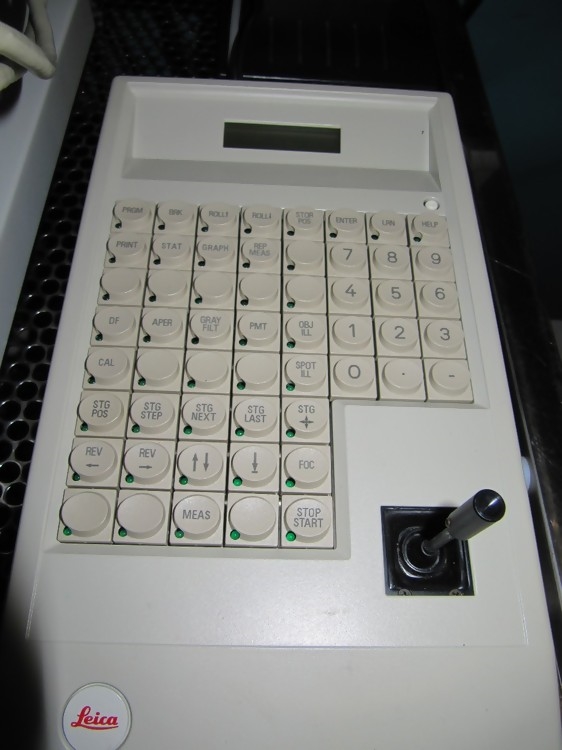

Used LEITZ MPV-SP #9283672 for sale

URL successfully copied!

Tap to zoom

ID: 9283672

Wafer Size: 3"-8"

Automatic Film thickness measuring system, 3"-8"

System Configuration:

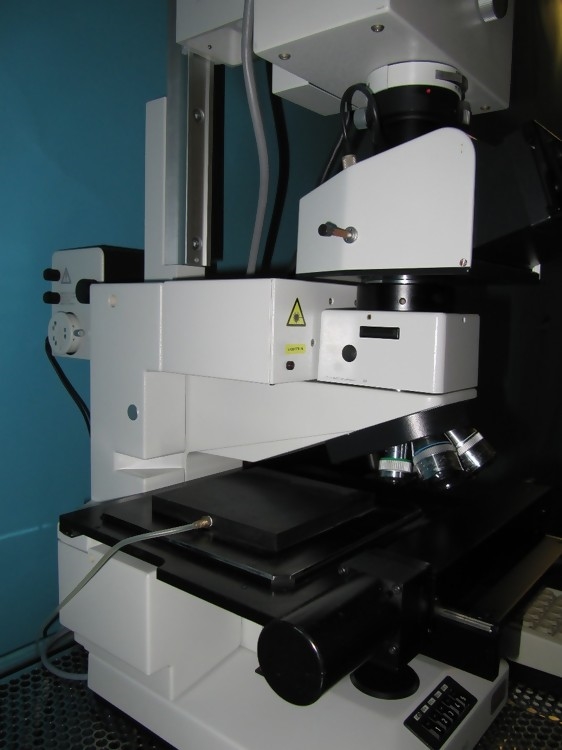

Stand alone Microscope type: Ergolux AMC

Periplan Ocular GF 10x / 18

Objective:

NPL Fluotar 10x / 0.22 DF

L 20x / 0.20

PL 50x / 0.60

NPL Fluotar 50x / 0.60 DF

NPL Fluotar 100x / 0.90 DF

Laser autofocus

Motorized, 8"

X/Y Stages

With SCAN 2000 electronics and software

Interface for RS232, IEEE or SECSI (optional SECSII)

Wafersize from 3" to 8"

Illuminator Modulopak / 1

Computer: HP Vetcra 3 Pentium desktop

with 19" TFT Flat Screen monitor

System Specifications:

Spectrometer: Grating monochromator with grating constant 1200/mm

Detector: Hamamatsu type R 928 (S 20) photomultiplier

Spectral range: 220-800nm, reduced to 400-800nm for film thickness measurements

Spectral resolution: < 1 nm

Reproductibility of the spectral measurement: < 1 nm

Linearity error for spectral measurement: < ± 1 nm

Time for film thickness determination cycle: 6-20 seconds

Film thickness measuring range: 10 nm to 15µm

Lamp power supply stabilization: <0.1%

Operating conditions:

Working temperature from 15 to 35 °C

Measuring temperature 22 ± 2°C

Relative humidity < 75%

Electrical data:

Mains supply: 115/230 V, 50/60 Hz

Voltage tolerance: ± 10%

Power consumption: 600 VA maximum.

LEITZ MPV-SP Wafer Testing and Metrology equipment is a precision instrument designed to detect and measure defects in wafers as small as 25 nanometers. This system uses automated metrology and inspection systems to produce highly accurate results quickly and accurately. MPV-SP offers industry leading accuracy and throughput. Its automated metrology unit uses a 10-axis motorized Cartesian robot to ensure repeatable results and automated inspection. The machine also combines two microscopes to image the entire wafer and capture data points at the edges and corners of the wafer as well as in-die under the pattern area. This allows for more detailed analysis than is available with standard metrology systems. LEITZ MPV-SP Wafer Testing and Metrology tool features a variety of wafer test algorithms and processes. It can use two different types of sensors and offers both Linear Scanning (LSI) and Staired Scanning (SSI) techniques to detect defects. The asset can detect a wide range of defects and measure precise parameters like form factor, flatness, and edge placement accuracy. It is capable of running multiple tests simultaneously, providing precise and reliable results in a fraction of the time required by manual methods. The metrology model is highly flexible, allowing users to customize the testing and analysis process to meet their specific needs. MPV-SP also includes an intuitive user-interface, allowing for easy operation and setup. The equipment features powerful defect analysis and reporting capabilities, making it an indispensable tool for production line analysis. LEITZ MPV-SP Wafer Testing and Metrology system offers high-precision measurement and inspection capabilities for the wafer market. It is an invaluable tool for detecting and measuring defects in wafers as small as 25 nanometers. With its reliable and accurate results and intuitive user-interface, MPV-SP is a must-have for any wafer manufacturer or supplier.

There are no reviews yet