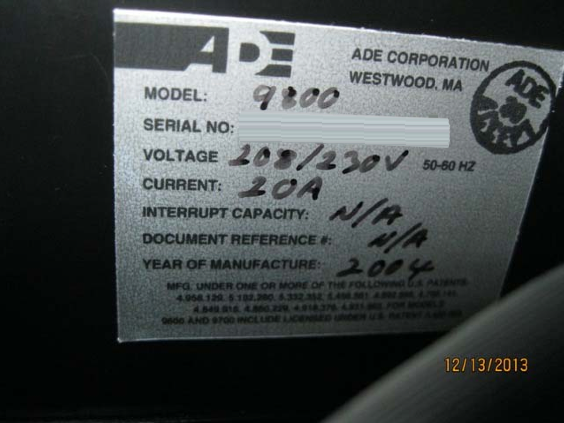

Used ADE / KLA / TENCOR 9800 UltraScan #9046074 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9046074

Wafer characterization system, 8"

ULTRASCAN 9800 Flat top standard base system:

Wafer Size 6" and 8"

High Accuracy Noncontact Prealigner

E-Squared Advanced/Thickness, B/W Station

May accommodate up to 5 cassettes

Auto A Probe included

Advanced System Controller 2000 and Accessories: UPS (uninterruptible power supply)

System Software and Operating System: SCO 5.0 UNIX System

Included:

Part No. 9300-DEET

Robot Dual End Effector Teflon Coated - 135°

Part No. 7800-150-ASC2K

Standard ASC Software for ASC2000

Part No. 7800-180

15" ViewSonic Flat Panel Monitor

(2) Part No. 9300-36ND

Send "Universal" cassette station

(3) Part No. 9300-37ND

Receive "Universal" cassette station

Part No. 7800-6HZ

System configured for 60 HZ

Part No. 7820-220

Line Conditioner and Transformer, 4.8 kVA

Input Voltage: 220 V 50/60 HZ

Input: 9 Foot Linecord with L14-30P Plug

Output: (1) L14-30R Receptacle

Part No. 025106-01

Topside Non-contact type

N or P type wafers

Resistivity 0.1 to 200 ohm-cm

Part No. 444001 ReportTools

Part No. 9300-57EMI

High Range EMI, High-Accuracy

Resistivity Station

(0.200 - 199.9 ohm/cm)

Robot error when attempting to run calibration

Currently installed

2004 vintage.

ADE / KLA / TENCOR 9800 UltraScan is a desktop wafer inspection and metrology equipment that performs a variety of tests to assess the quality and features of semiconductor wafers. The system offers high-precision analytics and metrology capabilities to determine the structural characteristics of wafers. A variety of tests can be conducted, including scanning for contaminants and defects, characterizing shapes and sizes, measuring electrical properties, and analyzing statistical process control data to reduce yield variability and manufacturing times. ADE 9800 UltraScan has a variety of features that enable it to quickly and accurately inspect semiconductor wafers. It is equipped with an automated wafer handling unit to ensure rapid sample exchange capabilities. It also features advanced imaging and optics to view the wafer's surface in high detail. In addition, the machine is optimized to support a range of applications with a variety of analysis techniques, including scanning electron microscopy and confocal microscopy imaging. The machine is also equipped with a variety of functionalities to facilitate wafer inspection. It has analytics capabilities to identify contaminants and defects on wafers and validate surface finish quality. It also has detailed inspection and metrology capabilities to measure critical charges of wafer shapes and sizes, such as pitch, edge profile, and radius. Additionally, KLA 9800 UltraScan has a powerful statistical process control (SPC) suite to generate SPC charts and control charts to monitor production yields and identify manufacturing irregularities. The machine also has advanced networking capabilities for remote machine control and data sharing. It has Ethernet ports to connect controllers to a local or wide-area network, as well as application programming interfaces to integrate with other systems. This enables 9800 UltraScan to be deployed in factory automation and data management systems. Overall, TENCOR 9800 UltraScan is a powerful, high-precision wafer testing and metrology machine. It offers a variety of features, including advanced imaging and optics, automated wafer handling, analytics capabilities, detailed inspection and metrology capabilities, and a powerful SPC suite. Additionally, it has advanced networking capabilities for remote control and data sharing. This makes it an ideal choice for assessing semiconductor wafers and monitoring production yields.

There are no reviews yet