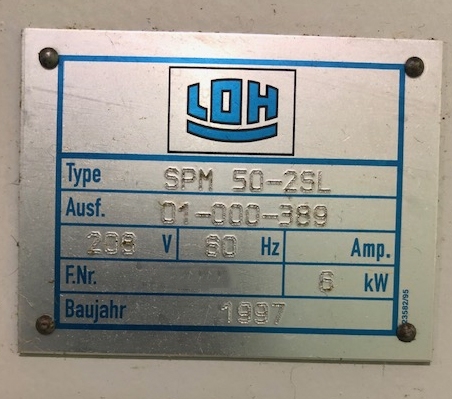

Used SATISLOH SPM 50-2SL #9253846 for sale

URL successfully copied!

Tap to zoom

ID: 9253846

Vintage: 1997

System

Controller:

Digitec industrial PC and color display

Pentium 233 MHz processor

7-Axis slot CNC

Flash disk: 512 MB

Working memory: 128 MB

Floppy Disk Drive (FDD), 3.5"

Operating system: Windows

Machine system: Y2K

Includes:

Automatic calculation of lens reception via center thickness measuring system

Sagittal height measuring instruments

Pivot-type generating process

Automatic feed regulation

Set-up mode for cutting simulation

Hydrodehn clamping system for holding the diamond grinding tool

Chiller unit to control the tool spindle temperature

Z-Axis measuring system for cross hutch pattern adjustment

Working range:

Work piece diameter: 5 mm to 60 mm System with synchrospeed mode

Dressing of polishing tools: Up to 80 mm

Work piece holder: Collet chuck / Vacuum chuck with 12.00 mm shaft

Work piece spindle: Directly driven by servo motor

Work piece speed: 20 to 1,500 rpm

Spindle controller: LUST MC Servo controller

Tool diameter: Up to 70 mm

Tool connection: Hydrodehn clamping system with diameter 12 mm

Tool spindle motor: (2) AC Spindle motors

Tool spindle speed: 2,000 Up to 30,000 rpm

Spindle controller: LUST VF-1408 Frequency converter

CNC Axis: 4-Axis with CNC controlled servo axis

Axis:

2-Linear axis

Rotary axis (Swivel head)

Rotary axis (Work piece spindle)

Servo drives:

(3) MOOG Servo valves (5 liters flow rate) motors with ITK-Kassen servo controller

AC Servo motor (work piece spindle) with LUST MC servo controller

Measuring system:

(2) HEIDENHAIN LS 406-170 Linear scales

HEIDENHAIN ERN 180-1024 Rotary encoder (Work piece spindle)

HEIDENHAIN ROD 450-0500 Rotary encoder (Swivel head)

MR 500 Sensors with scales and MR ISA Bus PC slot board

T18 Measuring sensor (CT-Measuring system)

Positioning accuracy:

X-Axis (Table): 0.001 mm

Y-Axis (Tailstock): 0.001 mm

C-Axis (Swivel head): 5 Seconds

Axis travel (Maximum):

X-Axis (Table): 116 mm

Y-Axis (Tailstock): 122 mm

C-Axis (Swivel head): ± 80°

Processing feed rate: Up to 30 mm/min

Coolant flow control: IFM Flow sensors ST 1604

Digitec Mini-PC:

TFT Color display with integrated standard keyboard

4-Axis CNC slot board

PLC Control: SIEMENS PLC Controller siematic S595U

Compressed air: 6 Bar

Power supply: 380 V + 10%, 3 Phase, 50 Hz AC

Power consumption: 6 kW

1997 vintage.

SATISLOH SPM 50-2SL is a state-of-the-art wafer grinding, lapping, and polishing equipment designed to provide superior results when working with a wide range of materials. The system features an integrated design that allows for efficient grinding and lapping operations without compromising quality. It is designed to accommodate various wafer sizes, ranging from standard 25-125mm to any custom size. SATISLOH SPM 50-2 SL unit includes a powerful polishing motor, advanced motor controller, precision travel machine, and advanced grinding head for optimum performance and precision. The tool's integrated drive asset includes a brushless DC motor, planetary gear, and innovative safetyShutTM technology which automatically shuts down the motor if grinding head overspeed is detected. The motor's speed range is adjustable, allowing for the delivery of constant polishing cycles or grinding cycles with a specific speed and force. The model also includes a precision positioning guide with digital readout, allowing for precision adjustments to ensure consistent and accurate results. The loading and unloading of wafers is easy with the integrated jig and adjustable tray. A special wafer clamp equipment helps ensure a secure fit and eliminates wafer chipping and gripping damage. The system offers the power of grinding, lapping, and polishing in one compact and efficient unit. SATISLOH patented Smart StartTM unit automatically detects when the process is initiated and sets the correct conditions for an ideal start. The machine also allows for fine process control adjustment during grinding and lapping operations. The tool offers two separate control systems with a graphical user interface to provide users with an intuitive experience. The first control asset allows full manual control of grinding and lapping operations, and the second control model provides additional features such as creating and editing programs and uploading data to a computer. The equipment also includes a traceability system to keep track of all operations and their results. SPM 50-2SL is an advanced unit for wafer grinding, lapping, and polishing. The machine's integrated design allows for efficient grinding and lapping operations and provides users with precise control of the process. The tool's intuitive control systems help to ensure reliable and consistent results every time.

There are no reviews yet