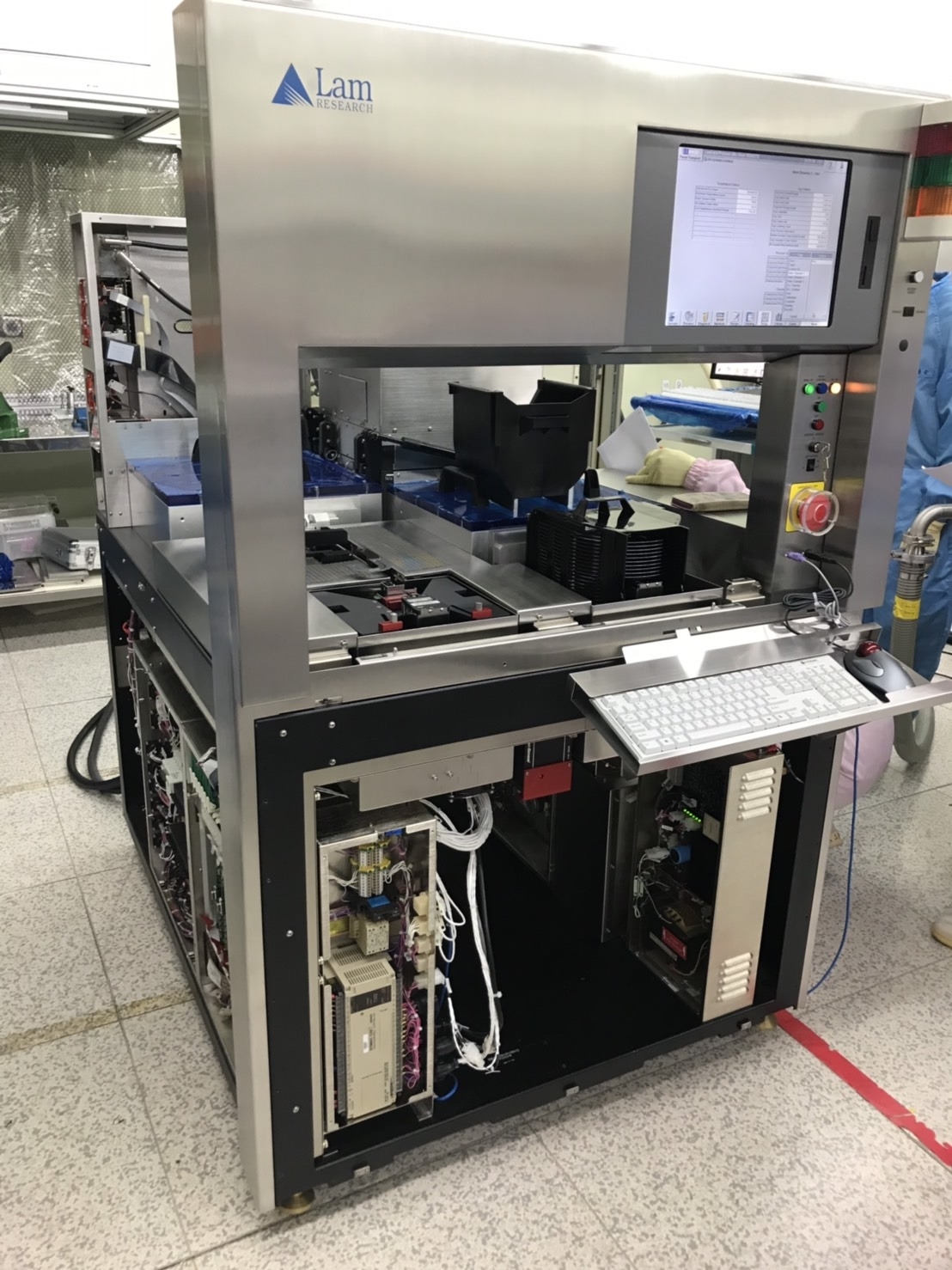

Used LAM RESEARCH 4500 for sale

Have one to sell?

Submit for sale

6

results found

Filters

Clear All

Filters

6 results

Wafer Size

-

(2)

-

(1)

Vintage

-

(1)

-

(1)

Can't find what you are looking for?