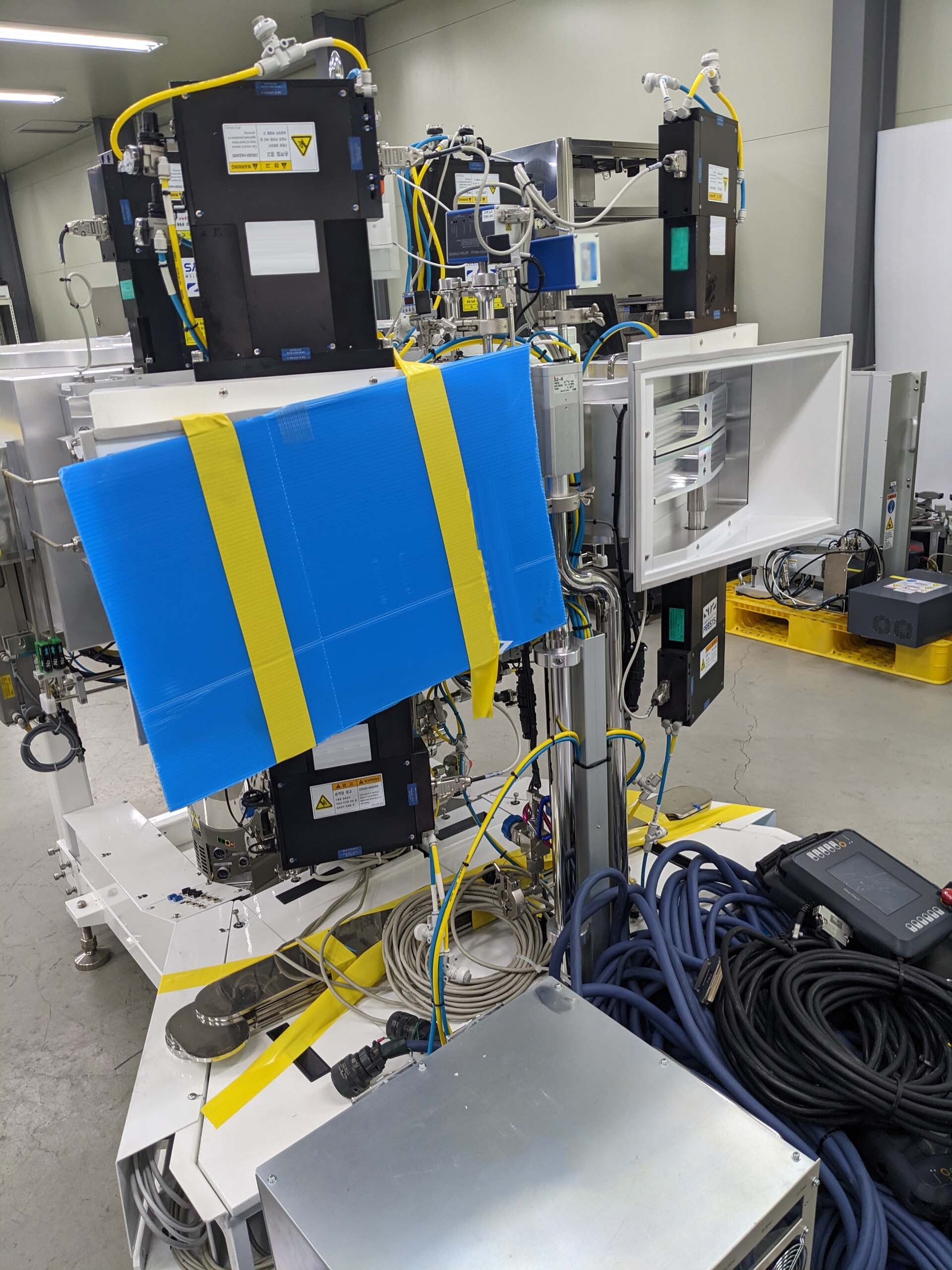

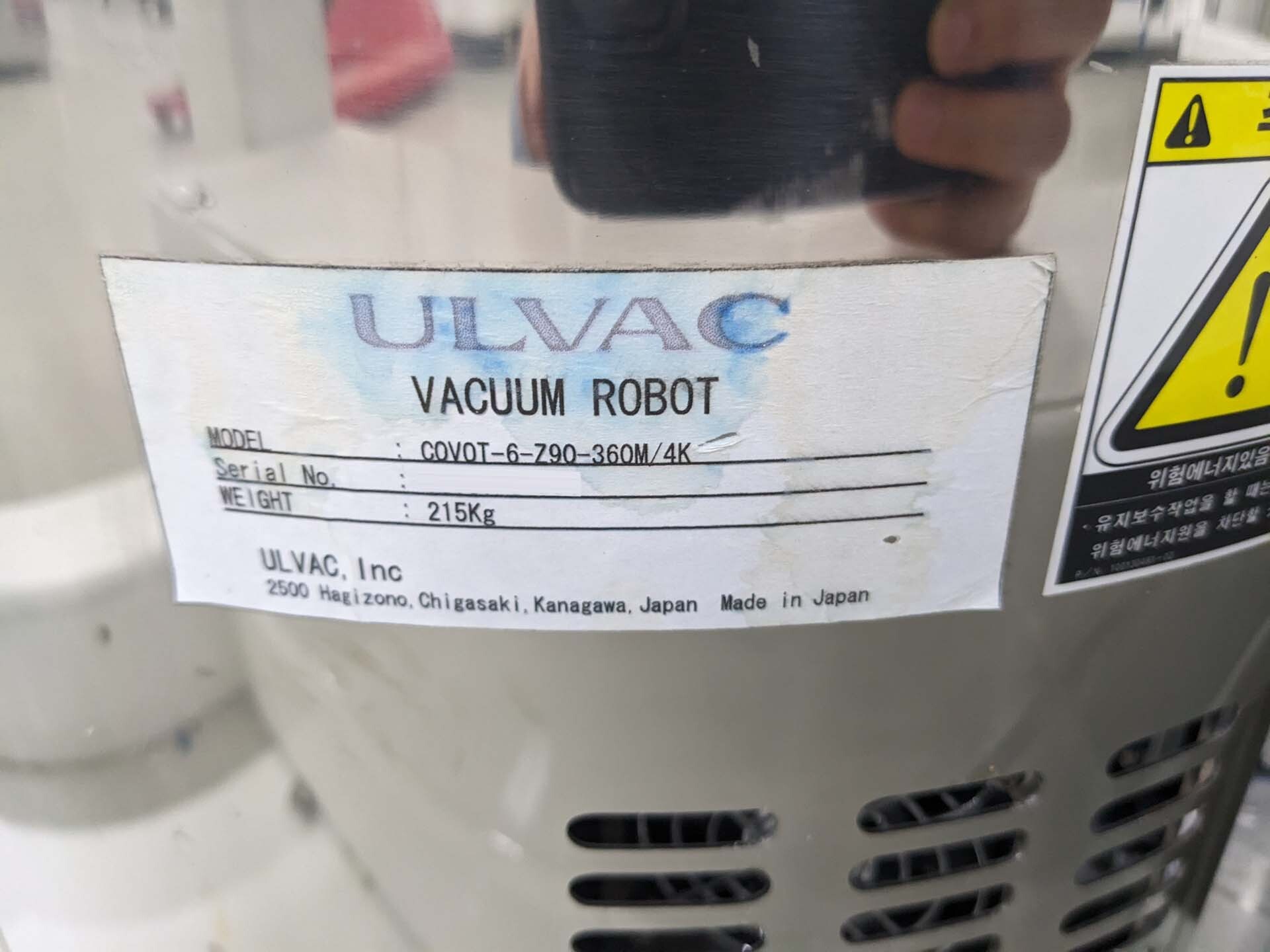

Used ULVAC COVOT-6 #293664126 for sale

URL successfully copied!

Tap to zoom

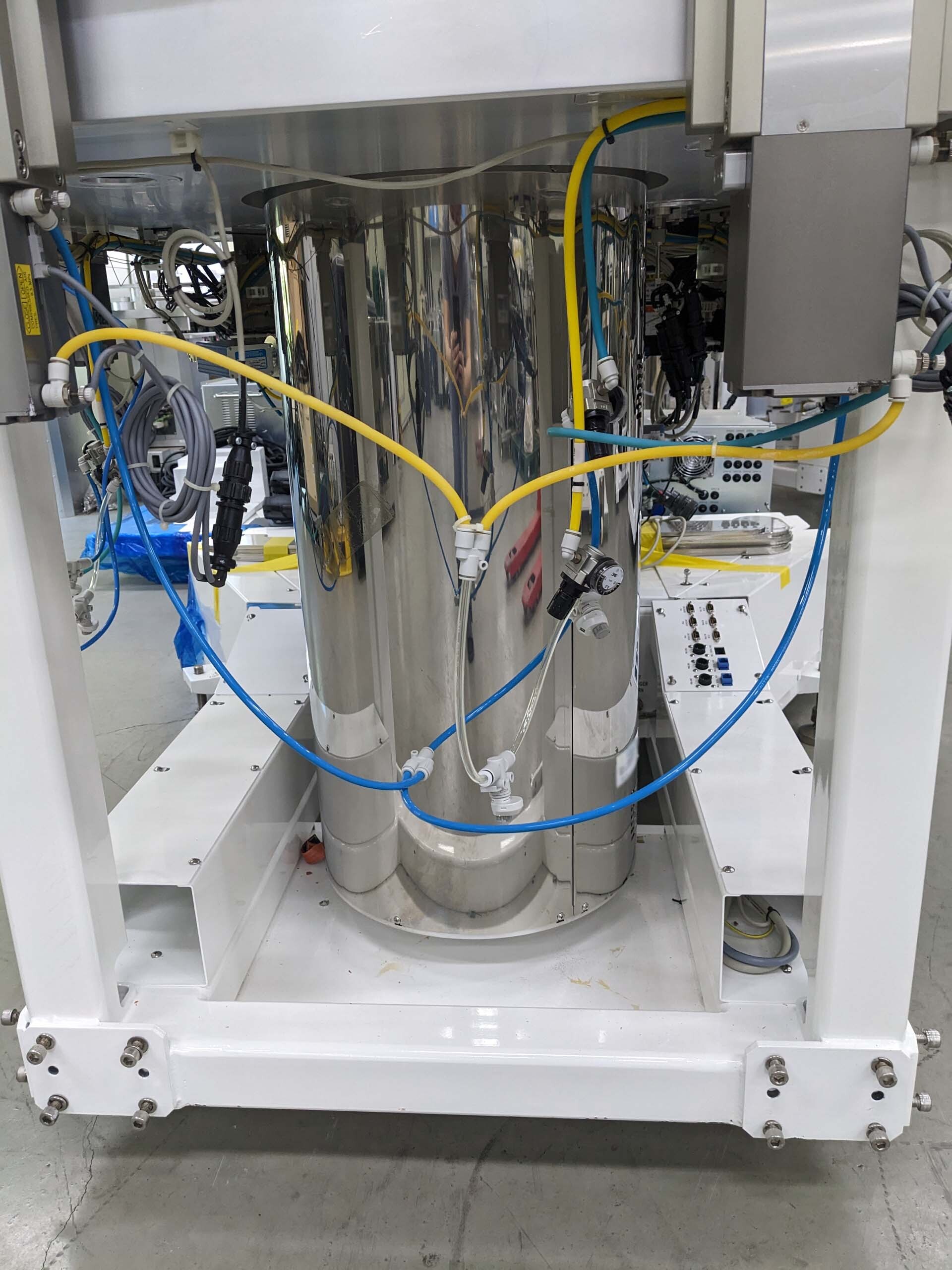

ULVAC COVOT-6 is a 6-inch wafer handler designed for use in vacuum applications, such as coating or etching operations. COVOT-6 is powered by a stepper motor that is capable of extremely precise and repeatable precision movements with a minimum step of 0.0025 mm. In addition, its vertical orientation allows for high accuracy when loading and unloading wafers and its exceptionally low profile resulting from its space-saving design ensures maximum compatibility with various wafer shapes and sizes. ULVAC COVOT-6 includes a user-friendly, intuitive operation panel that can be easily used to control all its functions, such as loading and unloading of wafers, the position or speed of the robot, and much more. It also comes equipped with a built-in alarm equipment that alerts the user in case of power failure or an alarm condition. To ensure its long-term reliability, the equipment is built with a solid foundation of robust, durable materials and components such as stainless steel frame, aluminum plate, and reinforced NEMA 17 stepper motor. On top of its built-in features, COVOT-6 also provides a wide range of customizability options to the user, such as addition of controller accessories, including feedback devices, encoder assembly, and motors to increase speed and precision. Its open-loop control system allows for easy integration of third-party controllers to create a dedicated automated solution to realize complex tasks. To improve user experience, ULVAC COVOT-6 is compatible with both PC- and PLC-based control systems, as well as industrial networks including PROFINET, EtherCAT, and CANbus. This ensures optimal integration with the user's custom-tailored unit without the need of complicated codes. Additionally, the machine's standardized modular operation panel is equipped with LCD touch-screen for advanced information and control displays. Overall, COVOT-6 is an ideal wafer handler solution for a wide variety of precision operations thanks to its automated loading and unloading of wafers, precise positioning of wafers, reliable motors, and easy integration into existing systems. Its combination of advanced technology, robust components, and customizability options make it one of the best choices for users looking for a reliable and efficient wafer handler solution.

There are no reviews yet