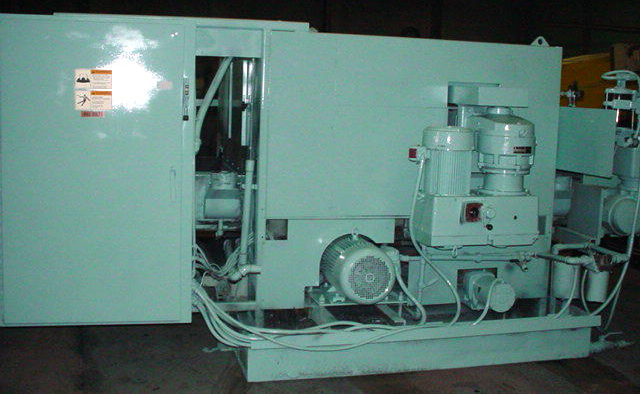

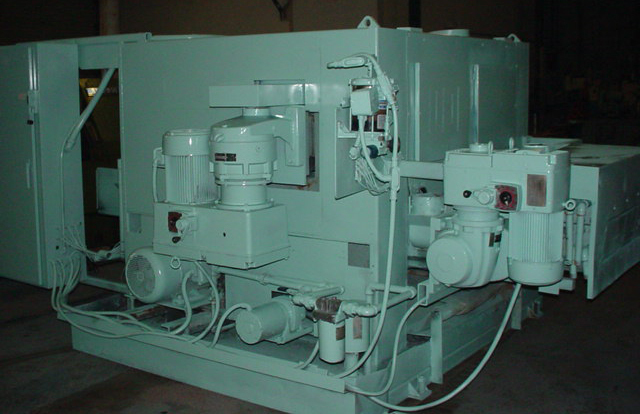

Used AEM DG-360 WET #147018 for sale

URL successfully copied!

Tap to zoom

ID: 147018

Vintage: 1993

Sheet deburring machine

Maximum sheet width: 37"

Abrasive sander head, 20 HP

SCOTCHBRITE rotary polishing head, 7.5"

Air filtration system, 20 HP

Paper filtration coolant system

Hours used: 3,059

Variable speed sheet conveyor

Air handler mounts to top of unit

1993 vintage.

AEM DG-360 WET is a compact and versatile wafer grinding, lapping and polishing equipment for wafers up to 36" diameter. Its versatile design and robust construction makes it an ideal choice for the research and development of new and improved wafers. Using the most advanced grinding and polishing technology, DG-360 WET provides superior surface finish at submicron levels. State-of-the-art surface finish is achieved using the wet grinding process and a variety of interchangeable polishing tapes. This allows users to modify the surface finish according to their specific needs, from low roughness (Ra < 0.25 μm) up to ultra-high-precision finish (Ra < 0.03 μm). The system is also equipped with a fully integrated air bearing, vibration damping and an auto-grind cycle for consistent surfaces. AEM DG-360 WET comes with a full range of accessories, including various wafer chucks, vacuum adapters, and polishing pads and tapes. An optional polishing machine is available to further polish the surface after the grinding process. The configuration of the unit is easy to adjust, while its compact design allows for convenient storage and transport. In order to ensure repeatable results and maximum post-processing productivity, the machine is equipped with a full-featured software package. It provides complete process control, including real-time process feedback, wafer clamping optimization, quality control and complete maintenance monitoring. Additionally, DG-360 WET is covered by a one-year warranty. AEM DG-360 WET is a versatile and robust wafer grinding, lapping and polishing tool that offers excellent performance, precision and repeatability. With its variety of functions, accessories, and software, it is suitable for a wide range of wafer applications, from development and research to high-precision fabrication.

There are no reviews yet