Used ADE / KLA / TENCOR 9600 #9229873 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9229873

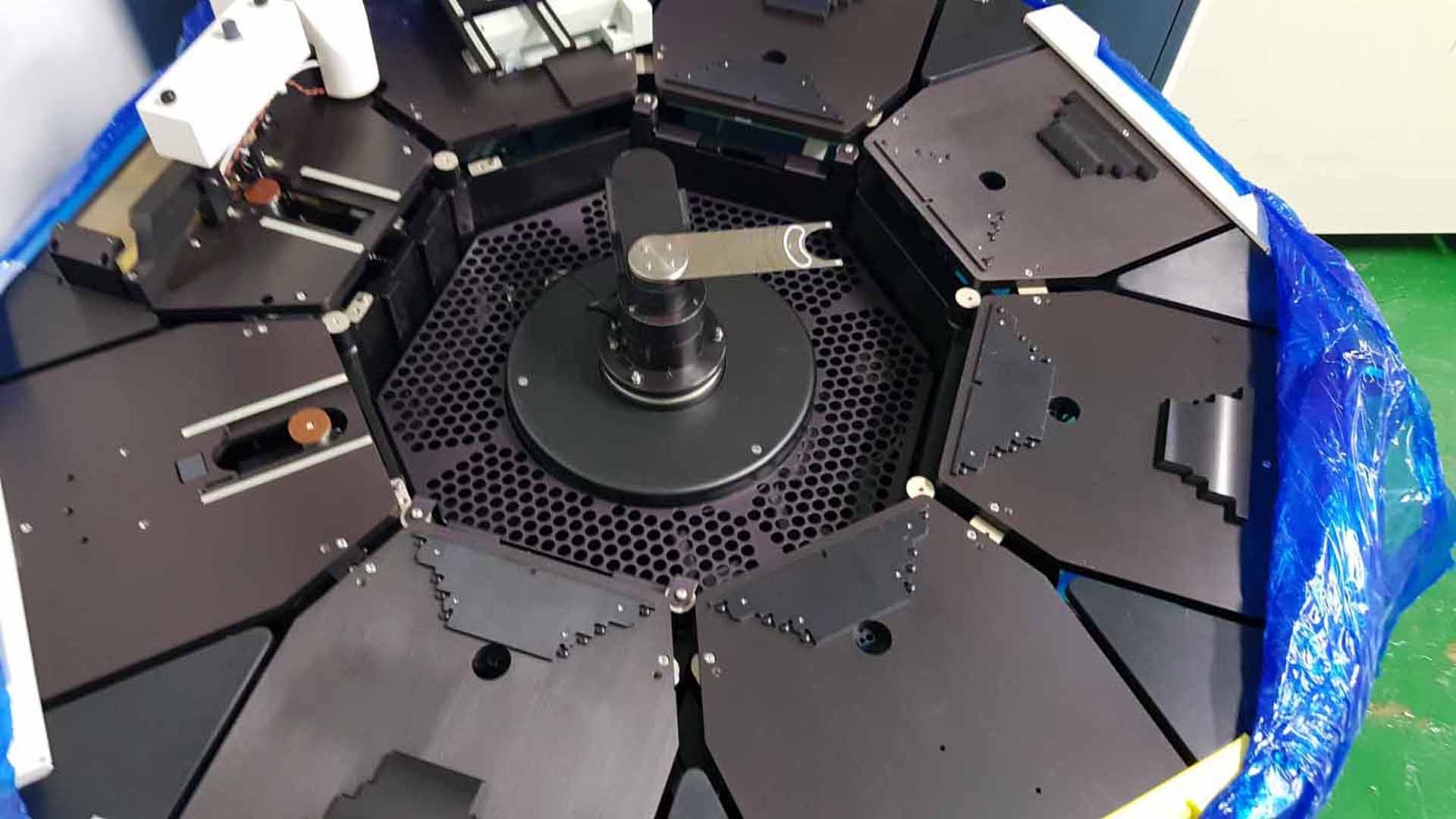

Wafer inspection system

(2) Cassette input stations

(3) Cassette output stations

Prealigner station

Hi-RES Station

E-PLUS Advanced / Thickness

B/W Station

Signal effector am robot

9600 Power supply

Non contact P/N type tester for wafer resistivity: 0.1 to 200 ohm-cm

ADE 350 Arm controller

Auto A probe

ASC Controller.

ADE / KLA / TENCOR 9600 is a wafer testing and metrology equipment designed to provide high precision measurements of 3D topography and surface properties from both processing solution and materials applied to wafers. It provides the flexibility required for cutting-edge research and development, as well as the reliability required for commercial production applications. Operating on a dual-beam, non-contact, scatterometry principle, the system has fast and accurate analysis capabilities. It uses an infrared (IR) CCD camera to collect topographic data from optical scatter signals arising from the tested samples. The unit operates across a range of excitation wavelengths in a unique broadband and imaging context. This results in a more accurate assessment of film and texture properties and total measurement of 1,000 or more points per second. The machine also offers voltage contrast imaging (VCI) at full-field or single-point with built-in feedback control. This feature allows for the capture of nano-level surface images and profiles on unpatterned wafers, helping to characterize wafer flatness and warpage. In addition to metrology capabilities, ADE 9600 features non-contact wafer analysis capabilities, allowing the user to measure up to 100 films or layers on a single wafer. It utilizes a global cavity resonator to measure wafer thickness at a higher resolution than standard contact measuring techniques. The advanced optics and image processing embedded in KLA 9600 make it an ideal choice for research and production environments. Maximum throughput, top-down imaging, and mapping capabilities make 9600 the perfect tool for examining wafer-level product. Its integrated software controls enable the user to configure process parameters and to monitor, track and analyze wafer test results. In conclusion, TENCOR 9600 is an essential tool for any semiconductor research and manufacturing environment. Its high precision and state-of-the-art measurement capabilities streamline the wafer testing and metrology process, resulting in more accurate measurement data. With a wide array of mapping, imaging and analysis techniques, ADE / KLA / TENCOR 9600 ensures high performance and reliability during the most demanding wafer testing applications.

There are no reviews yet