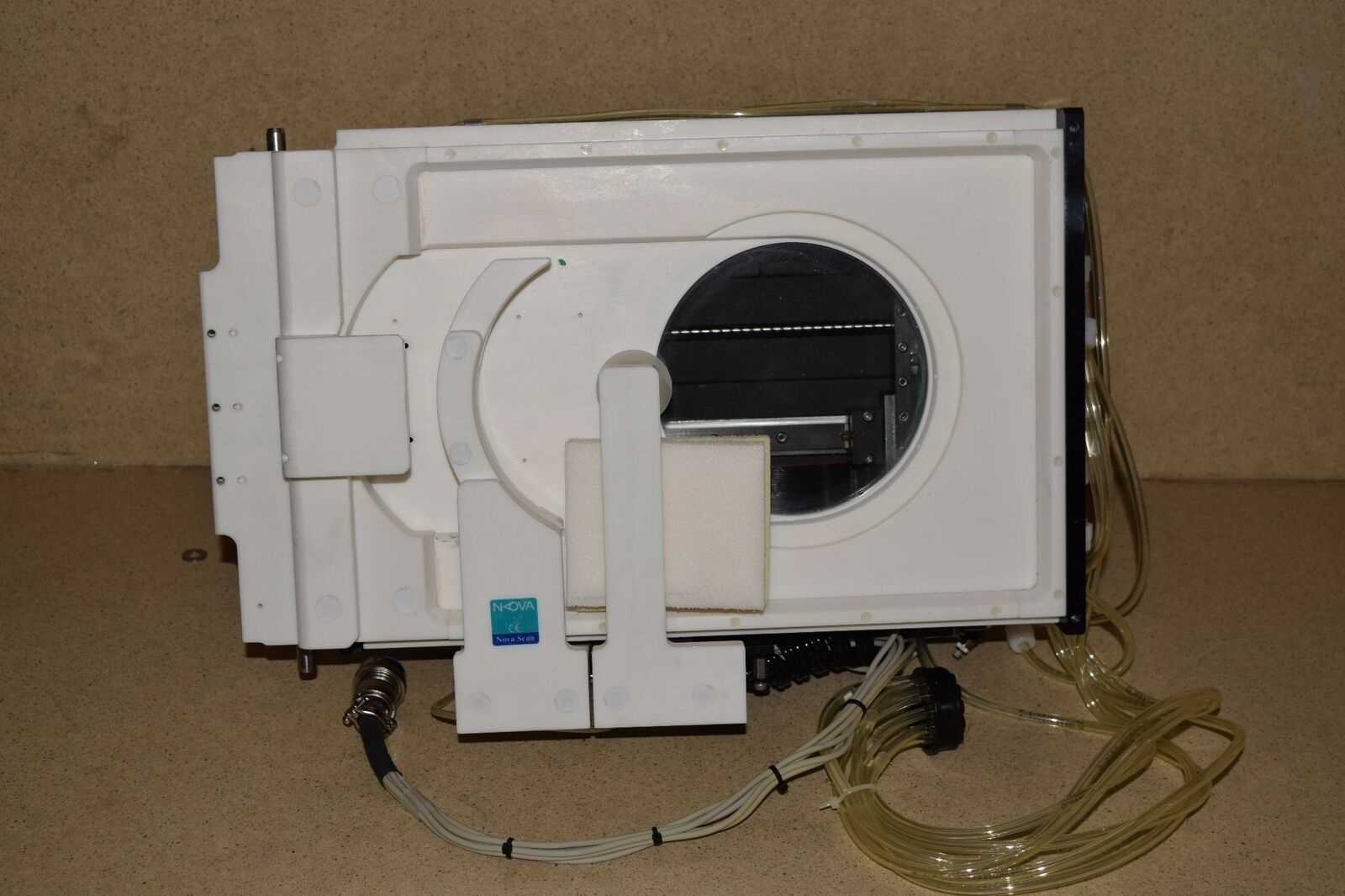

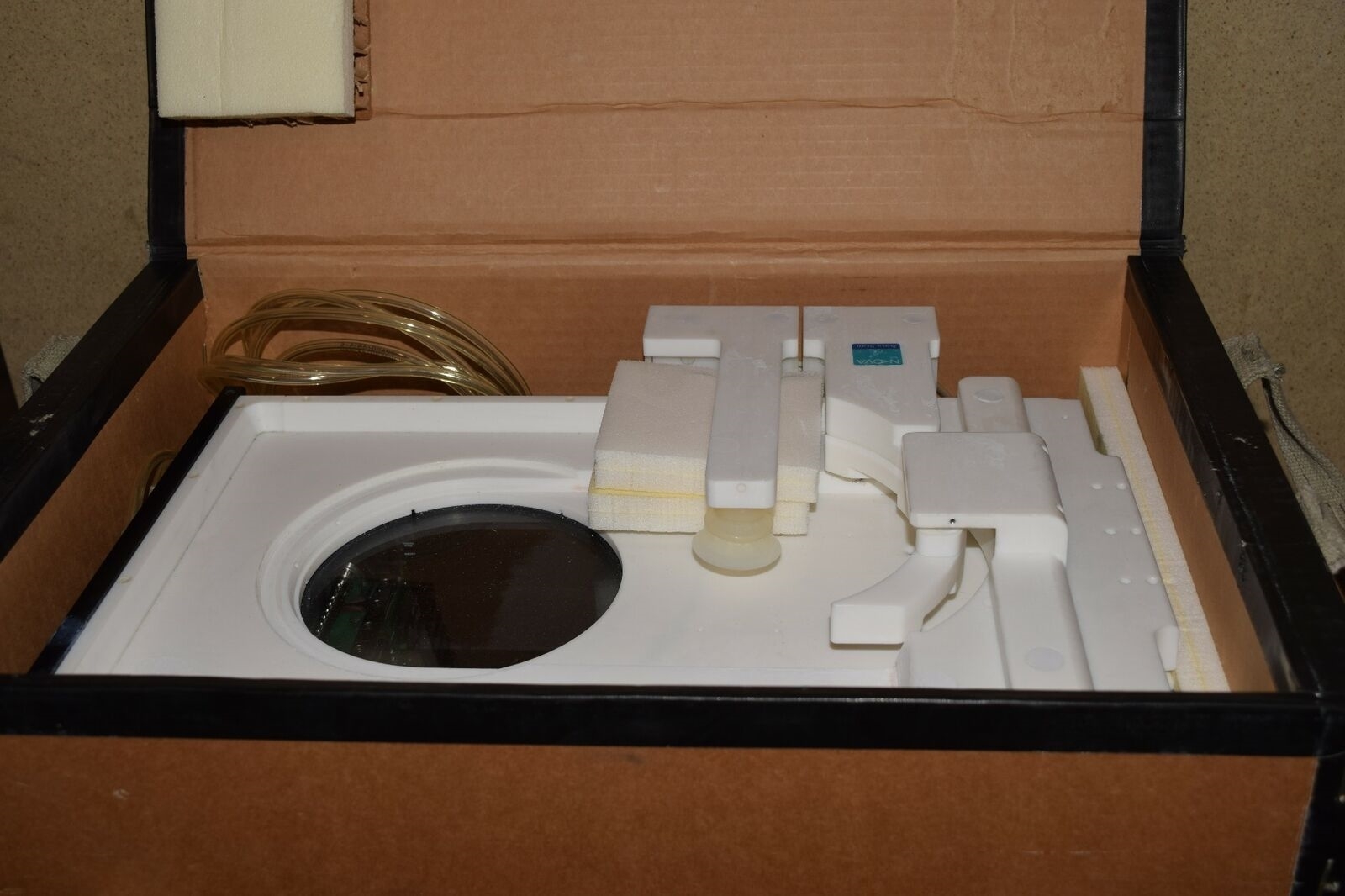

Used NOVA NovaScan 210 #9282463 for sale

URL successfully copied!

Tap to zoom

NOVA NovaScan 210 is a powerful automated wafer grinding, lapping, and polishing equipment capable of precision finishes on wafers with diameters of 4" - 6" at a very fine level of accuracy. It is designed to allow users to achieve a precisely uniform wafer surface, which can then be used in various applications such as semiconductors, bio-medical, and optoelectronics. The basic system allows for grinding of wafers using diamond and alumina grinding wheels. This method is employed primarily when grinding and lapping wafers made up of difficult-to-machine materials such as silicon, gallium arsenide, and indium phosphide. Once the grinding process has been completed, the wafer can then be subjected to lapping and polishing. Lapping and polishing of the wafers is done using diamond-embedded cloths mounted on a variety of tools. These tools can be manually operated or can be programmed to run automatically depending upon the needs of the user. Once the lapping and polishing process has been completed, the users can then measure the surface finish and flatness using the built-in laser sensor. NovaScan 210 also includes a variety of built-in safety features. These features include an emergency stop button, a unit diagnostic machine, interlocks, and other features that are designed to reduce the risk of injury from potentially hazardous materials. Additionally, the tool can be easily integrated into other equipment, providing users with a fully automated asset. NOVA NovaScan 210 model provides users with an efficient and reliable method for grinding, lapping, and polishing a variety of wafers. Its versatility and precise control of wafer finish allows for a wide variety of applications. Additionally, its array of safety features and the ability to be easily integrated into other systems make this a perfect choice for precise and reliable wafer operations.

There are no reviews yet