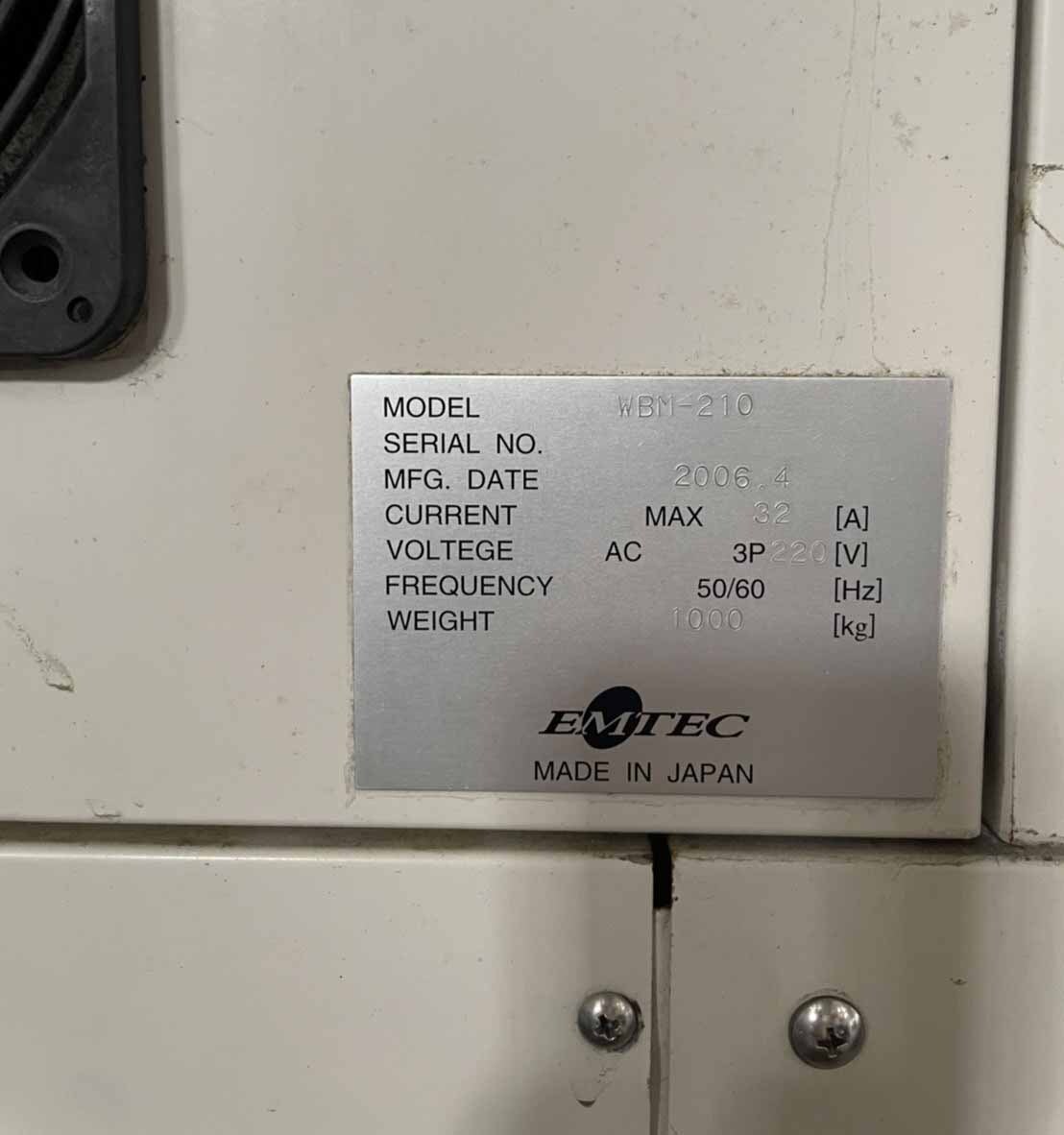

Used DAITRON WBM-210 #293630479 for sale

URL successfully copied!

Tap to zoom

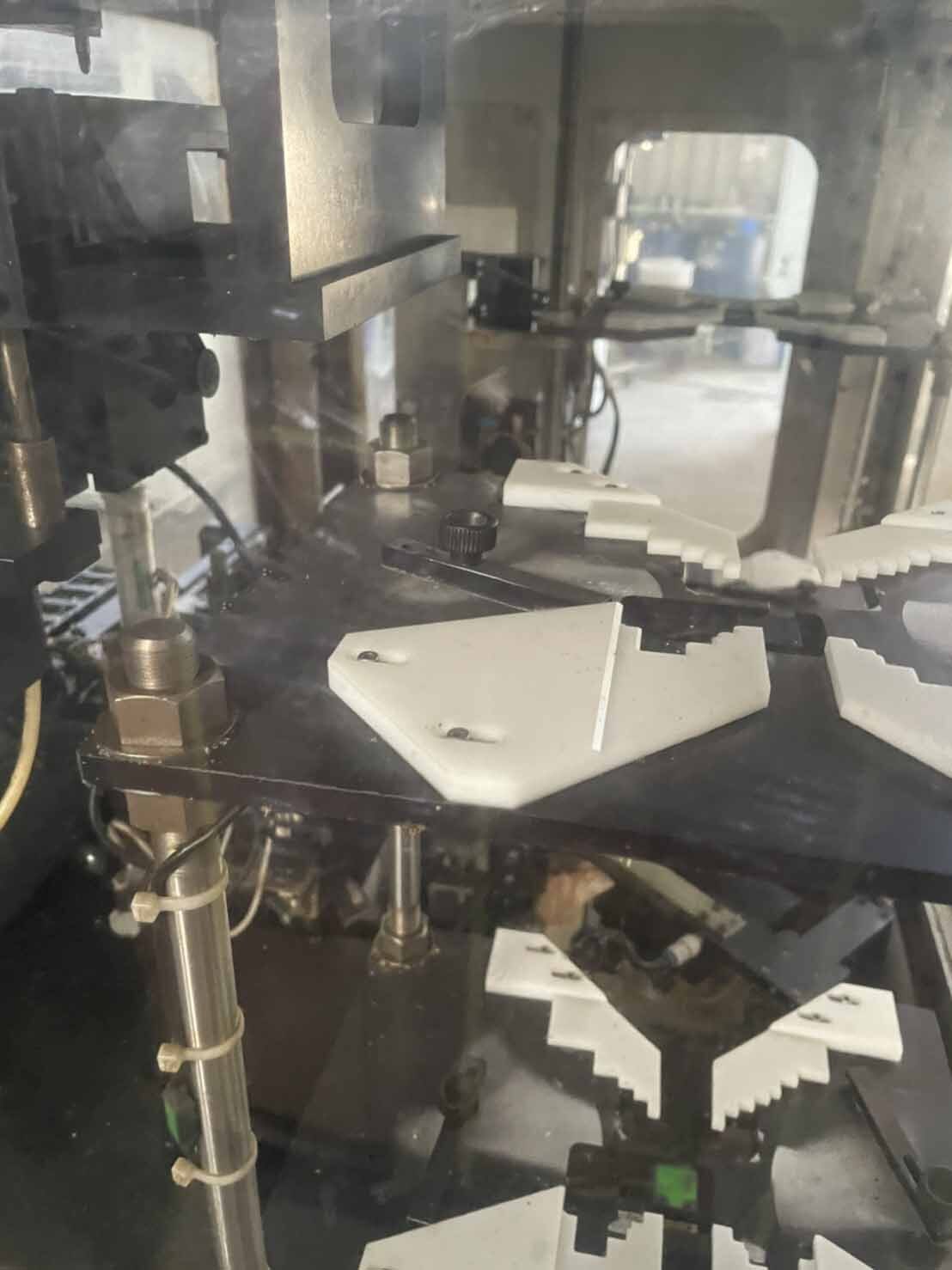

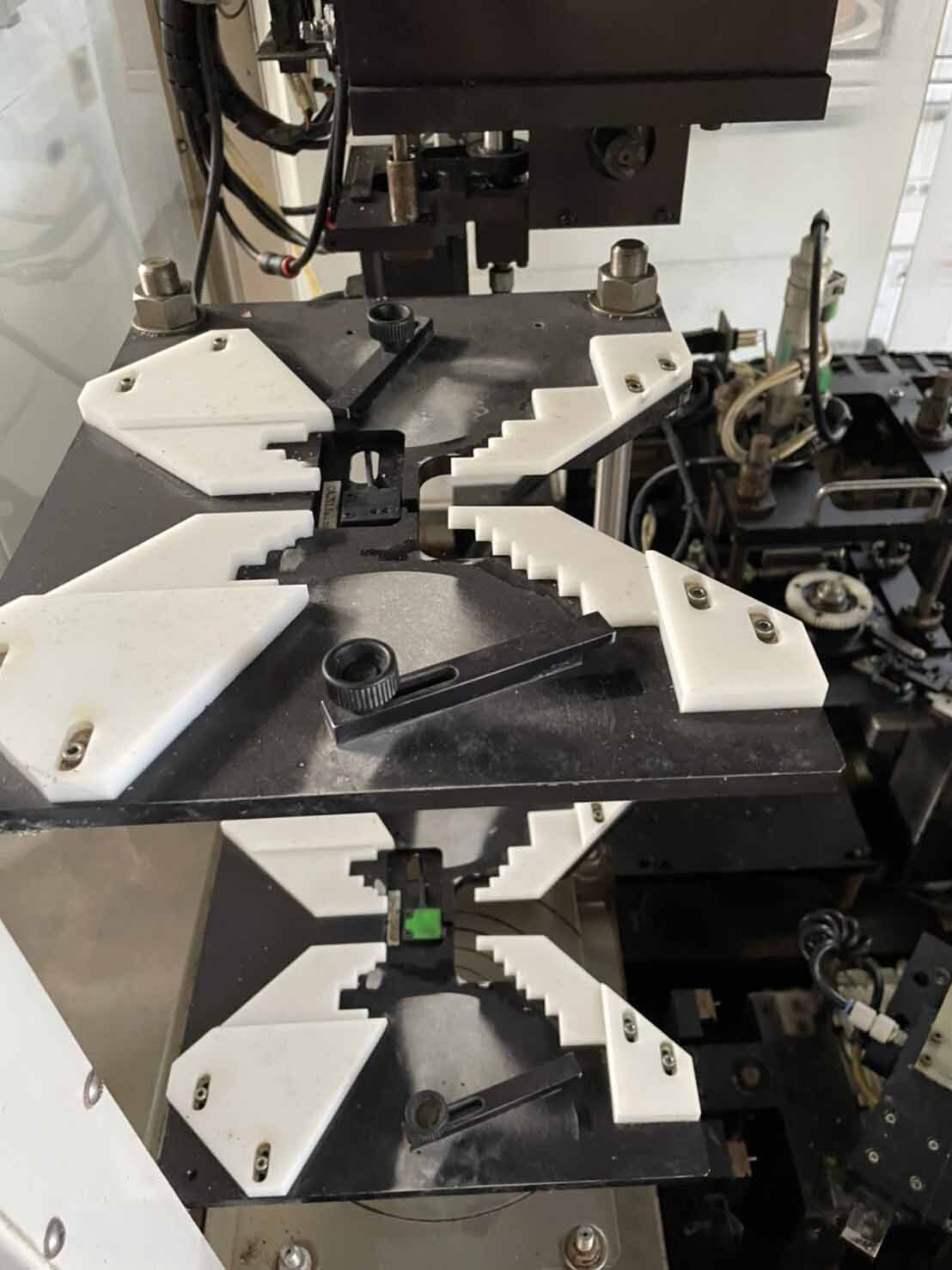

DAITRON WBM-210 Wafer Grinding, Lapping, & Polishing Equipment is a versatile tool for processing and fabricating wafer materials of various sizes and materials. This system is designed for both wet and dry operations, and the ability to control the speed ranges and media grade and size ensures that the lapping and polishing processes applied to the wafer material results in a polished, defect-free surface finish. WBM-210 consists of two main components being the main frame and the grinding/polishing head. The main frame consists of two vertical X-Y movement tables which facilitate grinding, lapping, and polishing of materials of various sizes. A key advantage of DAITRON WBM-210 is the flexibility of the operation and automation. This unit has a robust control machine with an easy to understand user interface that offers flexibility of production along with the superior performance required by industry. An important feature of WBM-210 is its ability to be adjusted in production depending on the size or shape of the wafer. DAITRON WBM-210 has a range of adjustment possibilities, varying from the rotation speed, media types and sizes, along with the pressure applied to the grinding surface. Additionally, WBM-210 can switch from wet operation to dry operation which allows for more control over the lapping and polishing process. DAITRON WBM-210 is equipped with ultra-fine precision motorized spindles with direct-drive transmission systems and a high degree of accuracy in positioning with an optional automated loading, unloading, and indexing functions. Multiple movement axes are available with WBM-210, and the X and Y axes feature adjustable range, speed, and pressure. Overall, DAITRON WBM-210 offers an effective and precise solution to grinding, lapping, and polishing of various materials. The tool is suited for a wide range of production environments, from highly controlled conditions to more flexible production settings, depending on the wafer and the type of parts being processed. The highly customizable settings, and ability to switch from wet to dry operation make WBM-210 the perfect choice for wafer processing.

There are no reviews yet