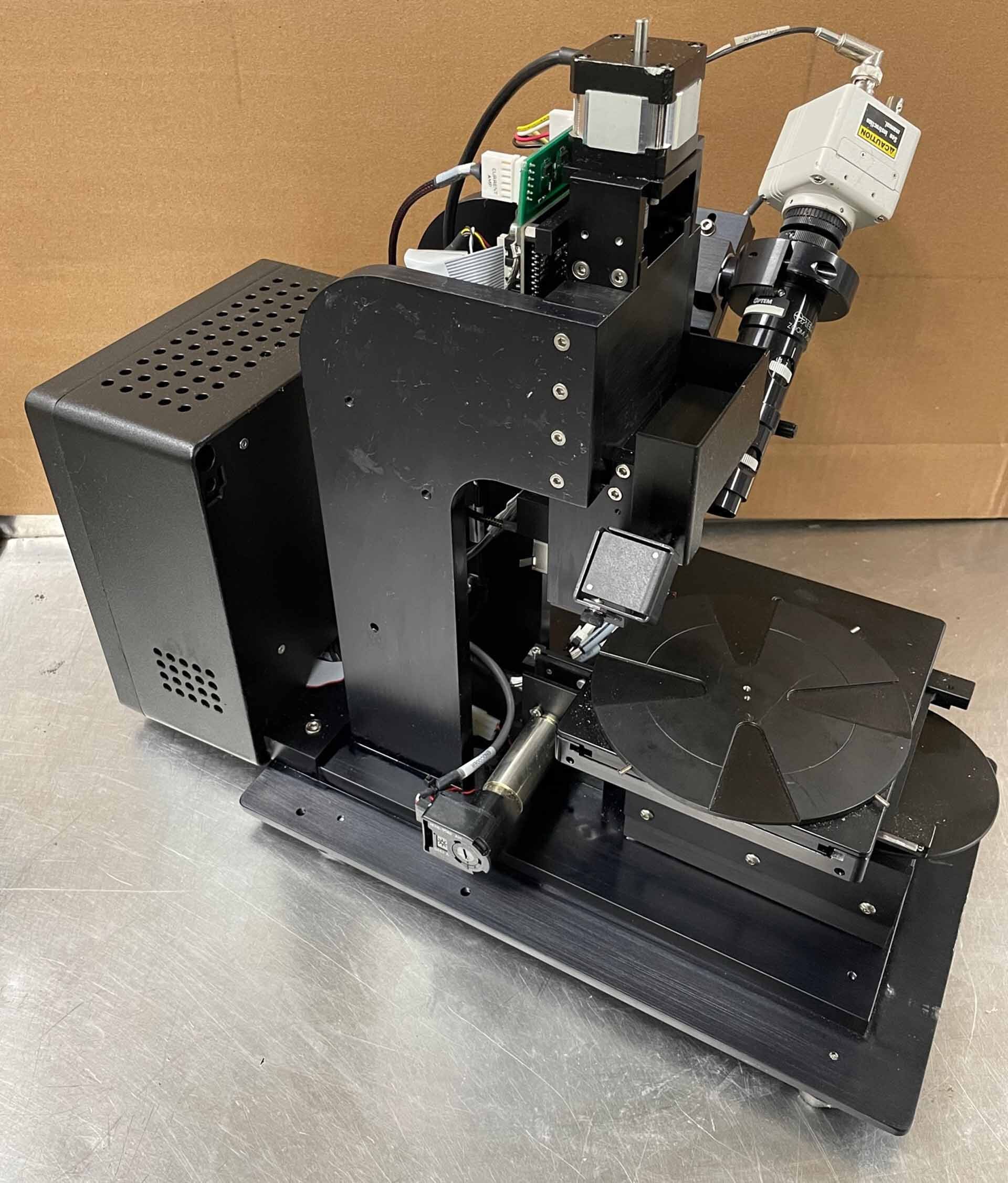

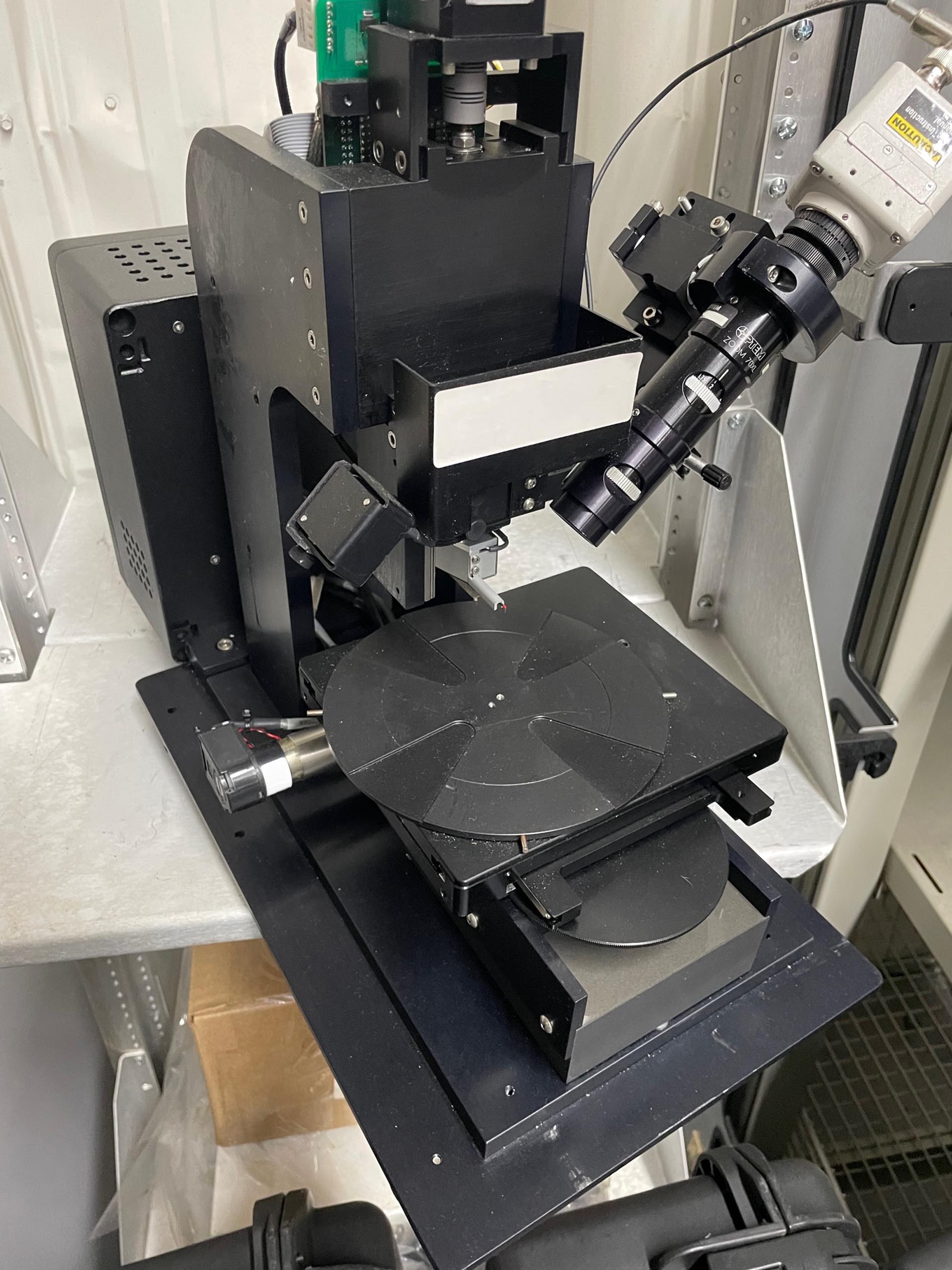

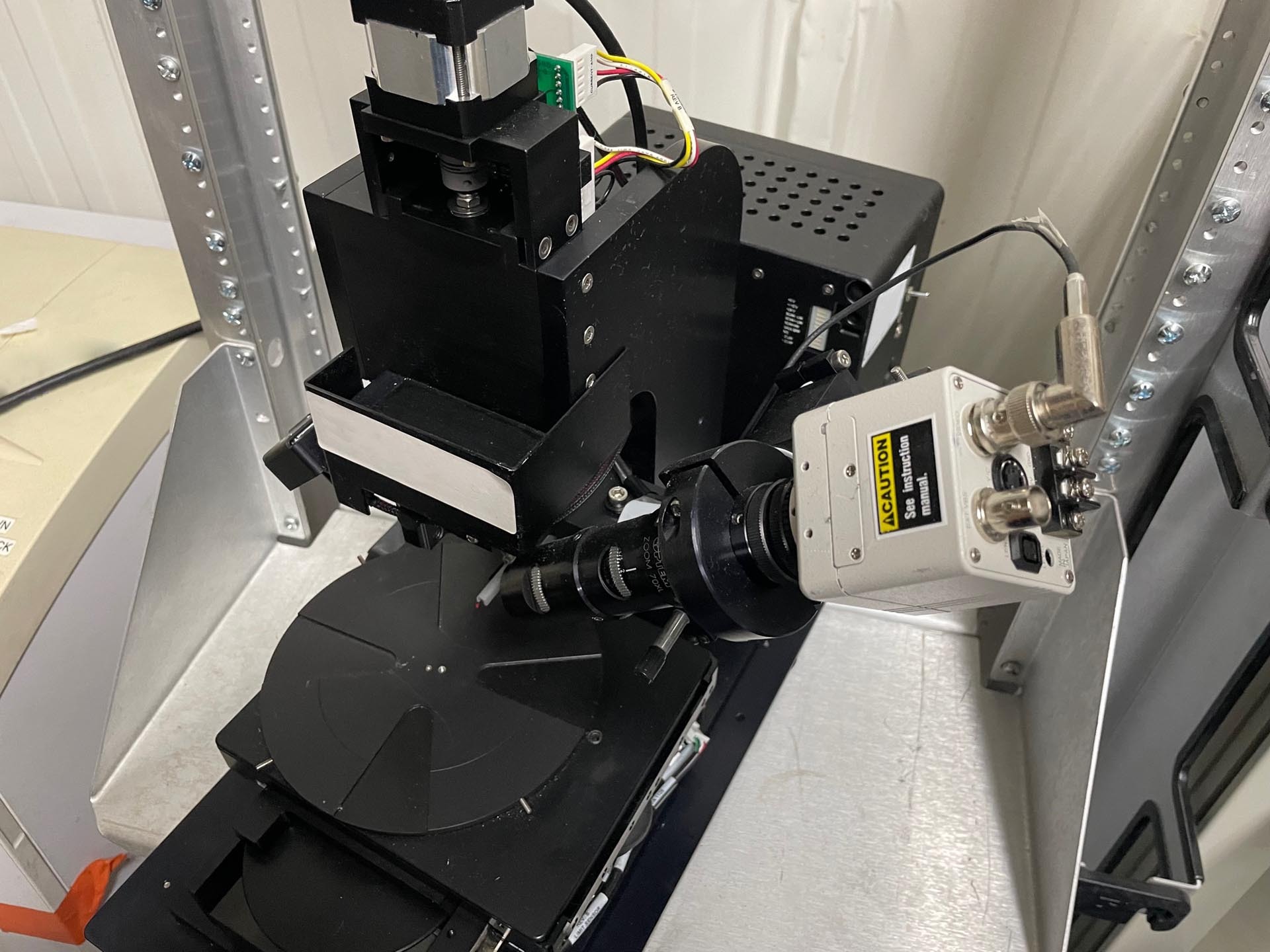

Used VEECO / SLOAN DEKTAK 6M #293646046 for sale

URL successfully copied!

Tap to zoom

VEECO / SLOAN DEKTAK 6M is a wafer testing and metrology equipment used in the semiconductor industry to measure thin film layers on semiconductor substrates. This system is used to create precise and accurate measurements of thin film layers of materials such as metals, oxides, silicon, and dielectrics. The unit is composed of a motorized stage, a conductive wafer carrier, a laser-based light projection machine, and a capacitance-based measuring tool. The motorized stage is used to precisely position a wafer for measurement. The speed of the stage is adjustable to fit different types of substrates, which makes it ideal for multiple applications in the semiconductor industry. The wafer carrier is used to securely hold the wafer for measurements, and the laser-based light projection asset is used to accurately measure thin film layers. The light projection model consists of a laser and a position-sensitive detector (PSD) array, enabling precise measurements of distances, shapes, and edge geometries. The equipment also includes a capacitance meter, which is used to measure thin-film layers as small as 15 nanometers. The capacitance meter utilizes a pair of electrode plates to detect changes in capacitance due to differences in the width of thin-film layers on the sample being tested. Additionally, the system is equipped with an integrated software suite, enabling real-time graphing, reporting, and data analysis of measurement results. VEECO DEKTAK 6M is designed to withstand harsh conditions and provide precise measurement results, even in high-pressure, high-temperature environments. Additionally, the unit can handle up to 12 process steps in a single machine, making it an ideal solution for high-volume semiconductor manufacturing. Furthermore, the tool can measure wafer substrates with lenses up to 125mm in diameter. Overall, SLOAN DEKTAK 6M is a powerful wafer testing and metrology asset that can quickly and accurately measure thin film layers, making it an ideal solution for semiconductor manufacturing. Its precision, accuracy, and versatility make it an invaluable tool in the industry and allows manufacturers to deliver the highest quality products available in the market.

There are no reviews yet