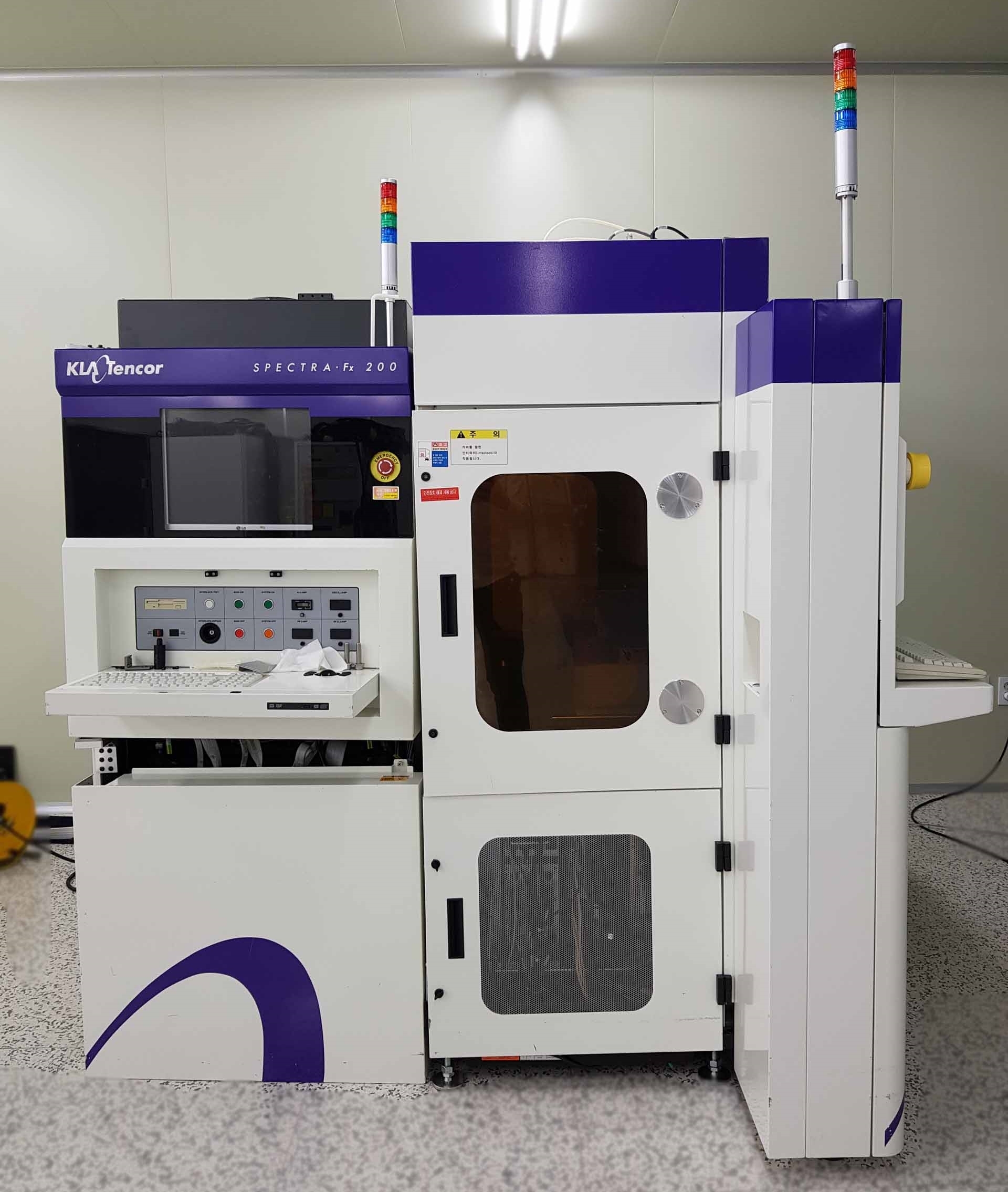

Used KLA / TENCOR / THERMA-WAVE Spectra FX 200 #9215204 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9215204

Wafer Size: 8"-12"

Vintage: 2005

Film thickness measurement system, 8"-12"

(2) Load ports

EFEM

UI

Insert type: Conversion, 8"

Data transfer: Floppy disk / DVD R/W

Operation: Mouse and keyboard

Door interlock

Recipe auto backup

Auto data deletion

Auto error log file save and classification

Queued loading (Queue recipe)

Spectroscopic ellipsometer

Spectrometer

Wavelength light source: 220 to 800 nm

Spot size: <30 µm (Thickness and Rl)

Spot size: <30 µm (Reflectivity)

2D and 3D Mapping function

Pattern recognition

Recipe copy with film library

SE and DBS Optics

Optic lens: 1x, 2x, 4x, 15x

Pattern score: FA

Screen

Recipe / Library import: TCP/IP (On-time intromit)

Wafer breakage: ≤1/1,00,000 Cycles

Signal tower

Options:

E30-98 Gem semi

E5-93 SECS II Semi

Recipe generator

Remote access capability

Carrier ID, 12"

E23, 12"

E84, 12"

E87, 12"

Safety shield for SO, 12"

HP 6122

HSMS Communication

Break beam mapper

Direct cable less power connection

E84 Enabled: OHT and AGV/RGV

OHT Lockout

Computer

Operating system: Windows XP

PHOENIX Handler

Controllers:

CPU: Pentium 4 3.0 GHz - P4 2.8 MHz

Memory: 1.024 GB DRAM

(2) Hard Disk Drives (HDD): 80 GB

Floppy Disk Drive (FDD), 3.5"

CD_R: 40X_8X (DVD RW)

Dongle

2005 vintage.

KLA / TENCOR / THERMA-WAVE Spectra FX 200 is a state-of-the-art wafer testing and metrology equipment. It is widely used in the semiconductor industry for testing wafers for a variety of parameters, from electrical characteristics to physical defects. The system is capable of accurately capturing a variety of data from the semiconductor wafer, and can be used to detect defects, measure electrical properties and perform statistical analysis. KLA Spectra FX 200 is comprised of three major components. The optical station houses the microscope, spectrophotometer, and polarimeters, which enable the unit to capture detailed information about the wafer's surface, structure, and composition. The interferometer unit is capable of capturing extremely precise measurements, including surface roughness, form factor, and layer thickness. Finally, the spectrograph station is equipped with a suite of analytical instruments that can measure and analyze the properties of the wafer in its entirety. This machine offers a wide range of features designed to improve accuracy and reduce testing time. It uses proprietary software and algorithms to speed up data analysis and provide better accuracy. A built-in databases makes it easy to store and recall data, while dual wavelength testing ensures that any deviations between the two sets of measurements are easily detected. The tool also offers a number of automated metrology processes designed to ensure optimal measurement and analyze results. The innovative design of TENCOR Spectra FX 200 ensures that it offers superior performance with fewer errors and a lower rate of failure. Its ability to detect minute defects and measure multiple parameters with incredible accuracy makes it one of the most reliable and advanced wafer testing and metrology systems available. Additionally, it can be configured to accommodate a wide range of wafer sizes and types, making it suitable for a variety of different applications.

There are no reviews yet