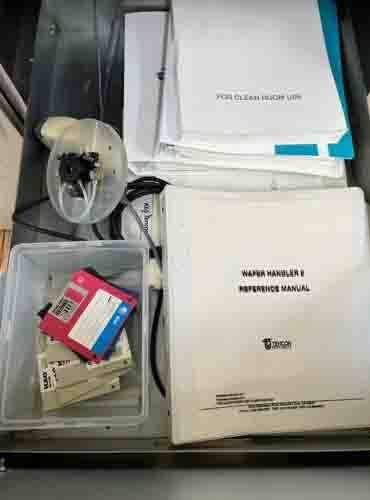

Used KLA / TENCOR / PROMETRIX 7200 Surfscan #9255577 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR / PROMETRIX 7200 Surfscan is a surface analysis and metrology equipment designed for wafer-level testing and measurement. It is a versatile wafer mapping tool capable of providing reliable and accurate measurements through multiple applications such as wafer thickness, defect location, and surface roughness. It is built to use optics and Non-Contact Atomic Force Microscopy (NCAFM) to provide 4X or higher resolution measurements in the range from 0.1 nm to 3+mm. The system runs on a Windows PC with a high-speed image acquisition unit to capture image data, allowing for real-time processing of measurements while the data is acquired. Surfscan 7200 uses a combination of Optical Microscopy (OM) and Non-Contact Atomic Force Microscopy (NCAFM) to provide detailed data on the surface morphology of a wafer. NCAFM uses a low-temperature nanometer resolution force microscope to measure the height, roughness, and shape of a surface in both 2D and 3D. The NCAFM machine includes a Z-Scanner which allows automated high-speed scanning of the entire surface, resulting in an accurate topography map. The OM tool uses a high-resolution color camera and LED backlight to view and measure the surface details of a wafer. It is the interface between the two systems that enables Surfscan 7200 to measure the surface of a wafer in minute detail. Surfscan 7200 features an X/Y stage with two independent measurement axes and a range of 6 mm diameter with a maximum resolution of 0.1nm. The XY stage can move the wafer across the optical and NCFFM measurement asset for detailed 3D scans. The model is also equipped with hardware and software components for custom automation, measurement, imaging, and data analysis. Surfscan 7200 includes additional hardware and software packages such as AutoFocus, Hot/Cold Decking, and DataLink software for connection to in-line metrology systems. The Surfscan 7200 features easy to use software which reduces user programming time by providing pre-configured and proven parameters, such as optimized scan speed and size, for wafer-level measurements. It also enables the user to customize settings for specific applications. The software is capable of generating detailed data analysis, including surface topography, defect inspection, feature analysis, and much more. Additionally, the software is compliant with various international standards as well as the SEMI-standards. Surfscan 7200 is an industry-standard metrology equipment designed for wafer-level testing and measurement. It is built with advanced technology that provides a highly accurate and reliable measurement in a fast and efficient manner. The integrated hardware and software components make it a versatile platform used in wafer-level testing and metrology applications.

There are no reviews yet