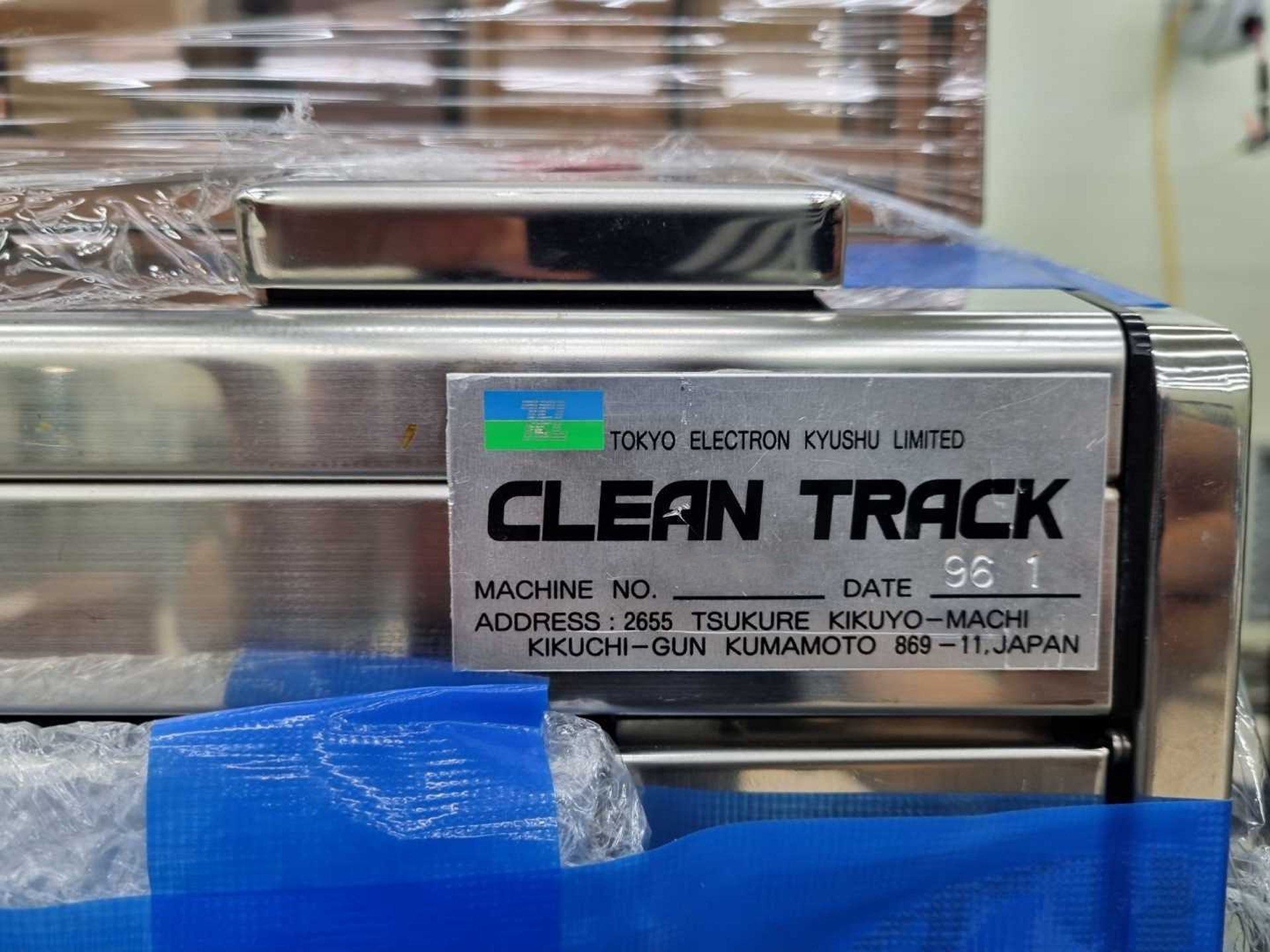

Used TEL / TOKYO ELECTRON Clean Track Mark 7 #9395128 for sale

URL successfully copied!

Tap to zoom

ID: 9395128

Wafer Size: 8"

Vintage: 1996

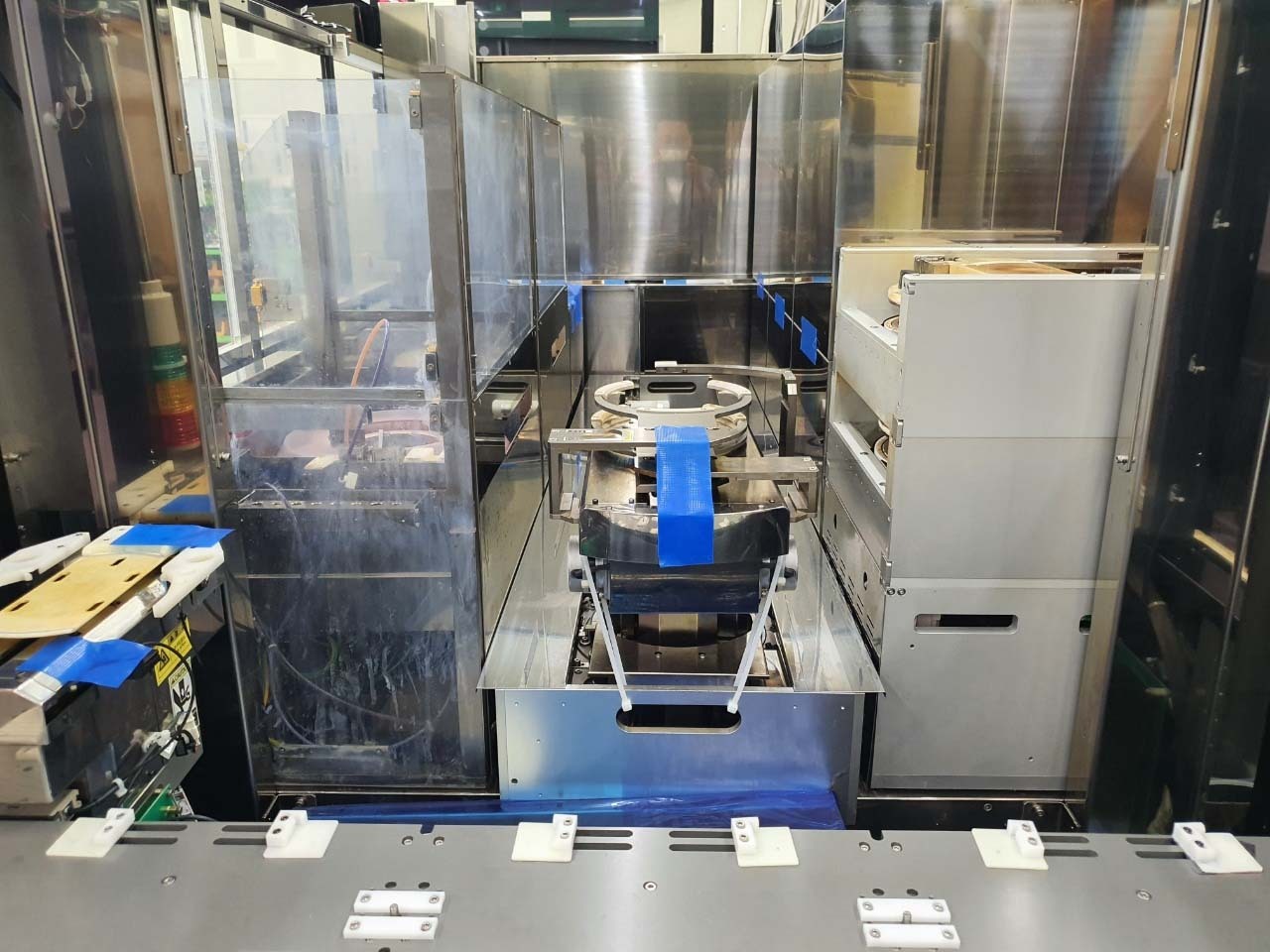

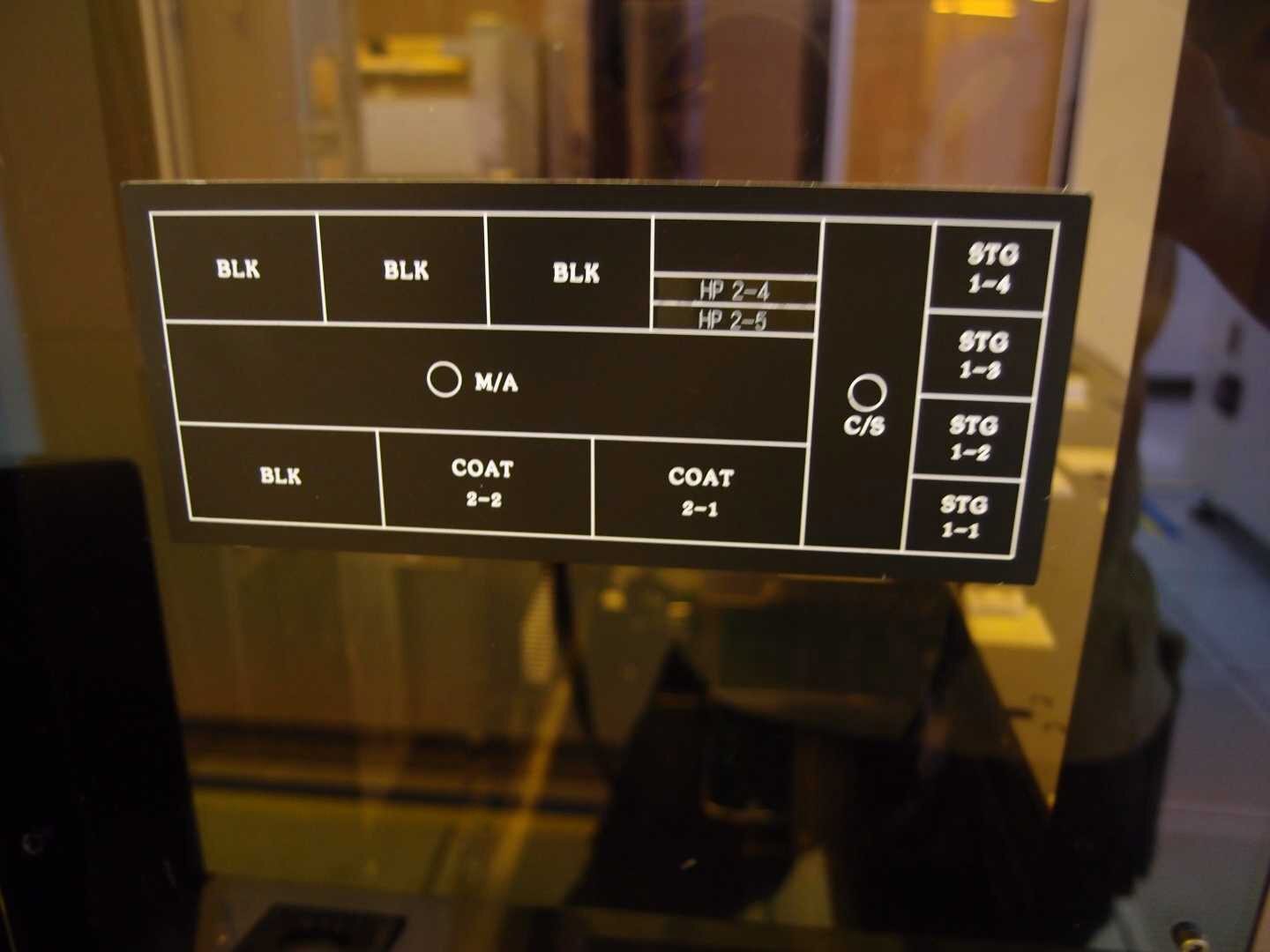

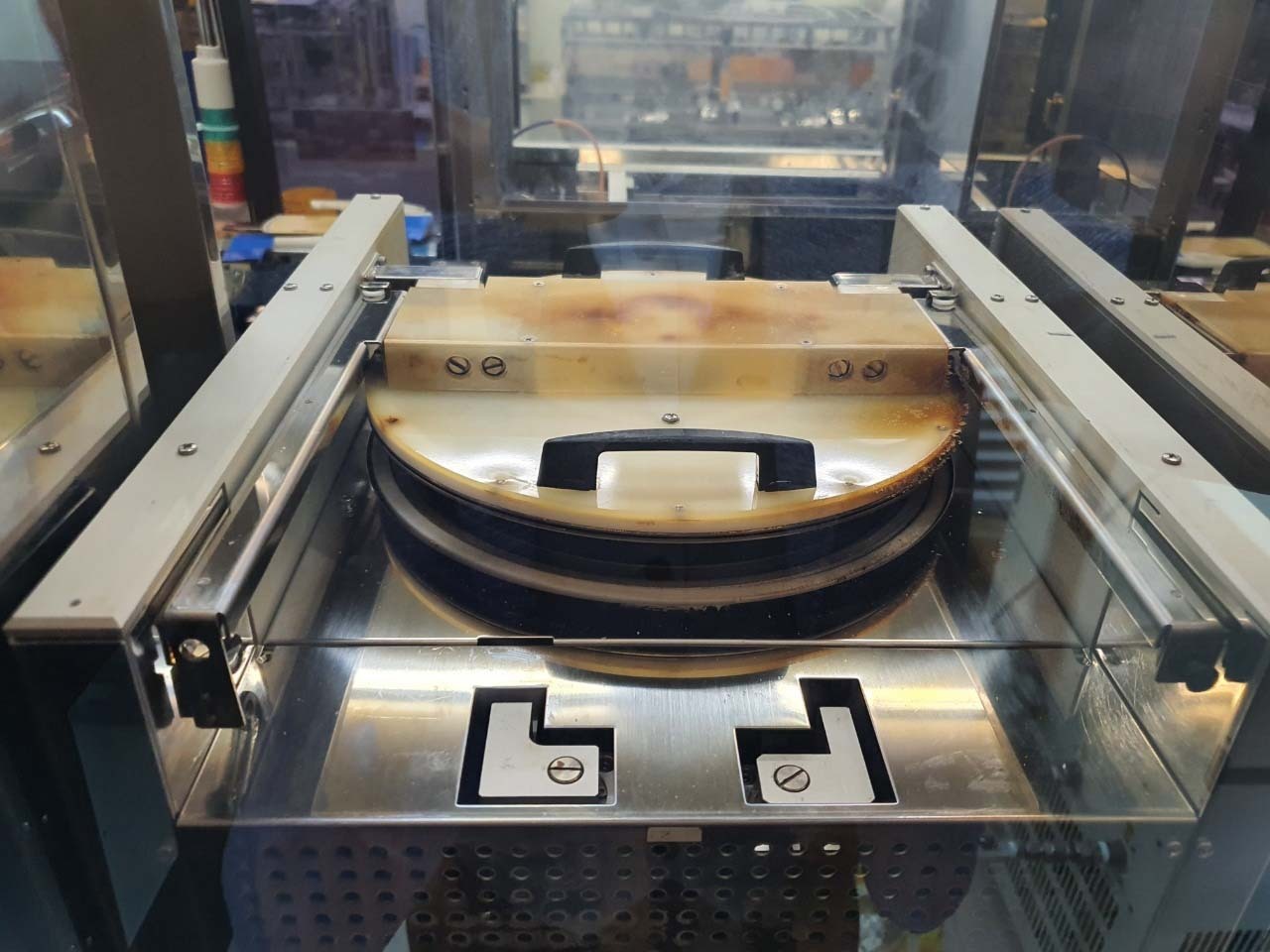

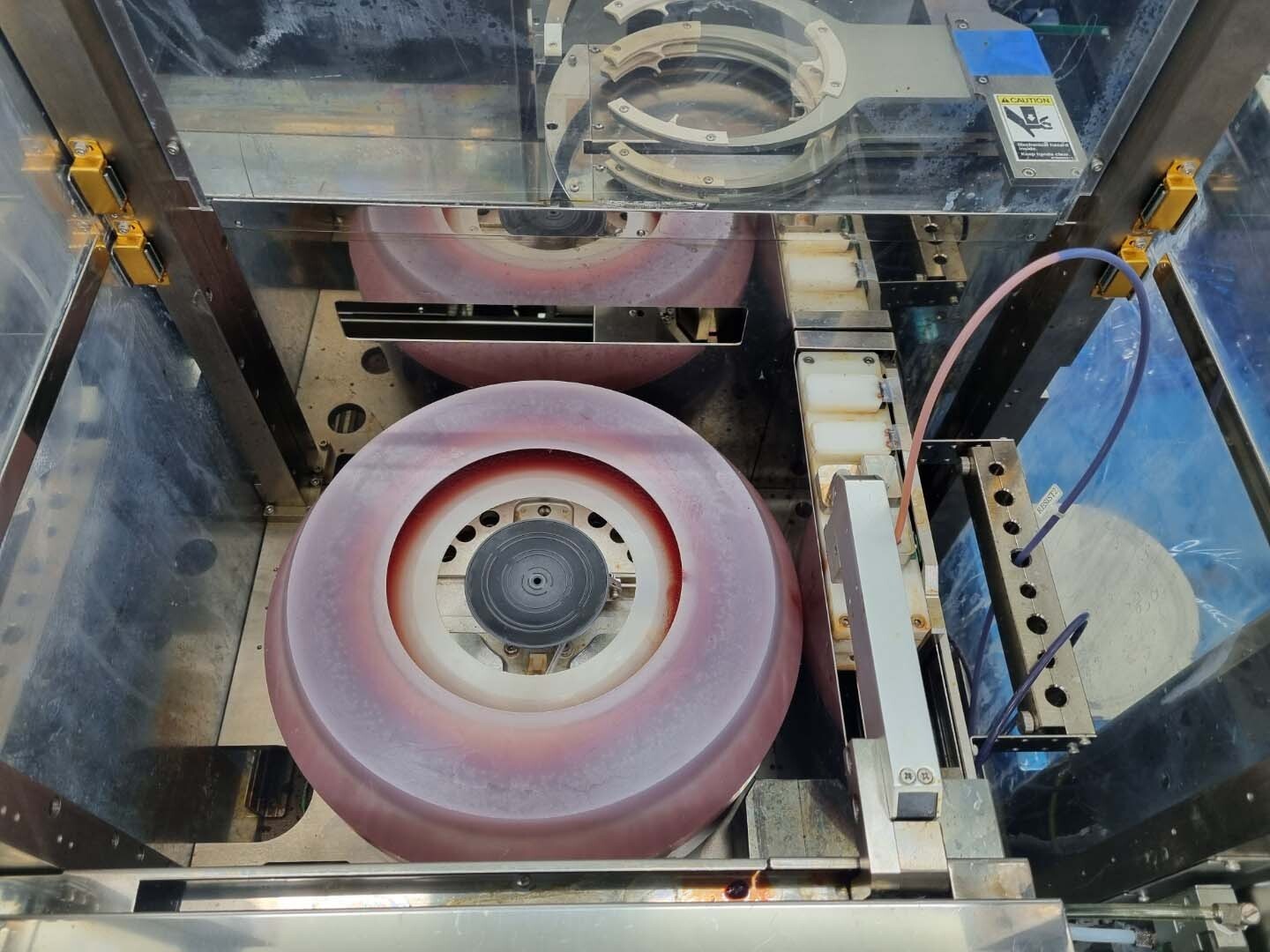

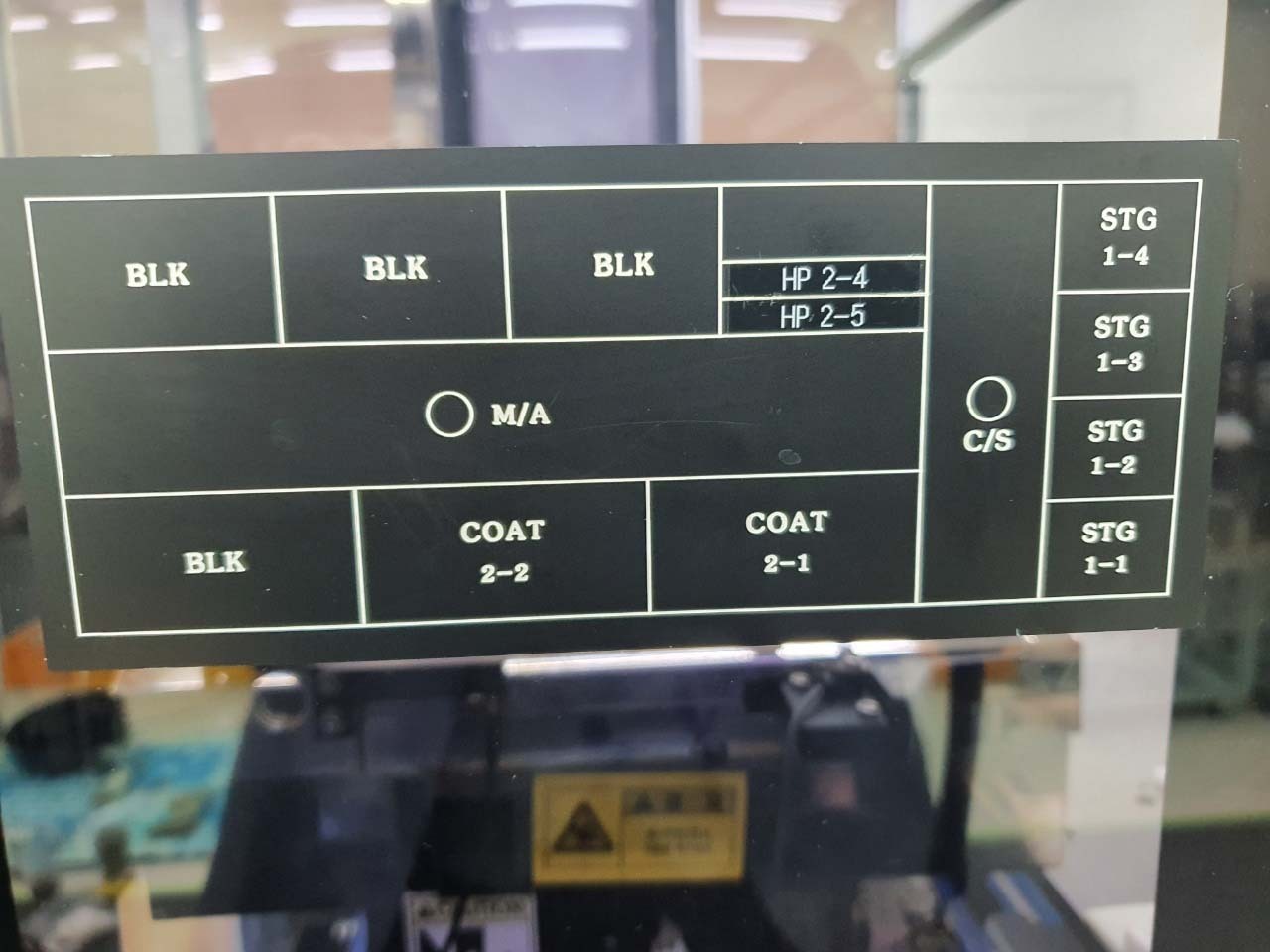

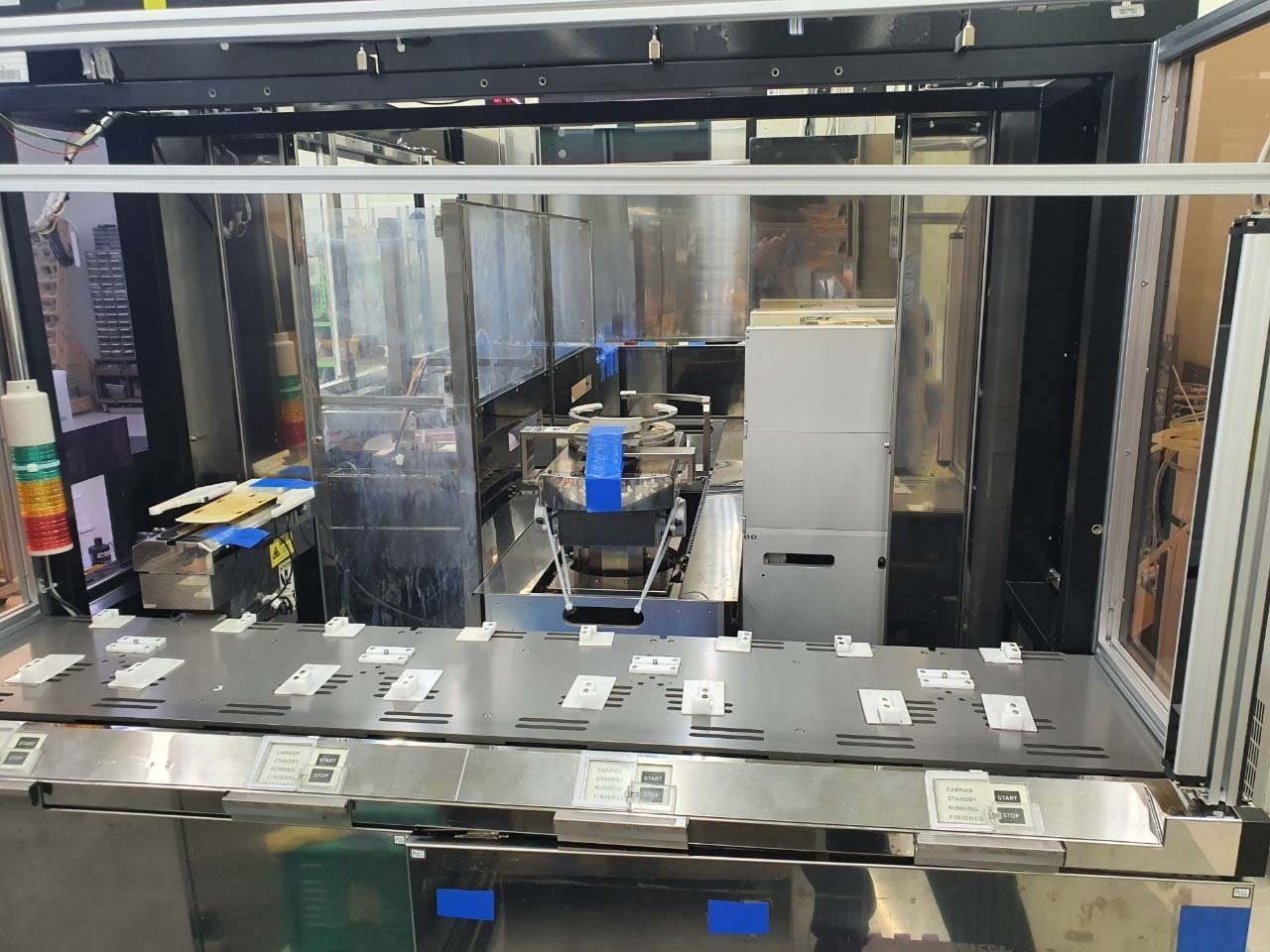

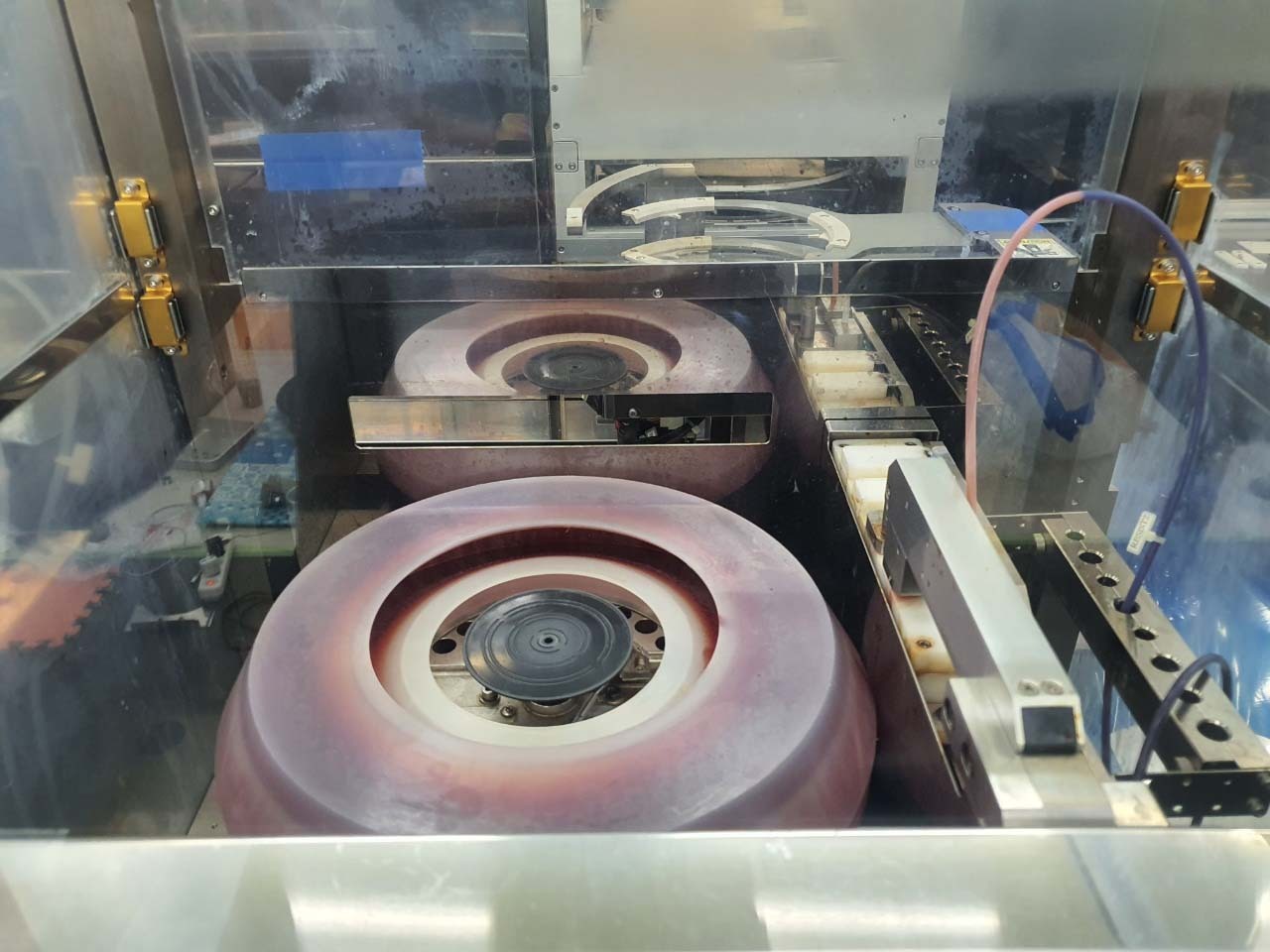

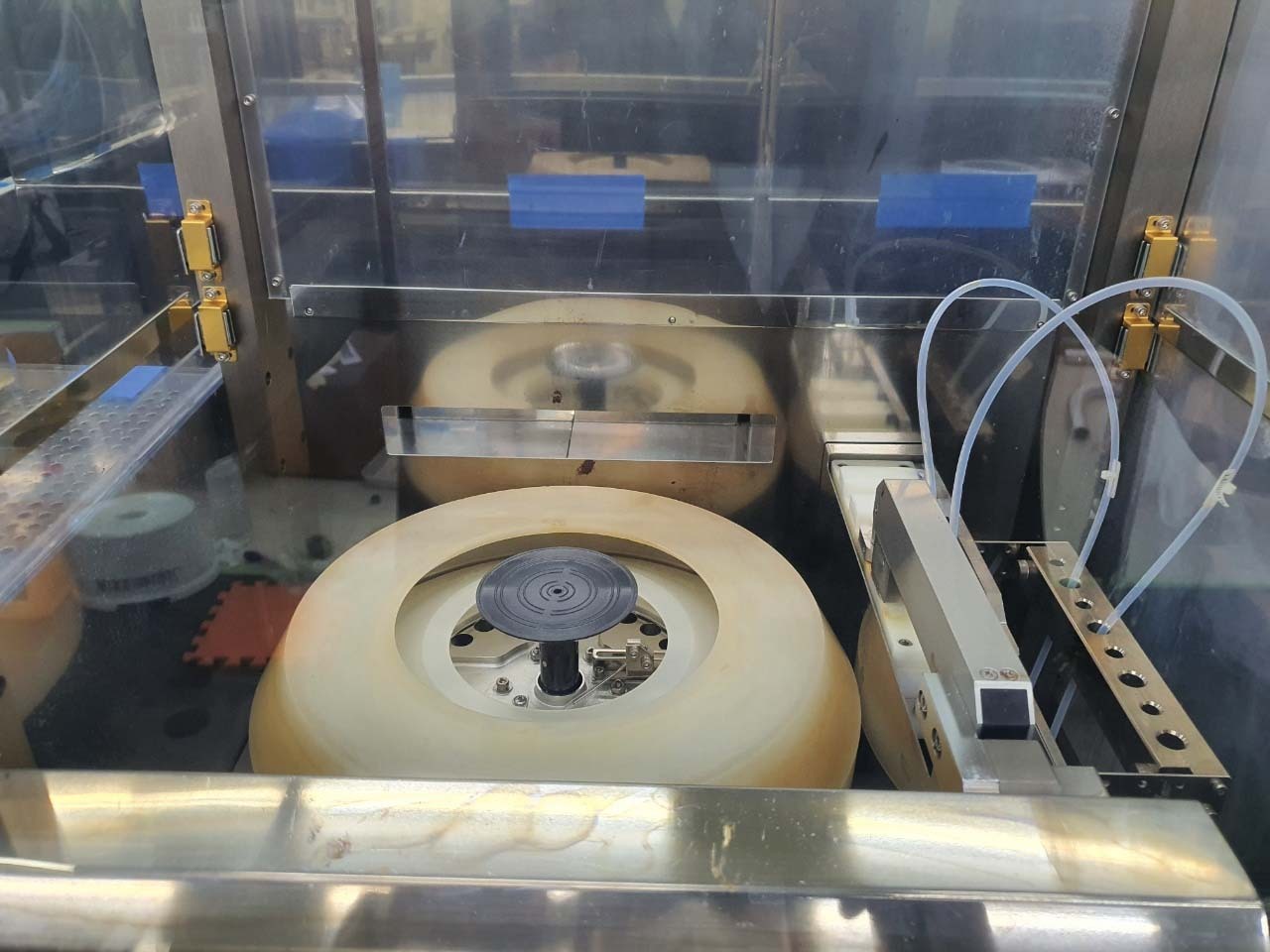

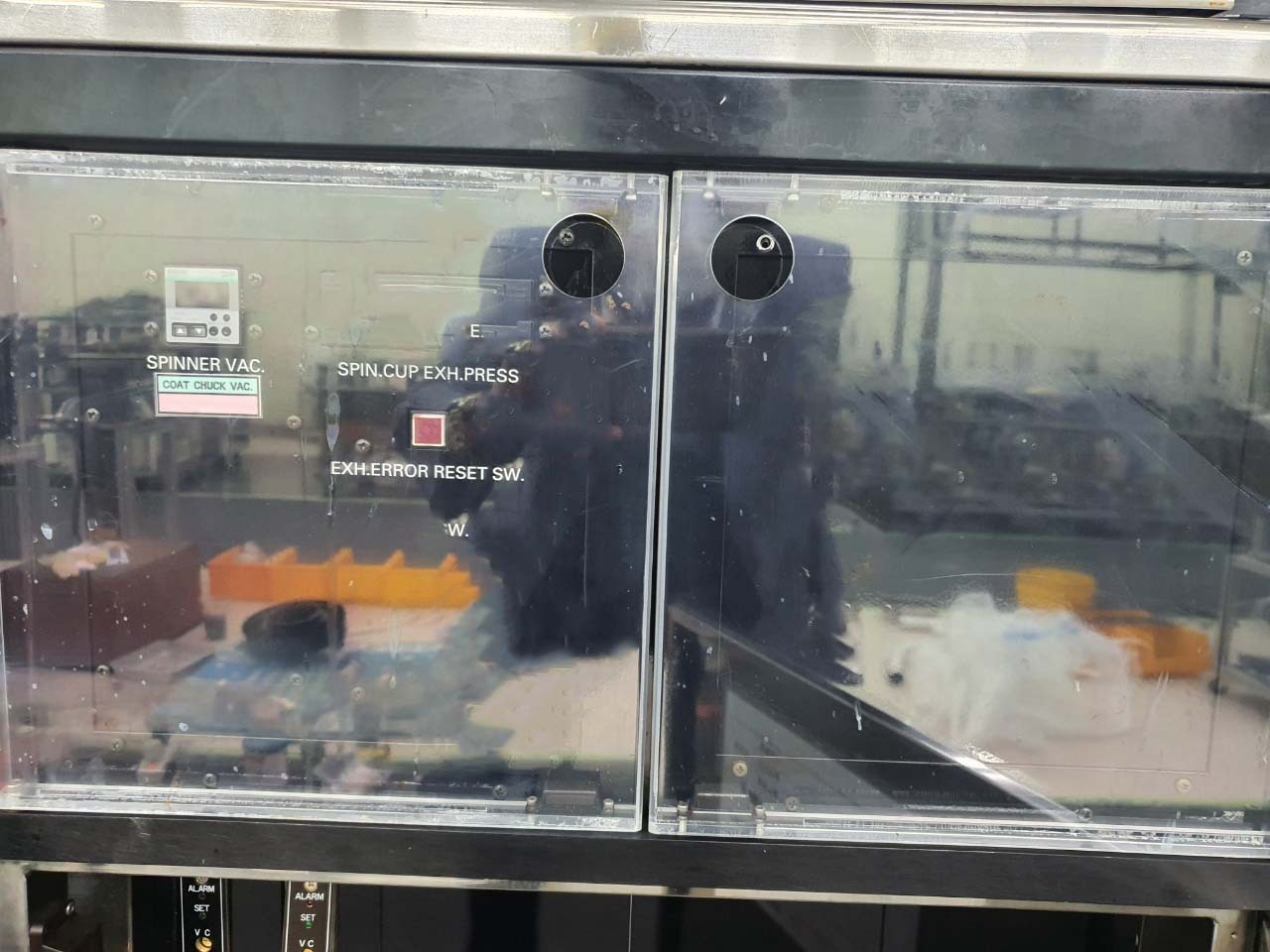

(2) Coater system, 8"

Wafer flow: Right to left

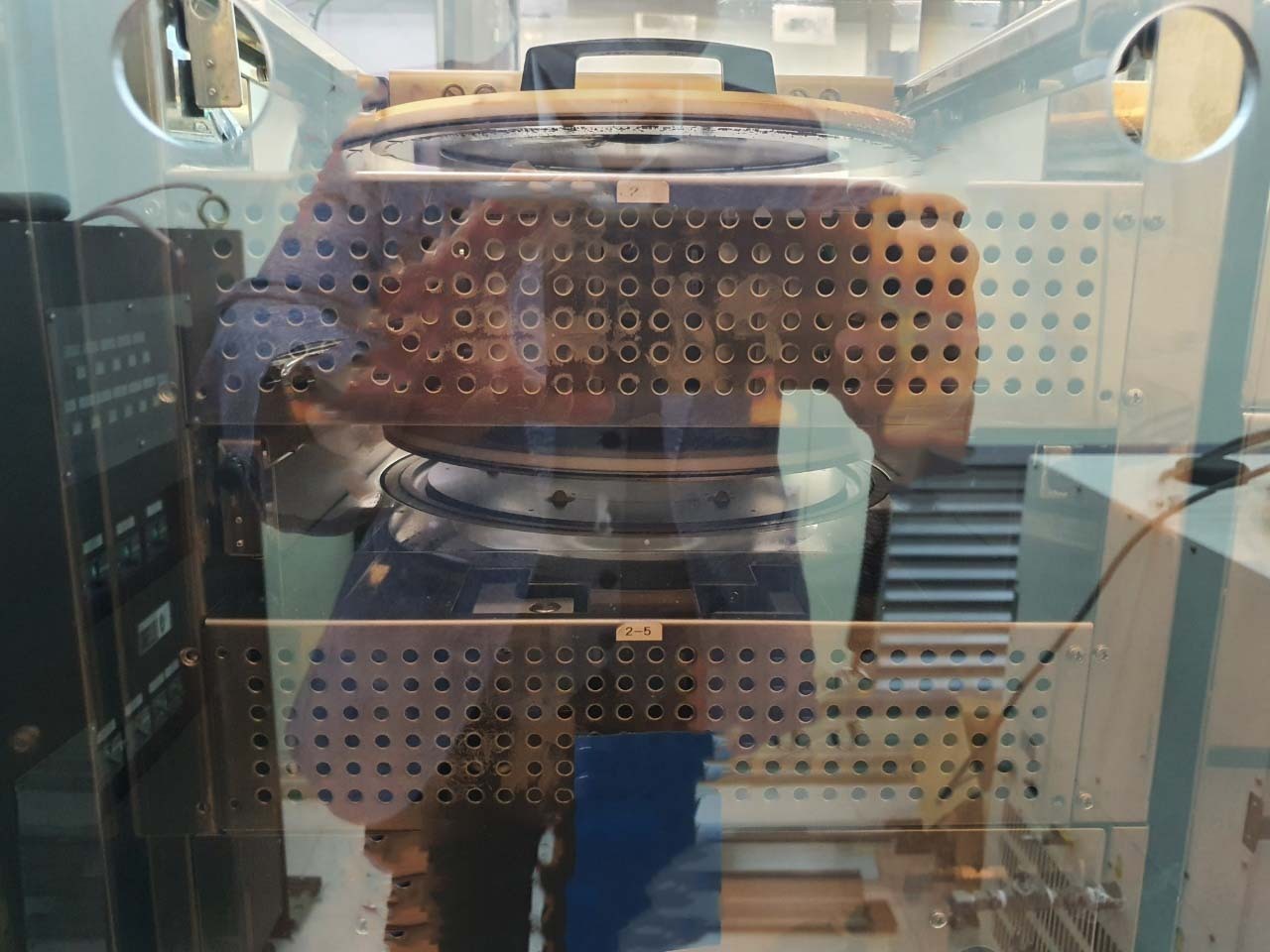

Single block system

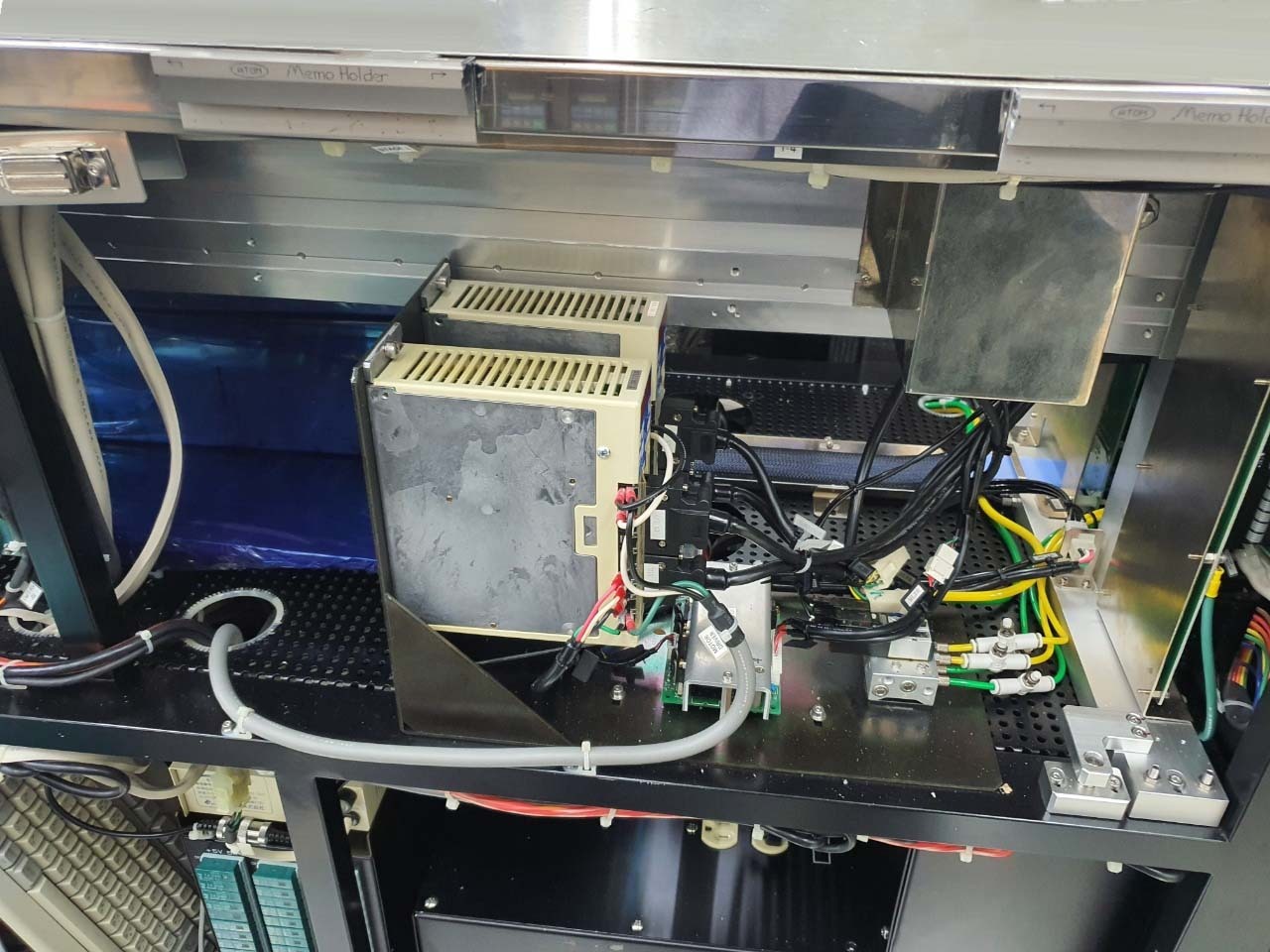

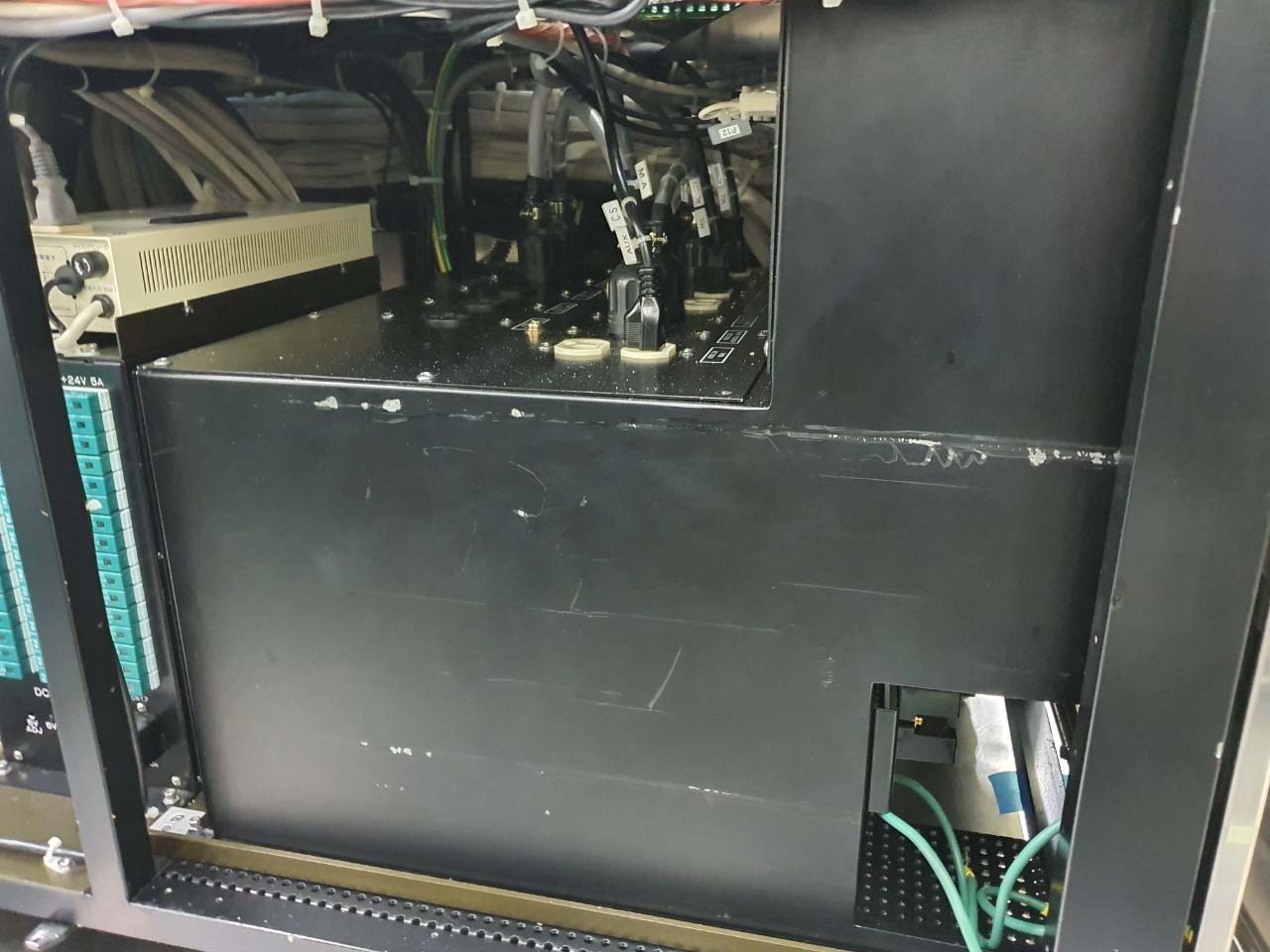

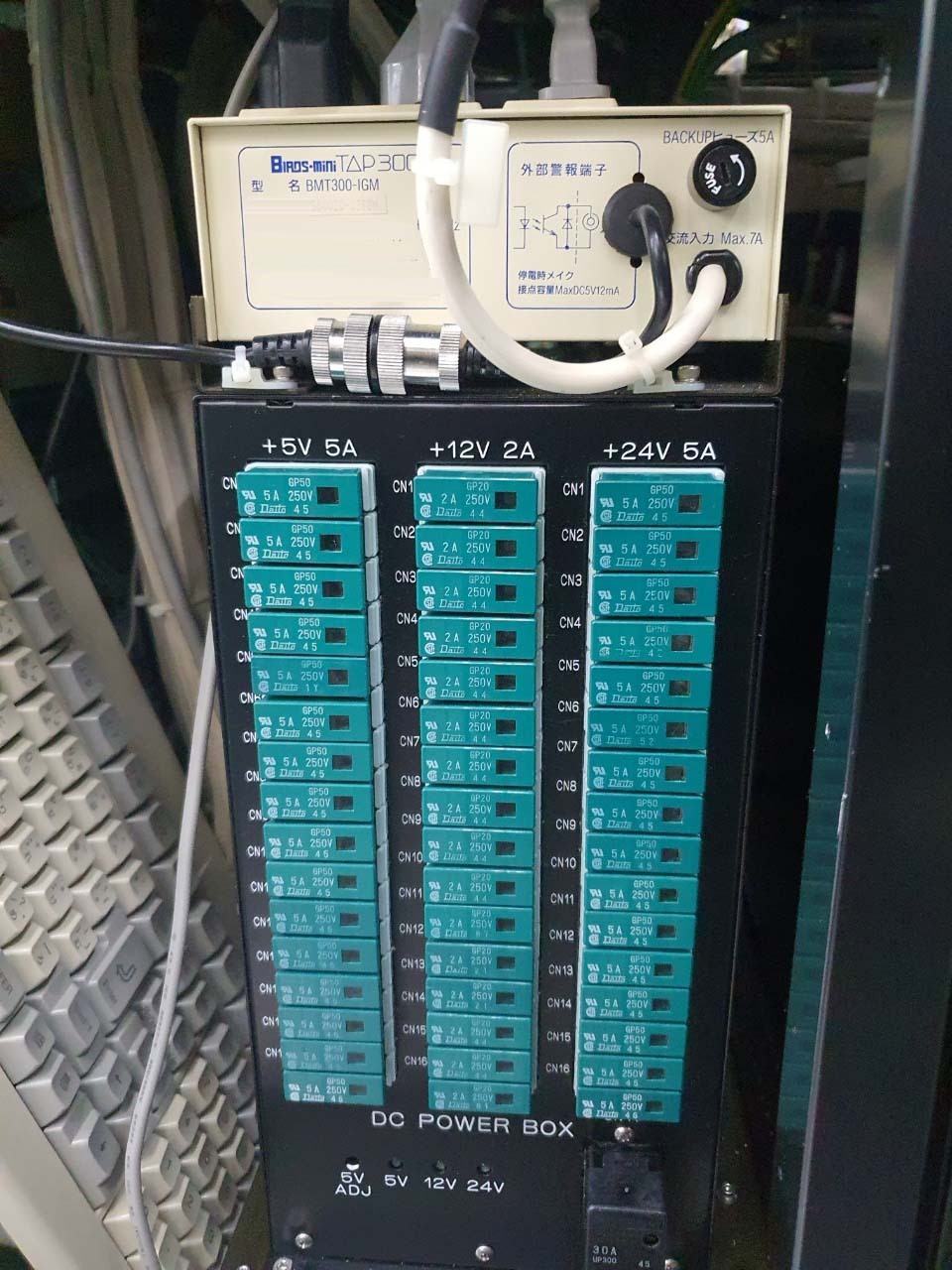

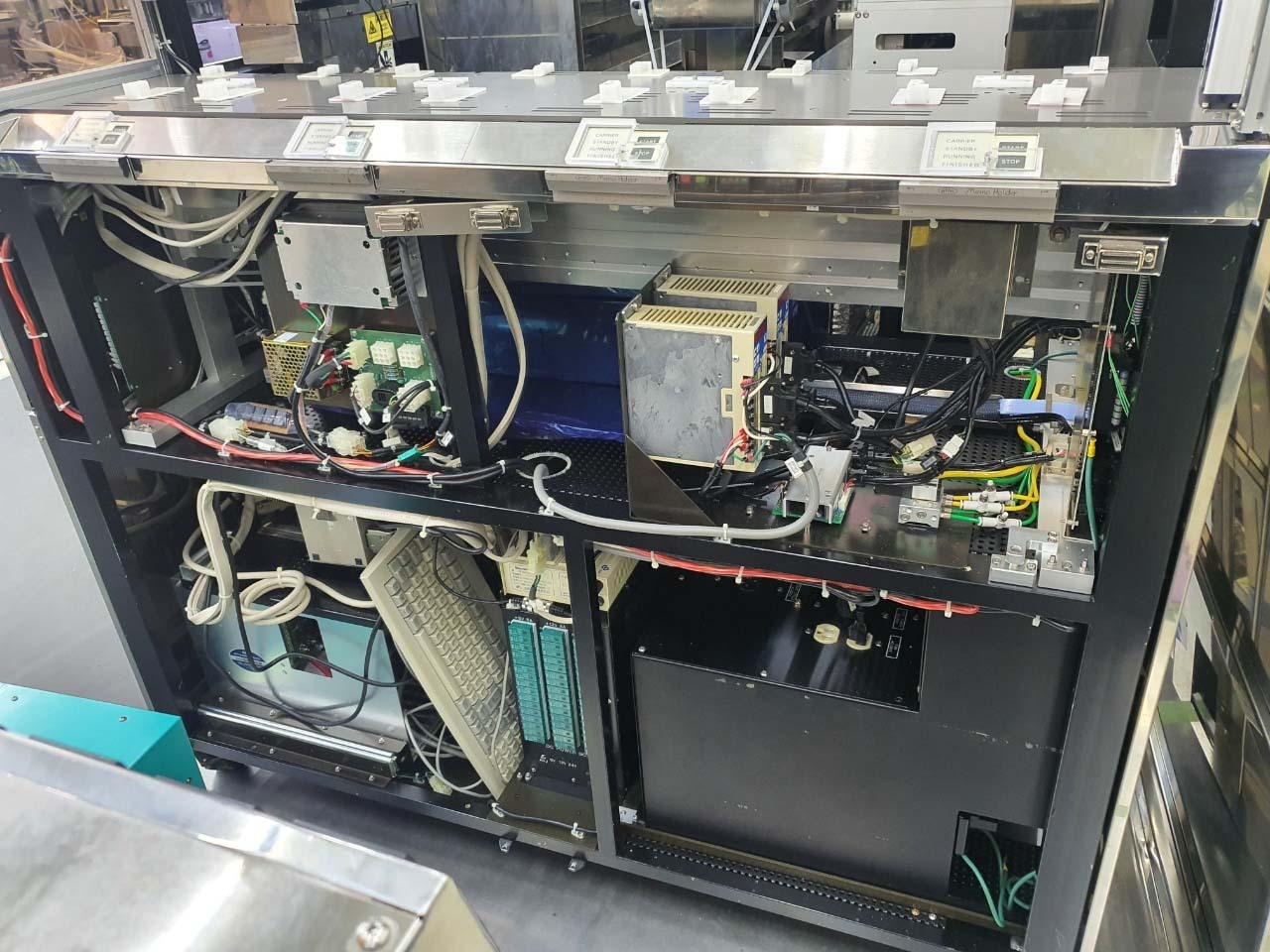

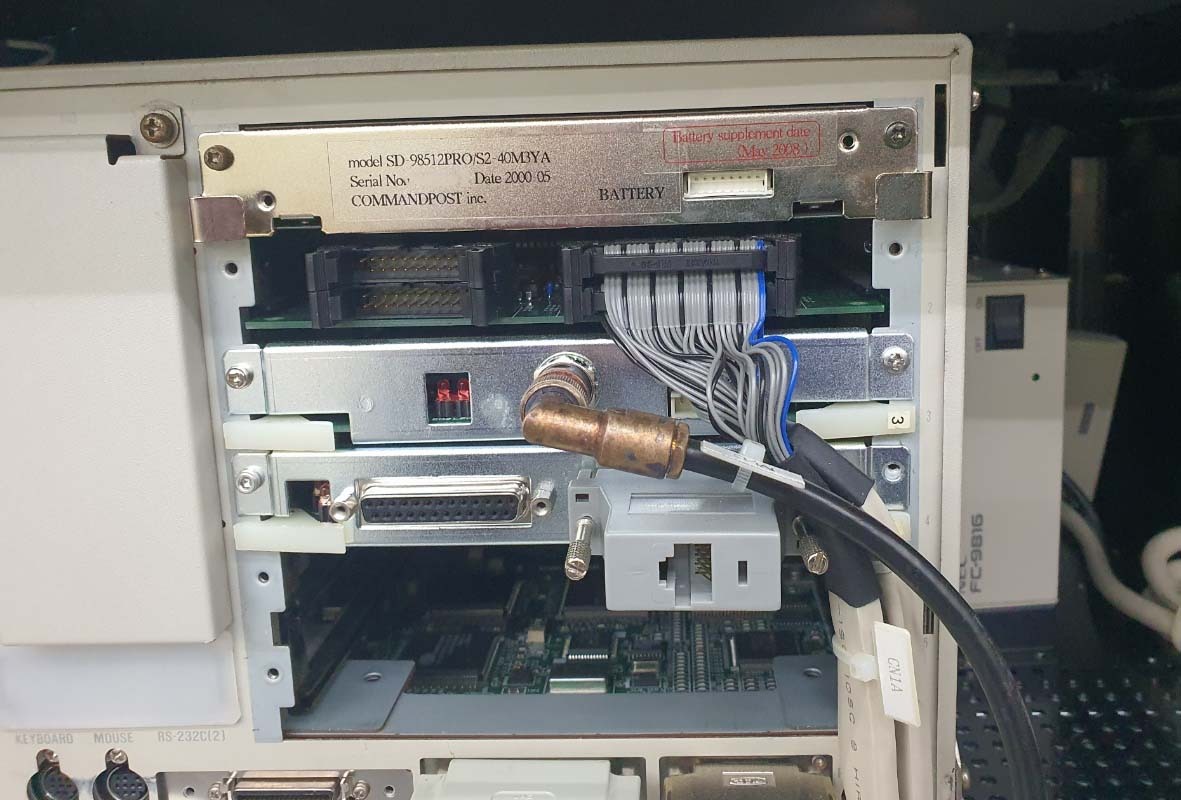

TEL Clean Track Mark 7 Controller

Stage/Indexer: Non SMIF/Open Uni-Cassette CS/Cassette Station

CSA/Cassette station arm

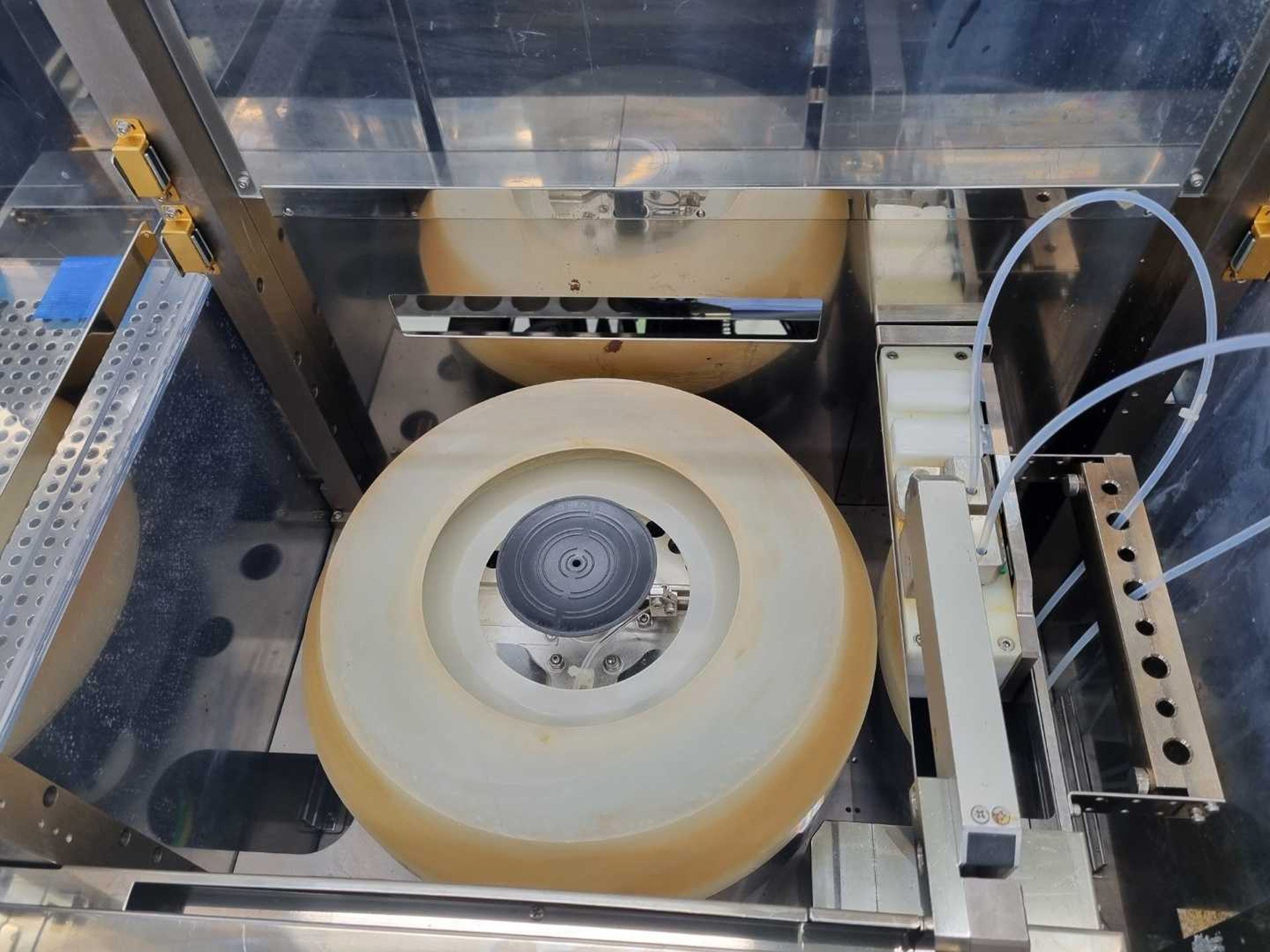

Normal photo resist coat 2-1

(2) Normal photo resist dispense nozzles per coat unit

(2) Normal photo resist dispense nozzles

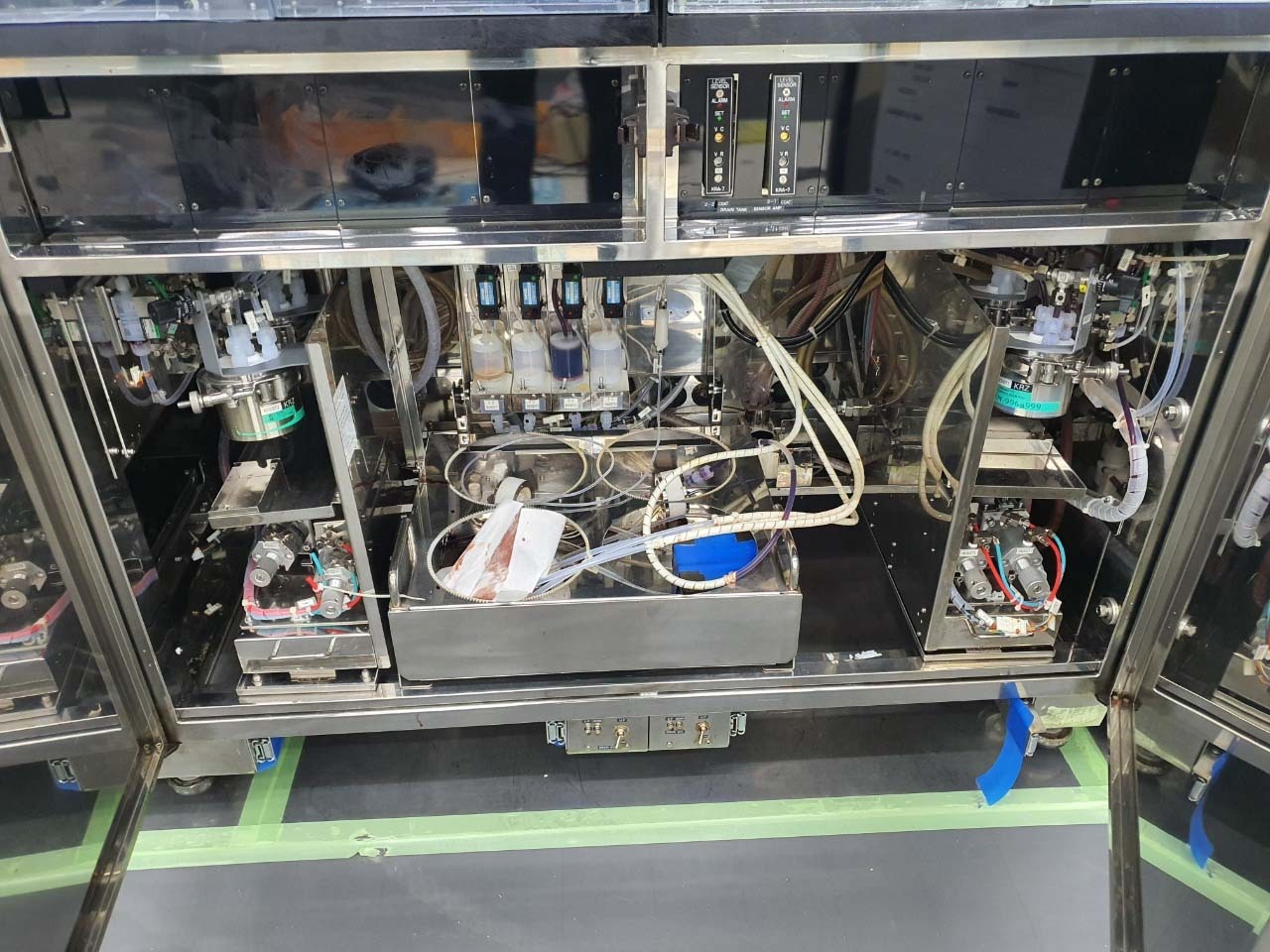

(2) Bellows resist pumps per COT Unit

Single back rinse nozzle

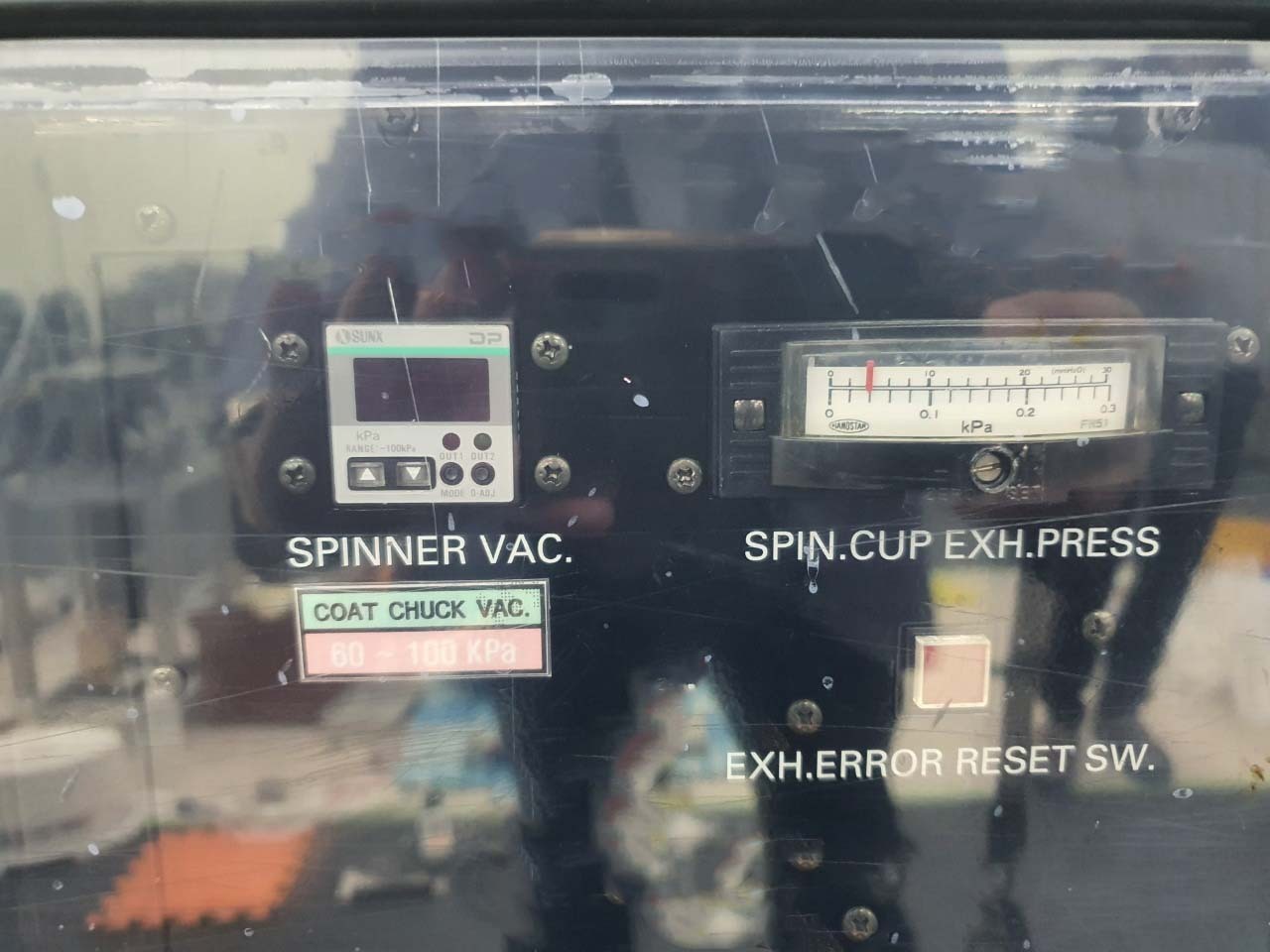

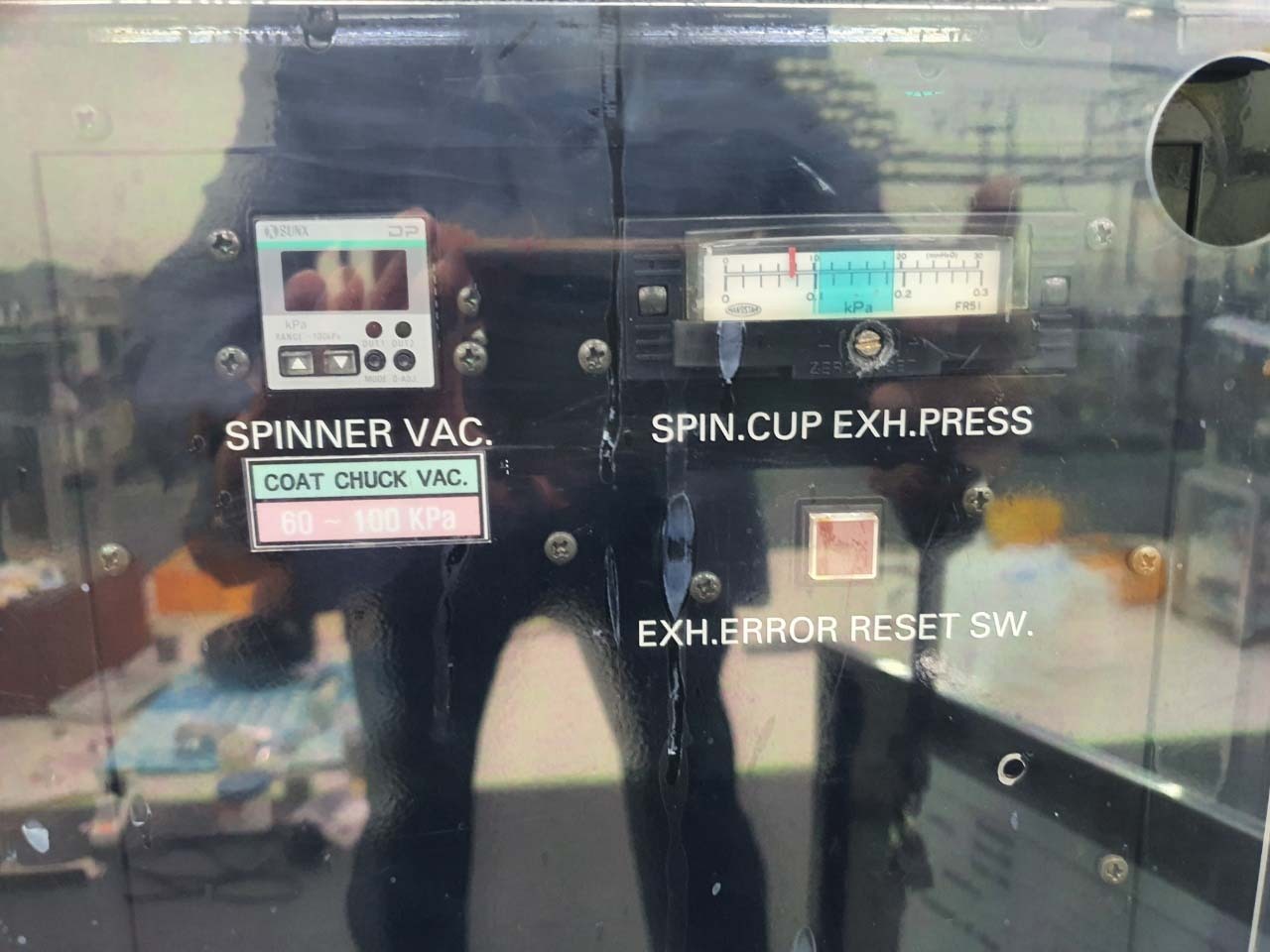

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Photo resist bottle quantity: (2) Spaces

Photo resist auto exchange

Cup type: PP for Upper cup and inner cup

Auto damper: Cylinder only

Normal Photo Resist Coat 2-2

(2) Normal photo resist dispense nozzles per coat unit

(2) Normal photo resist dispense nozzles

(2) Bellows resist pumps per COT Unit

Single back rinse nozzle

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Photo resist bottle quantity: (2) Spaces

Auto dummy dispense system

Cup type: PP for upper cup and inner cup

Auto damper: Cylinder only

PRA/Process Block Robotics Arm

(2) LHP/Low temperature oven unit

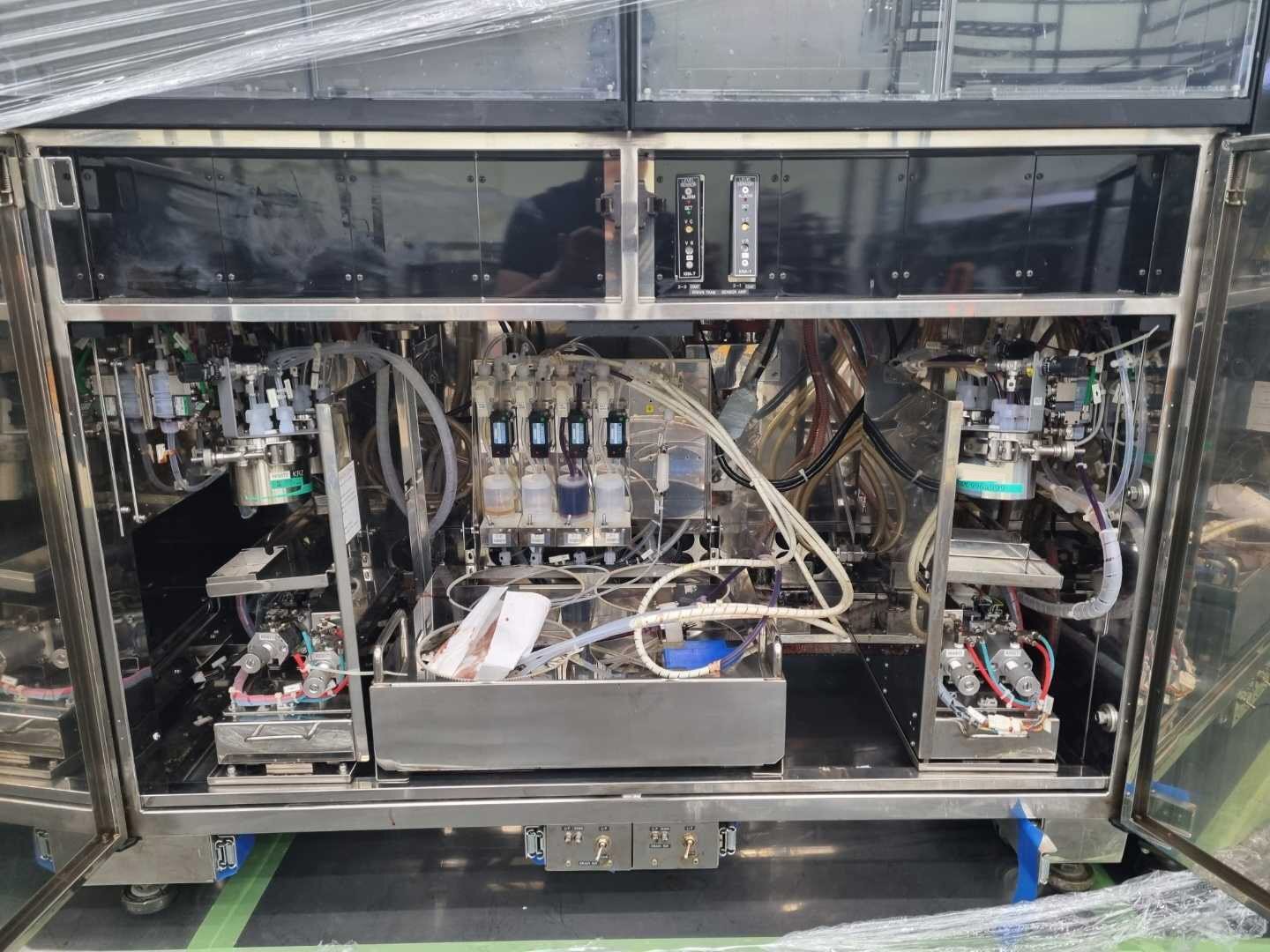

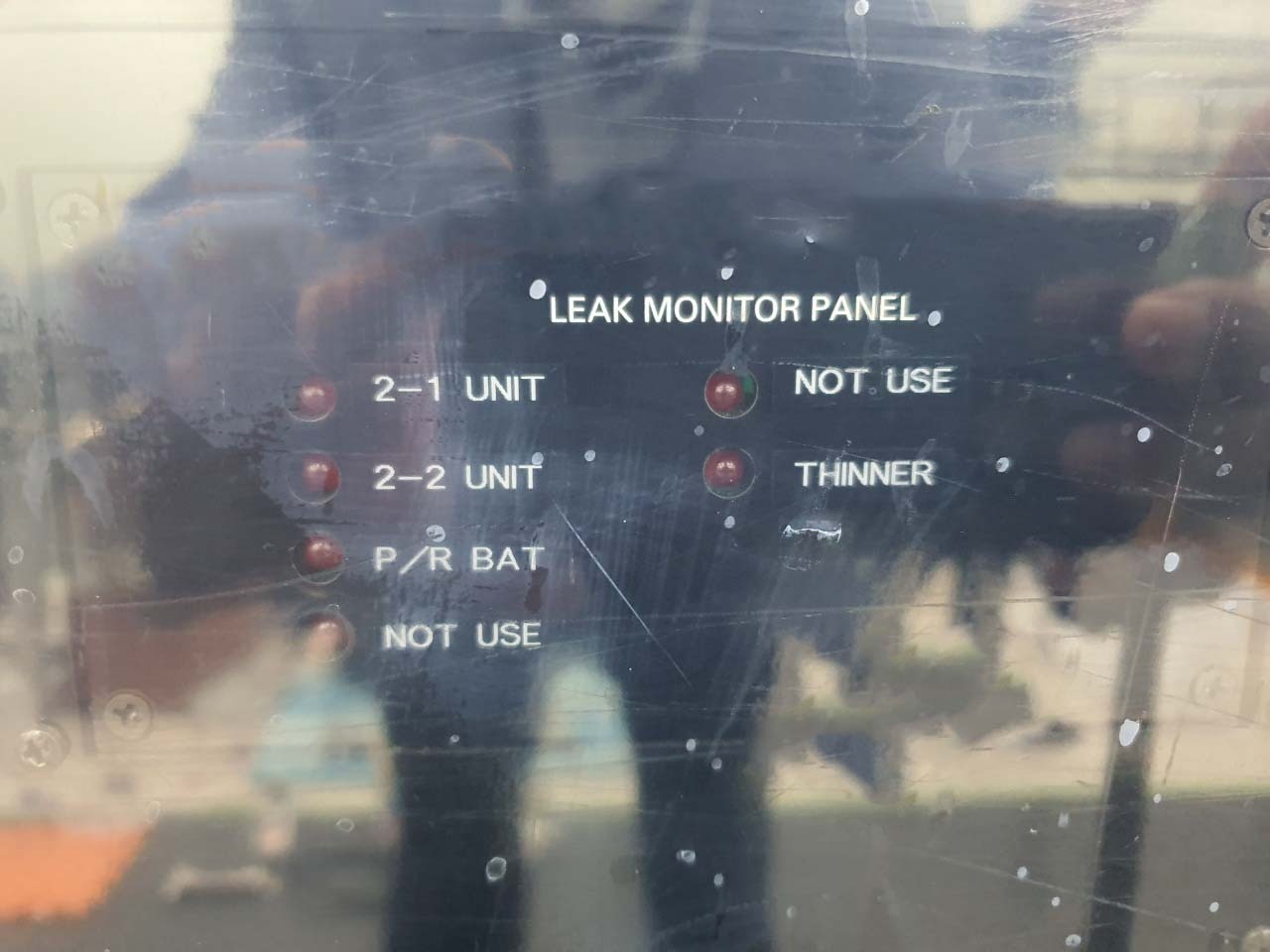

External chemical supply system

Solvent supply system

Solvent chemical type

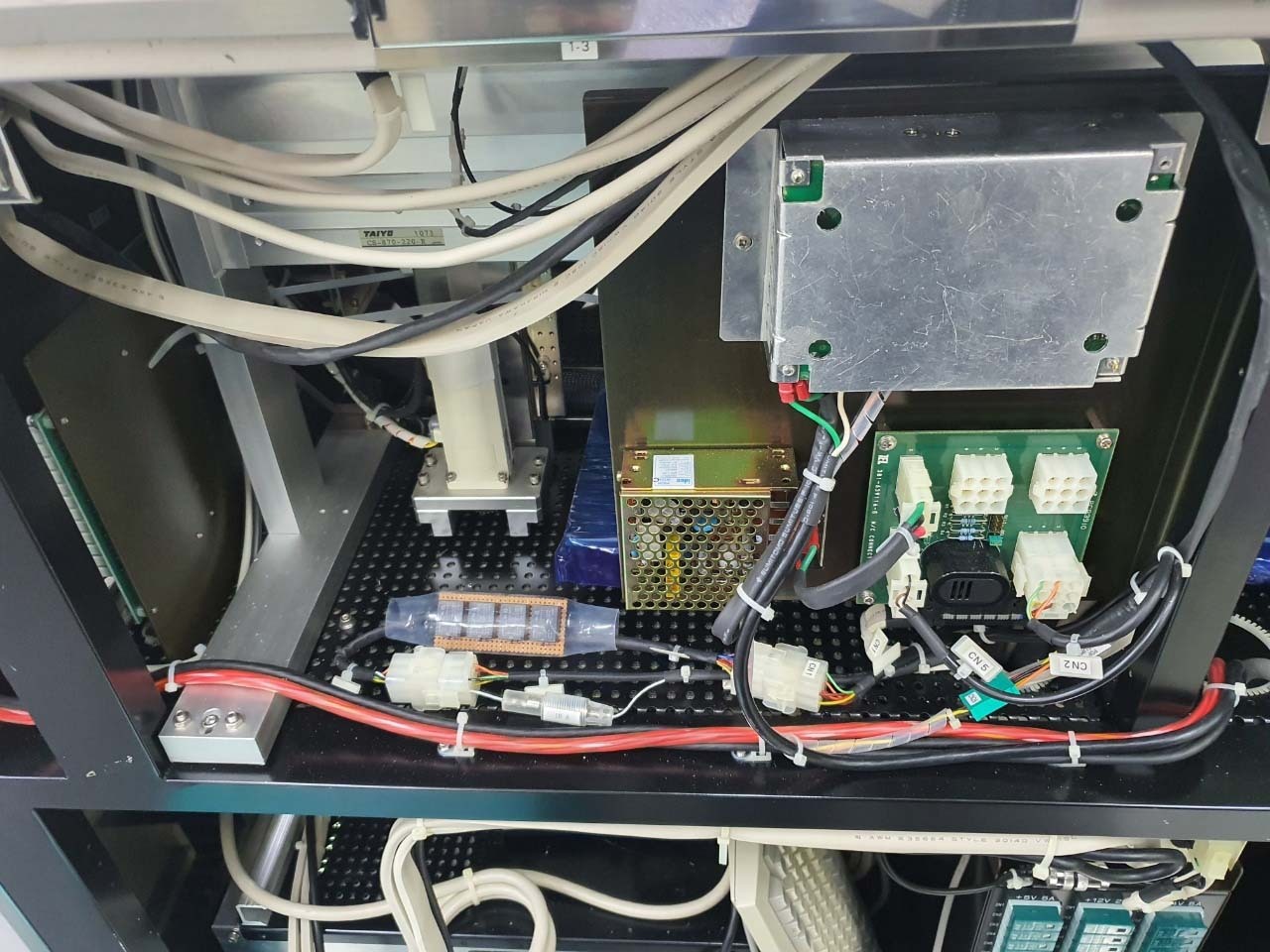

Chemical Center Supply System(CCSS)

With (2) 3L Teflon buffer tank

Tank type: 2 Buffer tank (3L/Tank, Teflon)

(2) Cover coat units

TEL OEM SMC Multi controller: Rear main body

Power transformer AC Cabinet : 208 VAC, 3 Phases, 50/60 Hz

1996 vintage.

TEL / TOKYO ELECTRON Clean Track Mark 7 is a photoresist equipment that enables high throughput production of integrated circuits. The system is designed to perfect photoresist coating and resist trimming processes with remarkable accuracy, enabling clean, symmetrical, and well-defined circuit patterns. At the heart of TEL Clean Track Mark 7 lies its cutting-edge automated coating station. This station works by precisely applying photoresists to wafer surfaces through atomic layer deposition (ALD). ALD is used to ensure uniform coating coverage, even accounting for anywhere on the wafer that is difficult to reach. Its low-pressure vapor jet spray also maximizes solvent efficiency. This is especially important for smaller devices where consistent coverage of the resist material is important. TOKYO ELECTRON Clean Track Mark 7 also features a high-accuracy resist trim process. It uses an advanced near-field beam optics unit to trim off unwanted resist residues. This machine features a unique light beam angle setting, allowing it to accurately profile the edges of the desired pattern. It also features a high resolution, 0.94 micron laser, enabling clean, precise trimming. The tool also offers automatic settings which monitor the trim levels and make sure they are maintained. Furthermore, Clean Track Mark 7's high-precision substrate aligner offers excellent uniformity of the resist material over the wafer. This asset also operates at a very low temperature, ensuring uniform coverage with minimal temperature fluctuations. By using a combination of optical recognition and direct displacement/alignment techniques, the substrate aligner can perform precise air gap measurements and resist pattern formation. In addition to its photoresist capabilities, TEL / TOKYO ELECTRON Clean Track Mark 7 also features several other processes which aid in the wafer production process. One of these is the lift-off process, which is used for the removal of non-processed areas upon the completion of the resistcoat process. This model is engineered for high accuracy- it utilizes an efficient drain-gasket equipment which prevents excess solvent from spilling and damaging the wafer. With TEL Clean Track Mark 7's lift-off process, accurate, clean edges can be achieved, ensuring maximum production efficiency and yield. Overall, TOKYO ELECTRON Clean Track Mark 7 is a highly capable photoresist system. Its carefully engineered coating station, automated trimming processes, and precise substrate aligner make it an ideal unit for producing clean, symmetrical, and well-defined circuit patterns for a variety of applications. Additionally, its integrated lift-off process allows for fast, accurate removal of non-processed areas to maximize yield and maximize production efficiency.

There are no reviews yet