Used ADE / KLA / TENCOR AFS 3220 #293645333 for sale

URL successfully copied!

Tap to zoom

ID: 293645333

Wafer Size: 12"

Vintage: 1999

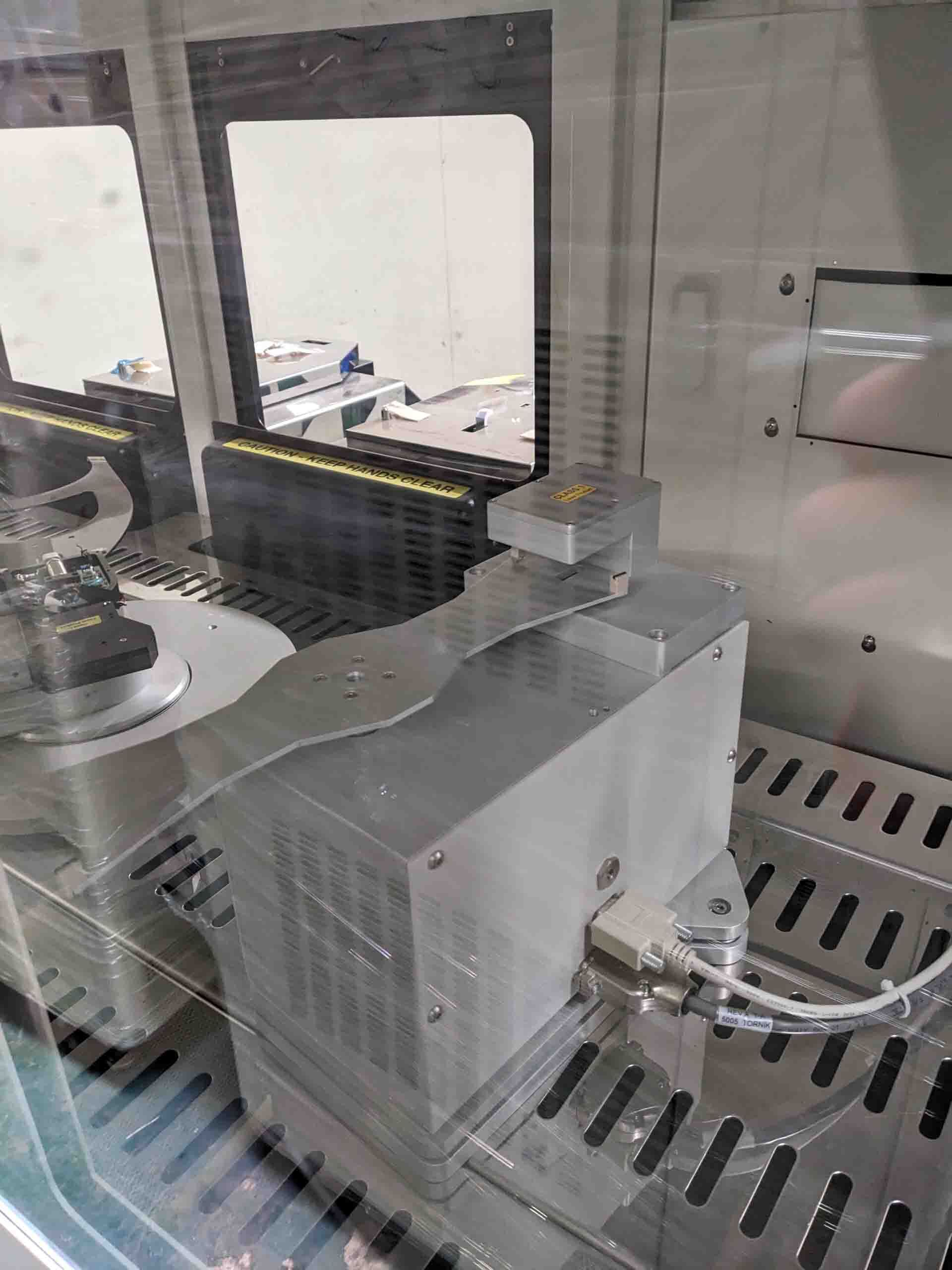

Wafer inspection system, 12"

1999 vintage.

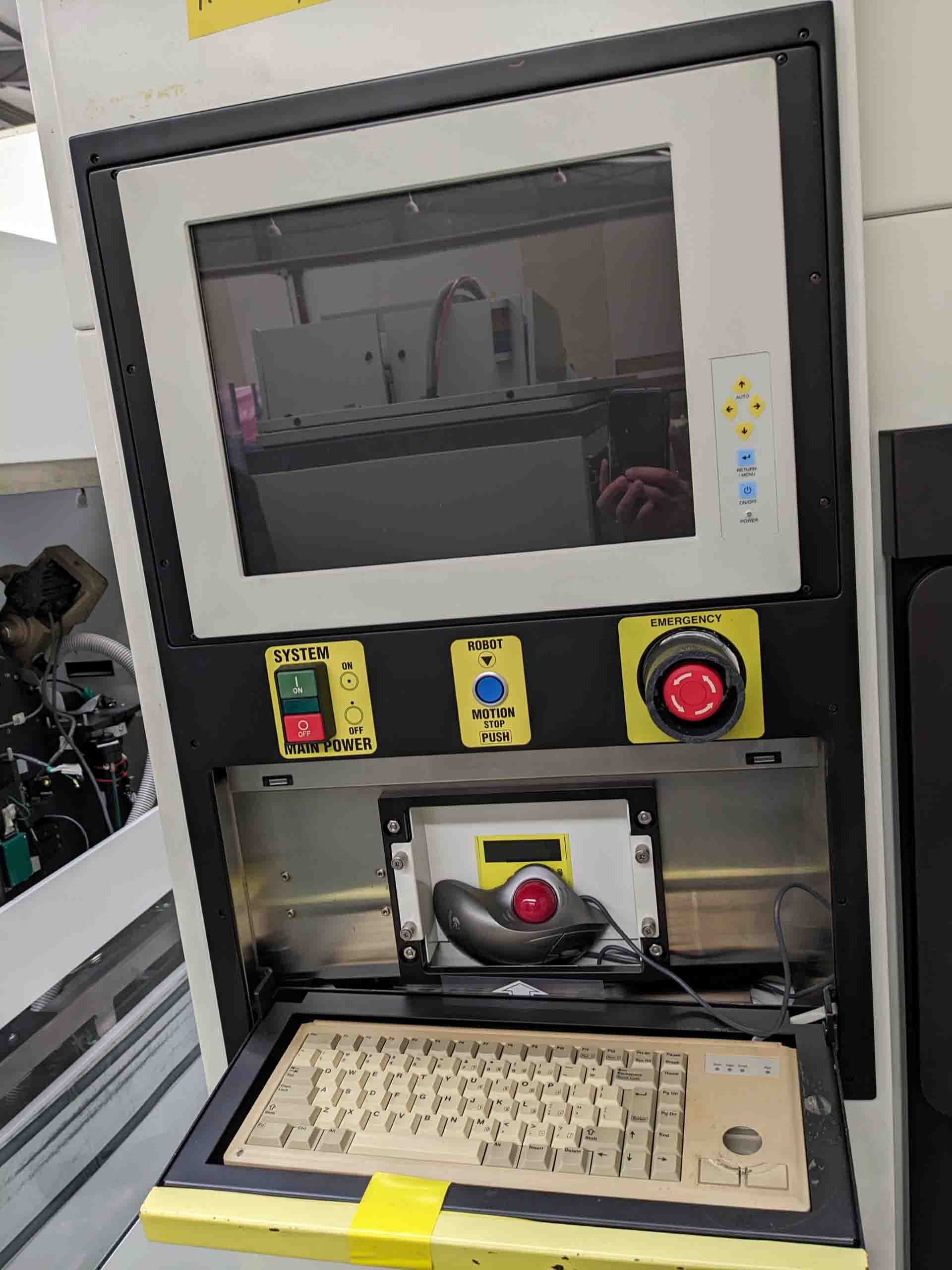

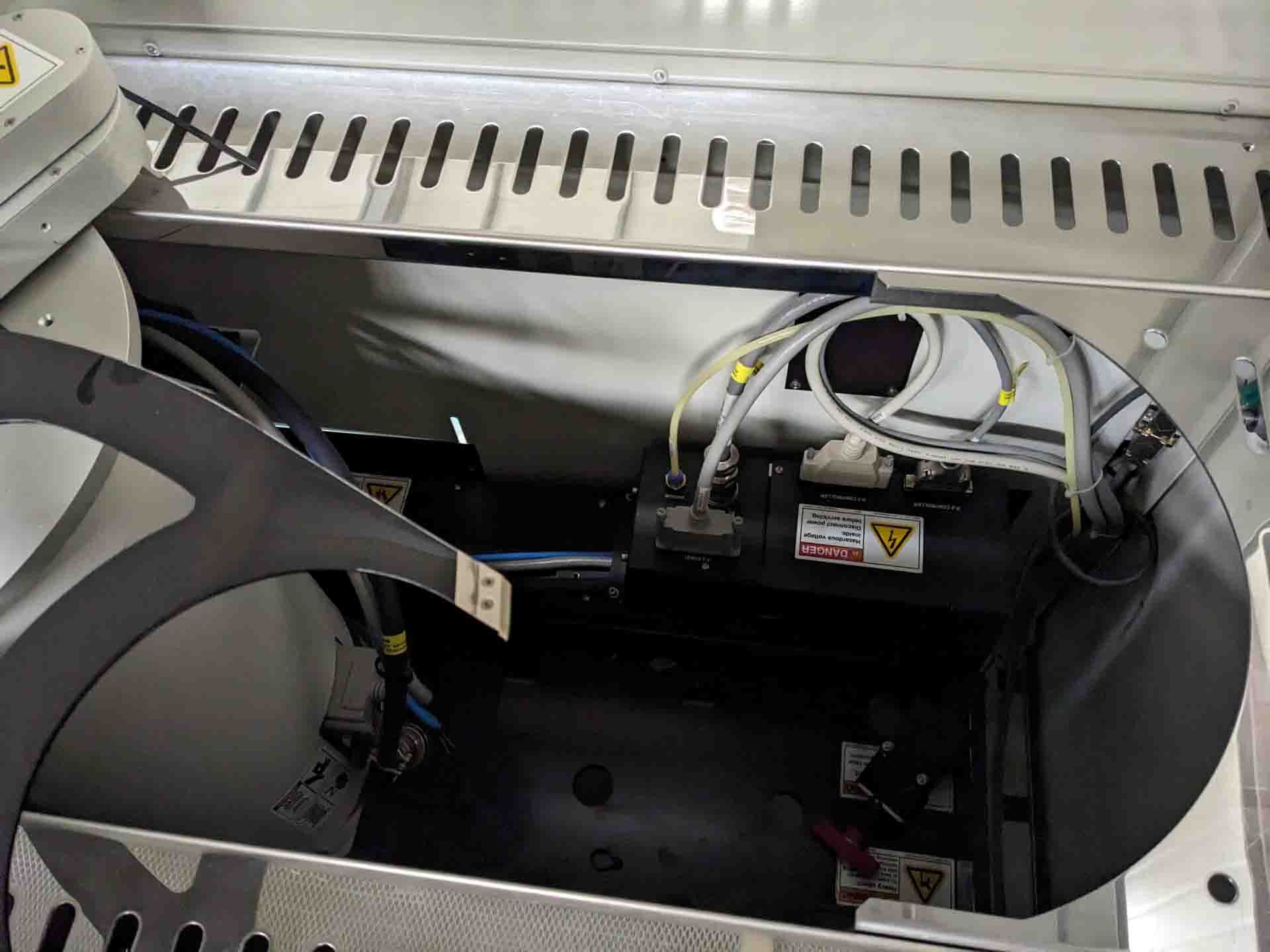

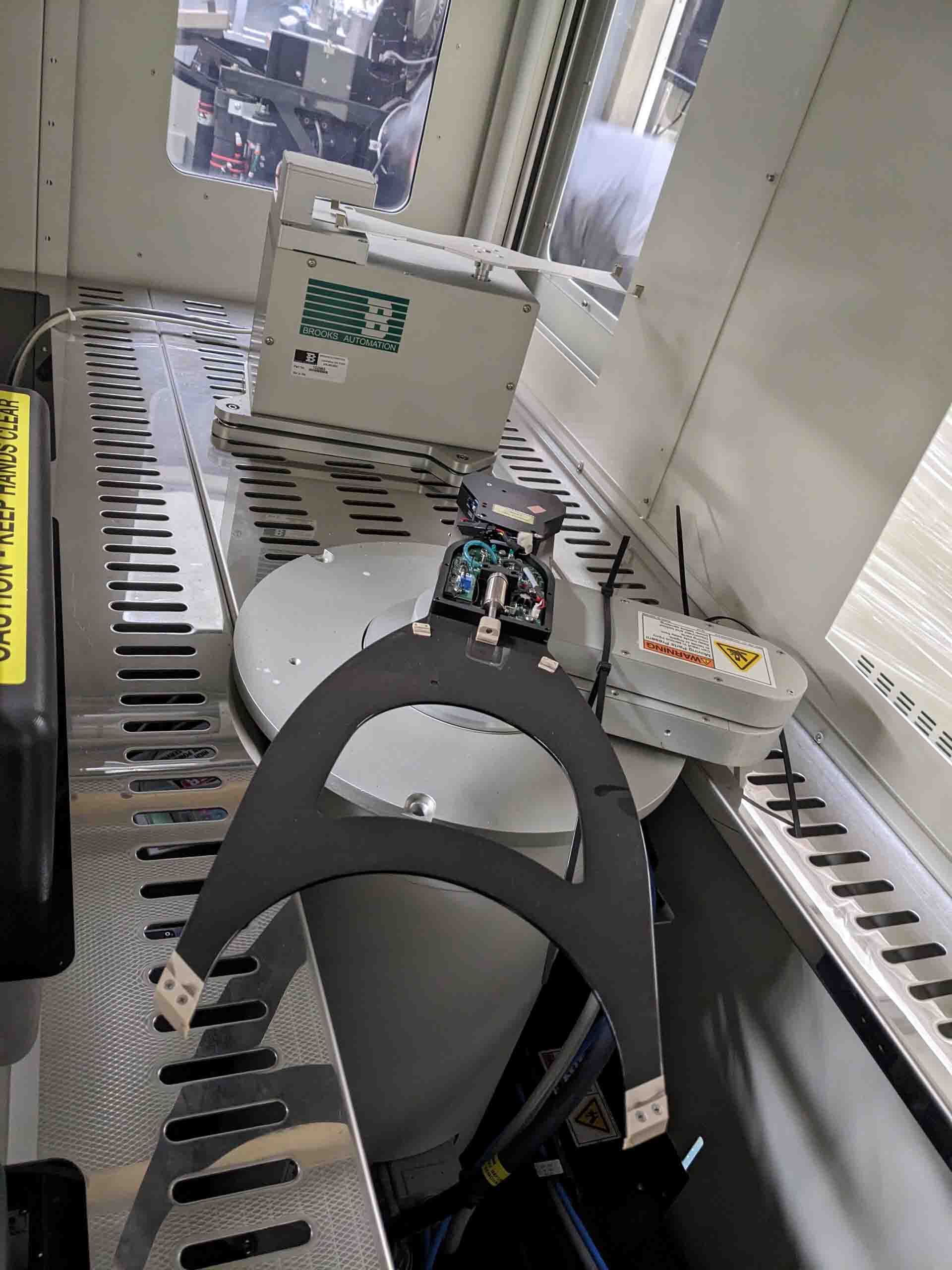

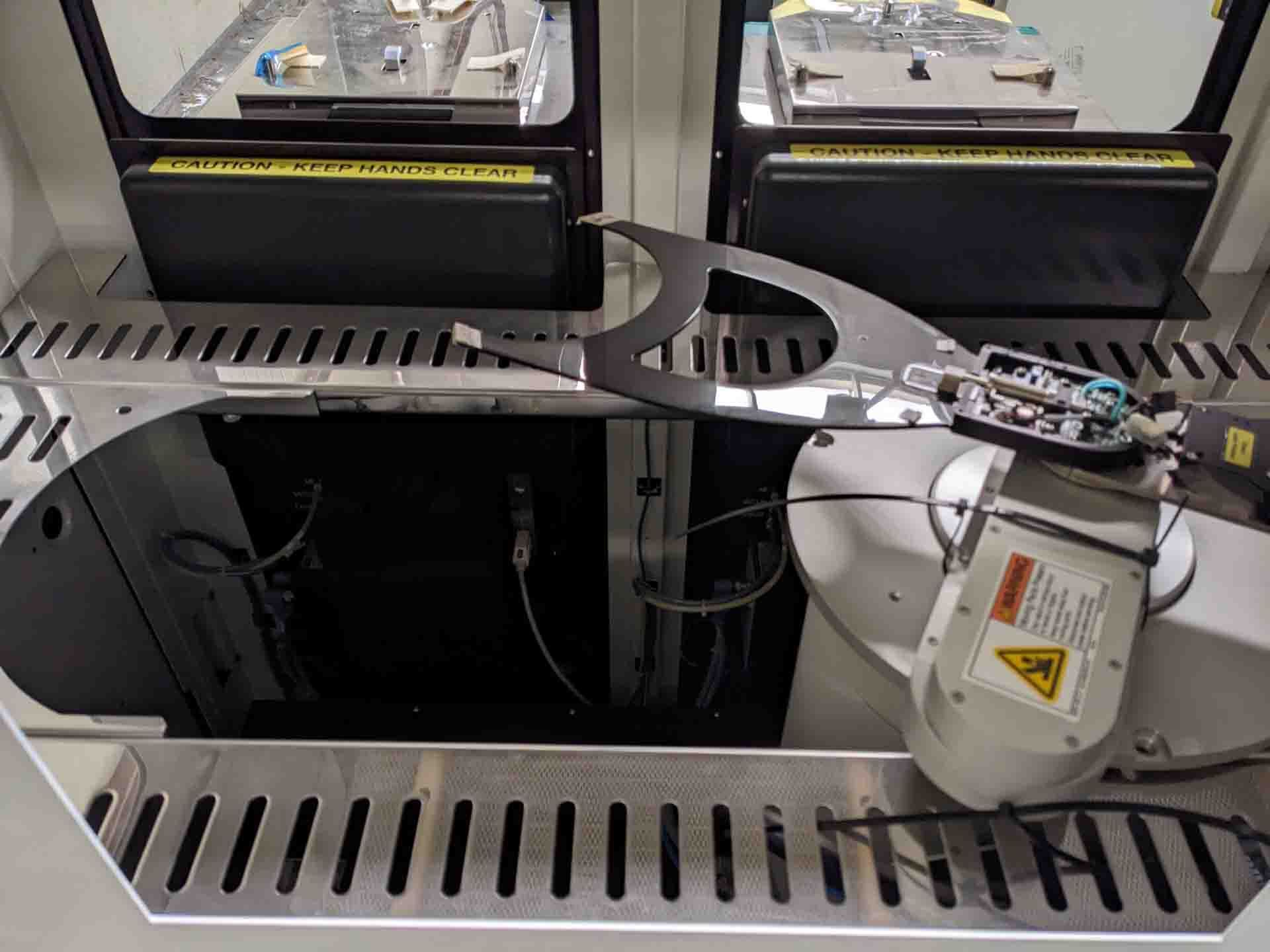

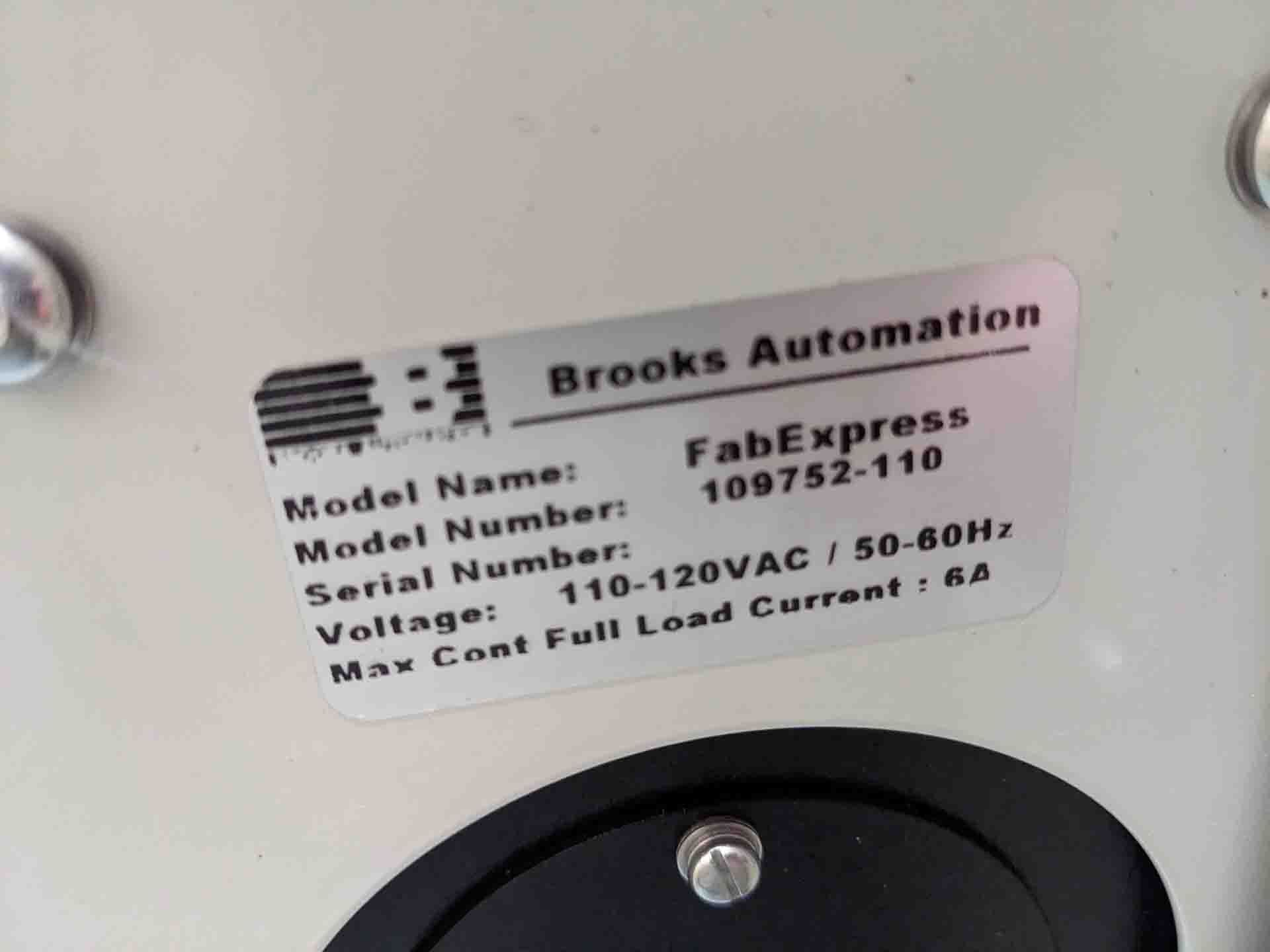

ADE / KLA / TENCOR AFS 3220 Wafer Testing and Metrology Equipment is an automated semiconductor metrology system designed for automated, high throughput monitoring of wafers in the production process. The unit is a fully integrated and automatic tool platform designed from advanced algorithms and software coupled with an automated wafer handling machine. ADE AFS 3220 is designed for rapid and precise measurement of wafers. The tool features multi-sensor optical metrology, process dynamics and defect inspection, data management, and correlation of multiple wafers. KLA AFS 3220 utilizes multiple sensors to simultaneously measure wafer parameters across the full face of the wafer in a short amount of time. Point-to-point scanning is available in both visible and infrared spectrums with accuracy down to 10 nanometers. Wafer mapping is also available with automated wafer centering. Defects on the wafer can be detected at the rate of several thousands per hour. AFS 3220 has several advanced process control and diagnostic capabilities such as integrated defect review, process feedback, and process monitoring. This allows for quick automation of the production process and improved yields and cost savings in a given batch. Additionally, the data management asset provides comprehensive wafer metrology data and can be integrated into factory automation systems. TENCOR AFS 3220 features an intuitive user-friendly interface with various graphical displays for data review and analysis. This allows for easy access to model parameters and in-depth review of the results. The equipment is also equipped with on-board self-diagnostics and automated calibration routines. Overall, ADE / KLA / TENCOR AFS 3220 Wafer Testing and Metrology System from ADE is a fully automated and integrated unit designed to provide accurate, fast and DRAM-free monitoring of wafers in the production process. The machine includes several integrated components such as multi-sensor optical metrology, process dynamics and defect inspection, data management, and correlation of multiple wafers, automated calibration routines, etc. that make it an excellent choice for high-efficiency manufacturers.

There are no reviews yet