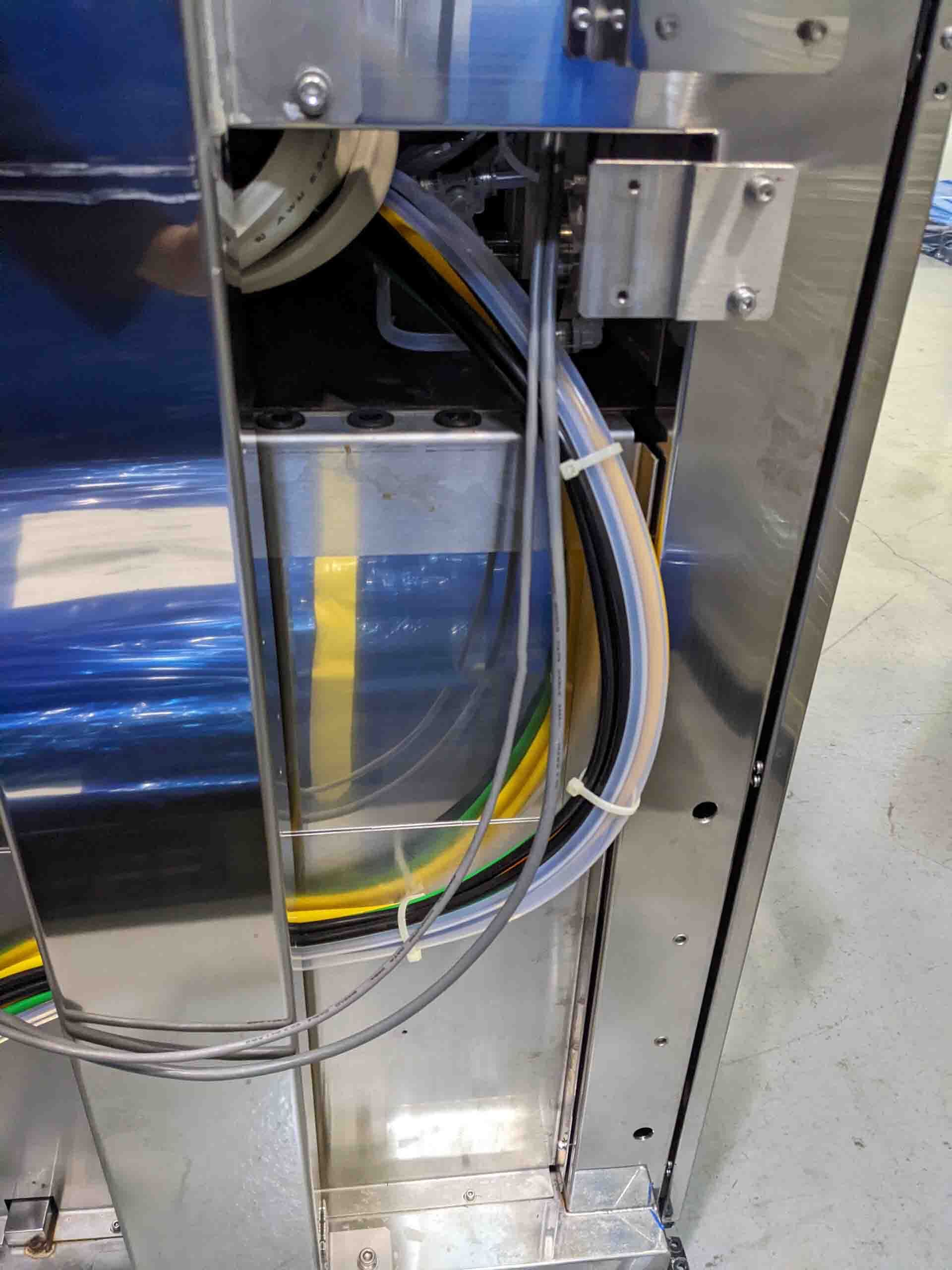

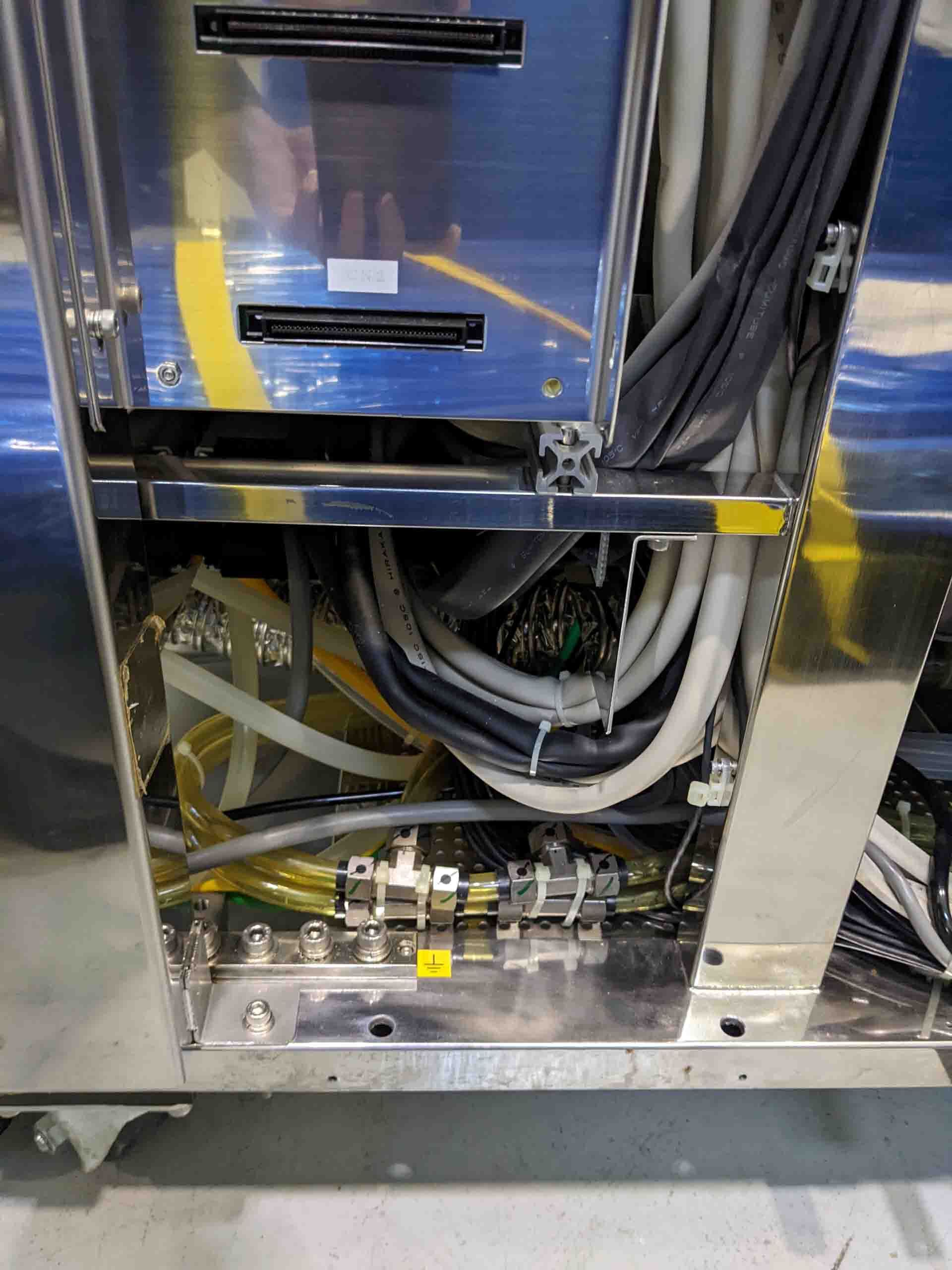

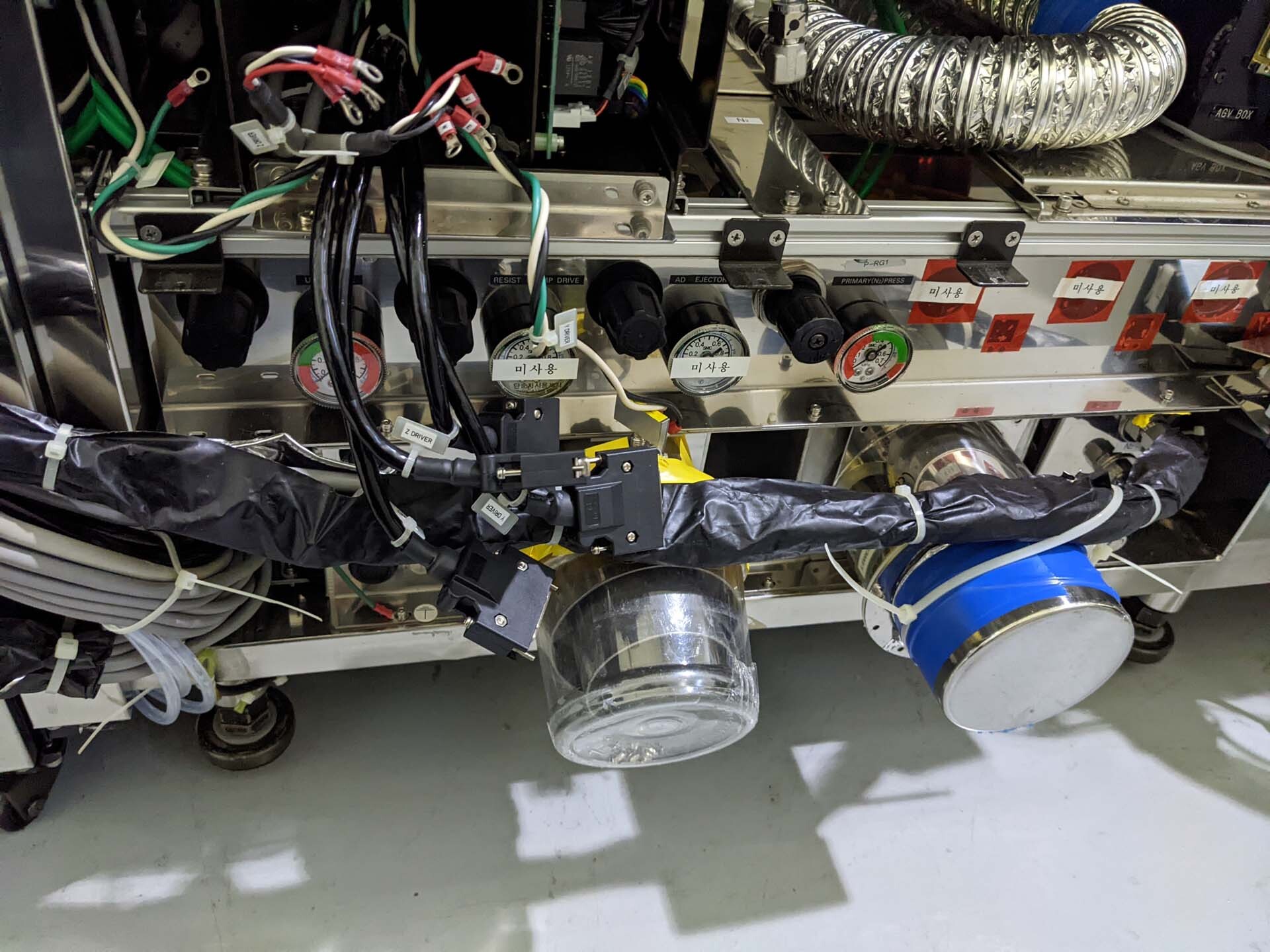

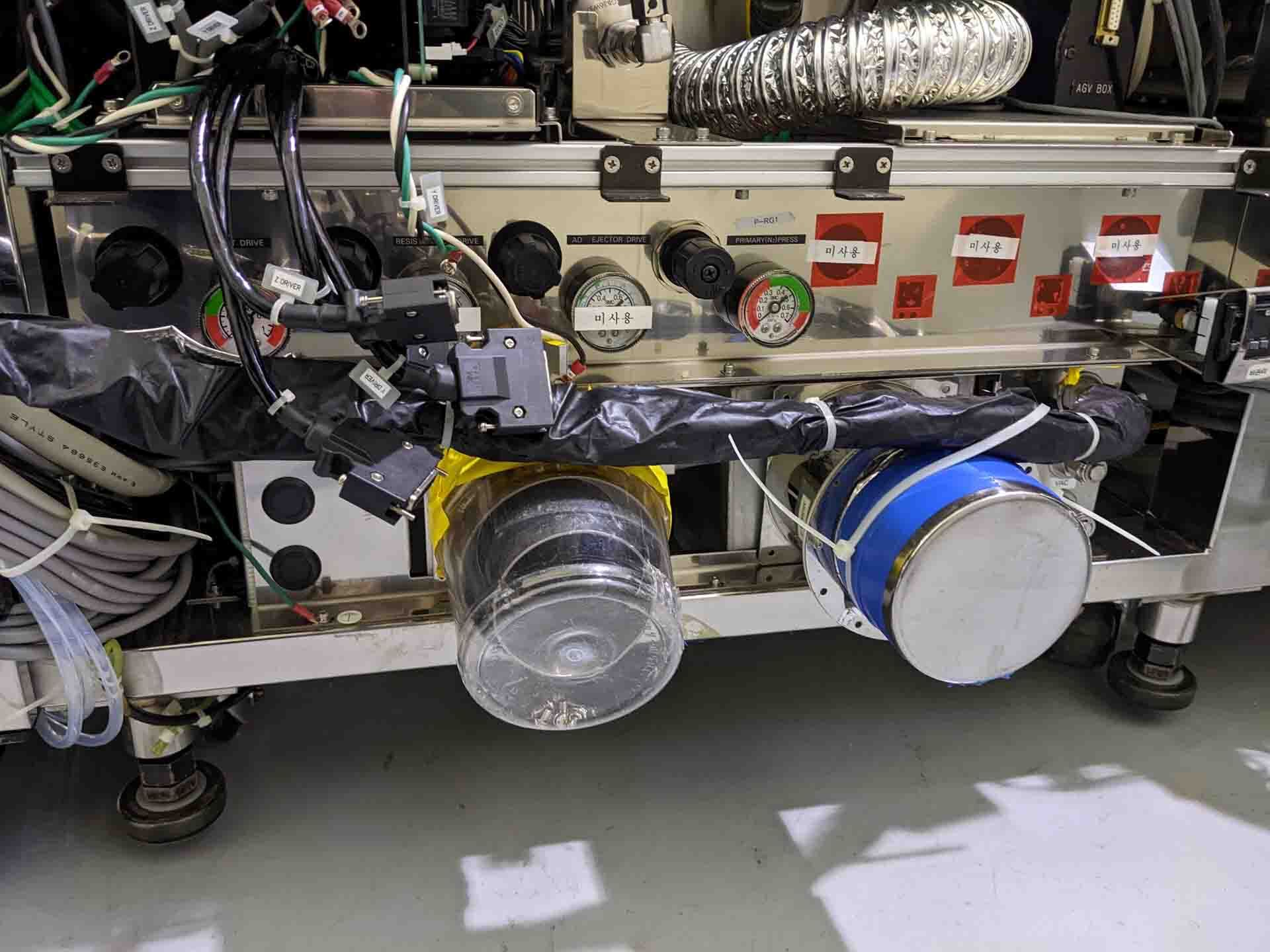

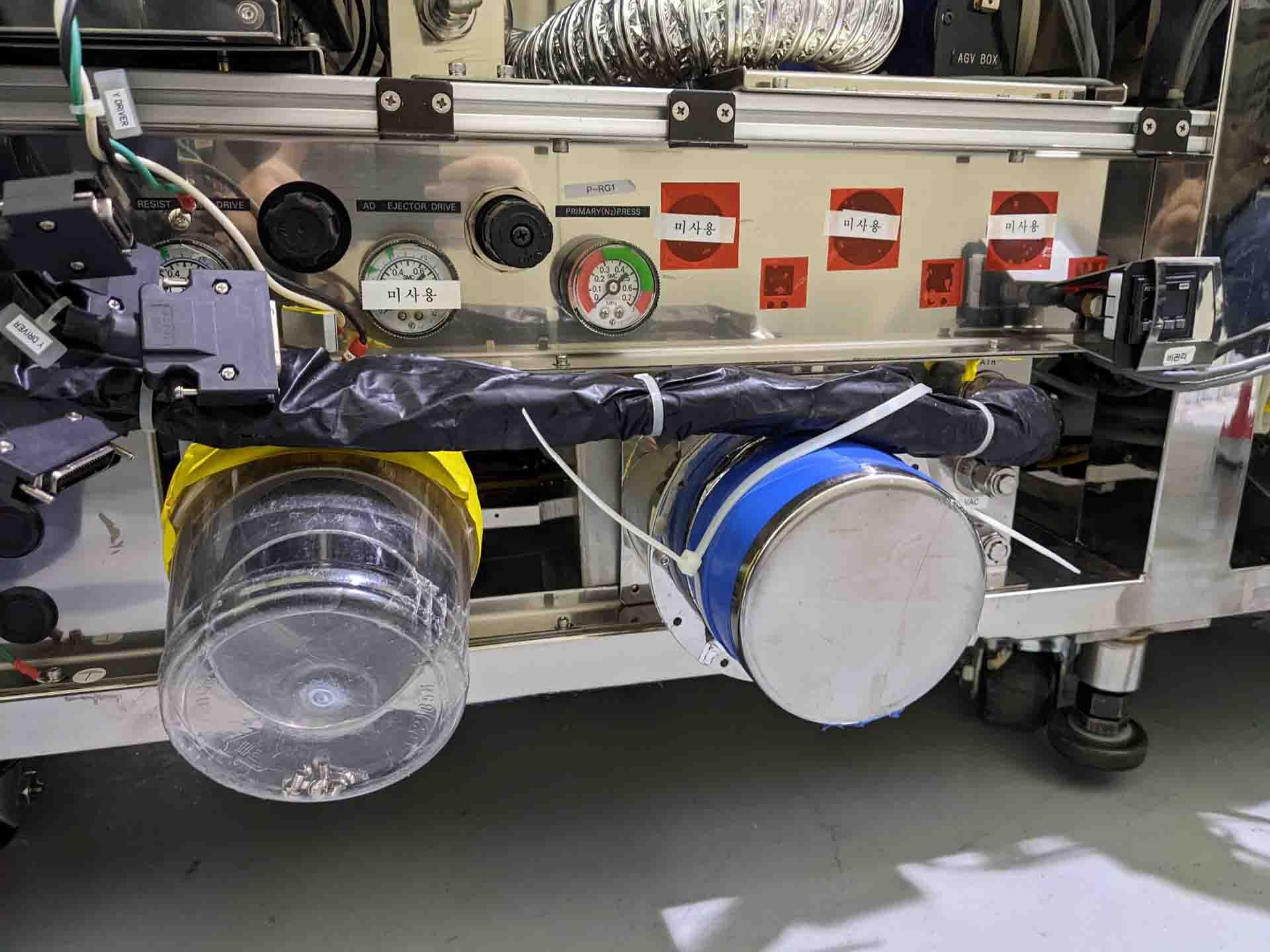

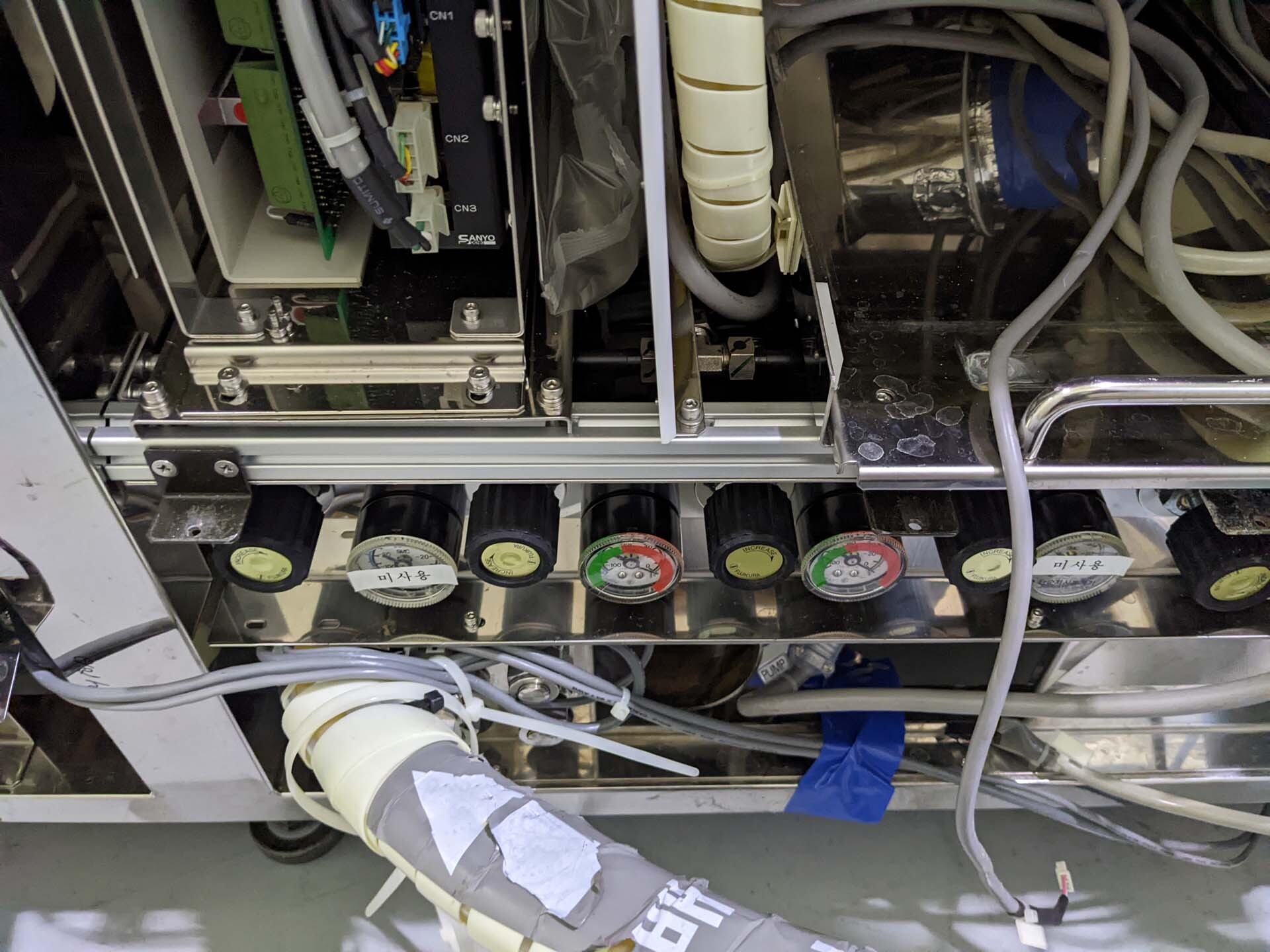

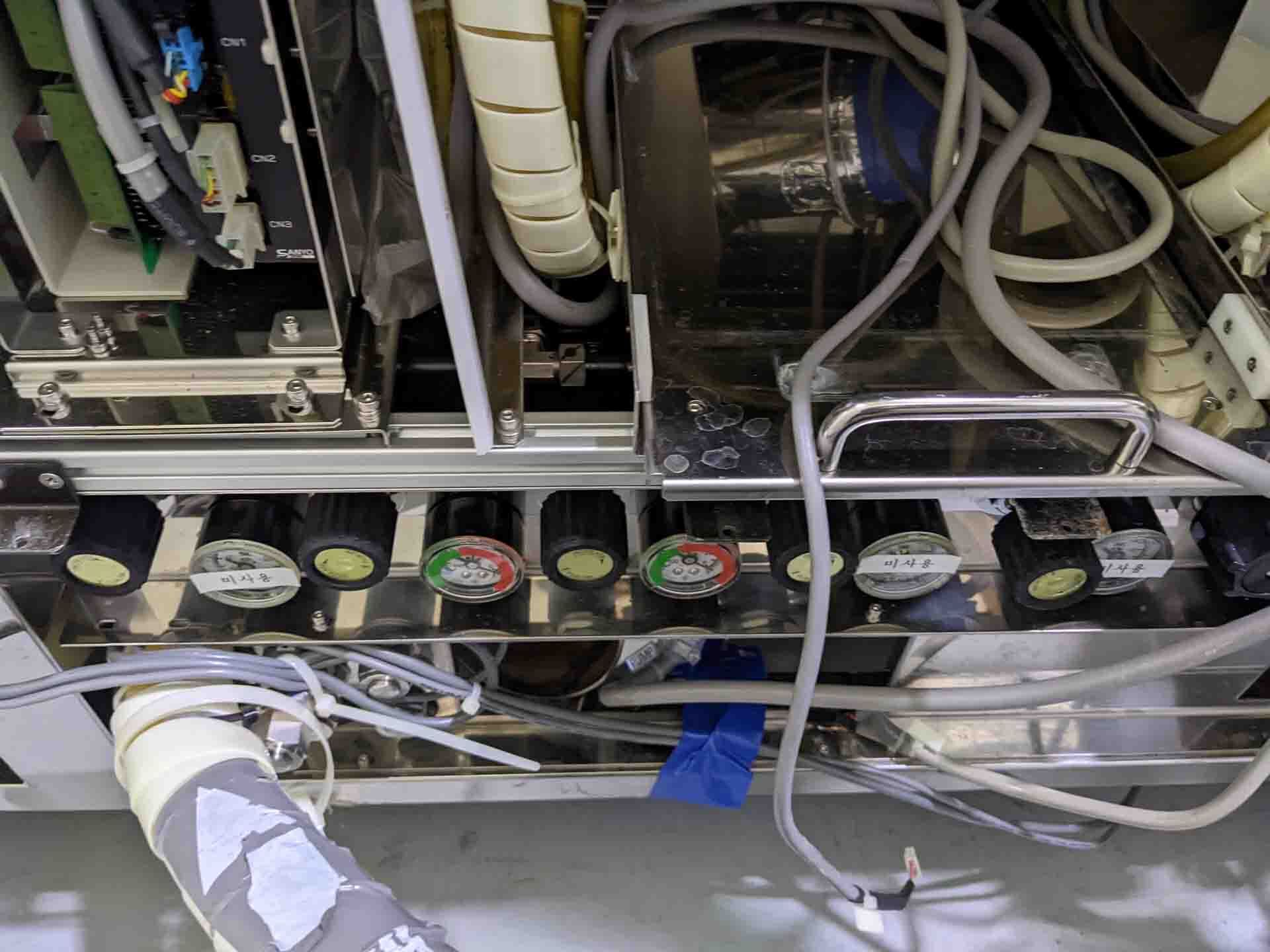

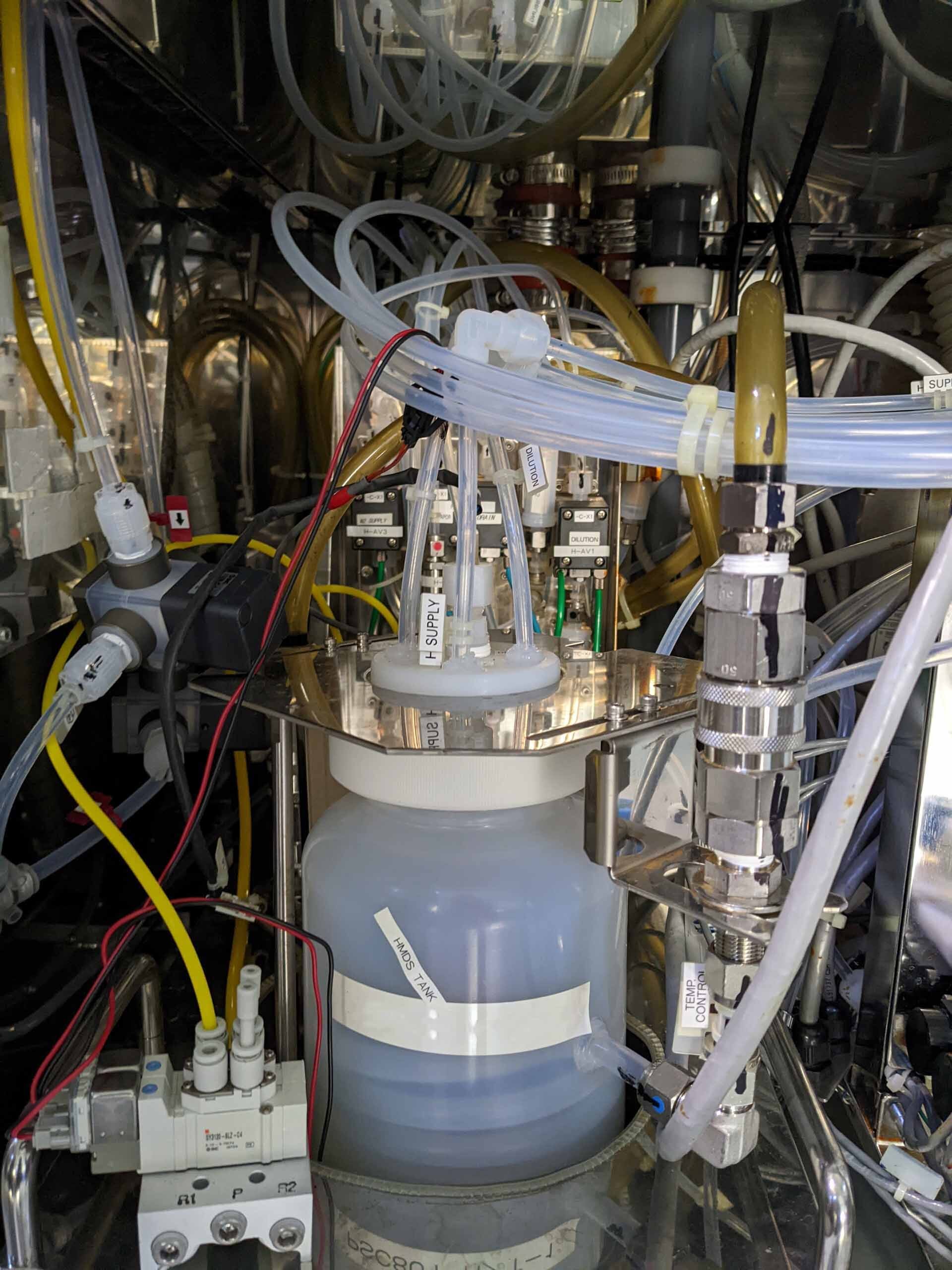

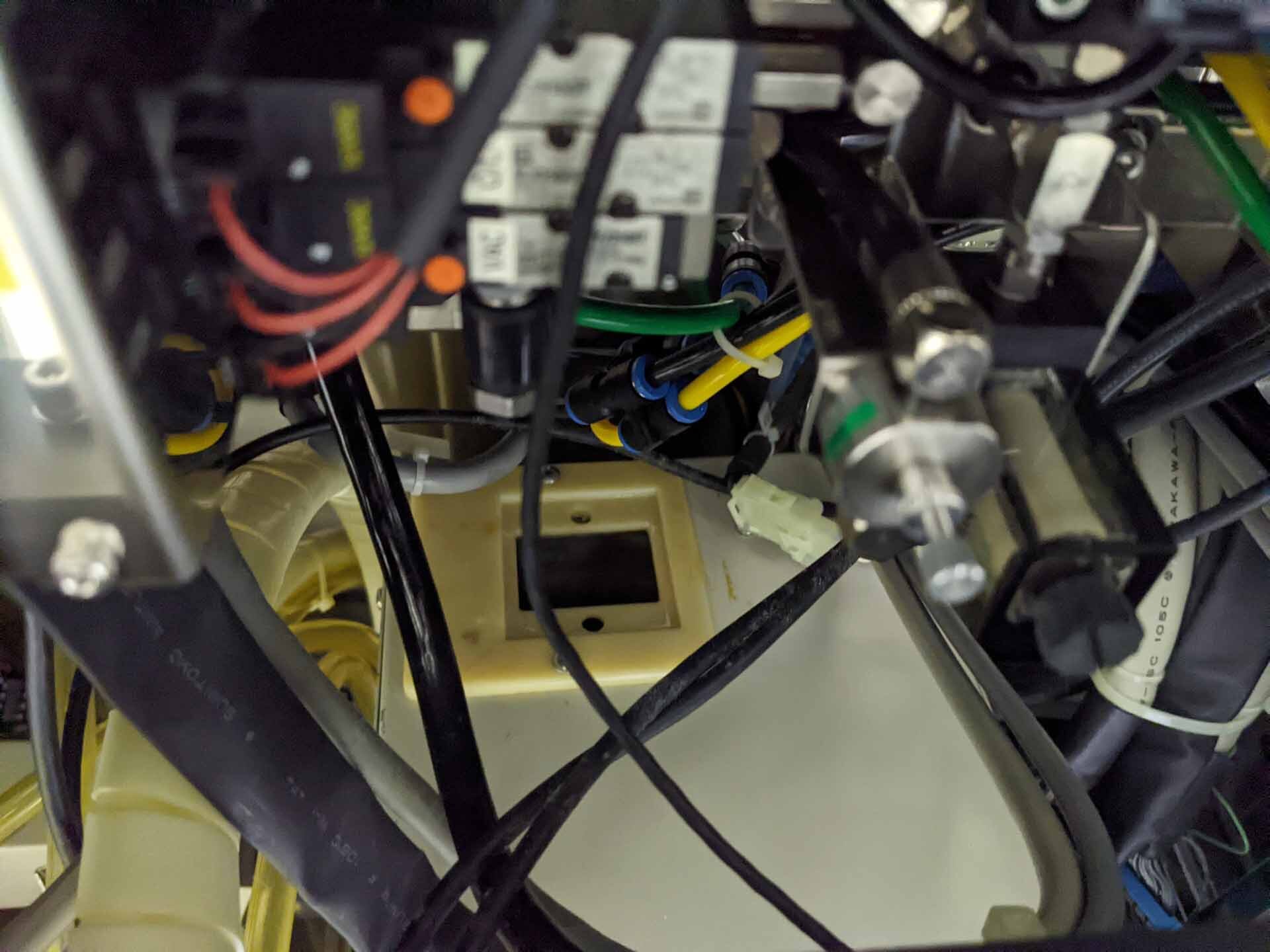

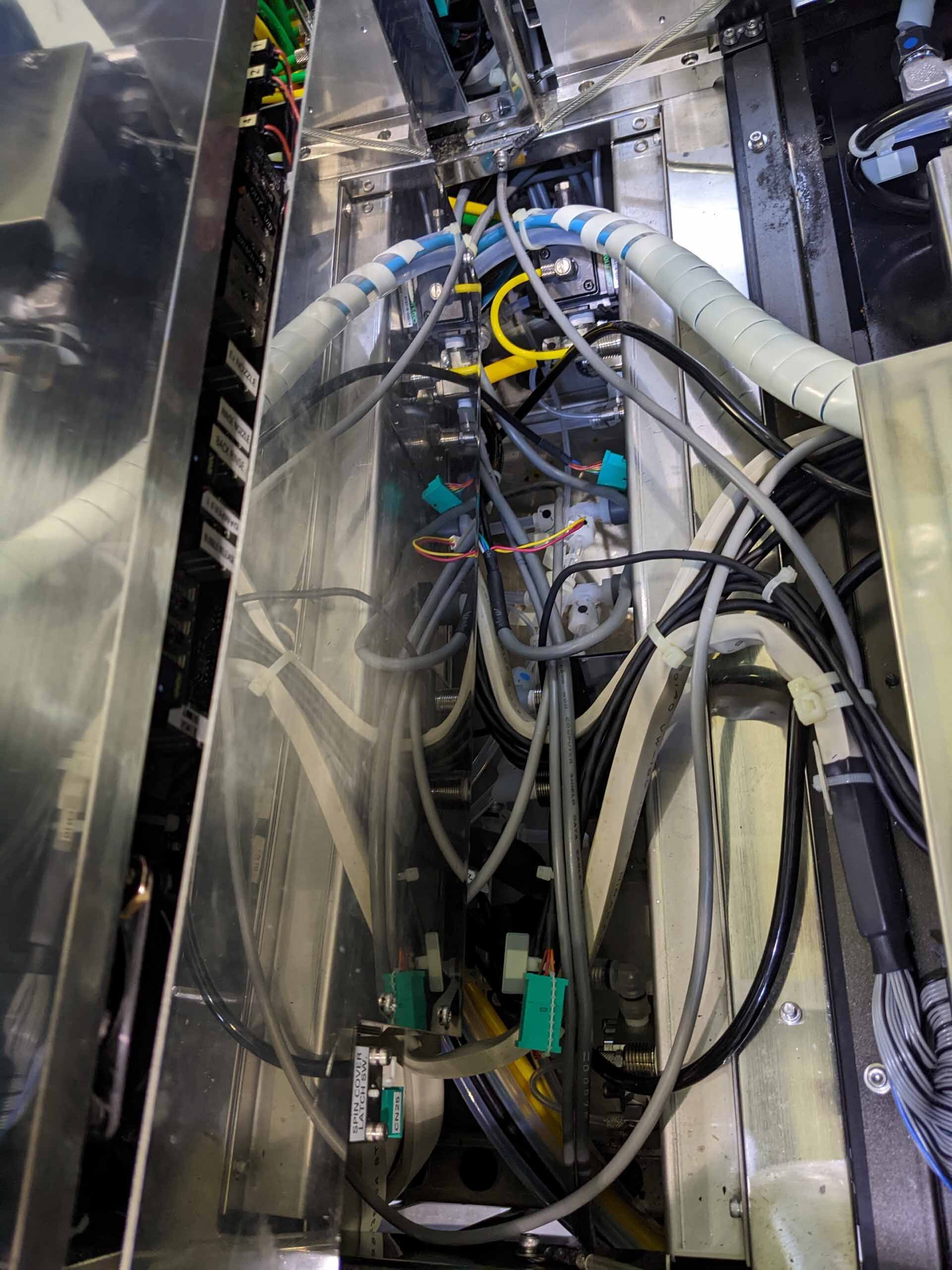

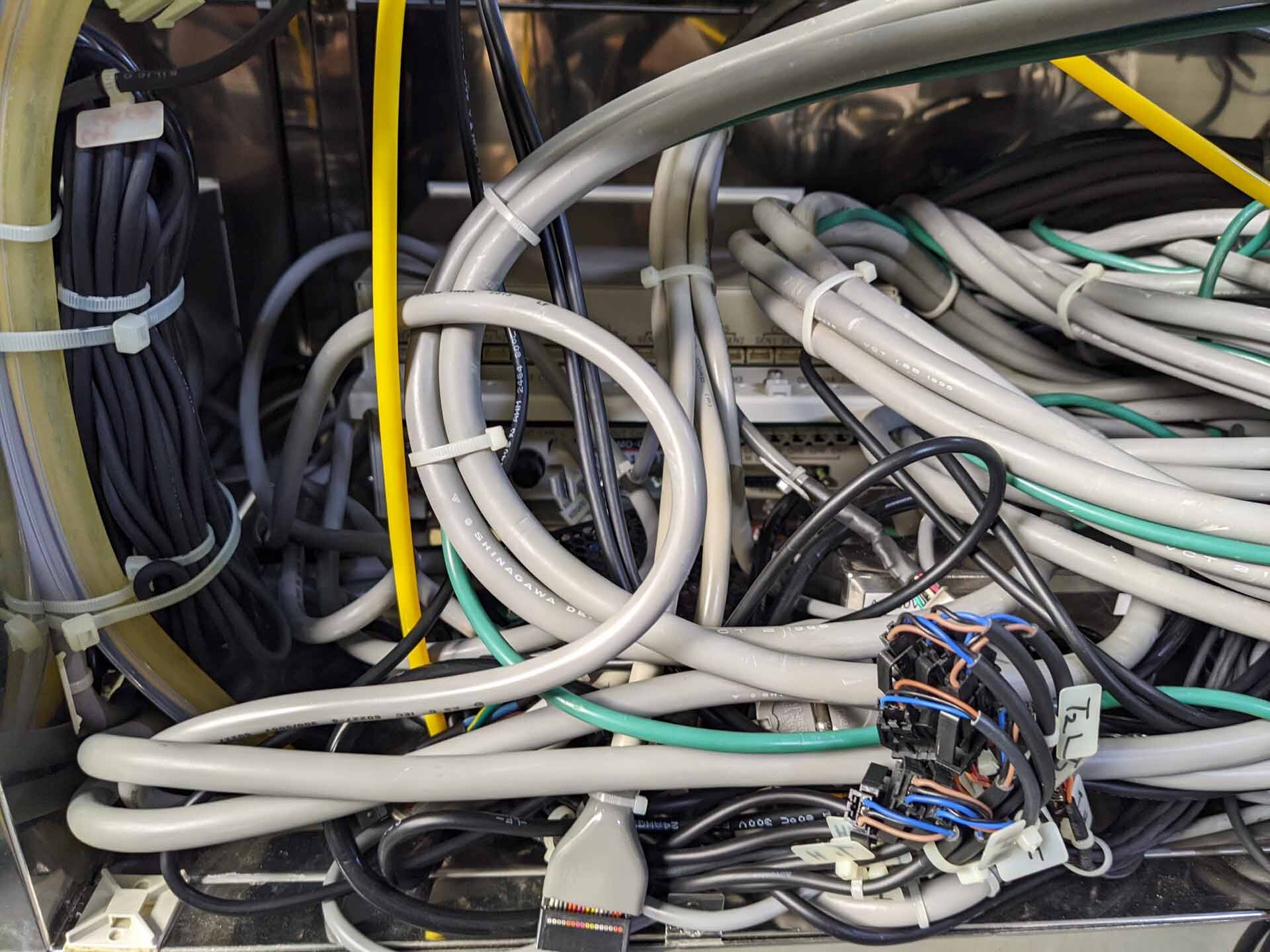

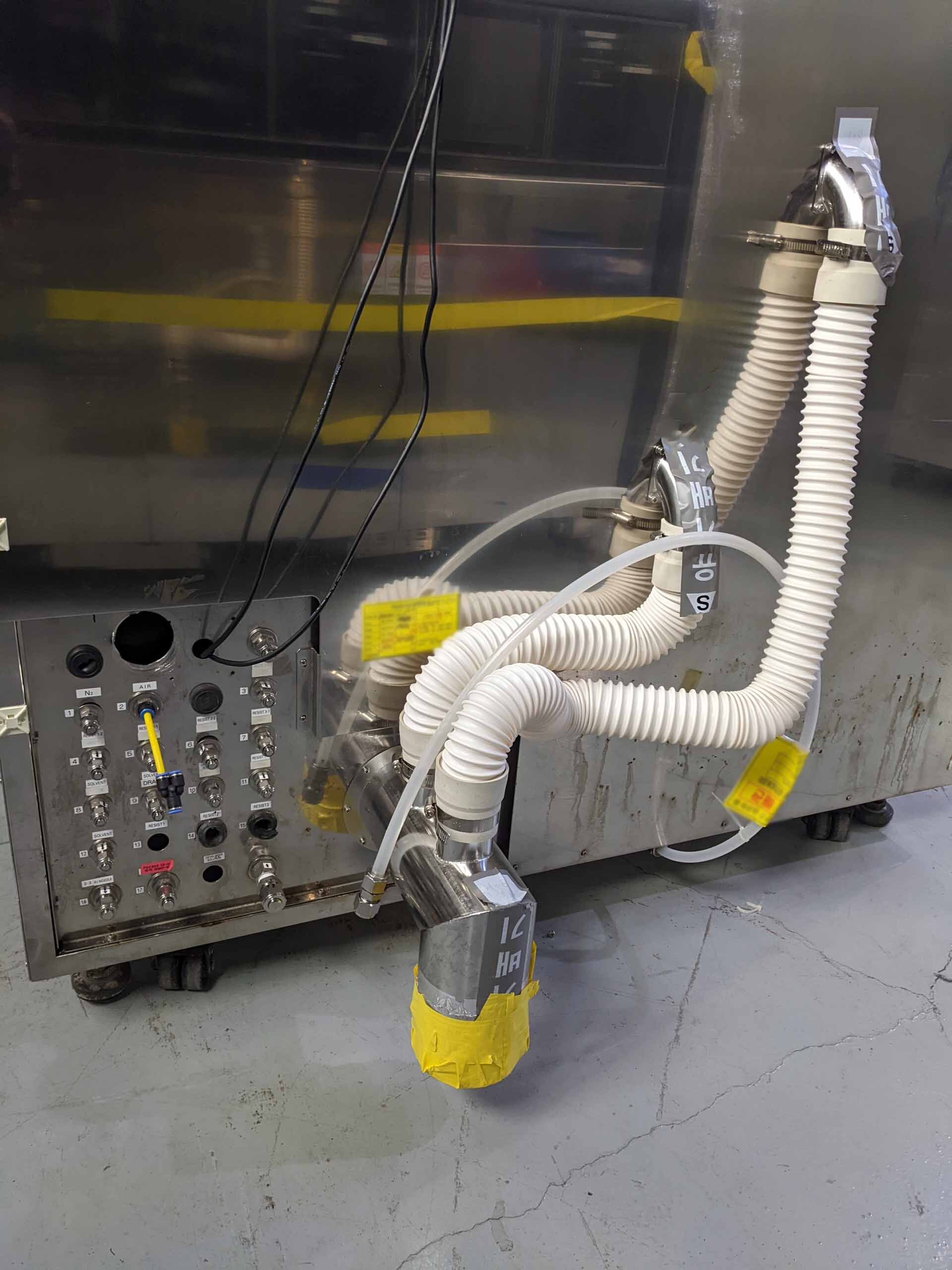

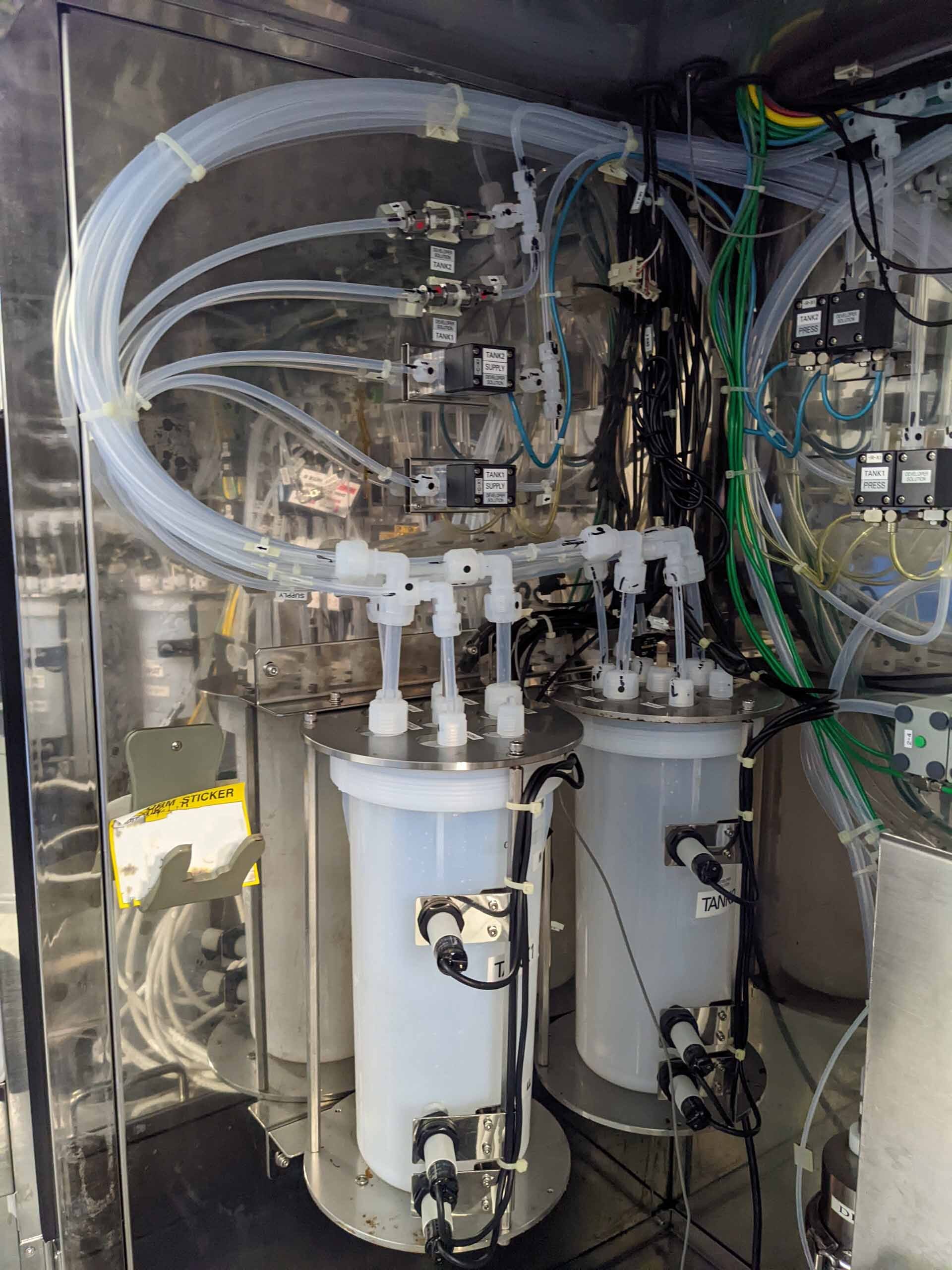

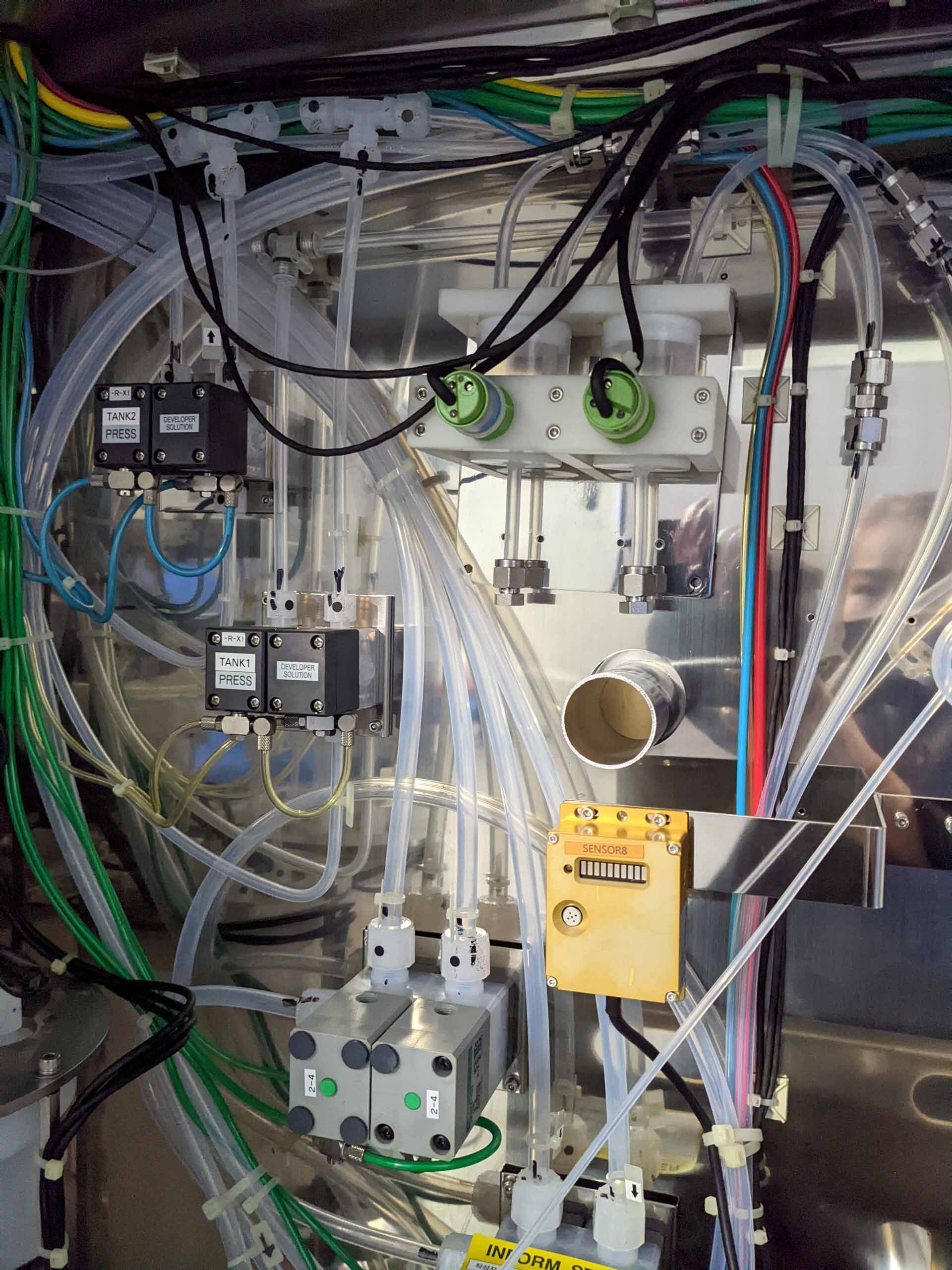

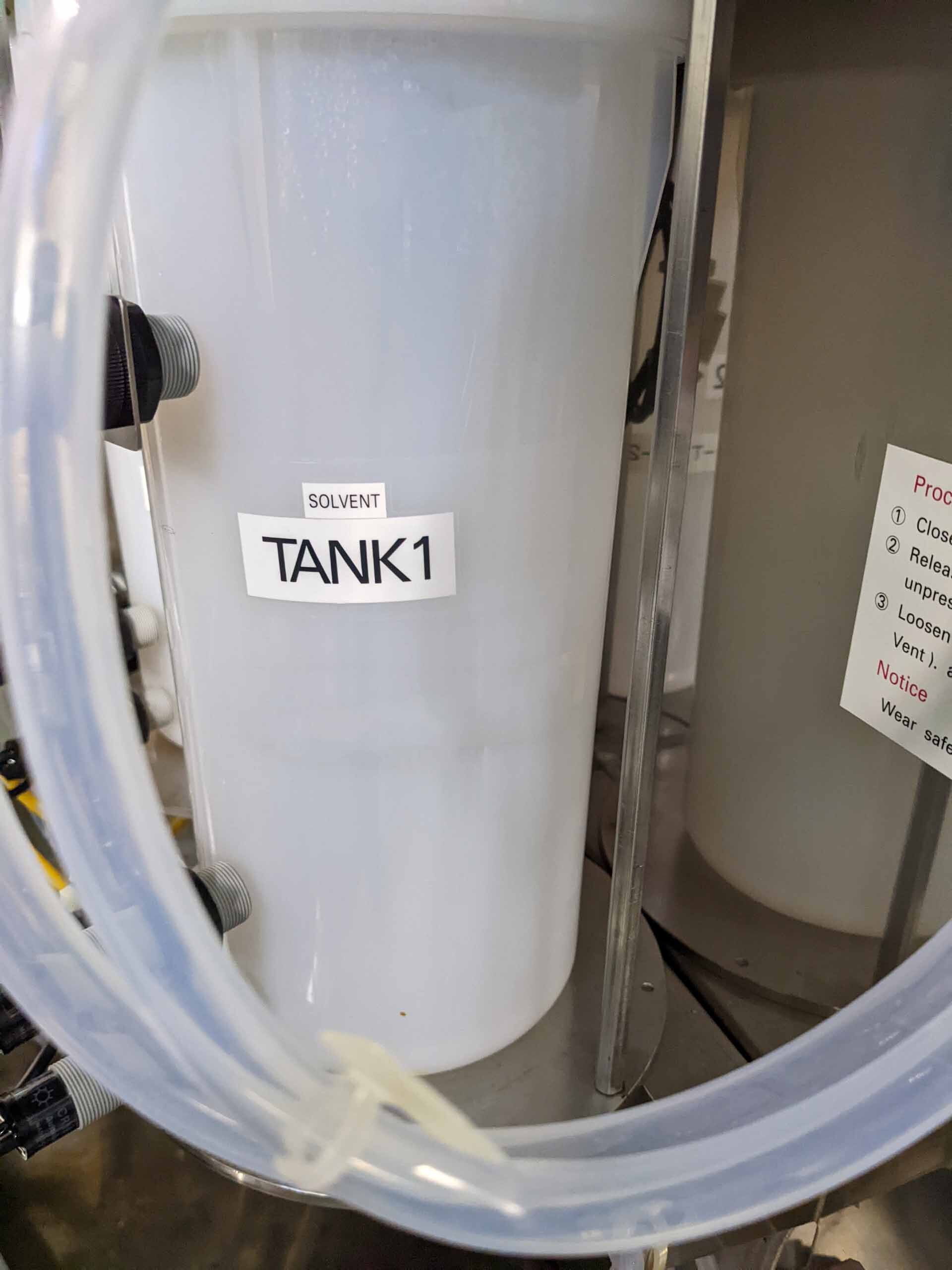

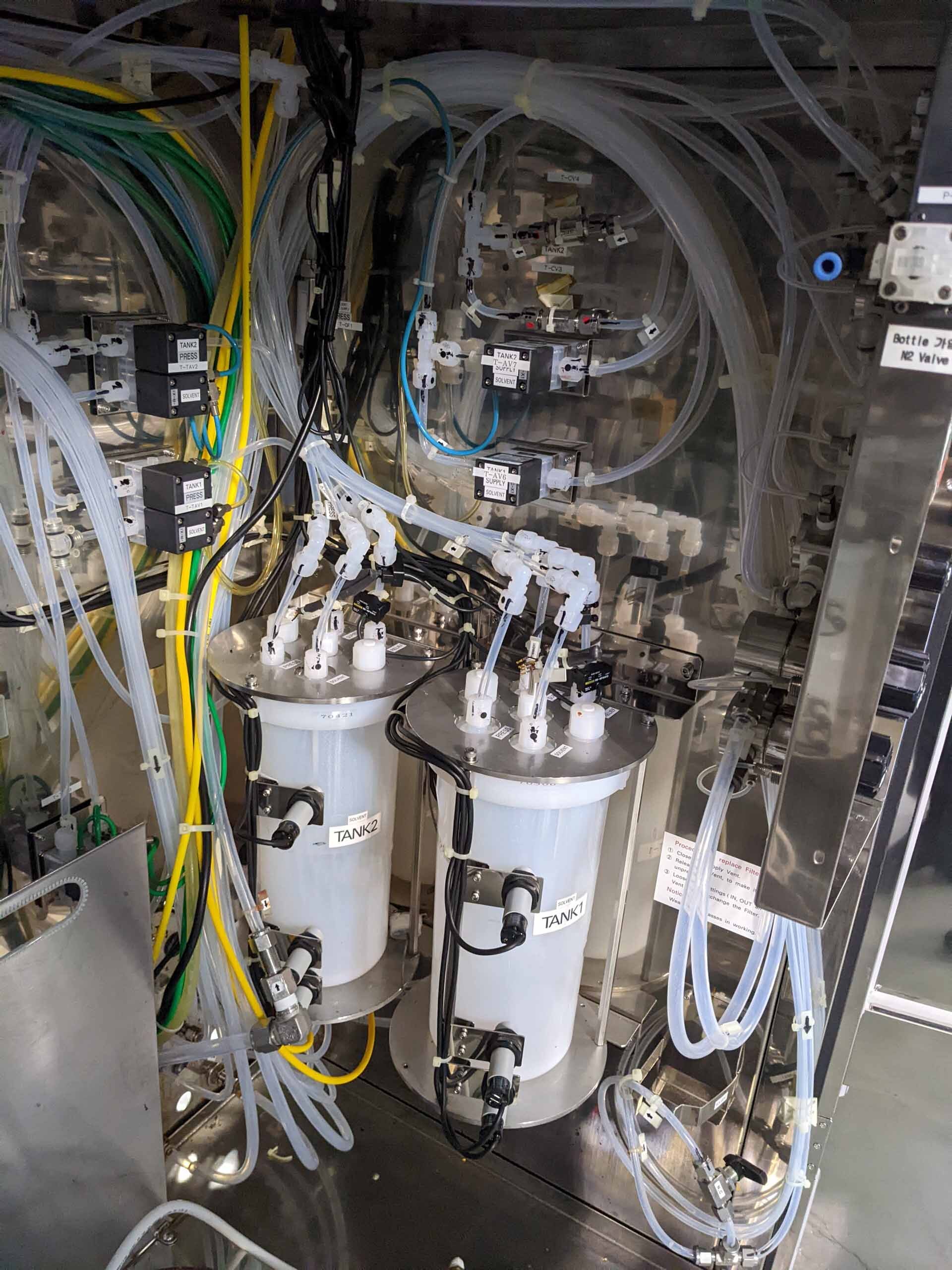

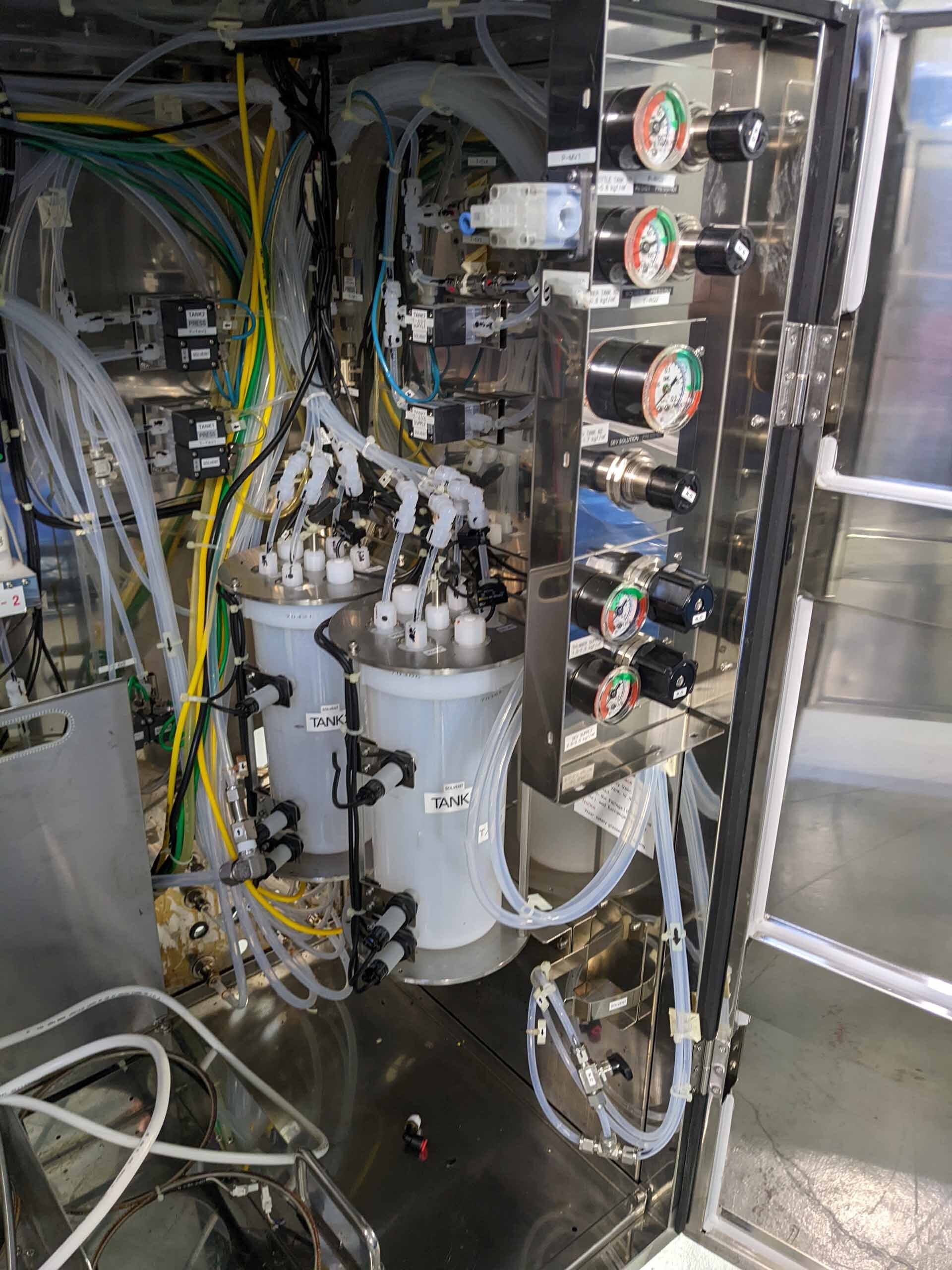

Chemical supply system:

Solvent supply for COT unit

Develop solution supply for (2) DEV units

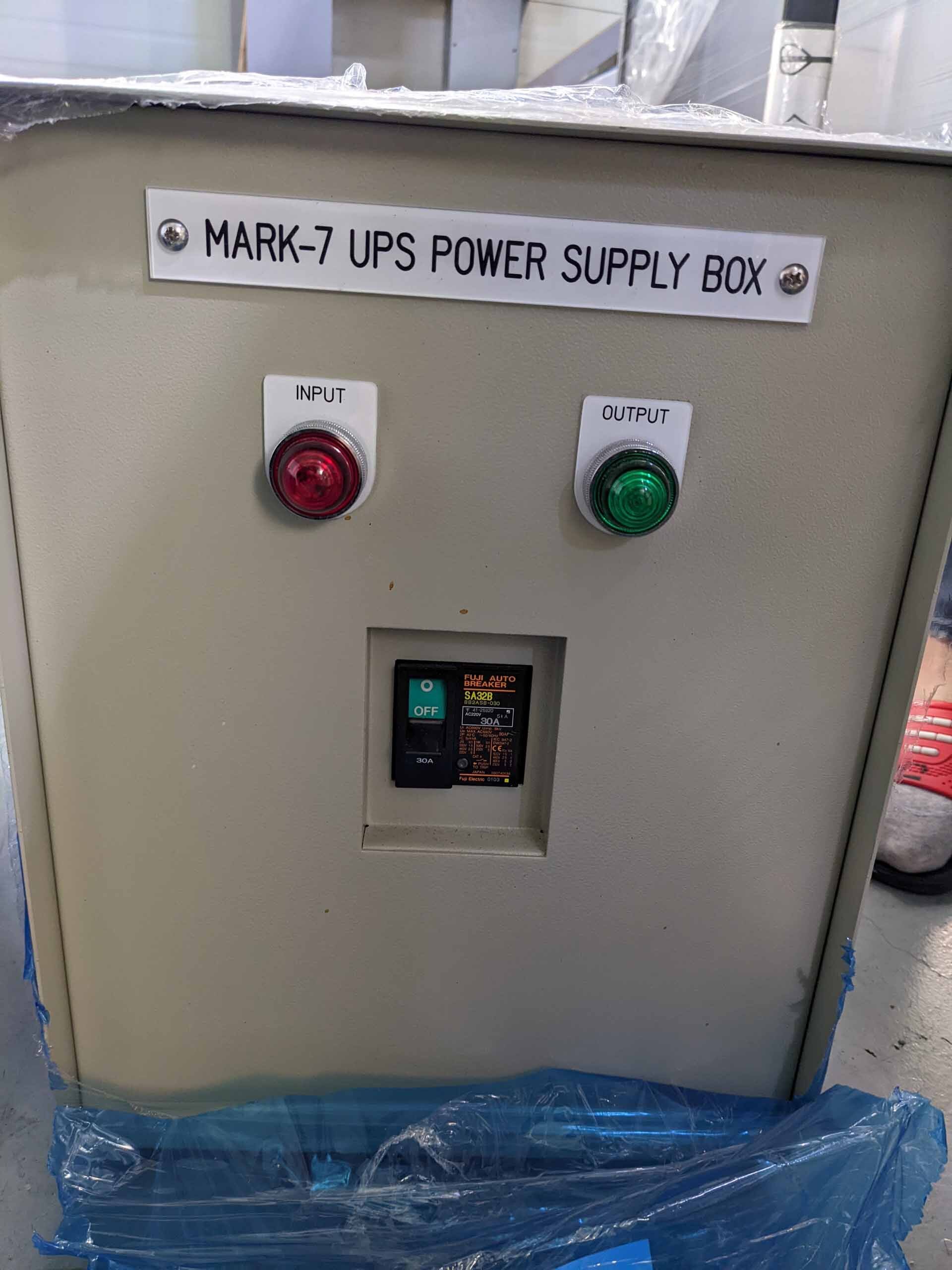

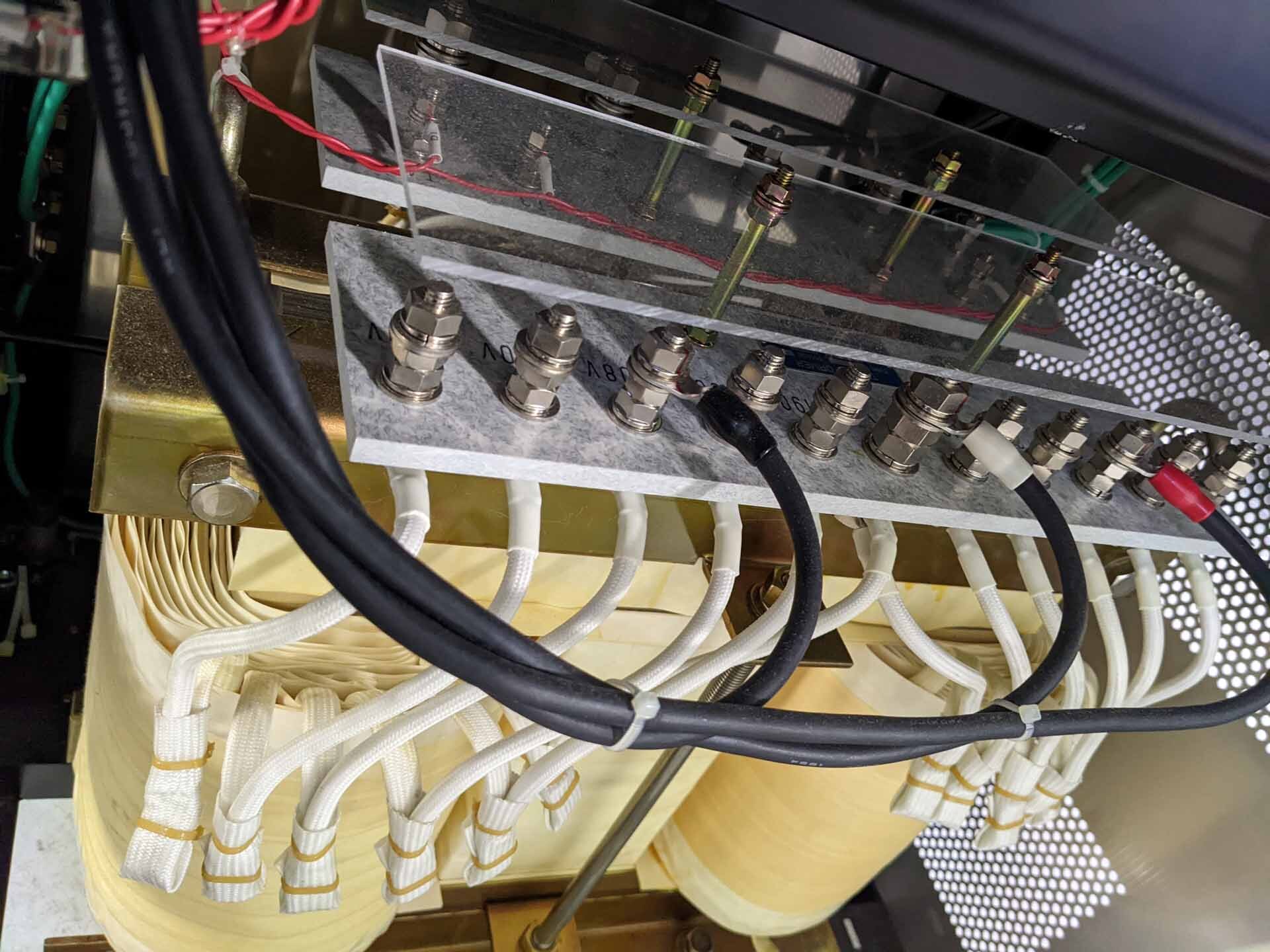

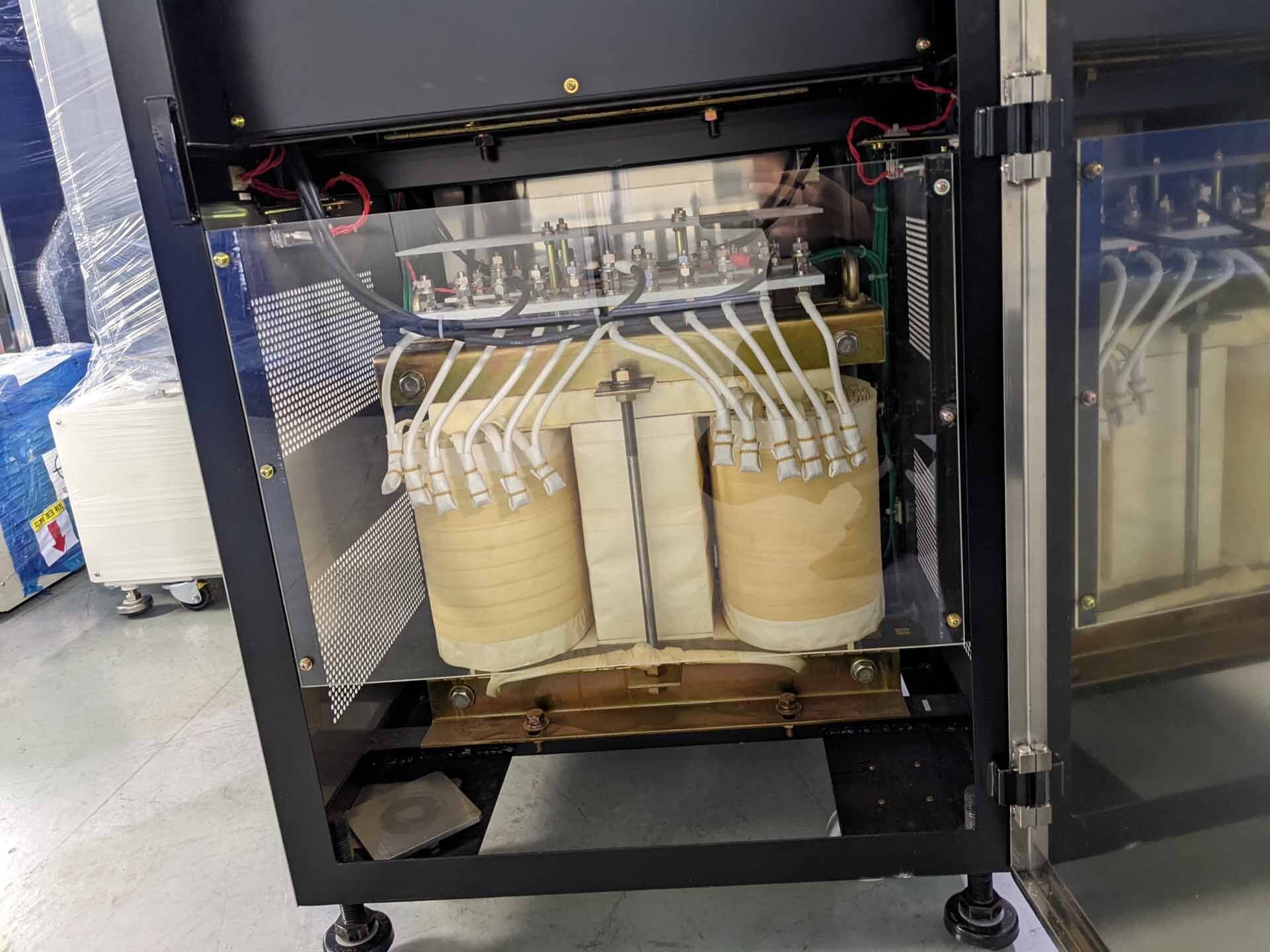

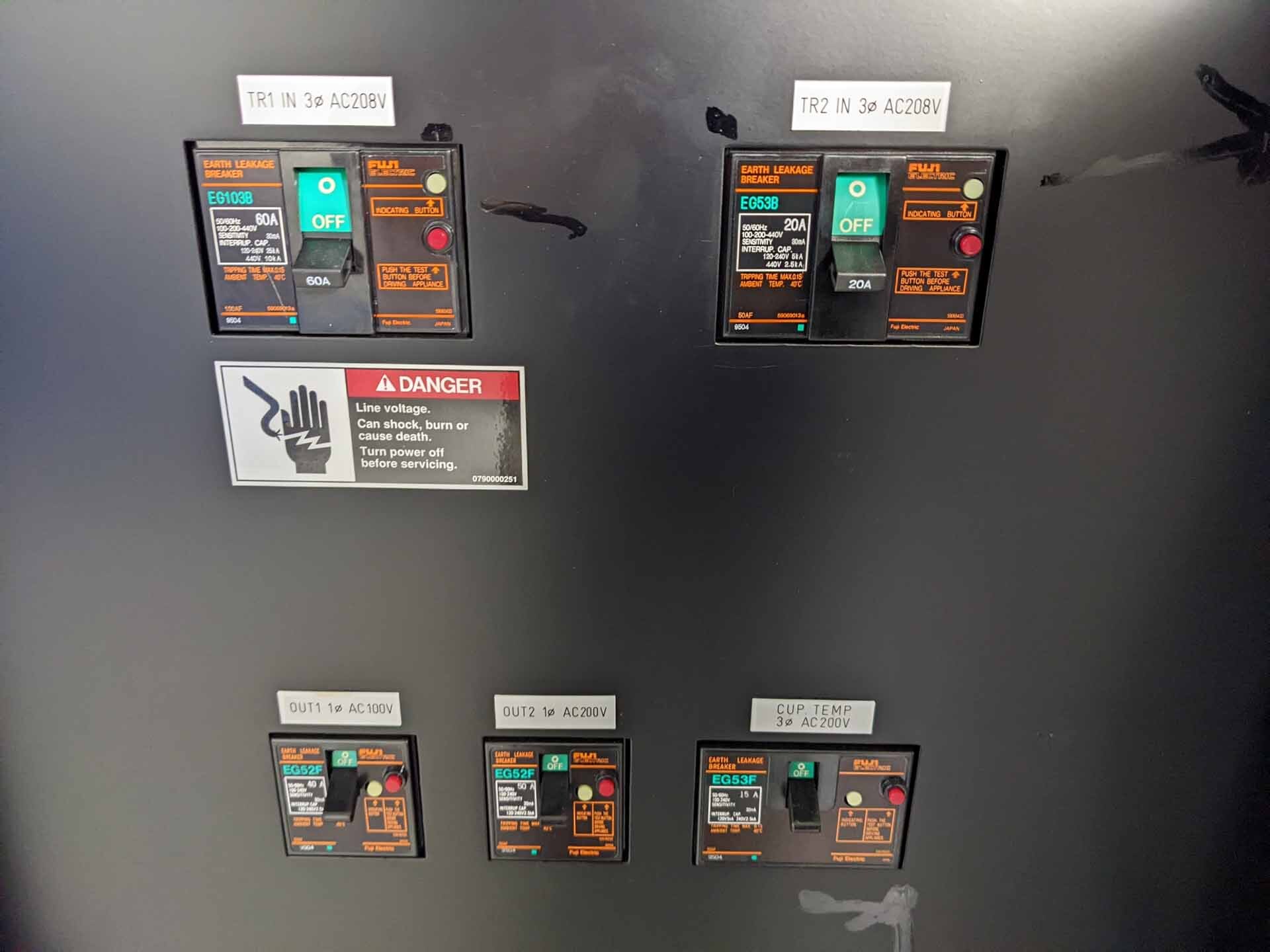

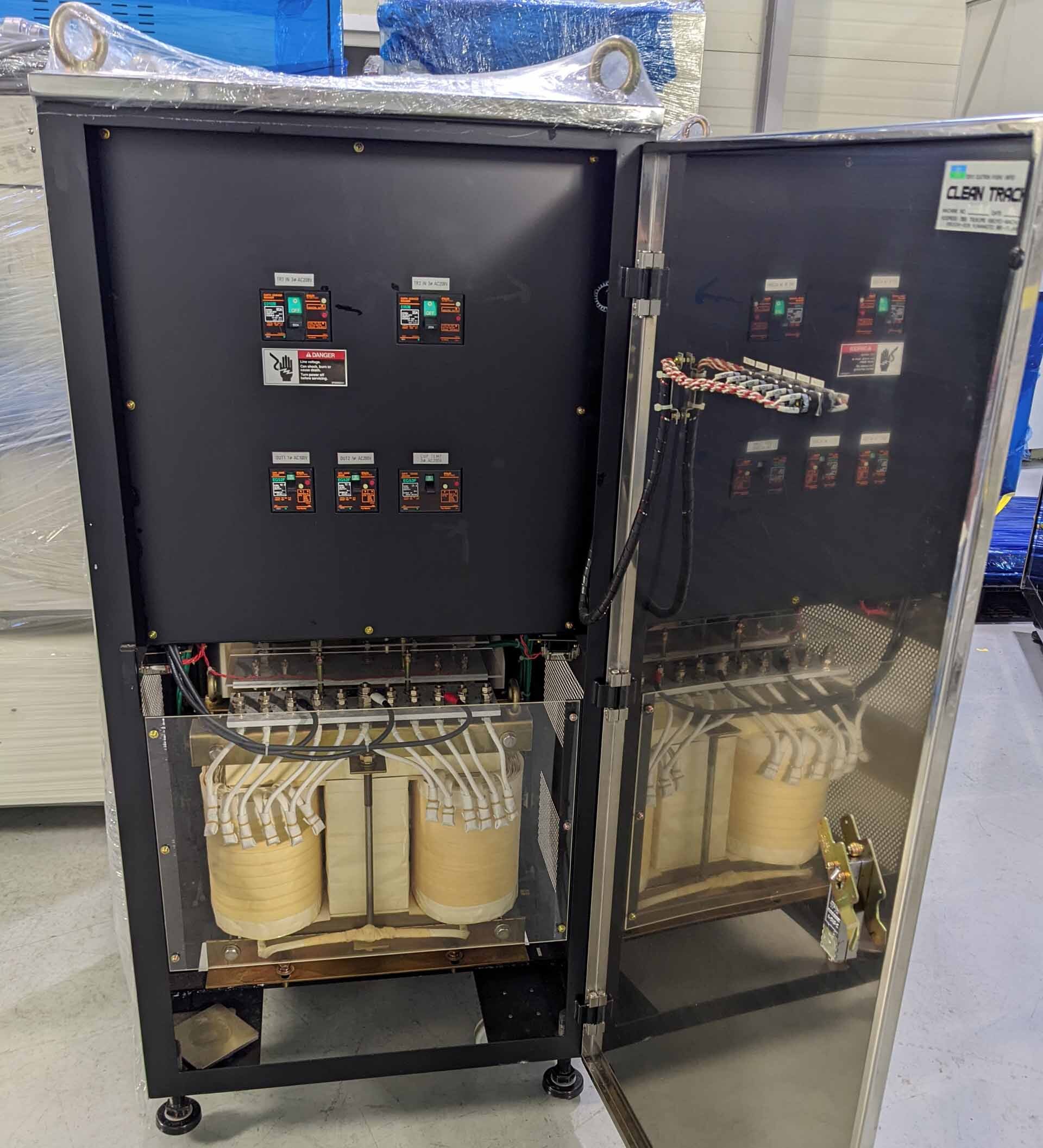

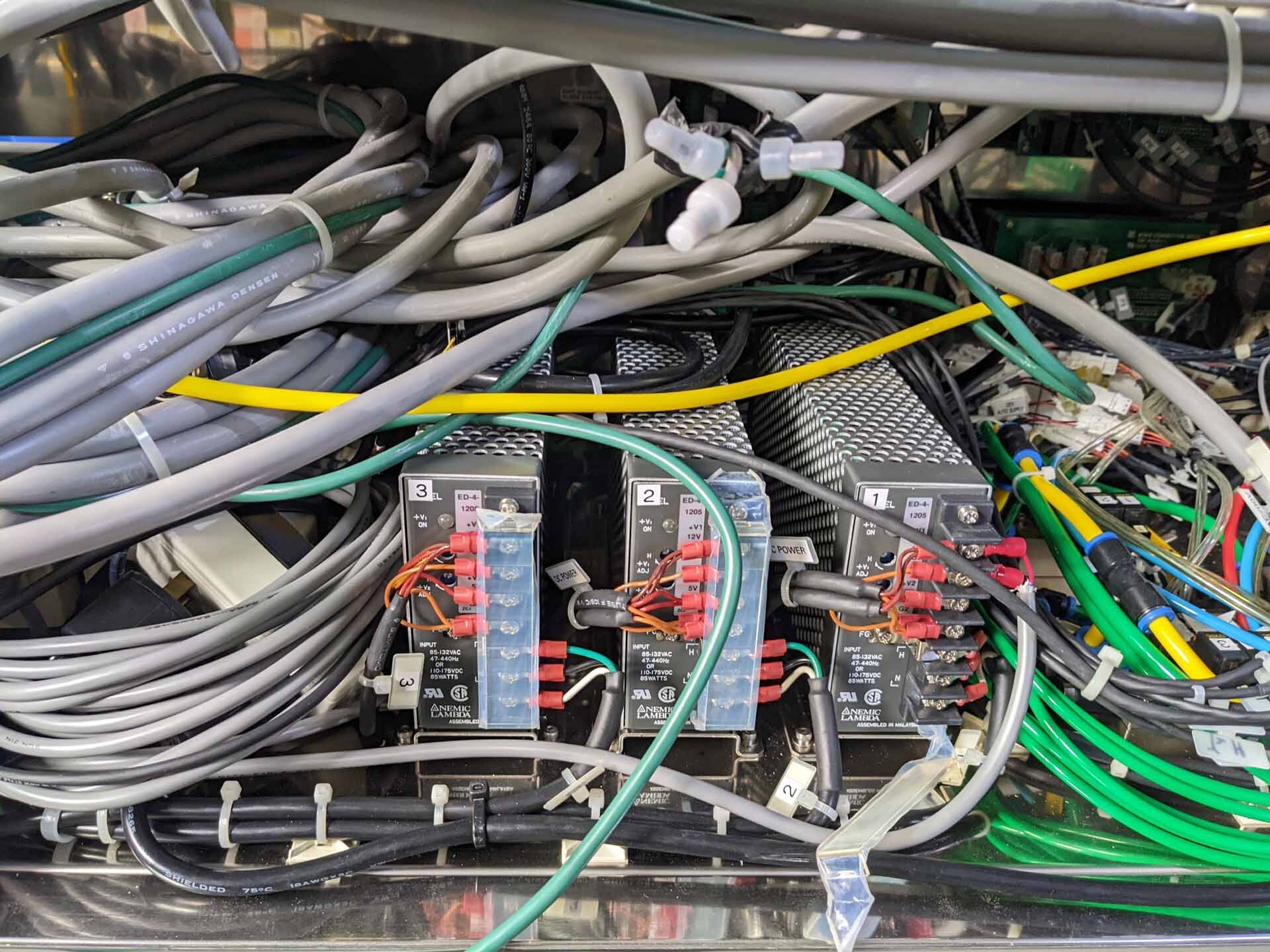

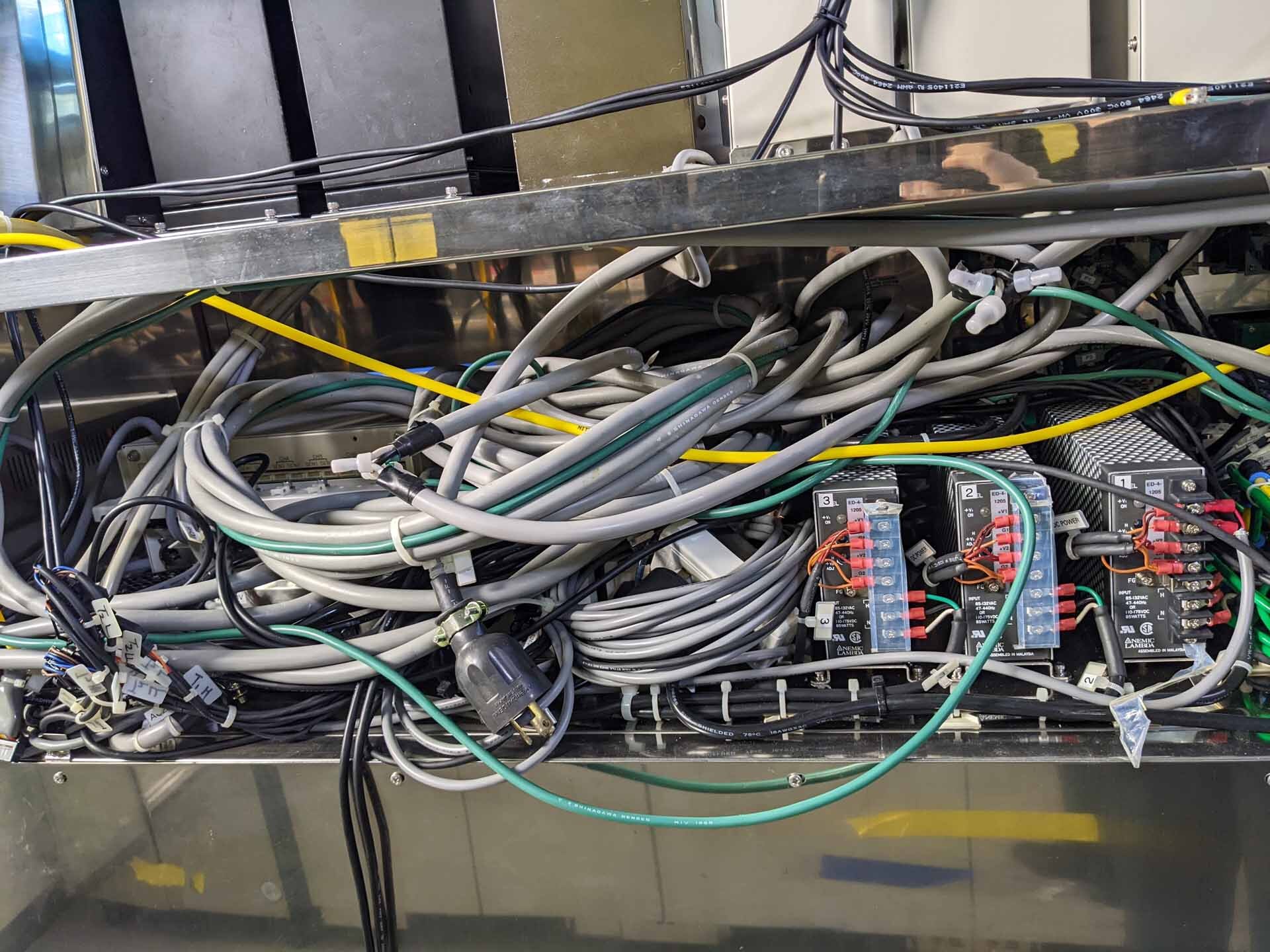

Power transformer

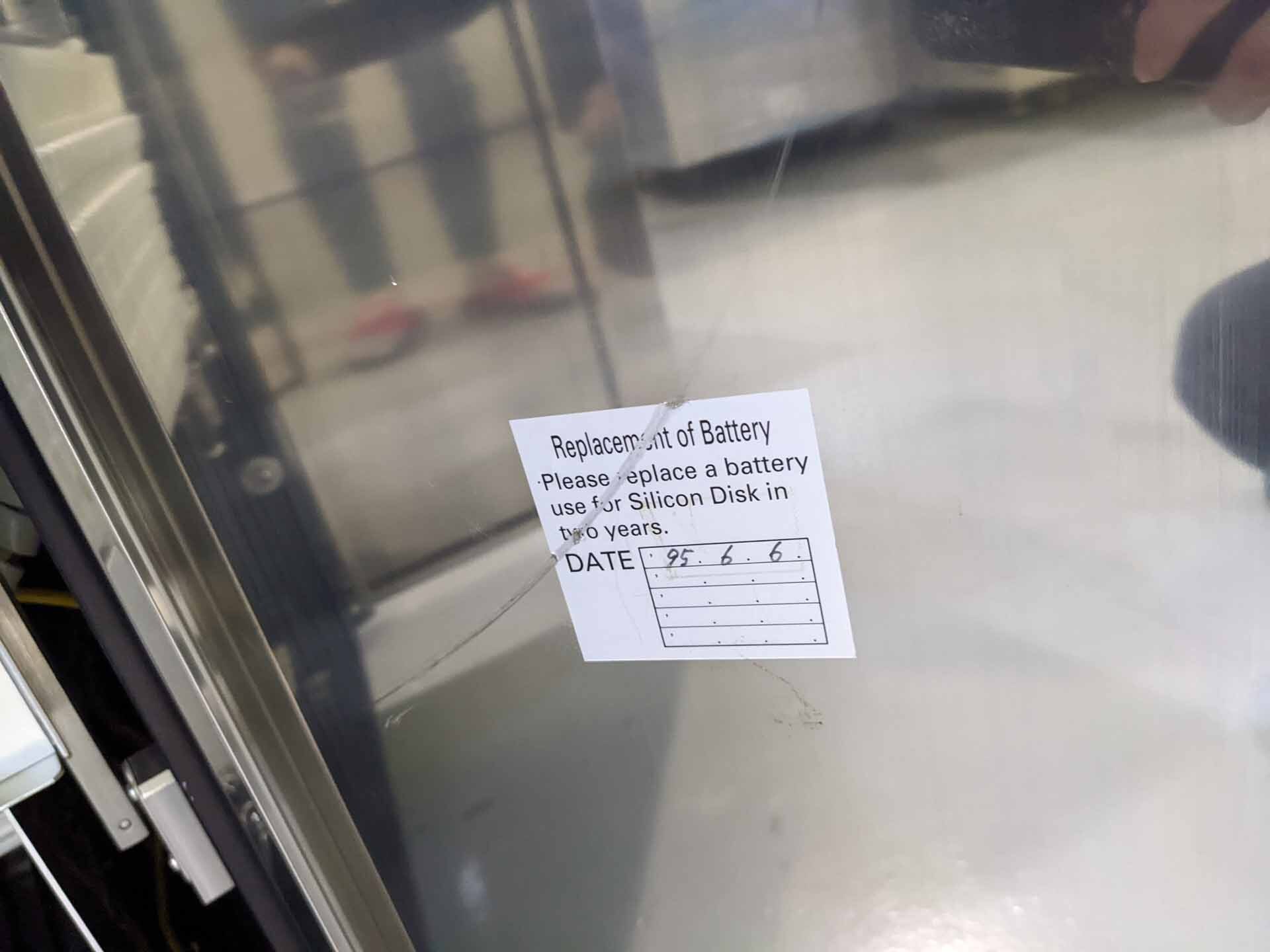

SHINWA THC Temperature and humidity controller

Hard Disk Drive (HDD) included

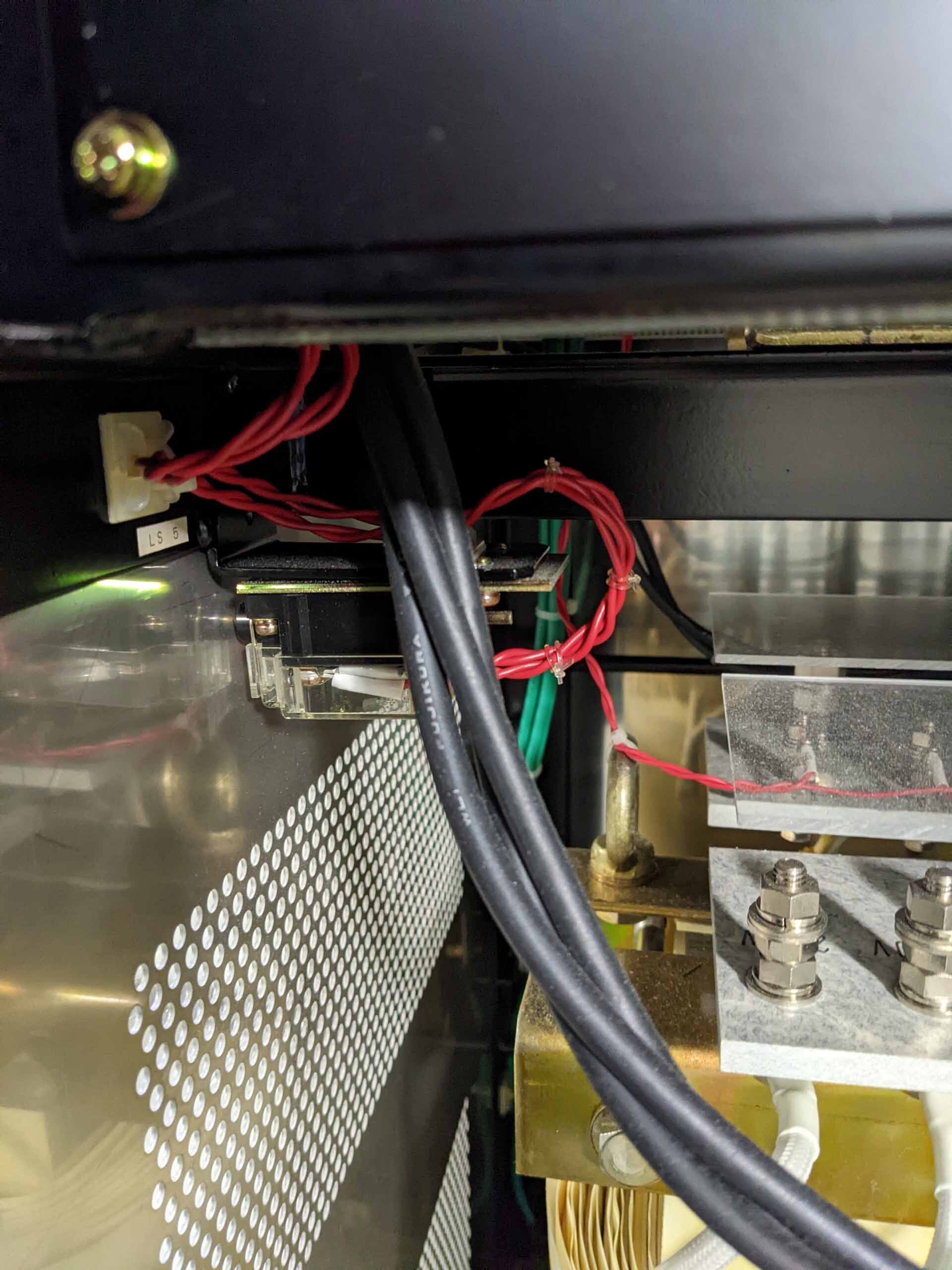

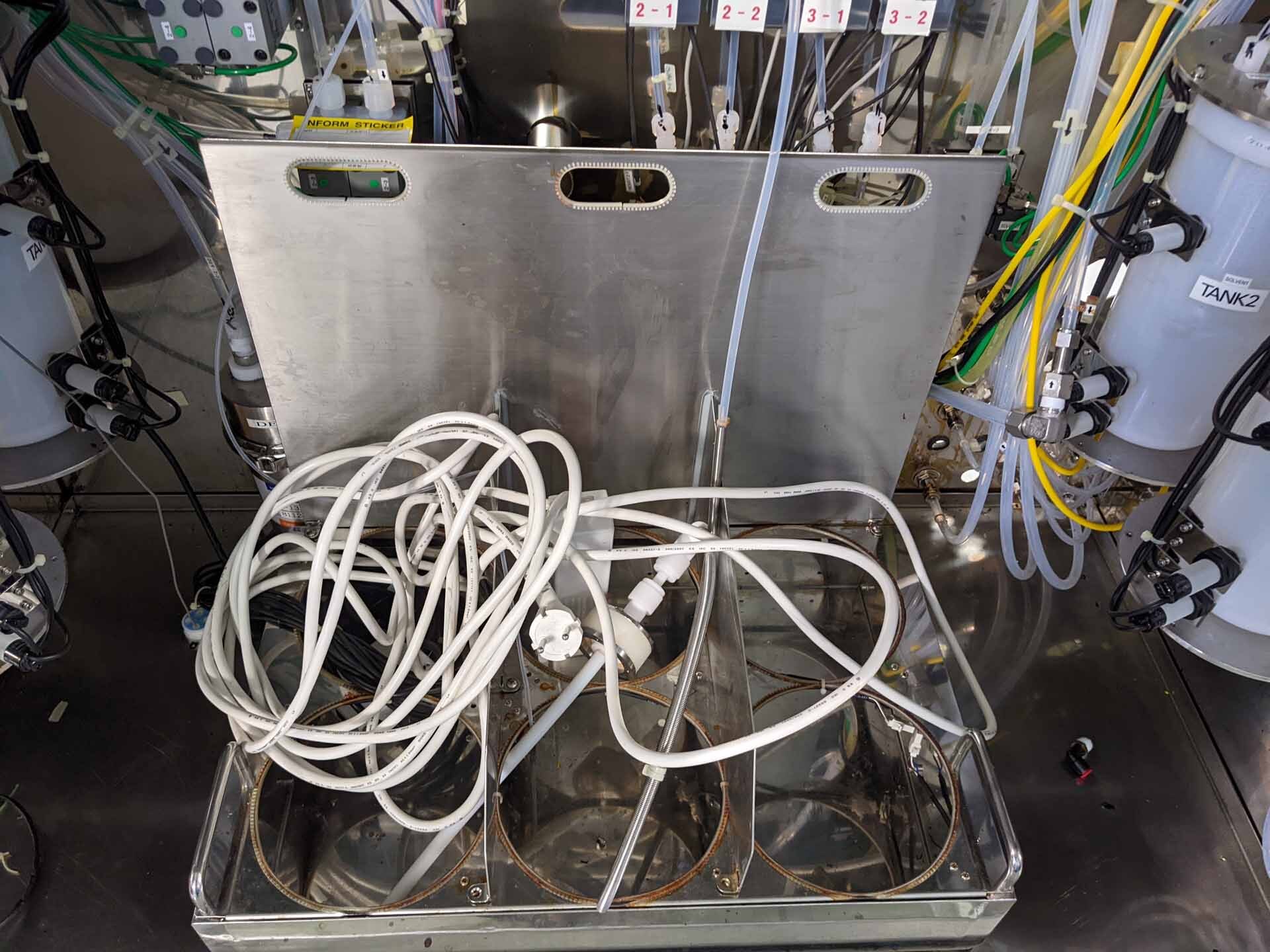

(2) Circular pumps missing

1995 vintage.

TEL / TOKYO ELECTRON Clean Track Mark 7 photoresist equipment is a high-end technology for photolithography, used in the production of high-end electronics products. It is used extensively in manufacturing semiconductor integrated circuits (ICs) and printed circuit boards (PCBs). TEL Clean Track Mark 7 system offers state-of-the-art features to ensure clean and efficient production of photomasks. TOKYO ELECTRON Clean Track Mark 7 offers advanced features such as a multi-zone, multi-patterned exposure process and anti-reflection coatings. This makes photomasks produced with the unit more precise, predictable and consistent. The machine also uses a high-end "super field" technology which offers the highest uniformity of illumination over the largest field possible with a single head exposure tool. This ensures precise and uniform exposure of the entire photomask. The "super field" technology also allows direct-on-wafer exposures for purposes of other applications such as post exposure bake (PEB) solutions. The asset also has a built-in data transfer model for communication with host systems. This feature allows for rapid downloads and analysis of data from the equipment. Clean Track Mark 7 photoresist system also has many advanced automation features such as integrated temperature control and shutter actuation. This allows precise and precise control of exposure times and allows for the precise tracking of product throughout the exposure process. This automation feature is critical for lowering the overhead costs related to photolithography production. TEL / TOKYO ELECTRON Clean Track Mark 7 photoresist unit also offers advanced protection features. These include a vibration isolation machine, static/dynamic protection, air filtration, and fault isolation. These features allow for greater protection of the tool's components during the exposure process and ensures that the asset remains in good operating conditions. Overall, TEL Clean Track Mark 7 photoresist model is an invaluable technology for the production of high precision and reliable photomasks. It offers advanced features and automation capabilities that enable the efficient production of complex circuits. The equipment is well suited for use in the semiconductor and PCB industries.

There are no reviews yet