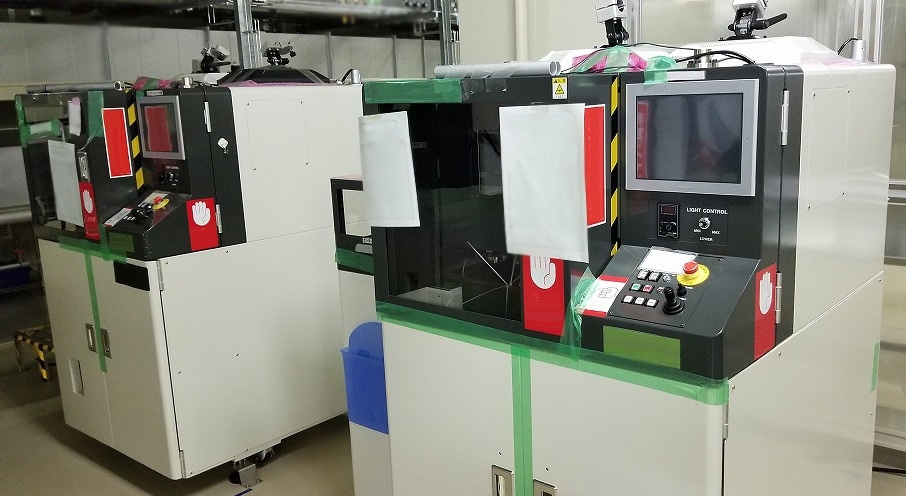

Used DAITRON DBM-603NR #9248398 for sale

URL successfully copied!

Tap to zoom

ID: 9248398

Wafer Size: 6"

Breakers, 6"

Frame: 2-8-1

Materials: Si, SiC, GsAs, InP, Al2O3

Thickness: 80~400 µm(Al2O3 80~200 µm).

DAITRON DBM-603NR is a wafer grinding, lapping and polishing equipment designed for ultra-precision die-attached applications and high-yield production. Featuring a modular design and powerful hardware, the system is ideal for jobs that require abrasive machining of multiple parts simultaneously. The unit is equipped with a 6-axis robot, a full-surround table, a precision linear guide, and an illuminated observation window. A range of grinding, lapping and polishing heads are available for customizable operations. The robot can move up to 10 parts on each of its axes and provides a full cycle timing of 2ms. DBM-603NR is designed for grinding and polishing flat and curved surfaces with high precision. The high-speed direct drive spindle ensures a smooth operation and low vibration, to provide the highest quality precision. It is capable of automated processes with a high degree of precision thanks to its motorized platform head, grinding and polishing head, and a full-featured control machine. For powerful and efficient lapping and polishing, DAITRON DBM-603NR includes a high-precision diamond polish head with an adjustable speed and accuracy. The tool also features an advanced dust collection asset which provides superior dust suppression and superior cleaning. DBM-603NR is built with heavy-duty components and an extensive range of features for efficient and quick processing of multiple parts. The user-friendly operating model allows to quickly set up, calibrate, and control the machines for a high-performance grinding and polishing of complex parts. This equipment is well suited for a wide variety of applications such as the fabrication of multi-layered products and the manufacturing of components for aerospace, automotive, and electronics industries.

There are no reviews yet