Used MOORE 450-CPZ #9395059 for sale

URL successfully copied!

Tap to zoom

ID: 9395059

Grinding machine

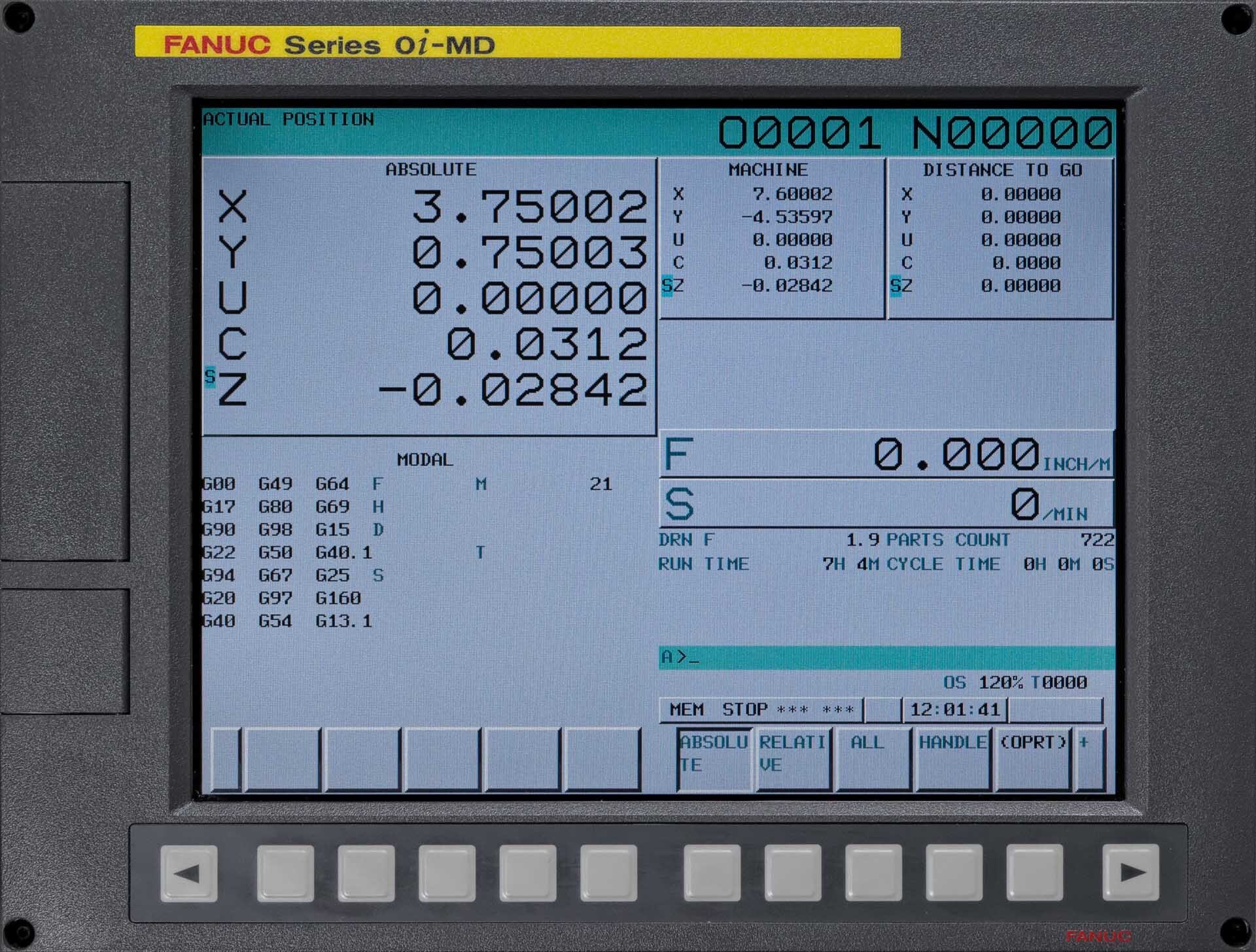

FANUC Oi-MD Controller

Y-axis: 10.5" CNC cross travel

X-axis: 17.5" CNC longitudinal travel

Z-axis: 3.5" CNC vertical travel

360° CNC rotation of C axis (Automatic C axis Normalcy)

Rapid traverse rate: 60 IPM

Contouring rate: 15 IPM

Ultra-precision ball screws on the X and Y axes, with motors

Encoders mounted directly on ball screws for high accuracy

Precision roller bearing way system with accordion way covers

Oil bath for ball screw

FANUC Closed loop AC digital servo drive motors with quick connector

FANUC Closed loop AC digital servo drive system (25 A peak)

Automatic lubrication systems with low-level alarms for roller-way system

Programmable, ball screw driven, Z-axis

Programmable main spindle speeds CW / CCW / OFF (Planetary)

Programmable chop grind ON / OFF with head-up micro switch

Programmable air grinding spindle ON / OFF

Programmable 110 VAC outlets ON / OFF

Programmable U-axis outfeed

Manual pulse generator (hand wheel) for easy setup

X, Y, U, C and Z home switches with indicator lights

X,Y, C and Z limit switches

X,Y, C and Z limit switch indicator lights

Minimum Programmable resolution: 0.000010"

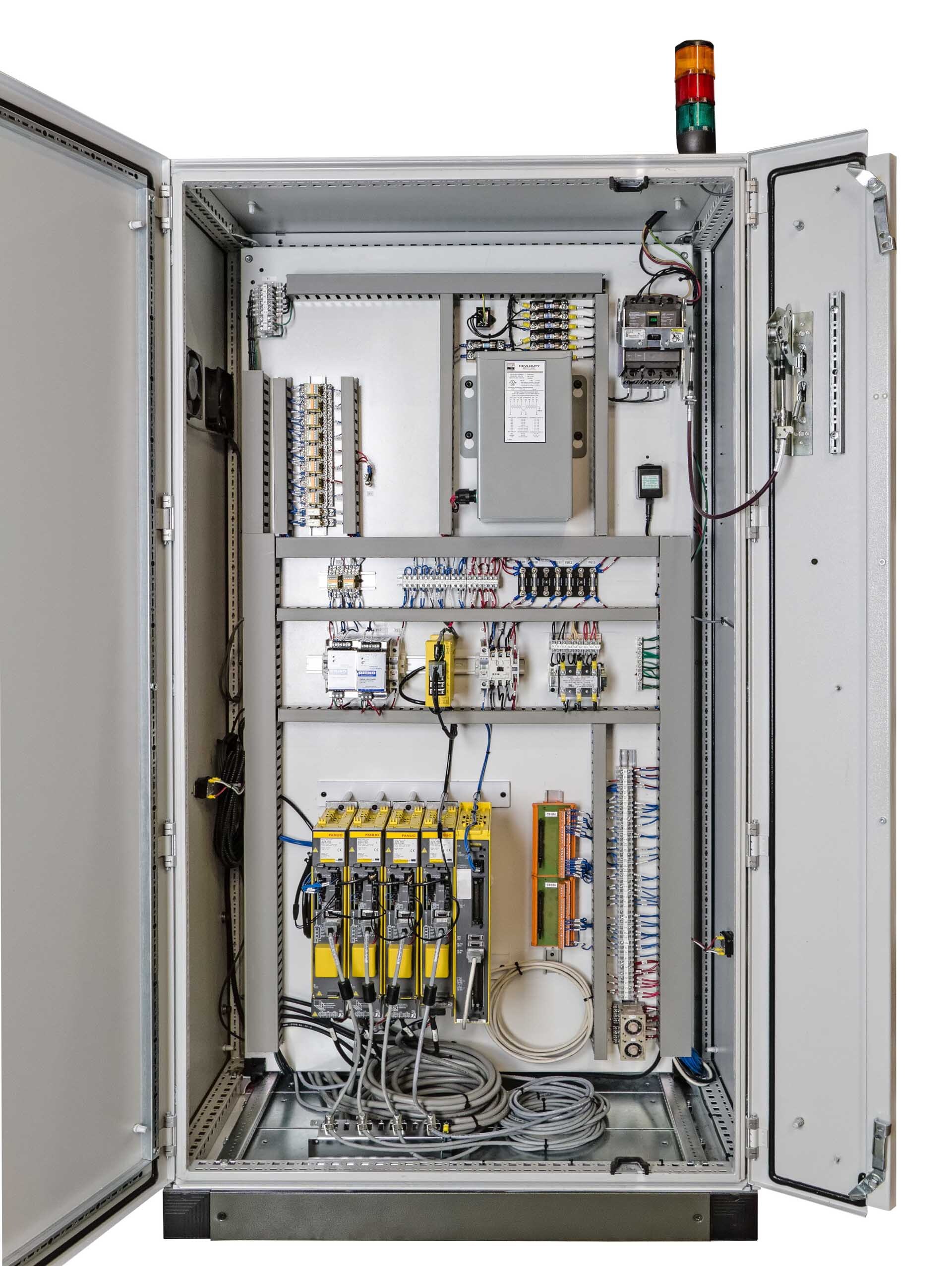

Pendant-type control cabinet mounted in a stand-alone electronics

(3) Coats of high gloss epoxy paint

Includes:

Spindle bearing

Outfeed bearing

U-cup, packing, wiper, seal, and o-*ring

Head thermometer

Chop valves (2-way and 4-way)

Micro switch

Link and link pins

Re-grind quill keyway

Scraping of the column geometry correction

Spotting of table surface

The lapping of the table and saddle ways for proper roller bearing contact

Accuracy:

Positioning accuracy: 0.000080"

Contouring accuracy: 0.000120"

Control:

5-Axis, 32-byte, microprocessor CNC

Graphics display with zoom functions

Flat screen color LCD, 10.4"

Sealed Mylar pushbutton keyboard with tactile and audible feedback

Menu-driven editing and modification

(10) Operating modes: Automatic, single block, playback, teach-in, dry run, jog / Zero setting, editing, input / Output, tool offsets, and special modes

Automatic C-axis normalcy:

Absolute / Incremental programming

Inch / Metric conversion

Standard 4 megabytes of memory

Minimum resolution: 0.000010"

Wheel compensation

Manual federate override: 0-120%

Mirror imaging

Subroutines with nesting

Linear interpolation

Cartesian and polar coordinate programming

Machine federate display

Wheel radius compensation

Program dwells

Manual data input via keyboard

Programmable zero offsets

3-axis simultaneous rapid positioning

Scaling factors

Help graphics

Zoom up / Down

Continuous and incremental jog

Canned cycles

Bolt circle programming

Circular and rectangular pocket grinding

Hole grinding cycles

Controlled comer rounding

Multiple absolute zeros

Programmable safety limits

DNC Communication

RS-232 Communication.

MOORE 450-CPZ Wafer Grinding, Lapping & Polishing System is a fully automated solution for grinding, lapping and polishing any size wafer. It is capable of producing sub-micron precision in a wide range of wafer sizes and thicknesses, from small dice wafers up to 8 inch diameter and thicknesses up to 10mm. It combines three processes in one machine, enabling it to grind, lap and polish in a single cycle. 450-CPZ is equipped with a high powered grinding motor, capable of achieving speeds of up to 12,000 RPM. This helps to achieve high levels of accuracy, without compromise. Its advanced electronics provide fully automatic control, allowing for precise operation and reproducible accuracy. MOORE 450-CPZ is equipped with a high precision CNC spindle, providing mechanical repeatability of less than a micron. The CNC spindle is capable of grinding, lapping and polishing using a range of abrasive materials such as diamond and cubic boron nitride. This ensures that the highest levels of accuracy are maintained during the grinding, lapping and polishing processes. Additionally, 450-CPZ is capable of handling wet grinding, making it suitable for use in a range of machining processes. MOORE 450-CPZ also benefits from advanced safety features, including non-contact sensors and automatic shutoff devices. This helps to prevent damage to the machine and the wafers in the event of a machine malfunction. Additionally, the machine is equipped with an intuitive user-friendly interface, making it easy to operate. 450-CPZ Wafer Grinding, Lapping & Polishing System is an ideal choice for any industrial application requiring grinding, lapping and polishing of wafers. With its high performance capabilities, precise CNC spindle and safe operation, MOORE 450-CPZ is an excellent choice for achieving sub-micron precision results.

There are no reviews yet