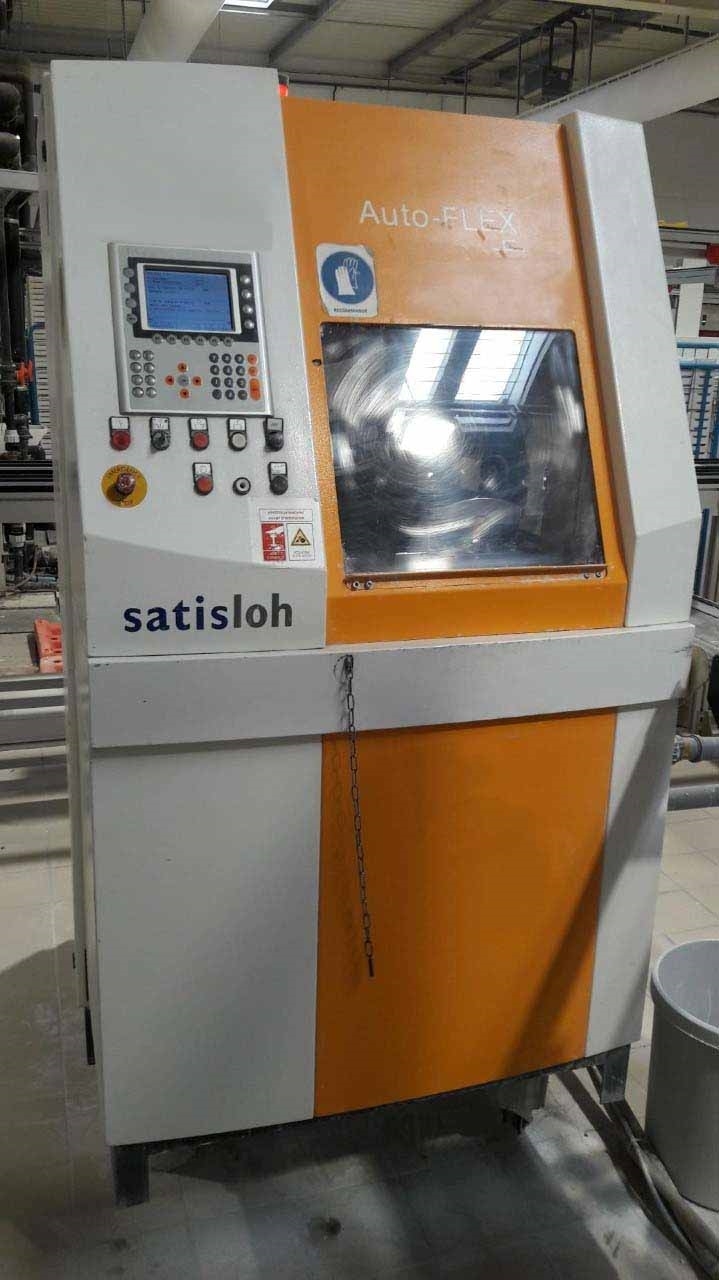

Used SATISLOH Auto-Flex #9255706 for sale

URL successfully copied!

Tap to zoom

SATISLOH Auto-Flex is a highly advanced wafer grinding, lapping, and polishing equipment designed to improve efficiency and overall production capabilities in the wafer fabrication industry. Its advanced automation capabilities allow it to perform precision grinding and lapping of wafers and optical components with remarkable speed, consistency, and accuracy. Auto-Flex system is equipped with an array of advanced robotic features that simplify and streamline the grinding and lapping process. Its advanced robotic positioning technology allows it to automatically acquire position parameters in order to precisely and accurately adjust to various surface shapes and sizes. The advanced grinding and lapping capabilities of SATISLOH Auto-Flex make it an ideal solution for wafer fabrication tasks where consistent results are essential. In addition, Auto-Flex unit is capable of performing a wide range of surface operations including grinding, lapping, polishing, and surface finishing. The machine's variable-speed drive tool allows for precise speed control, which allows for a range of different surface operations and finish types. Furthermore, the asset is also capable of performing multiple passes on multiple wafers at once, allowing for faster and more efficient production. SATISLOH Auto-Flex's advanced automation capabilities also make it capable of monitoring, tracking and logging production data. This feature allows operators to track and analyze performance, and adjust their processes for maximum efficiency and production output. In conclusion, Auto-Flex is a highly advanced and automated wafer grinding, lapping, and polishing model designed to optimize the production process in the wafer fabrication industry. Its array of advanced robotic features allows it to simplify and streamline the grinding and lapping process, enabling consistent results and improved production efficiency. Its variable-speed drive equipment, automated tracking and logging capabilities, and its ability to perform multiple operations on multiple wafers simultaneously, make it an ideal solution for wafer fabrication tasks.

There are no reviews yet