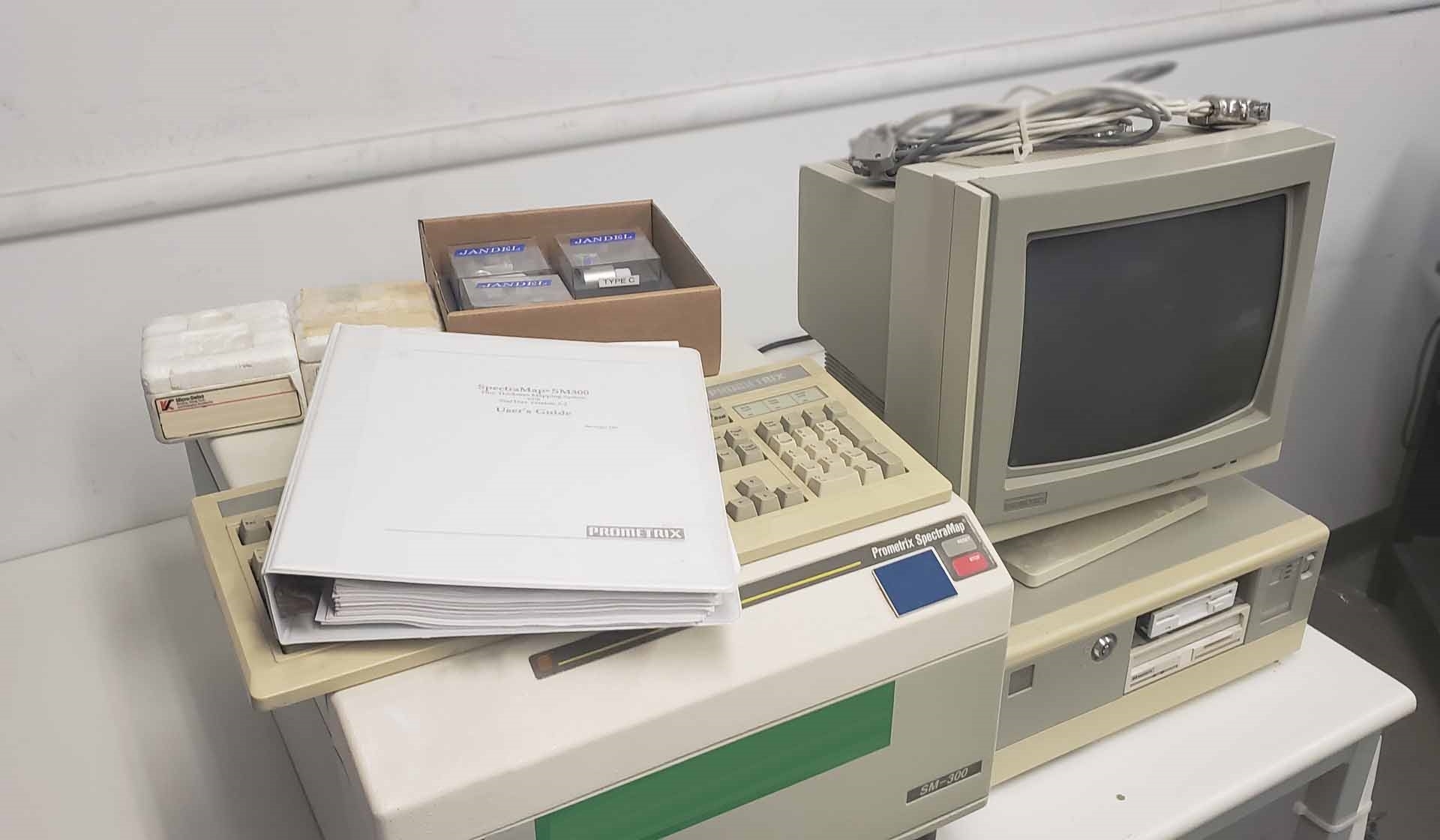

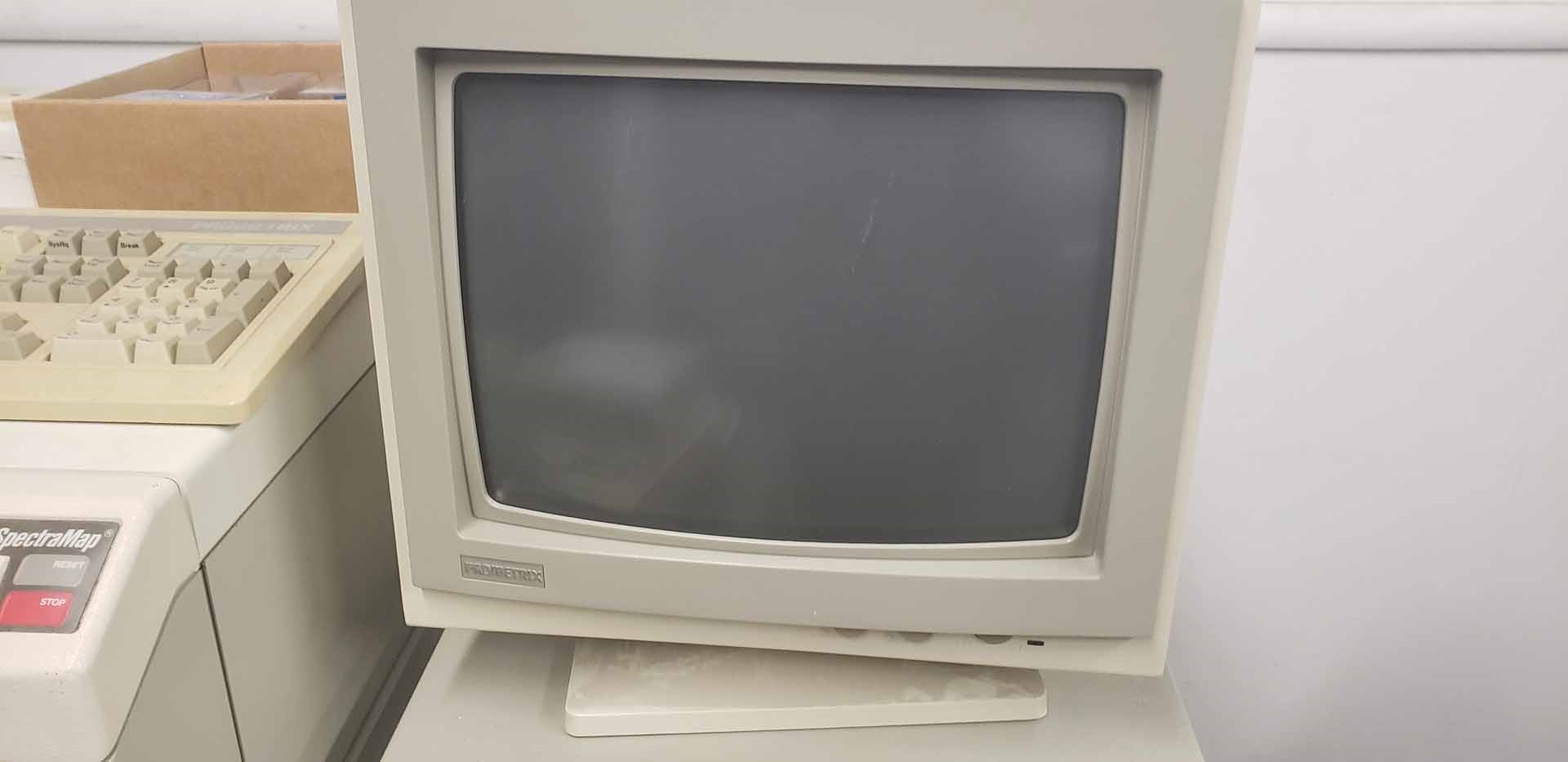

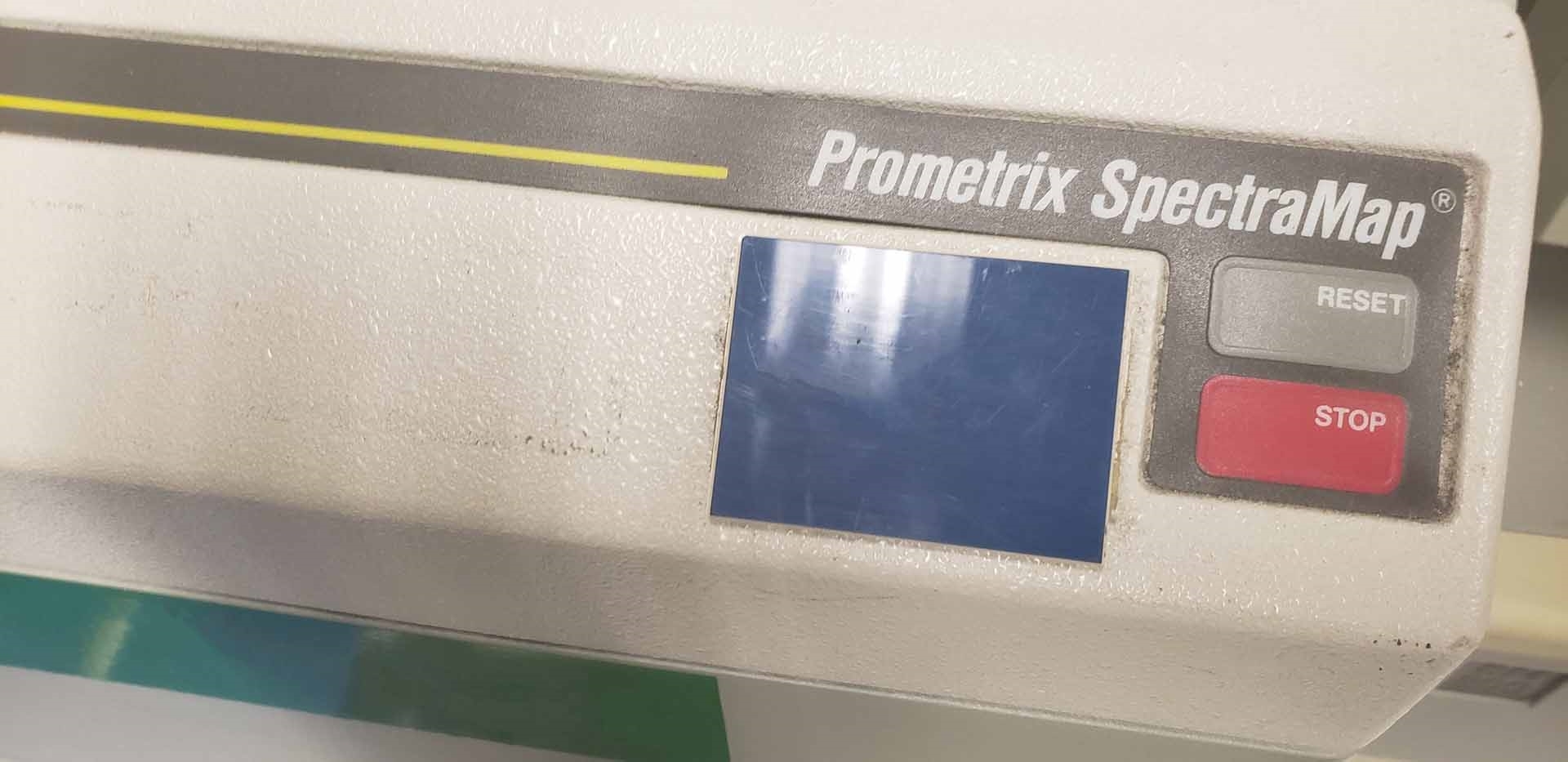

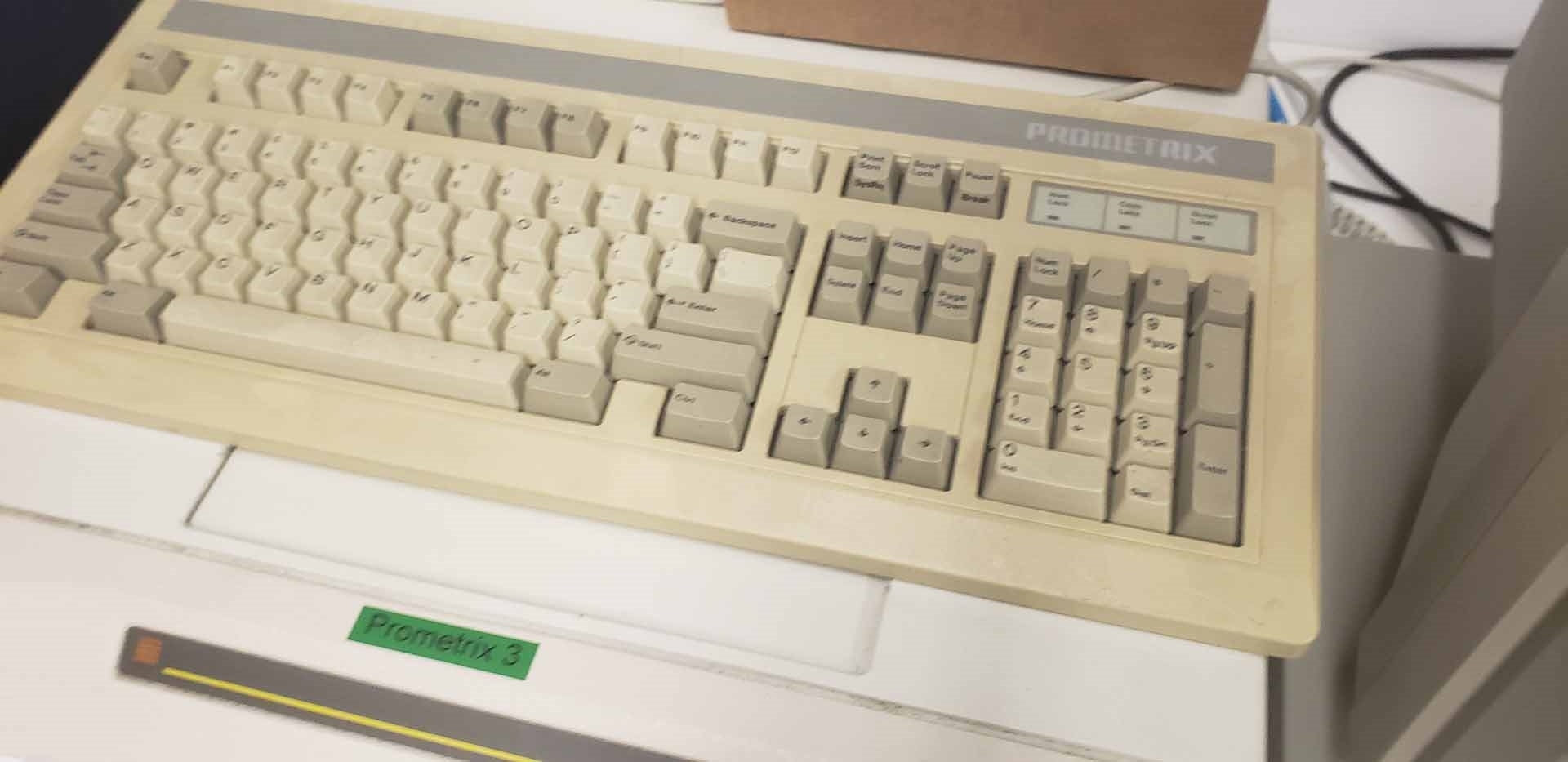

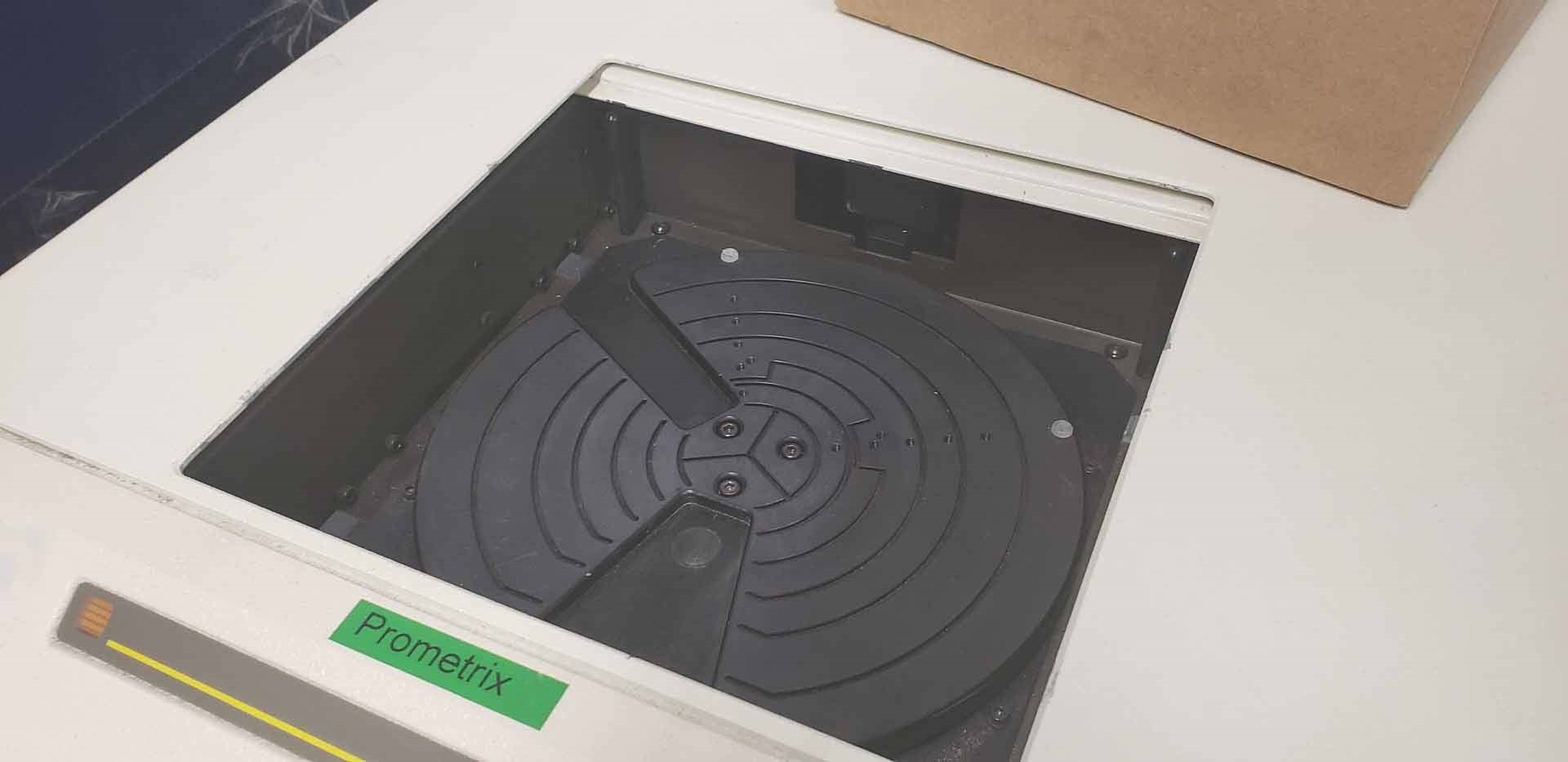

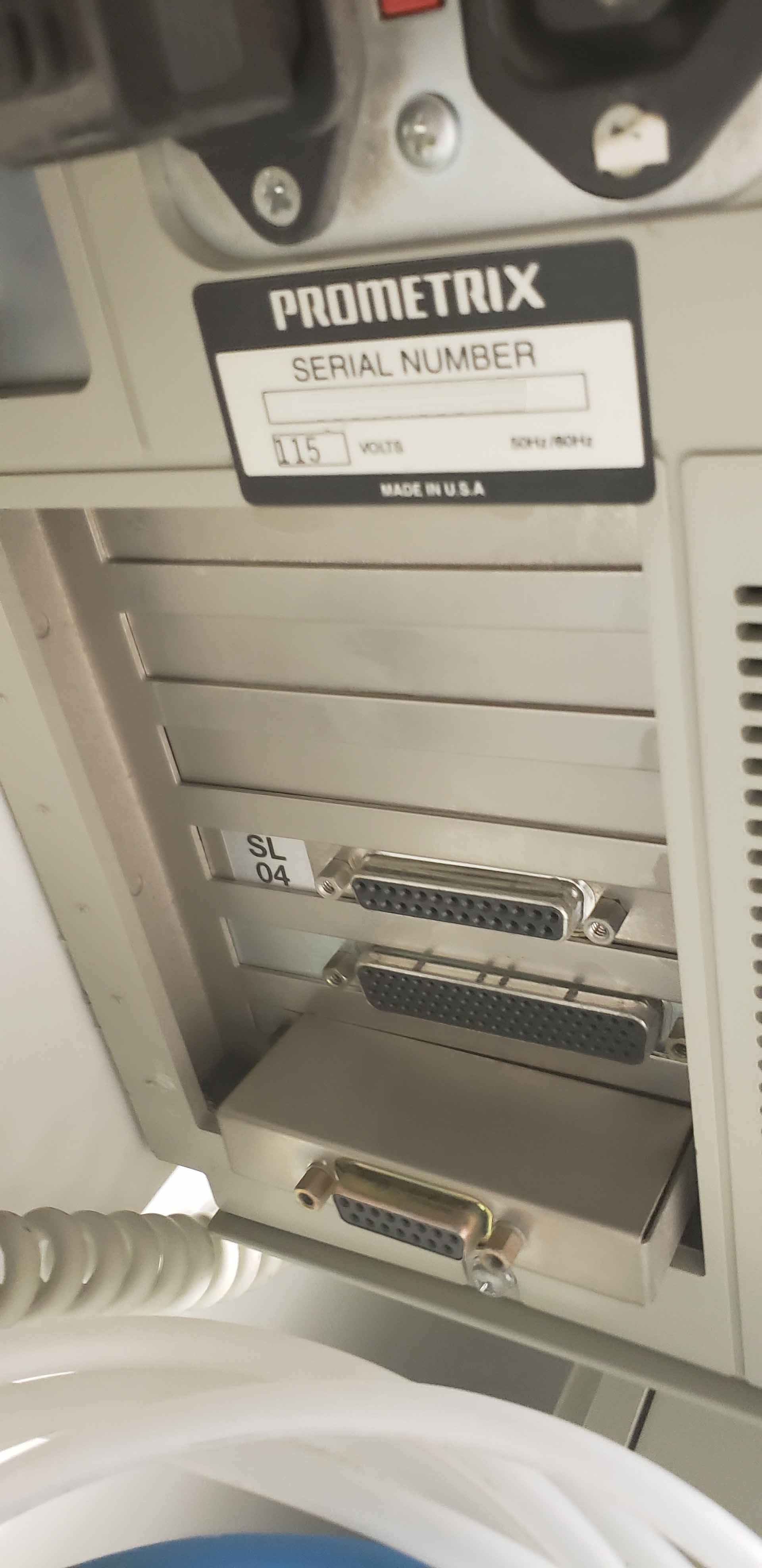

Used KLA / TENCOR / PROMETRIX SM 300 #9188572 for sale

URL successfully copied!

Tap to zoom

KLA / TENCOR / PROMETRIX SM 300 is a equipment created specifically for measuring and testing the quality of wafers. It boasts a high speed, high accuracy, and a large capacity for both broad and variable applications. KLA SM 300 is designed to be a part of a complete metrology system, following through from the manufacturing process to be sure that components are properly manufactured. It offers several capabilities, such as imaging, defect recognition, and positional accuracy for wafers that are important in modern semiconductor production. This unit is composed of various components that work together to ensure that wafer quality is maintained. The optical subsystem of TENCOR SM 300 uses both a white and red laser beam, depending on the application. These lasers are used together and serve to measure, inspect, and recognize defects quickly and accurately. The alignment machine offers precise and precise imaging, while the inspection systems offer real-time and in-depth analysis. The measurement subsystem of PROMETRIX SM 300 has a high-speed and precise linear measurement capability, which means that wafer quality is maintained. The measurement systems offer details on wafer shape, surface roughness, and edge features. The defect-detection subsystem uses optical microscopy, acoustic microscopy, and imaging to detect wafer defects quickly and accurately. Finally, the metrology software in SM 300 processes the input from the measurement, image capture, and analysis subsystems. This data is then used to analyze, compare, and evaluate the productivity, accuracy, and performance of a wafer. The software also allows for reporting and plotting functions that provide metrics on wafer performance. Overall, KLA / TENCOR / PROMETRIX SM 300 is a reliable and efficient tool to measure and test the quality of wafers. It offers high speed, high accuracy, and a large capacity that can be used for a variety of applications. Its various components and software ensure that wafer quality is maintained and that productivity and performance are tracked.

There are no reviews yet