Used RUDOLPH MetaPulse 200X-Cu #9223287 for sale

URL successfully copied!

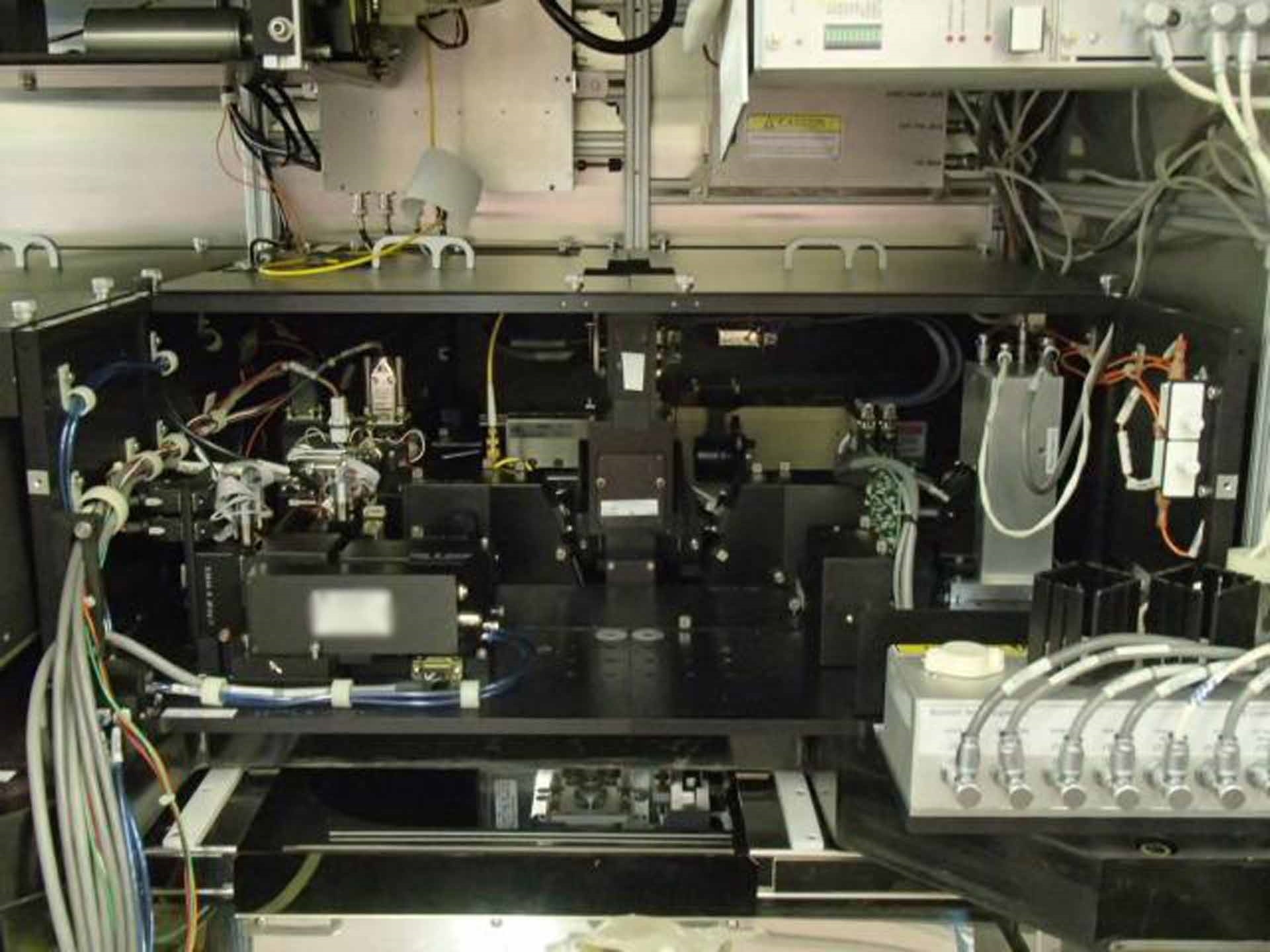

Tap to zoom

ID: 9223287

Wafer Size: 8"

Vintage: 2002

Thin film thickness metrology system, 8"

System type: SMIF

Cu Measurement

Illumination (Diode pumped ultra-fast laser):

Wave length: 800 nm, Output 1000 W

Wave length: 400 nm, Output 250 W

Plus band: 100 x 10^-15 sec

Laser incident angle: 40° Fixed

Measurement spot size:

Wave length 400 nm: 7 x 10 μm

Wave length 800 nm: 14 x 20 μm

Measurable pattern size: ≦50 μm

Measurement film:

Single layer metal film

Multi layer metal film

Measurement module:

Calibration W sample wafer

Delay stage

Microscope

ULPA Filter

Wafer positioning

X-Y Wafer stage

Full auto flat / Notch finder

Diode laser (670 nm, Max output: 3 mW)

Controller:

PC: IBM Compatible

OS: IBM OS/2 Warp (Version 3)

Keyboard

LCD, 15"

Wafer transfer module:

Robot module

Wafer handling robot

Cassette interface

Chiller module:

Cooling water flow: 5 L/min

Capacity: 5 L DI Water

Water temperature: 25°C±1°C

Supply water temperature: 25℃±5°C

2002 vintage.

RUDOLPH MetaPulse 200X-Cu is a wafer testing and metrology equipment designed to provide dimensional, optical, and electrical measurements to ensure wafer quality. This system uses an innovative laser interferometer stage to provide fast, accurate, and repeatable measurements. The repeatability of the measurements provided by the unit is less than 1 μm in the X and Y directions. The machine features a comprehensive suite of software including electron beam microprobe scanning software, as well as process and defect analysis. It also offers a feature-rich die-to-die comparison package that allows for the comparison of topographical, electrical and feature-level measurements across multiple substrates. The process control provided by the tool ensures that critical dimensions remain uniform and within desired specifications. The asset can measure parameters such as thickness, electrical contact resistance, surface finish, and process features. It also has a variety of metrology tools such as a defocus lens inspection model, a light microscope, and a voltage measurement equipment. The system also has a precise auto-focus feature that removes the need for manual focusing of the microscope. The 200X-Cu unit is also outfitted with an advanced high precision die inspection machine, which enables accurate and repeatable die-to-die comparison measurements. It also offers a high-precision die-to-die dimensional measurement tool and a high-accuracy impedance measurement asset. In addition to its comprehensive metrology tools, the model also provides a configurable hardware/software environment to ensure maximized throughput and data collection accuracy. Furthermore, the equipment is equipped with intuitive touch screen user interface which allows the user to quickly and easily switch between different measurement modes. The very feature rich RUDOLPH METAPULSE 200XCU Interferometer is an excellent choice for wafer testing and metrology. With its comprehensive set of software and hardware tools and intuitive user interface, the system ensures fast, precise, and repeatable measurements with unparalleled accuracy. This unit is an invaluable addition to any semiconductor fabrication and clean room facilities.

There are no reviews yet