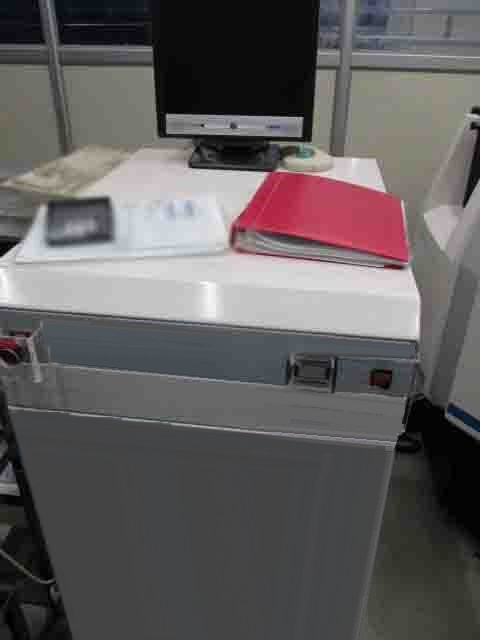

Used ADE / KLA / TENCOR UltraScan 9600 #9200036 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9200036

Wafer metrology system

Non-contact capacitive probe measurement:

Resolution: 10 um

Wafer thickness range: 400 to 800 Microns

E-PLUS Advanced / Thickness between stations

Signal effector arm robot

9600 Power supply

Non contact P/N type tester

Wafer resistivity: 0.1 to 200 ohm-cm

ADE 350 Arm controller

Auto A probe

ASC Controller

Includes:

Capable of measuring-lapped, etched, polished and patterned wafers - measures bow and warp

Site and global flatness

(2) Cassette input stations

(3) Cassette output stations

Prealigner station

Hi-RES Station

Operation manual

Maintenance manual.

ADE / KLA / TENCOR UltraScan 9600 is a state-of-the-art wafer testing and metrology equipment made for the semiconductor industry. It is designed to offer research and development scientists a powerful suite of modular test instruments to perform advanced wafer-level measurements. UltraScan is capable of automated metrology of a variety of test parameters such as stress-strain, film thickness, surface characteristics, electrical properties, and more. It can measure the structure, properties, and chemical composition of wafers with high accuracy and can be used for a wide range of surface and deep level metrology. The system has a 514mm² field of view, a 12.6μm image spot size, and a 0.6nm resolution. It can process up to 8 wafers per hour with a process throughput of 15 to 40 minutes per wafer, depending on the measurement needed. The unit is equipped with an imaging machine consisting of a charge-coupled device (CCD) sensor and an optical microscope to detect the measurement information on the surface of the wafer. It can read out, analyze, and store test images with high-precision calibration. This imaging tool is also used for focusing, positioning, and performing non-contact surface alignment. The asset is capable of taking a wide range of samples, such as silicon-on-insulator, multilayer wafers, thin films, polysilicon, wafer level packaging, and others. It also has the ability to support a variety of metrology techniques, such as axial scan, stress test, and etch depth. ADE UltraScan 9600 is controlled and monitored from a user-friendly interface. It supports data transfer, analysis, and storage over local or wide-area networks. It is equipped with a built-in software model that supports automatic diagnosis and sorting of wafers. Finally, the equipment is designed for easy maintenance and repair. Overall, KLA ULTRA SCAN 9600 is a powerful wafer testing and metrology system that offers highly accurate measurements and is capable of supporting a range of user-defined applications.

There are no reviews yet