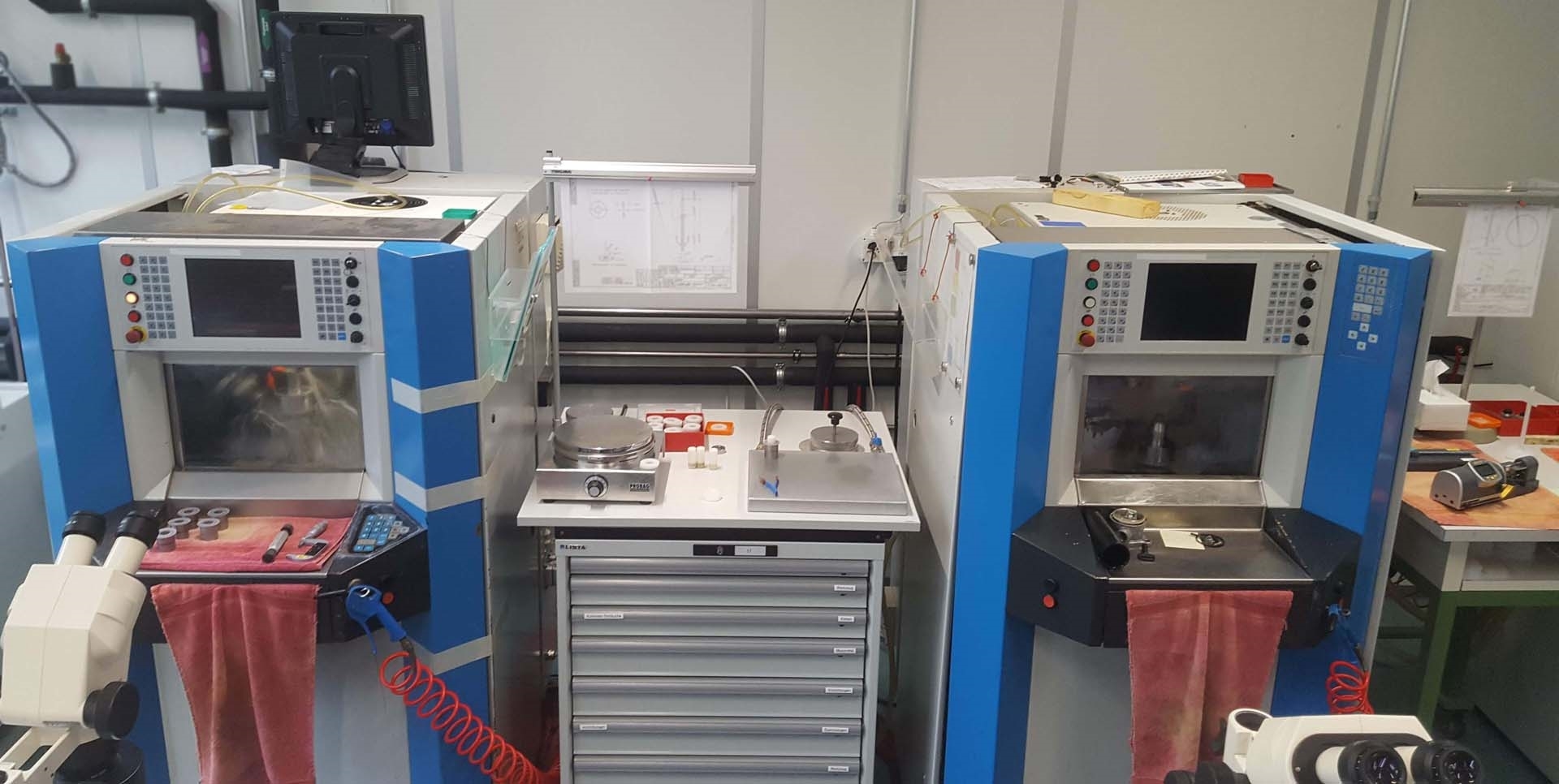

Used SATISLOH SPM 50-2SL #9271649 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9271649

Vintage: 2000

System, parts system

Damaged parts:

PC Hard Disk Drive (HDD)

Pneumatic pressure regulator for clamping pressure

Hydraulic pump

Lamps

Diskette drive

Workpiece probe

Spindle cooler

Does not include cooler

2000 vintage.

SATISLOH SPM 50-2SL is a multifunctional wafer grinding, lapping, and polishing equipment designed to analyze and process wafers up to 200mm in diameter. The system utilizes a direct drive diaphragm spindle assembly to provide high-precision single-crystal diamond grinding for a variety of applications such as grinding wafers for semiconductors, MEMS, solar cells, and other devices. The unit is also used for planarization of wafer surfaces in face grinding, back grinding, lapping, and polishing processes. The machine features a spindle module assembly with a rotary table and three linear axes to support the variable spindle. The variable direct drive spindle is supported by a high-precision bearing and provides variable speeds up to 50,000 rpm. It also features an automatic spindle oscillation control which ensures even and consistent wafer separation. The tool is designed with a rigid table assembly equipped with a single-crystal diamond grinding wheel and an adjustable hydrostatic bearing asset to provide a freely floating platform. This ensures stability and accuracy while ensuring a high repeatability accuracy level of 0.002µm. In order to ensure a high accuracy of grinding, SATISLOH SPM 50-2 SL is equipped with a computerized positioning model. This includes a digital camera which displays the micro-wafer surface for precise positioning and three servo-driven linear axes for micro-processing operations. SPM 50-2SL also includes an integrated optical measuring probe for continuous monitor-and-control of the process. The probe includes a non-contact optical equipment for measuring the relative position and angular orientation of the wafer surface, as well as a multispectral imaging system for detecting surface defects. Finally, the unit is designed with an intuitive user-friendly touch screen display which provides a visual representation of the entire process. This allows the operator to view parameters and settings and make real-time adjustments as needed. SPM 50-2 SL is ideal for a variety of leading-edge wafer processing applications.

There are no reviews yet