Used KLA / TENCOR / PROMETRIX AIT I #293595751 for sale

URL successfully copied!

Tap to zoom

ID: 293595751

Wafer Size: 6"-8"

Vintage: 1997

Inspection system, 6"-8"

1997 vintage.

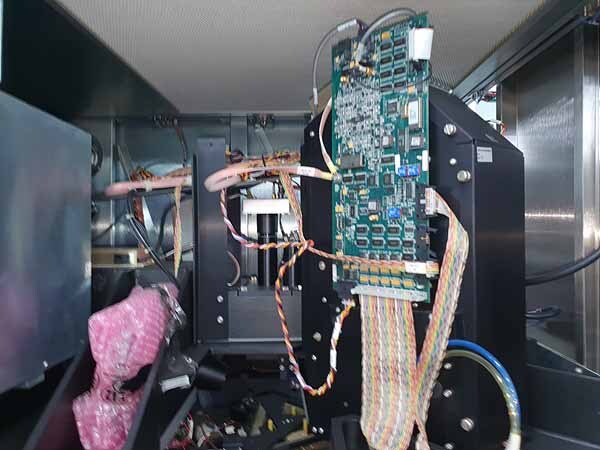

KLA / TENCOR / PROMETRIX AIT I is a wafer testing and metrology equipment that helps to improve process control and reduce cost in the production of semiconductor devices. The system uses optical and electrical metrology technology to measure wafer and die characteristics with low-noise and high-accuracy and speed. The unit performs optical measurements of scan areas, non-destructive measurements of defects, and other processes with minimal impact on process throughput. The machine consists of a variety of components, including a test chamber, a measurement arm, and a data processor. The test chamber is a specially designed environment to reduce noise and improve measurement accuracy. The test chamber includes a light source, a camera, and a beam splitter. The light source illuminates the wafer and die components. The camera captures images of the light reflected by the components and transmits them to the measurement arm. The light patterns generated by the illuminating light sources are compared with pre-defined reference patterns to detect and quantify differences. The measurement arm contains an array of sensors that measure the obtained images and sends them to the data processor for analysis. The data processor processes the information gathered from the measurement arm and generates results. The results, which can include quantitative measurements and defect detection, are typically saved in a database for later retrieval and analysis. The tool also offers a variety of features to improve process control. For example, the asset supports backside inspection, which analyses the backside of a die for quality issues. Furthermore, users can create custom defect types and databanks, which makes it easier to identify more complex defects. Additionally, users can make use of advanced algorithms to improve the accuracy of the measurements. Overall, KLA AIT I is a powerful wafer testing and metrology model that provides users with a reliable and efficient method of measuring quality on their products. With its low-noise and high-accuracy measurements and multiple features, the equipment can help to significantly improve process control and reduce costs.

There are no reviews yet