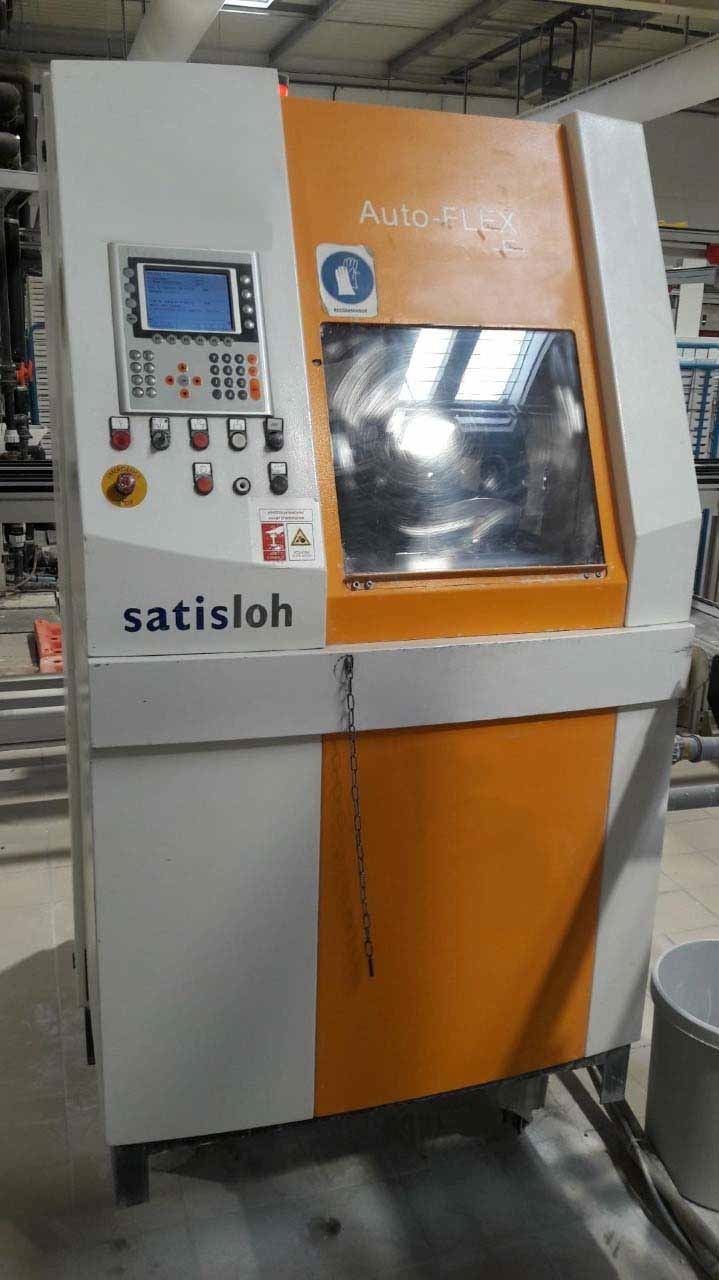

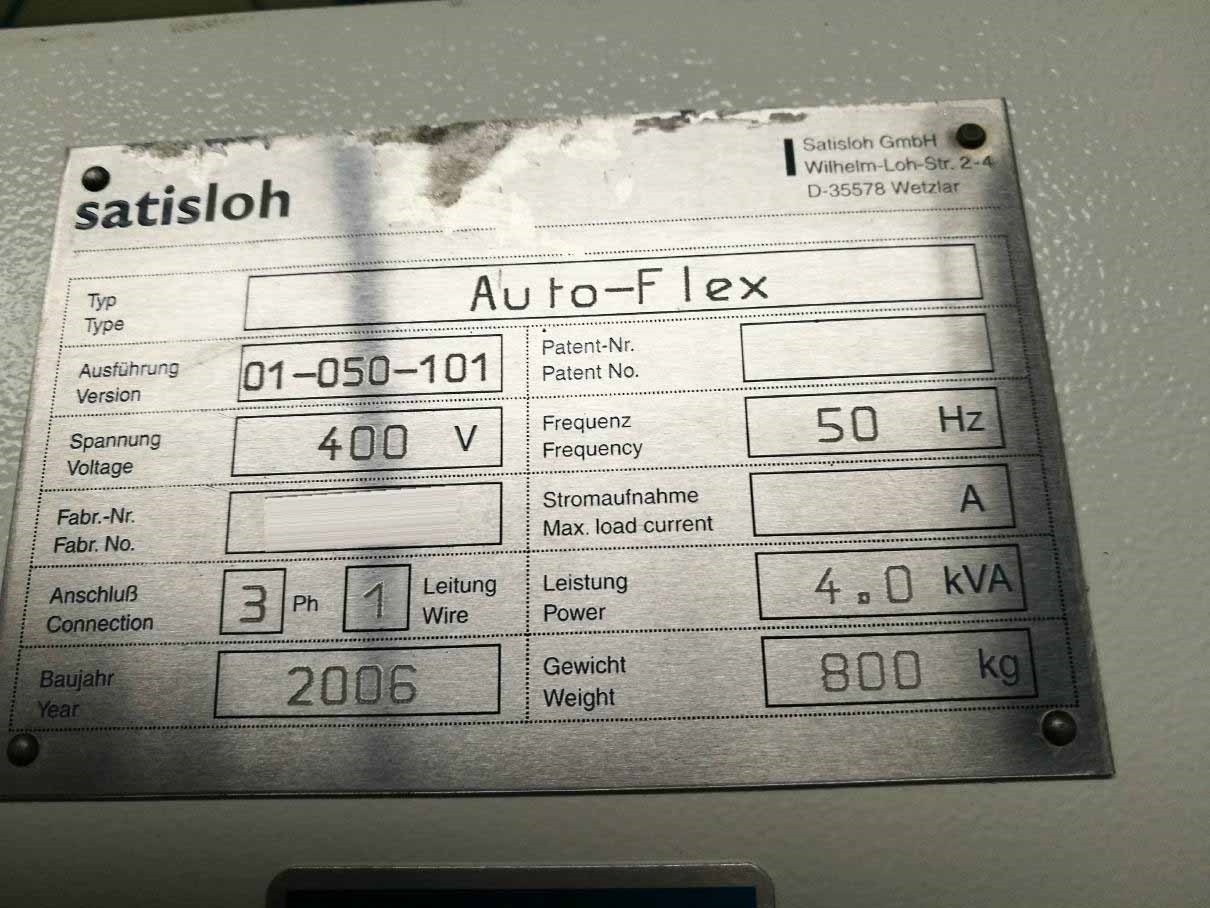

Used SATISLOH Auto-Flex #9192338 for sale

URL successfully copied!

Tap to zoom

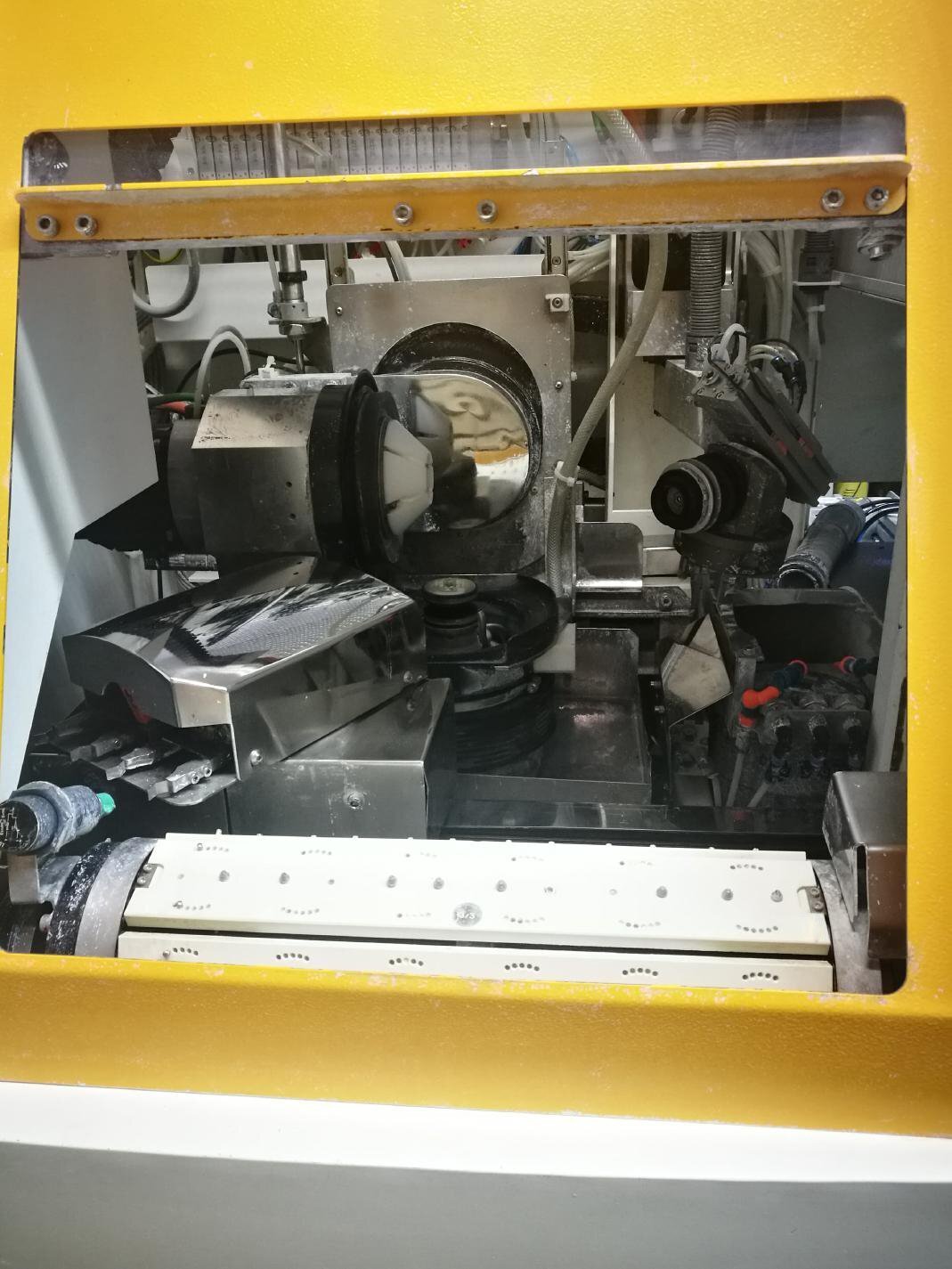

SATISLOH Auto-Flex is a precision wafer grinding, lapping and polishing equipment designed to facilitate quick turnover on high-volume production orders. The system boasts a dynamic design, ensuring high accuracy, uniformity and repeatability with every application. This provides the highest level of efficiency and cost-effectiveness, particularly with processing individual wafers. Auto-Flex base is constructed from robust aluminum components, and offers the stability and rigidity needed to ensure full consistency. Its spindle drives are separate from the grinding unit and its variable frequency drives allow for precise control of grinding speeds. This brings vendors comprehensive solutions to their fuel grinding applications. The innovative design helps to reduce the number of tools and spindles required for operation ; operational setup time is also reduced, thereby improving the overall grinding process. Endurance and the life of the tools used are increased by the Contact Super-cutting mechanism, while advanced tool protection systems and anti-vibration mounting prevent unnecessary wear and tear of the components. SATISLOH Auto-Flex features a series of automated modules to streamline the production of wafers. The machine supports three-axis motion control, along with an in-process measuring solution to track the progress of grinding. This is further enhanced by a programmable graphic user interface and an automated vision machine, which can accurately measure the micro-geometry of the wafer. The cutting process is controlled by Auto-Flex LS polishing tool. This offers a stationary single-segment polishing technique, as well as a rotating double-segment polishing wheel. This ensures that all the edges of the wafer can be polished without damaging them. An advanced asset of compensation also ensures the highest quality outcomes. SATISLOH Auto-Flex is equipped with QuickScan and a Contact-Identification model, allowing for quick and precise measurement of each wafer. The QuickScan allows for inspection and analysis of the wafer geometry before and after each step, ensuring consistent and uniform results. Auto-Flex provides reliable, precise and cost-effective solutions to manufacturers and service providers in the field of wafer grinding, lapping and polishing. The sophisticated design, advanced technology, and automated process control reduces manufacturing costs while increasing throughput and maintaining consistent product quality.

There are no reviews yet