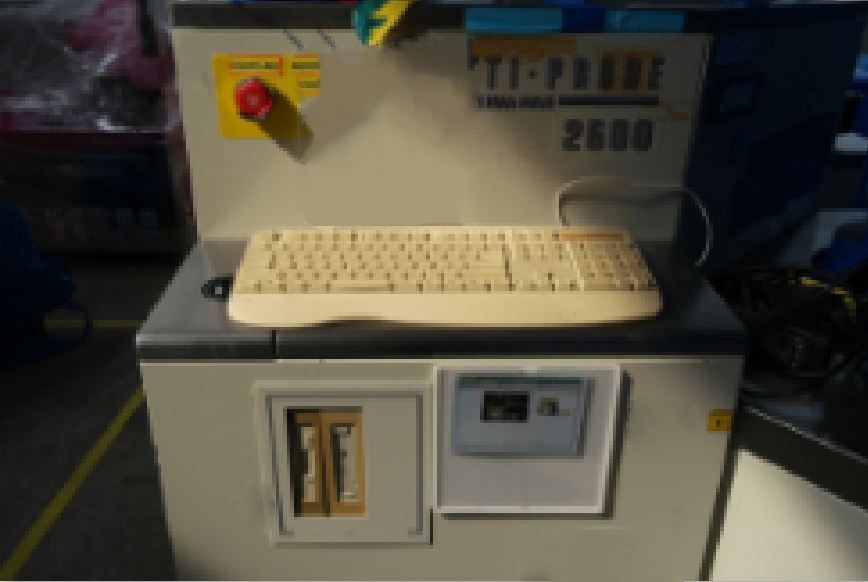

Used KLA / TENCOR / THERMA-WAVE OP 2600 #9214770 for sale

URL successfully copied!

Tap to zoom

ID: 9214770

Wafer Size: 8"

Vintage: 1997

Film thickness measurement system, 8"

1997 vintage.

KLA / TENCOR / THERMA-WAVE OP 2600 is a wafer testing and metrology equipment that enables critical measurements on semiconductor devices. This highly precise system is used for researching and developing next-generation chips and integrated circuits. It utilizes two optics for measuring wafers, including an automated scanning optical microscope (ASOM) and a white light interferometer (WLI). The ASOM is capable of producing both 2D contour images and 3D topography maps of the surface of a semiconductor device. It has high resolution of up to 1nm while also able to distinguish features with vertical heights as small as 10nm, allowing for a high degree of precision and accuracy. The WLI is an imaging technology that relies on interference of reflected light to create a 3D map of a surface. It is also able to reveal the three-dimensional shapes of micro features and surface roughness that cannot be seen under an optical microscope. The WLI has a resolution of 40nm and can be used to measure roughness of between 0.2nm-2.0nm. KLA OP 2600 is powered by the ProgRScan program, which is a software package specifically designed for wafer and device research. It is able to control and synchronise both the ASOM and WLI, and integrates several functions such as feature recognition, parameter measurement, and data analysis. It also allows for different analysis methods such as regression analysis, histogram analysis, and principal component analysis. This software is designed to be user-friendly and allows for results to be easily exported for other processes in the manufacturer's production line. TENCOR OP 2600 unit is also fully automated, allowing for greatly increased testing throughput while also providing repeatable results with minimal effort from the user. The automated processes with this machine also help to reduce errors associated with manual processes. Additionally, it is able to significantly reduce turnaround time and costs of operations, such as device development and production testing. Overall, THERMA-WAVE OP 2600 wafer testing and metrology tool offers high-precision measurements for device and semiconductor research and development. It is able to reliably measure wafers at a very high resolution, providing the accuracy and detail needed for developing leading-edge chips and integrated circuits. In addition, its automated processes help to reduce errors, decrease turnaround times, and increase profitability.

There are no reviews yet