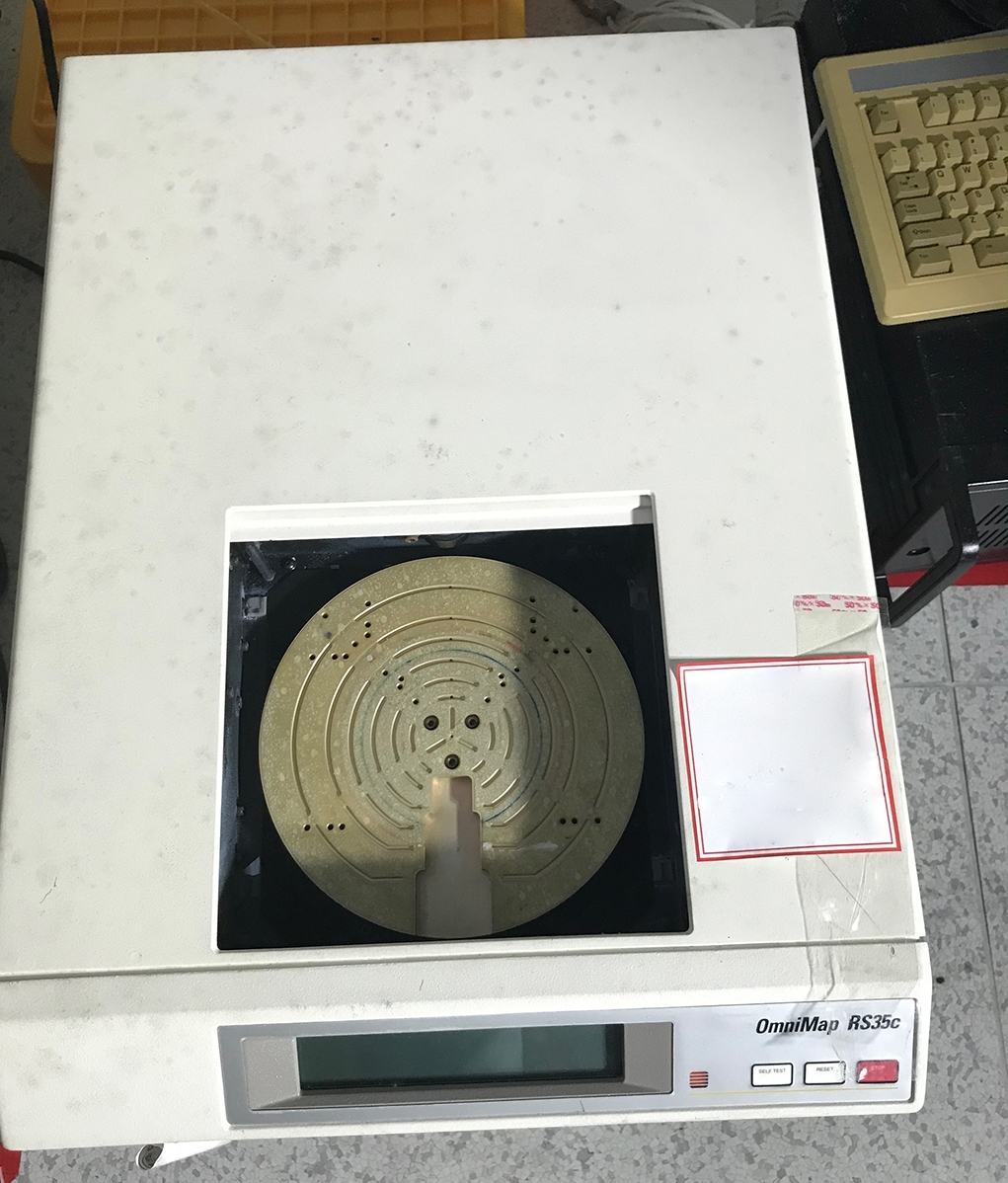

Used KLA / TENCOR / PROMETRIX RS-35C #9276502 for sale

URL successfully copied!

Tap to zoom

ID: 9276502

Resistivity mapping system

4-Point probe

Vacuum: 300 mmHG

Hard disk

PC

Color monitor

XY Pattern test

Measurement range: 5 mΩ to 5 mΩ

Maps: Average, difference, and ratio

Calibration curves and correlation equations

Trend and SQC charts

Data import and export

ASCII Copy to diskette

Measurement options: Mapping (up to 625 sites)

Qualification test:

Contour maps

3D Maps

Diameter scans (Up to 625 sites)

Quick tests: standard and user-definable tests (up to 30 sites)

Accuracy:

± 0.2% (Standard resistor)

± 1% (NIST Wafer)

Repeatability : <0.2% (1 sigma)

Power supply: 115 / 230 V, 8 A, 50/60 Hz.

KLA / TENCOR / PROMETRIX RS-35C is a high-performance wafer testing and metrology equipment designed to meet the most stringent requirements for accuracy and repeatability. It is comprised of a series of components that allow for the automated, accelerated and extremely accurate measurement of a variety of characteristics related to semiconductor materials. The first element of the system is its Optical Zone Sensor, which is the basis for precise inspections of the structures and features of individual wafers. It is a scanner unit which includes a suite of special optics, electronics and software that is capable of making detailed measurements on small sections of the wafer, even down to the nanometer scale. With the ability to measure a wide range of parameters in the smallest of feature sizes, this machine can scan at multiple speeds and resolutions to quickly and accurately measure wafer feature characteristics such as width and depth. The tool's Optical Reticle allows for complete 3-dimensional analysis of wafer patterns. This asset is extremely accurate, with an ability to analyze a variety of patterns to a nanometer resolution level. The Optical Reticle also employs special optics and software that allows for an exceedingly accurate determination of particle size on the wafer surface. The model also contains a MicroStepper equipment which provides for the multi-directional measurement of micron-sized design features on the wafer surface, even in the presence of objects such as solder bumps and smudges. With the ability to measure from two or more directions, this system is able to measure up to the nanometer scale with a high level of precision. KLA RS-35C unit also includes the AutoAlign machine, which is a sophisticated algorithm designed to quickly and accurately align the optics of the scanner and optics reticle to any pattern on the wafer surface. This ensures that each measurement taken by the tool is precise and without error. Finally, the station includes a Vacuum Chuck asset, which ensures that the wafer is perfectly parallel and level during measurement. This is extremely important, as even the slightest variation in the wafer's position can lead to imprecision in the results. In sum, TENCOR RS 35C provides a solution for high-precision wafer testing and metrology. With its suite of components, including the Optical Zone Sensor, Optical Reticle, MicroStepper, AutoAlign and Vacuum Chuck, this model is designed to provide an extremely accurate and reliable analysis to any wafers tested.

There are no reviews yet